Setting notes:

1. It only can be written when count of CH0 and CH1 are disabled (bit 0 and bit4 of CR#4 are 0).

2. After writing, it will initial controlled registers as follows: CR#1=0, CR#4,5=65,536, CR#6,7=65,536,

CR#10,11=0, CR#12,13=32,767, CR#14,15: 32,767, CR#16,17=0, CR#18,19=0, CR#20,21=0, CR#22,23=0,

CR#24,25=0 and CR#26,27=0.

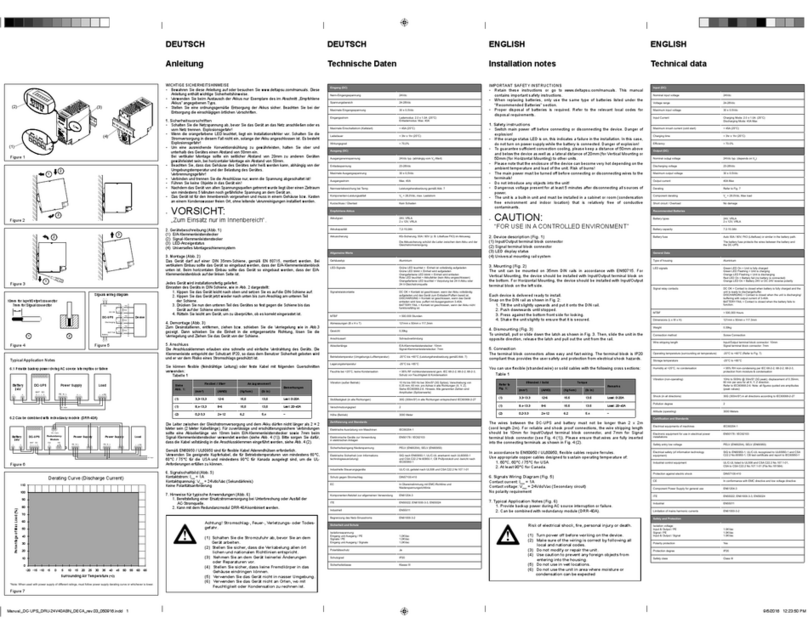

1-phase 1 input (K8~K11) 1-phase 2 inputs (K6~K7)

$External input count up/down

control (K8~K9)

$Internal controlled register count

up/down control (K10~K11) $1-phase 2 inputs counter (K6, K7)

count up count down

Off ( )count up On ( )count down

A i np u t

B input

count

value

K0 K1

CR#1

A i n p ut

count

value

count up count down

11220333

A inp u t

B input

count value

pulse of count up

pulse of count down

2-phase 2 inputs (K0~K5)

$Normal frequency (K0, K1) $Double frequency (K2, K3) $Four times frequency (K4, K5)

A i n p ut

B input

count value

112002

A i n p ut

B input

count value

1122034 30

A i np ut

B input

count value

1357024 67531

64 2

#5 #4 H 4162 ╳R/W Ring length of CH0 16-bit mode, factory setting: K65,536

#7 #6 H 4164 ╳R/W Ring length of CH1 16-bit mode, factory setting: K65,536

Example:

M0

DTO K0 K4 K200 K1

Take CH0 as example:

Write K200 into first extension module CR#5 and CR#4 (i.e.

CR#5 = 0, CR #4 = 200). Setting range: K2 to K65,536.

198 199 10

01 199 198

Count up

Count down

When ring length is set to K200, the count value will be as

shown on the left.

Count up: when count value reaches 199, the next count

value will be 0.

Count down: when count value reaches 0, the next count

value will be 199.

Setting notices:

1. It must write with 32-bit.

2. It only can be write-in when writing value is greater or equal to current count value.

3. It only can be set when counter stops counting and count mode is 16-bit.

#9 #8 H 4166 ╳R/W CH0 factory setting

Factory setting for CH0 counter (#10: Lower word / #11:

Upper word), factory setting: K0

Setting notes: in 16-bit mode, CR#9 will be cleared to 0

when writing factory setting.

#11 #10 H 4168 ╳R/W CH1 factory setting

Factory setting for CH1 counter (#10: Lower word / #11:

Upper word), factory setting: K0

Setting notes: in 16-bit mode, CR#11 will be cleared to 0

when writing factory setting.

#13 #12 H 416A ╳R/W YH0 comparison value

YH0 output comparison value (#12: Lower word / #13:

Upper word), factory setting: K32,767.

Setting notes: in 16-bit mode, CR#13 will be cleared to 0

when writing YH0 comparison value.

#15 #14 H 416C ╳R/W YH1 comparison value

YH1 output comparison value (#14: Lower word / #15:

Upper word), (factory setting: K32,767).

Setting notes: in 16-bit mode, CR#15 will be cleared to 0

when writing YH1 comparison value.

Take CH0 as example:

When current value of counter CH0= CH0 comparison value,

output YH0 will be ON and hold. User can clear output by using b8

and b10 of CR#2.

If count value of CH0 = comparison value by using PRESET or

instruction TO, corresponding output YH0 will be OFF. In other

case that count value = comparison value does not use PRESET

or instruction TO, corresponding output YH0 will be ON.

CR#2

b8 SET CR#2

b8 SET

current value

of counter

Comparison

value

Comparison

value

current value

of counter

current value

of counter

current value

of counter

#17 #16 H 416E ╳R/W Current value of counter

for CH0

Current value of counter for CH0(#16: Lower word / #17:

Upper word), factory setting is K0.

Setting notes:

1. It must write with 32-bit.

2. In 16-bit mode, value that is written must be less than

ring length (CR#4, 5).

3. In 16-bit mode, CR#17 will be cleared to 0 when

writing into current value of counter.

#19 #18 H 4170 ╳R/W Max. count value for CH0 Max. count value for CH0 (#18: Lower word / #19: Upper

word), factory setting is K0.

#21 #20 H4172 ╳R/W Min. count value for CH0 Min. count value for CH0 (#20: Lower word / #21: Upper

word), factory setting is K0.

#23 #22 H 4174 ╳R/W Current value of counter

for CH1

Current value of counter for CH1(#22: Lower word / #23:

Upper word), factory setting is K0.

Setting notes:

1. It must write with 32-bit.

2. In 16-bit mode, value that is written must be less than

ring length (CR#6, 7).

3. In 16-bit mode, CR#23 will be cleared to 0 when

writing into current value of counter.

#25 #24 H 4176 ╳R/W Max. count value for CH1 Max. count value for CH1 (#24: Lower word / #25: Upper

word), factory setting is K0.

#27 #26 H4178 ╳R/W Min. count value for CH1 Min. count value for CH1 (#26: Lower word / #27: Upper

word), factory setting is K0.

#28 H 417A

╳R Comparison result Comparison result

CR#28 ‘0’(Off) ‘1’(On) CR#28 ‘0’(Off) ‘1’(On)

b2 Setting value≦

current value

Setting value >

current value b6 Setting value≦

current value

Setting value >

current value

YH0

b1 Setting value≠

current value

Setting value =

current value

YH1

b5 Setting value≠

current value

Setting value =

current value

CR#28 ‘0’(Off) ‘1’(On) CR#28 ‘0’(Off) ‘1’(On)

b0 Setting value≧

current value

Setting value <

current value b4 Setting value≧

current value

Setting value <

current value

#29 H 417B

○R Action status The indication of CH0/CH1 count up/down and terminal

status(On/Off)

CR#29_CH0 ‘0’(Off) ‘1’(On) CR#29_CH1 ‘0’(Off) ‘1’(On)

b0 - Count up (Up_0) b8 - Count up(Up_1)

b1 - Count down (Dn_0) b9 - Count down (Dn_1)

b2 A0 input is Off A0 input is On b10 A1 input is Off A1 input is On

b3 B0 input is Off B0 input is On b11 B1 input is Off B1 input is On

b4 PRE0 input is Off PRE0 input is On b12 PRE1 input is Off PRE1 input is On

b5 DIS0 input is Off DIS0 input is On b13 DIS1 input is Off DIS1 input is On

b6 YH0 output is Off YH0 output is On b14 YH1output is Off YH1 output is On

b7 Reserved b15 Reserved

#31 H 417D

╳R Error Status Data register that is used to save all error status. Refer to table below.

CR#31 Error Status

b0 Overflow indication of CH0 count up. When count-up value exceeds upper limit(upper limit is CR#4,5 in 16-bit

mode and it is K2,147,483,647 in 32-bit mode)

b1 Overflow indication of CH0. When count-down value is less than lower limit(lower limit is 0 in 16-bit mode and

it is K-2,147,483,648 in 32-bit mode)

b2 Overflow indication of CH1 count up. When count-up value exceeds upper limit(upper limit is CR#6, 7 in

16-bit mode and it is K2,147,483,647 in 32-bit mode)

b3 Overflow indication of CH1. When count-down value is less than lower limit(lower limit is 0 in 16-bit mode and

it is K-2,147,483,648 in 32-bit mode)

b4~b5 Reserved

b6 The CR number designated by FROM/TO instruction exceeds range

b7 RS-485 communication setting (CR#33 and CR#34) error

b8~b15 Reserved

#32 H 417E

○R System version Hexadecimal, display current software version, such as version 1.0A

will be displayed as H’010A.

#33 H 417F

○R/W Communication

address setting

Setting RS-485 communication address. Setting range is 01-254.

Factory setting is K1.

#34 H 4180

○R/W Baud Rate

Setting

Communication baud rate could be 4800 / 9600 / 19200 / 38400 /

57600 / 115200. For ASCII mode, data format is 7Bits, even, 1 stop bit

(7 E 1). For RTU mode, data format is 8Bits, even, 1 stop bit (8 E 1).

b0: 4800 bps. b1: 9600 bps. (factory setting)

b2: 19200 bps. b3: 38400 bps.

b4: 57600 bps. b5~b14: Reserved.

b15: ASCII / RTU mode switch.

CR#0~CR#34: The corresponding addresses are H 415E-H 4180 for user to read/write by using RS-485.

1. Baud rate could be 4800, 9600, 19200, 38400 and 57600bps.

2. Communication protocol can be Modbus ASCII mode and RTU mode. For ASCII mode, data format is 7Bits,

even, 1 stop bit (7 E 1). For RTU mode, data format is 8Bits, even, 1 stop bit (8 E 1).

3. Function code: 03H: read register data. 06H: write one WORD data into register. 10H: write multiple WORDs into

register.

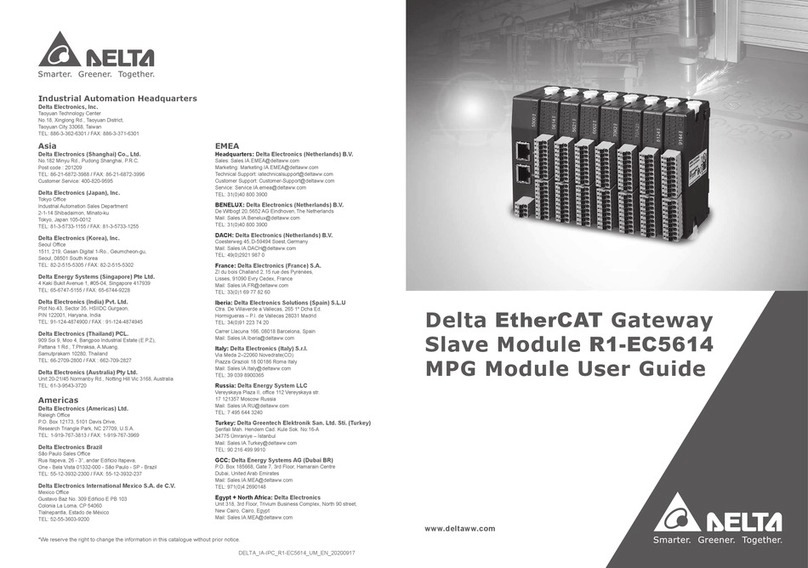

5 TRIAL RUN & TROUBLESHOOTING

MPU connects to HC extension module

1. Make sure that the power of MPU and extension unit is OFF before wiring.

2. Open extension port of EH MPU and connect to HC extension unit with cable. There is no connection order for

EH MPU to connect extension unit, mix connection is allowed.

3. The power supply of HC extension unit must be external +24VDC power supply.

4. Before power up, check if the load circuit of outputs YH0 and YH1 is correct, especially the circuit between YH0+,

YH0- and YH1+, YH1-. There is a Zener Diode that is connected between YH0+, YH0- and YH1+, YH1- in HC. If

the positive/negative pole is wrong, it may cause unexpected result.

YH0+ YH1+

YH1-

YH0-

DC 5~24VDC

Load

YH0+ YH1+

YH1-

YH0-

DC 5~24VDC

load

5. Before power up, check if A phase or B phase connects to correct voltage level. (there are three voltage level:

+24, +12V and +5V) If +24V signal connects to +5V input terminal, it may damage internal circuit.

6. After power up MPU, it will start to detect extension module. If no external +24VDC power is applied to HC at

this time or power is applied after EH MPU completing detecting extension module, the connection will fail.

Therefore, power wiring and power supply timing should be as following.

Power wiring

85~264VAC

AC/DC +24V_EXT

+24V_INT

01HCEH MPU

+24V input

LNG

+24V 24G

+24V 0V

Power supply

Timing analysis

When power supply for HC is +24V_INT:

t5>t3, power is ON and the connection of HC extension

unit is normal.

When power supply for HC is +24V_EXT:

Because start time (t2) of external power supply for HC

extension module is unknown, user must make sure that

t2+t4<t1+t5, otherwise HC extension module cannot be

detected by MPU.

Power supply timing

+24V_INT

+24V_EXT

t1

t2

t3

t4

t5

t1:1~2 seconds

t2:1~3 seconds

t3:0.5~1 seconds

t4:0.5~1 seconds

t5:2 seconds

AC power input

complete initialling HC

(supply from +24_INT)

complete initialling HC

(supply from +24_EXT)

MPU starts to detect

extension unit

7. After completing above steps, power up MPU and connect to PC with cable DVPACAB215. When using

WPLSoft to read peripherals status to make sure that HC connects to MPU.

Open WPLSoft

Click View> Workspace

Workspace display

Double click “ ” for communication.

It is communicating.

Note: All communication settings, including baud rate,

communication port and communication

address, should be set before communicating.

Complete communicating.

$It means communication is successful when

“02HC” displays in special module.

8. The maximum special extension modules number for EH MPU connects is 8 special extension modules. After

power is ON, EH will save module codes of connected special modules in D1320~D1327 in order. The module

code of 02HC is H’0220. It indicates communication is OK when H’0220 is displayed in the corresponding

special D register by using HPP02 or other monitor software.

Troubleshooting

Judge the errors by the indicators on the front panel. When errors occurred on DVP PLC, please check:

☼“POWER” LED

The “POWER” LED at the front of HC extension module will be lit (in green) if the power is on. If the

indicator is not on when power up, please remove the wiring on terminals +24V. Once the indicator lights

after this, it means that the 24V DC power supply of the PLC is overloaded. Please do not use the DC

power supply from the +24V terminals, but use a DC24V power supply instead.

☼L.V. LED

The “L.V.” LED at the front of HC extension module will be lit if input voltage is not enough. The extension

module won’t active at this time.

6 RELATIVE INSTRUCTIONS AND EXAMPLES

API

78 DFROM P Read Special Module CR Data

Instruction

Explanation

: number of special module (m1=0~7). : CR number of special module that will be read.

: address for saving reading data. : data number for reading once.

Program

Example

Writing special module #0 of CR#24 into D0 and special module #0 of CR#25 into D1. only write

two data once (n=2).

X10

FROM K0 K24 D0 K2

API

79 DTO P Special Module CR Data Write In

Instruction

Explanation

: number of special module (m1=0~7). : CR number of special module that will be

wrote in. : data to write in CR. : data number to write in once.

Program

Example

Using 32-bit instruction DTO to write D11 and D10 into special module#0 of CR#3 and CR#2. only

write a data once (n=1).

X11

DTO K0 K2 D10 K1

Application Example:

Following program is the application example of CH0 for 02HC:

Setting CR#2 to disable count mode before setting.

Setting counter to be 1-phase 1 input (CR#3) of 16-bit mode, ring length of CH0 is 2000 (CR#4, 5) and

factory setting is 100 (CR#8). When count value of CH0 reaches 500, YH0 is ON (CR#12).

Using X0~X11 to set instructions (CR#2).

Reading values, including current value of counter for CH0 (CR#16), max. count value for CH0 (CR#18),

min. count value for CH0(CR#20), comparison result for CH0(CR#28), terminal status (CR#29) and error

status (CR#31).

K0 K1

K0

K2

K9 K1

M1002

K0

TO

TO

M100

K0 K1

DTO

K0 K100 K1

K8

DTO

K0 K500 K1

K12

DTO

K3

K4 K2000

X0

M101

X1

M102

X2

M108

X3

M109

X4

M112

X7

K4M100 K1

K2

M1000

K0

TO

D0 K1

K0

K16

D2 K1

M1000

K0

DFROM

K18

K0 D4 K1

K20

K0 D6 K1

K28

K0 D8 K1

K29

K0 D10 K1

K31

DFROM

DFROM

FROM

FROM

FROM

CR#2: count is disabled

CR#3: setting to K9 to indicate

16-bit and 1-phase 1 input counter

(hardware).

CR#4,5: ring length: 2000

CR#8,9: factory setting=K100

CR#12,13: YH0 comparison value=500

X0: start counting

X1: PRESET is enabled

X2: YH0output is enabled

X3: clear YH0 (RESET

X4: YH0 is ON (SET)

X7: clear error flag

CR#2: transmit instruction

CR#16,17: current value of counter

CR#18,19: max. count value

CR#20,21: min. count value

CR#28: comparison result

CR#29: terminal status

CR#31: error status