I-776 Page 13of 18

Rev. G29208

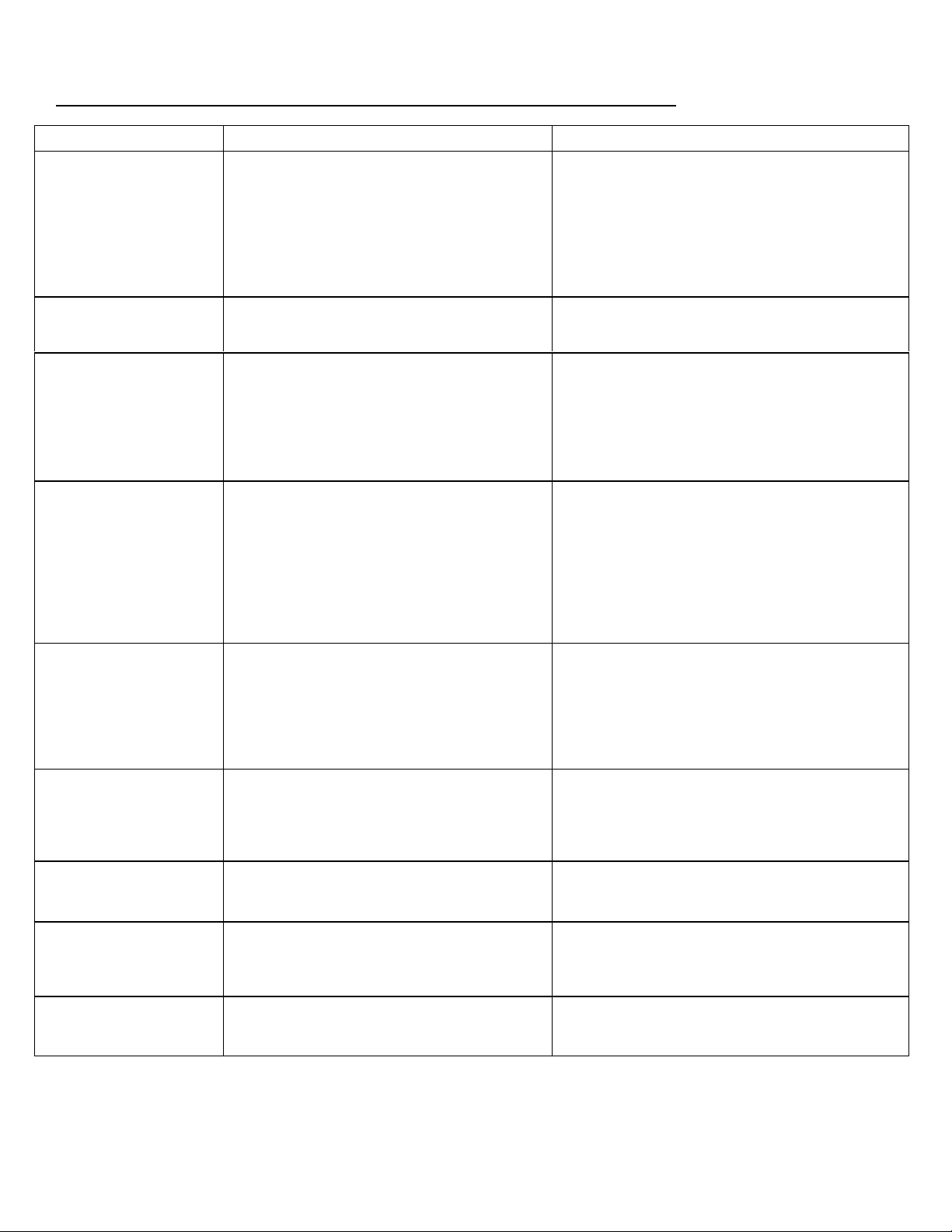

Trouble Shooting

(Some models may not include all items listed below)

Water supply pressure should in the 20-125 psi range and water temperature must not exceed 150°F.

See section labeled “Maintaining and Servicing the DAH Blend Center” on page 9 for more information.

Trouble Probable Cause Remedy

Proportioner fails to draw

chemical properly. 1. Insufficient water supply pressure.

2. Inspect foot valve for dried chemical or dirt.

3. Proportioner metering tip clogged with dried

chemical.

4. Inspect Air Gap proportioner for mineral

deposit build up on top nozzle or inlet screen.

1. 20 PSI is the minimum allowable pressure. Seek

Plumber if necessary to increase water pressure.

2. * Soak in hot water to clean.

3. * Soak in hot water to clean interior passages.

4. * Soak nozzle and inlet screen in hot water or off

the shelf product such as CLR to clean and remove

mineral deposits.

“Air Gap” Proportioner is

dripping or spraying a mist

(fan pattern) of water.

1. Inspect “Air Gap” proportioner for mineral

deposit build up on top nozzle or inlet screen. 1. * Soak nozzle and inlet screen in hot water or off

the shelf product such as CLR to clean and remove

mineral deposits.

Sliding Lift Button won’t

“Lock” open for

continuous flow of

chemical/water solution.

1. “Sliding lift button” return spring may be

missing. (Note: Lift button must be slid up

before it will push in.)

2. Not using the proper procedure for locking the

water valve open.

1. Shut water supply off first. Slide “lever” all the

way up and hold it in place. Now push the button

in towards the wall. Let go of button and spring

should return lift button out to its original position.

Replace if missing.

2. See step 1 in section labeled “Getting to Know

Your DAH Blend Center” on page 2.

Water valve is not shutting

off completely. 1. “Sliding lever” return spring may be missing.

2. “Sliding lever” is not returning all the way

down due to interference between the sliding

lever and either the chemical supply and/or

outlet tubing.

3. Bucket fill outlet hose is catching the bottom

edge of the sliding lever during normal usage.

1. Remove cover and visually check for sliding lever

return spring. Replace if missing.

2. Remove cover and visually check for any tubes

rubbing the sliding lever. Routing of chemical

supply and outlet tubing must not restrict the

movement of the sliding lever. Reroute tubing.

3. Don’t pull the bucket fill outlet hose too tight from

either side otherwise sliding lever may not return

properly.

Water valve is leaking. 1. Enclosing tube nut is too loose.

2. One or more of the valve o-ring connections

are out-of-position. Clearly identify each leak

prior to disassembly.

1. Shut water supply off first. Hand-tighten the

enclosing Hose nut. Do not overtighten w/tool.

2. “O-ring” seals may be pushed out of place or

missing when subassembling valve together. See

section labeled “Adding a DAH blend center to an

existing DAH blend center” on page 10-13 for

reassembling.

Threaded connections are

leaking water. 1. The connection between the blend center and

water supply line is too loose or rubber washer

is missing.

2. Backflow prevention devices and/or

proportioners are too loose.

1. Shut water supply off first. Carefully tighten the

female hose coupling on the blend center to the

inlet water supply line. Do not overtighten.

2. Tighten loose connection(s) with tools if

necessary. Do not overtighten if using tools.

Proportioner continues to

draw chemical after water

valve is closed.

1. Concentrated chemical is positioned higher

than the proportioner. 1. Move the concentrated chemical so it is lower

than the proportioner.

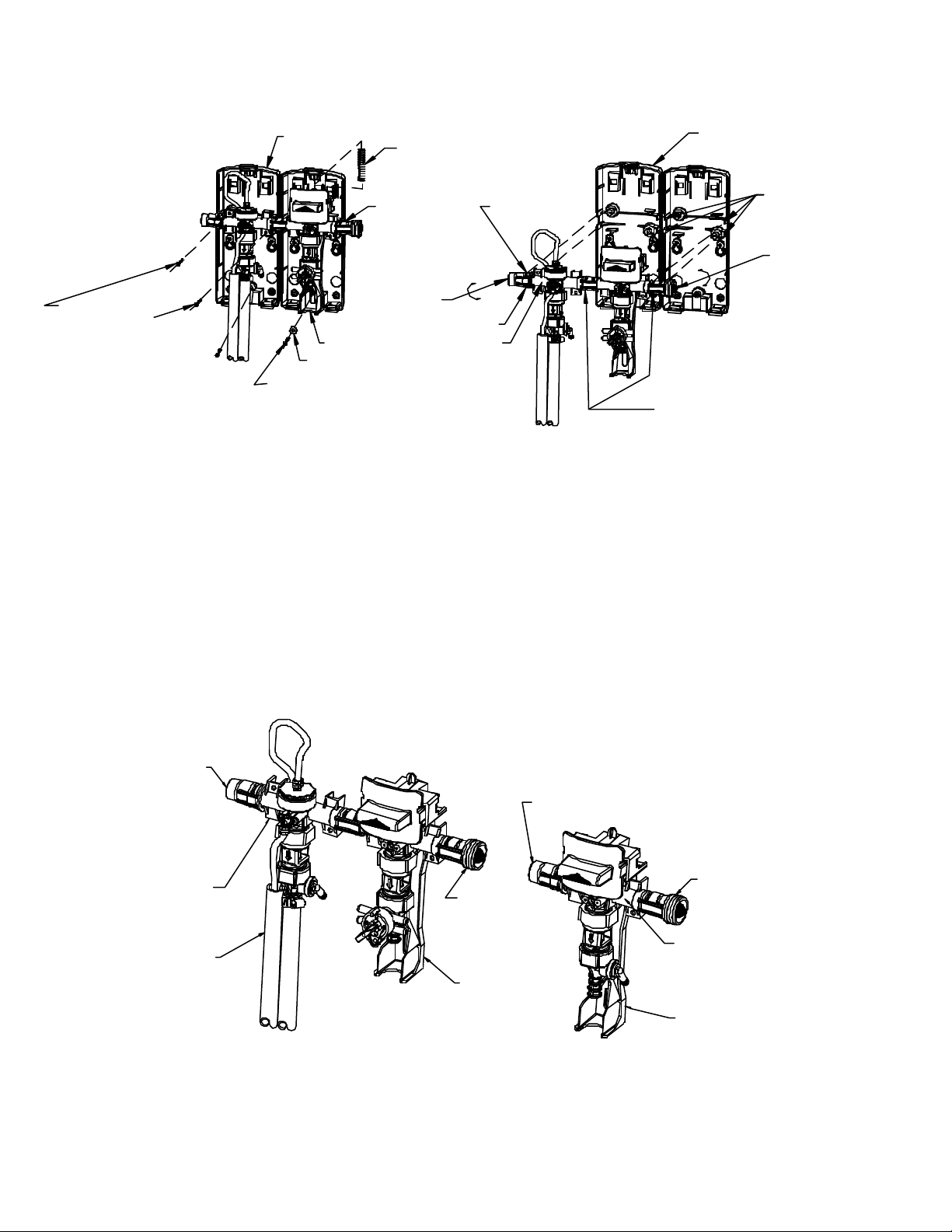

Can’t pull the Remote Fill

Hose Assembly off of the

proportioner.

1. Hose Clamp is not loose enough.

2. Both 1/8” I.D. tubes must be removed prior

to removing the double hose.

1. Loosen clamp more.

2. Remove 1/8” I.D. tubes. See section labeled

“Disassembling & reassembling the remote fill

hose assembly” on page 9.

Trigger on Remote Fill

Gun is very hard to

squeeze.

1. High pressure and low pressure (blue and

clear) hoses are crossed. 1. Install the blue and clear hoses according to

Figure 3 & 5 in the section labeled “Parts list for

DAH Blend Center” on page 15.

* (See section labeled “Checking backflow prevention device/proportioner, metering tip(s), and/or foot valve(s)” on page 10 for more information.)