10

Safety

Only connect hydraulics when system is without pressure

You should only connect the hydraulic hoses to the tractor's hydraulics

when the hydraulic system on both tractor and machine is depressu-

rised.

There is a risk that the machine will move unintentionally.

Unintentional movement of the machine may result in serious injuries.

The hydraulic system should be checked regularly

All hoses and fittings should be checked regularly for visual damage.

Hydraulic hoses also age without visual damage.

Defect hydraulic hoses can result in personal injury or fire.

Colour marking of the hydraulic connections

The hydraulic connections between the tractor and the machine must

be colour marked.

By colour marking the hydraulic connections you avoid wrong opera-

tion of the machine.

Incorrect operation or unintentional movement of the machine may re-

sult in serious injuries.

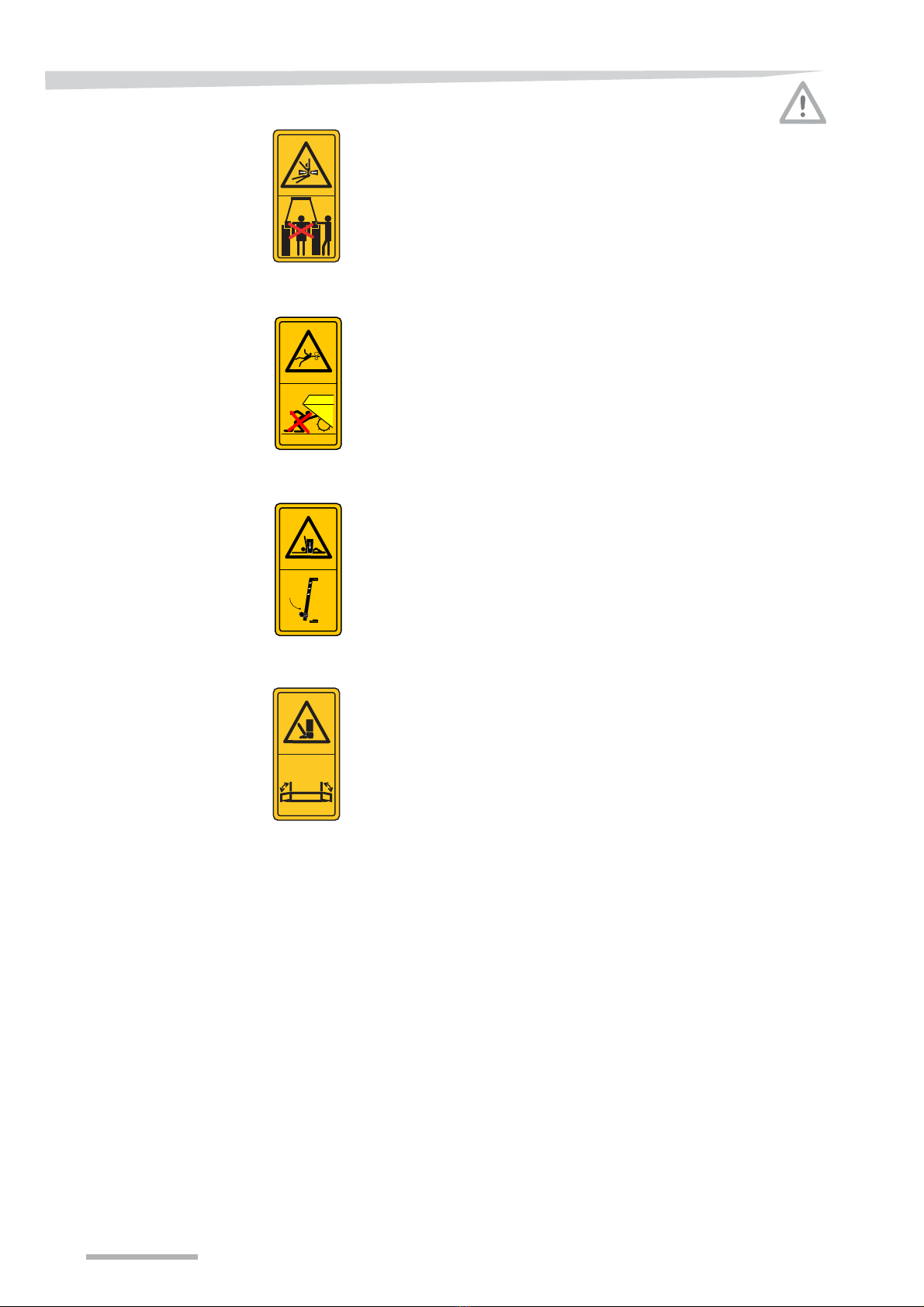

Load capacity

Comply with total weight, axle pressure, the carrying capacity of

the tyres, and minimum weight.

Neither the tractors total weight, axle pressure or thecarrying capacity

of the tyres may be exceeded with frontal mounted and rear mounted

machines.

To ensure the manoeuvrability of the tractor, the load on the front axle

must be minimum 20% of the tractors own weight.

Transgression can result in uncontrolled driving and accidents.

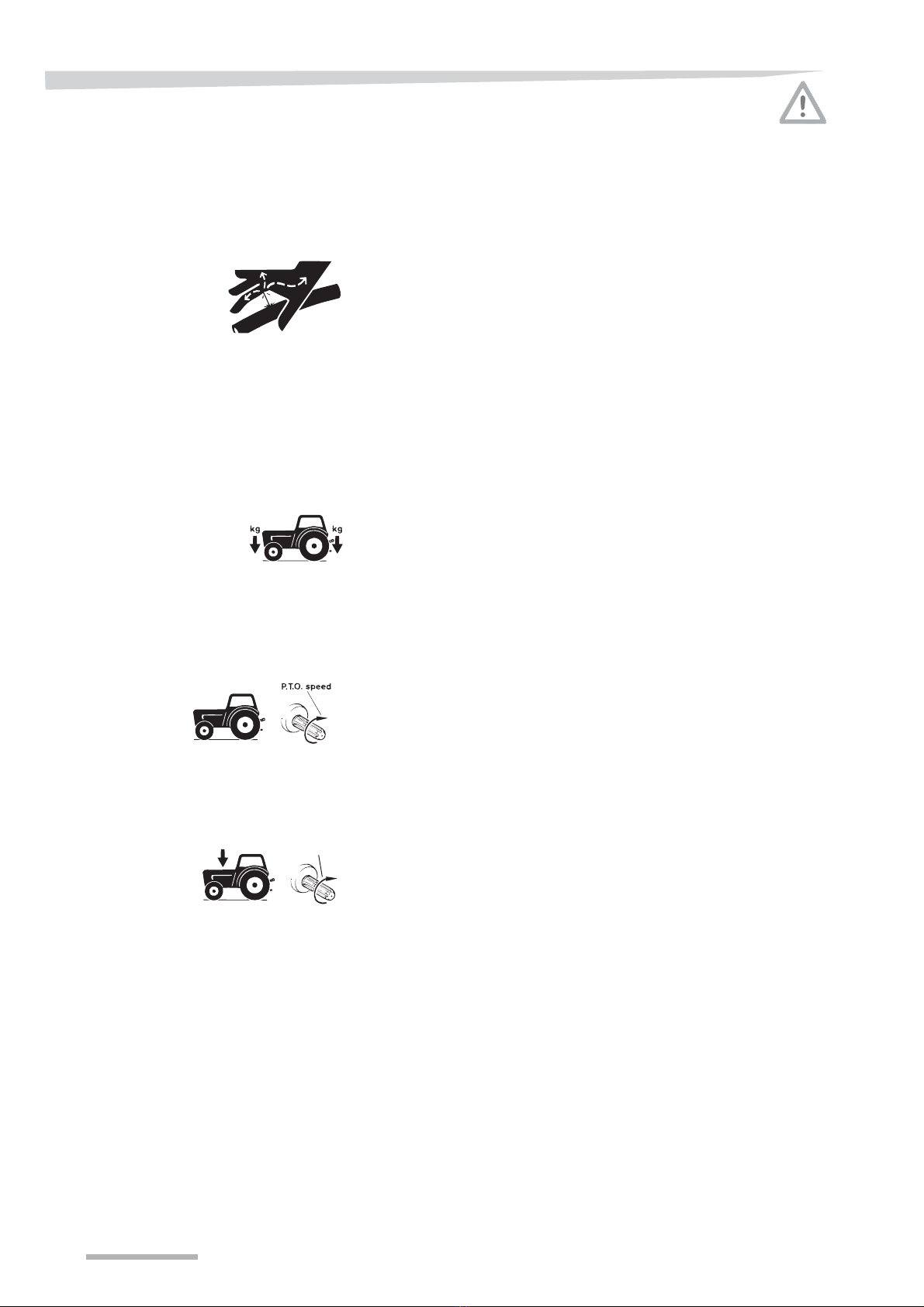

Be attentive when working around the P.T.O shaft

When working on the P.T.O. shaft, the tractorP.T.O. outlet must be dis-

connected, the tractor must be stopped and the ignition key should be

removed.

This prevents the PTO shaft from suddenly starting to rotate.

If the tractor and the PTO shaft have not been connected according to

the instructions serious accidents resulting in torn off limbs can occur.

Weight/power ratio between machine and tractor

The machine may only be connected to a tractor with a proper size

and performance.

The tractor's size and PTO outlet must correspond to the power con-

sumption of the machine and its weight.

Wrong weight/power ratio can result in damages on both machine and

tractor.

95-009

kg

HP/kW