aXcs

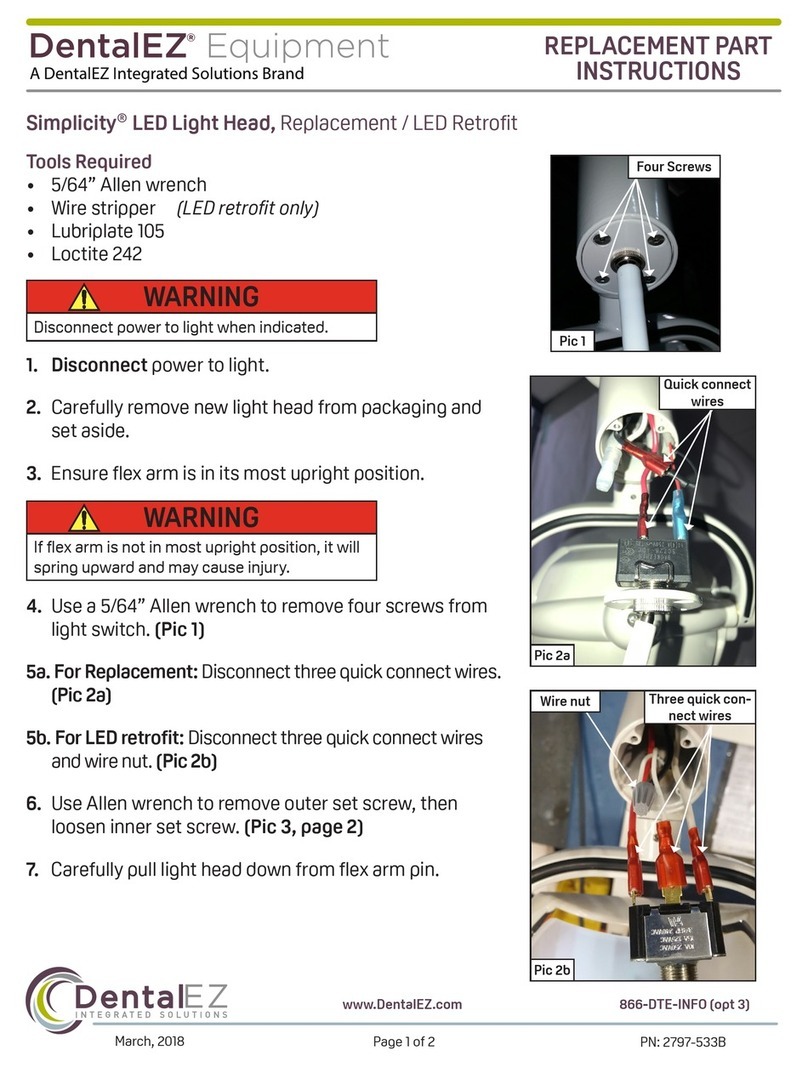

®

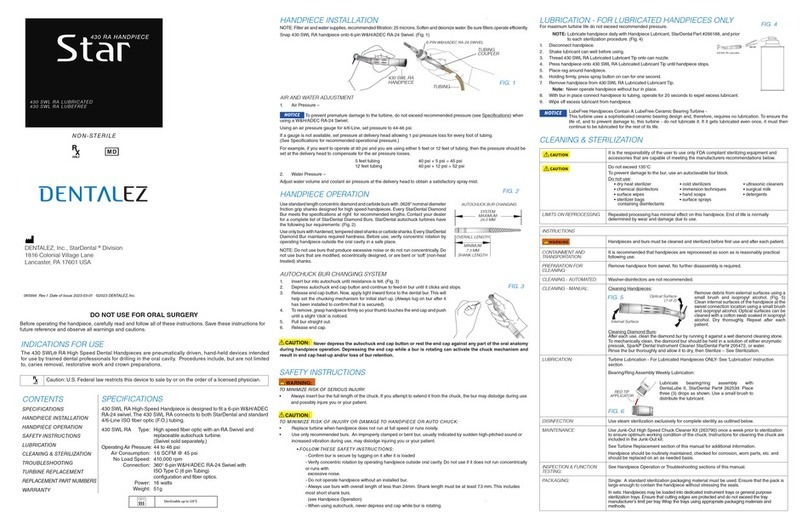

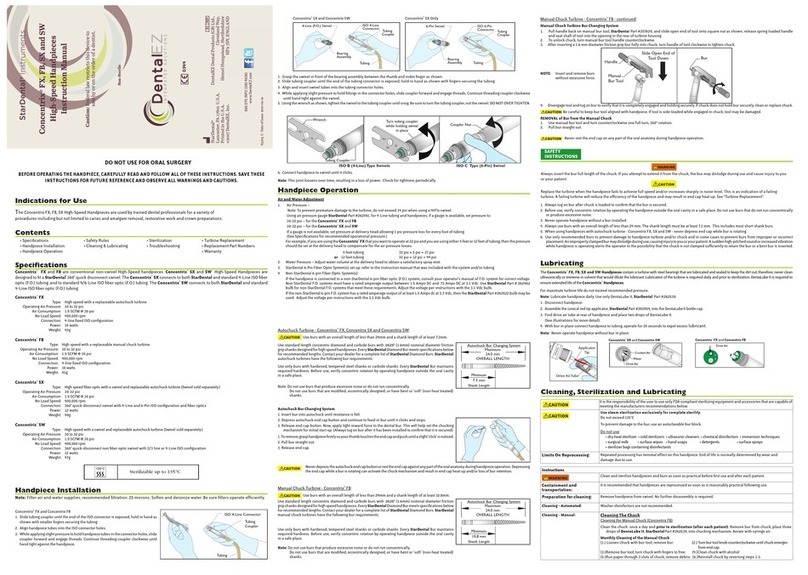

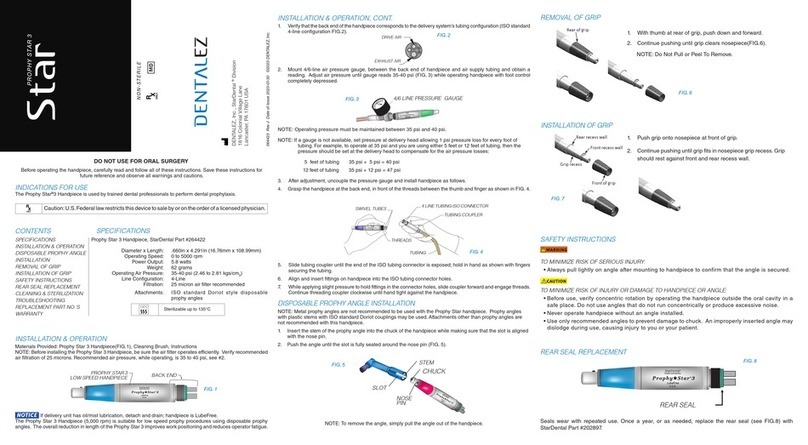

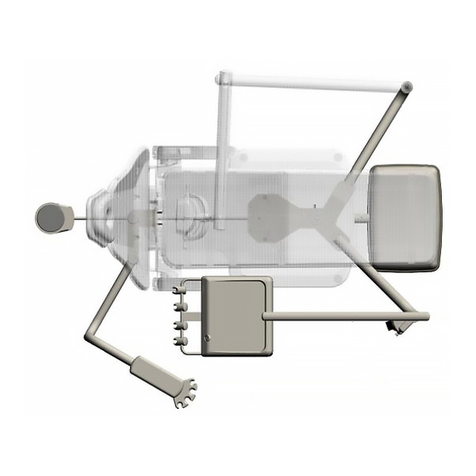

Wall/Cabinet Unit 19

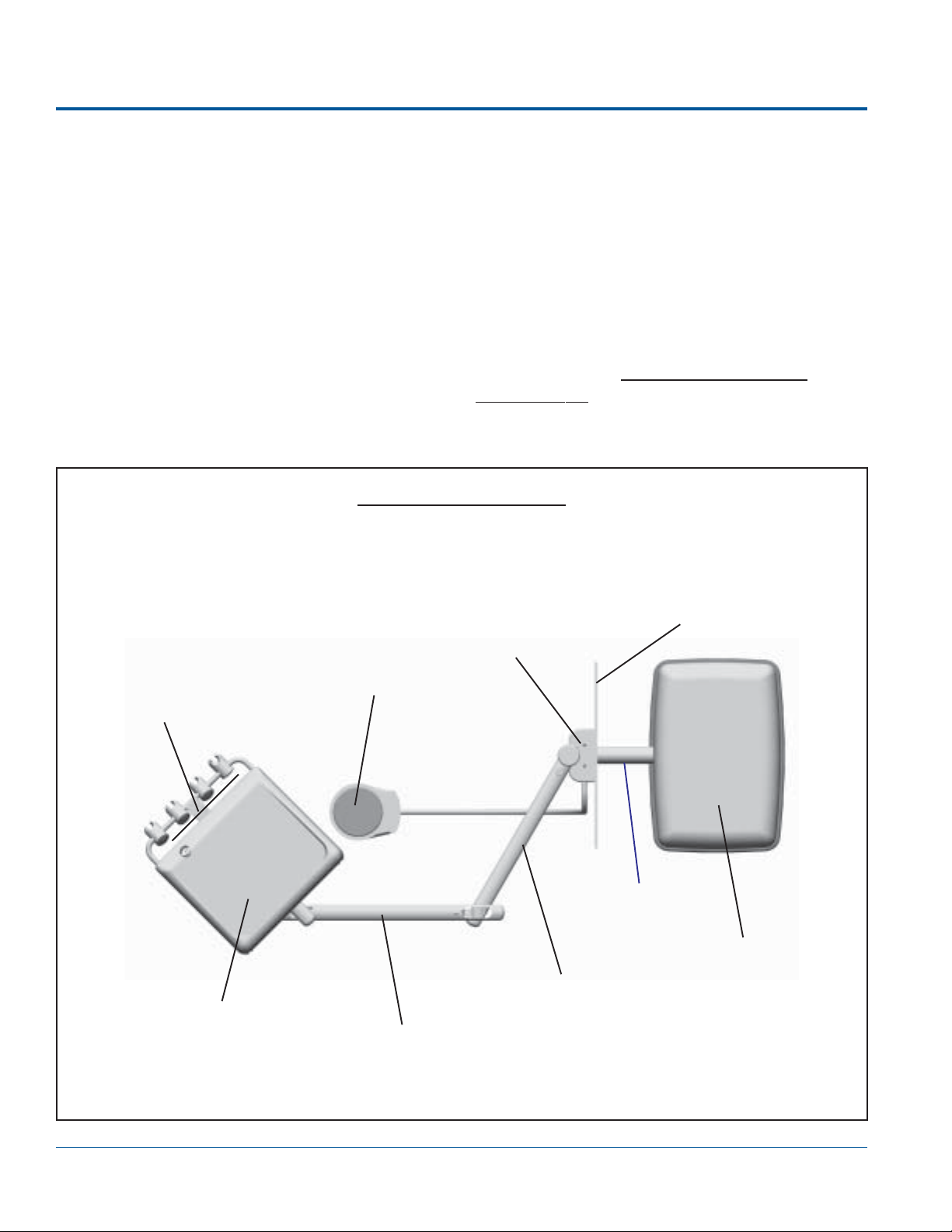

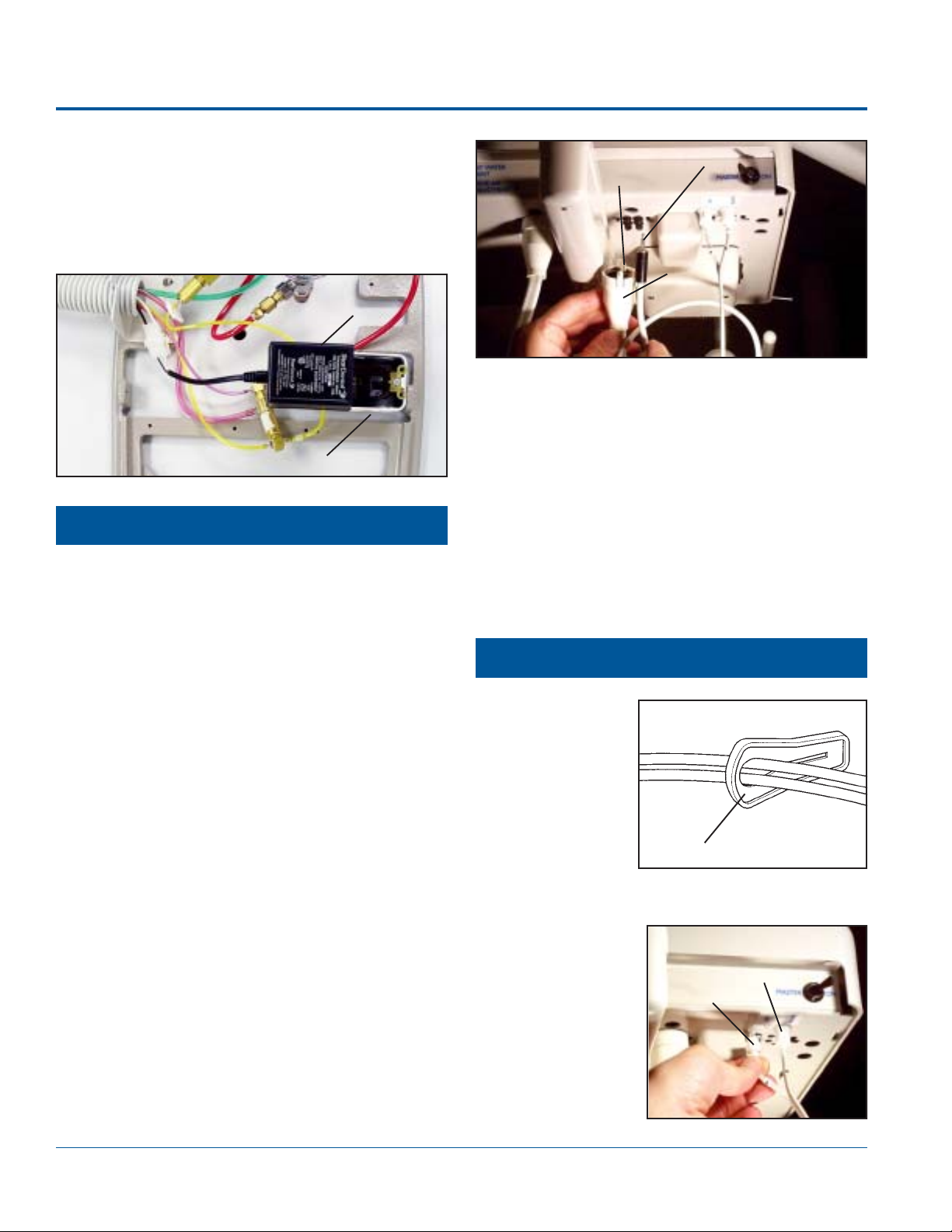

Flush Toggle

Optional

Chipblower

WET/DRY

Toggle Valve

Disk

Section V Operation

FLUSH to le, located at the rear of the

2. While operatin the handpiece, turn the valve

counterclockwise to increase the volume of

coolant water spray. To decrease the volume,

turn the valve clockwise.

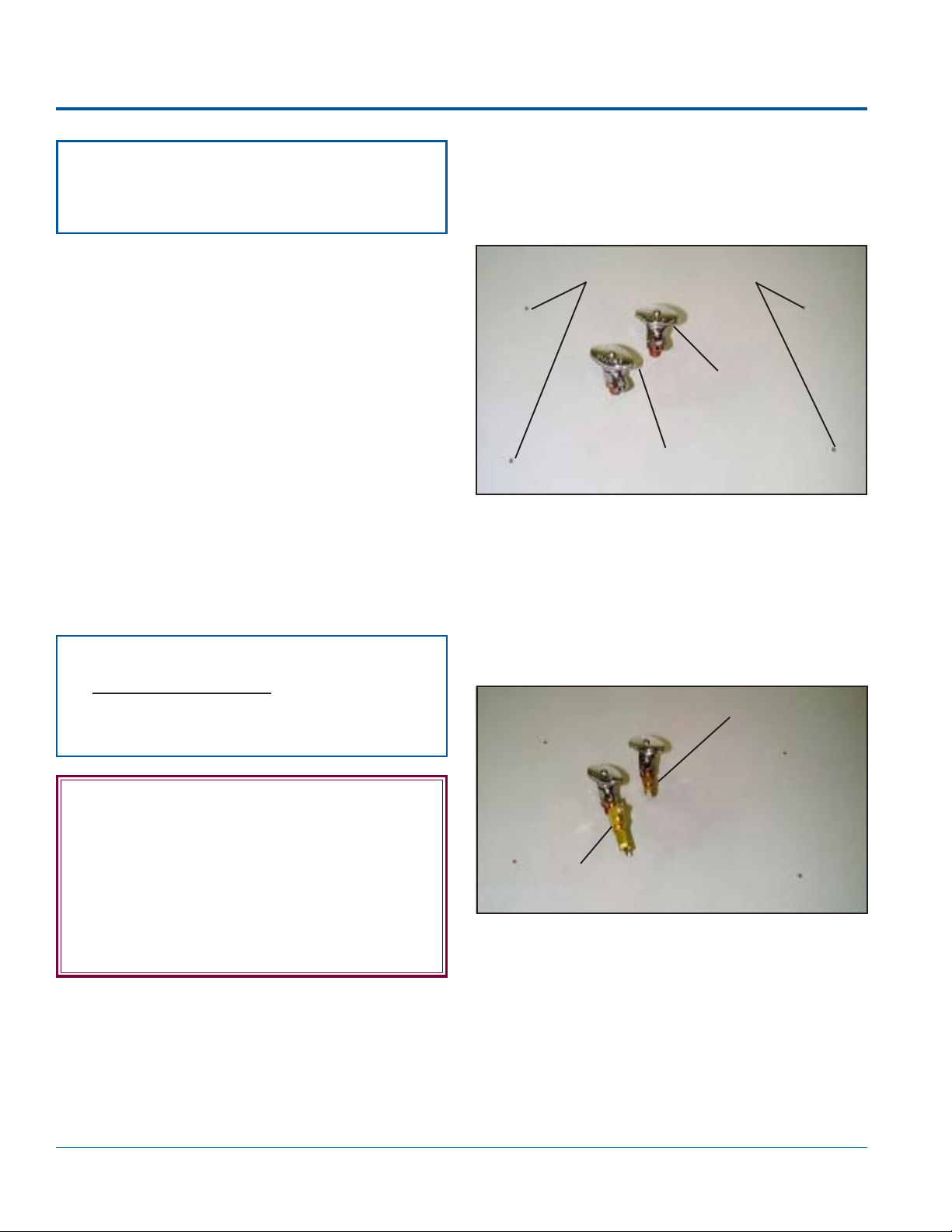

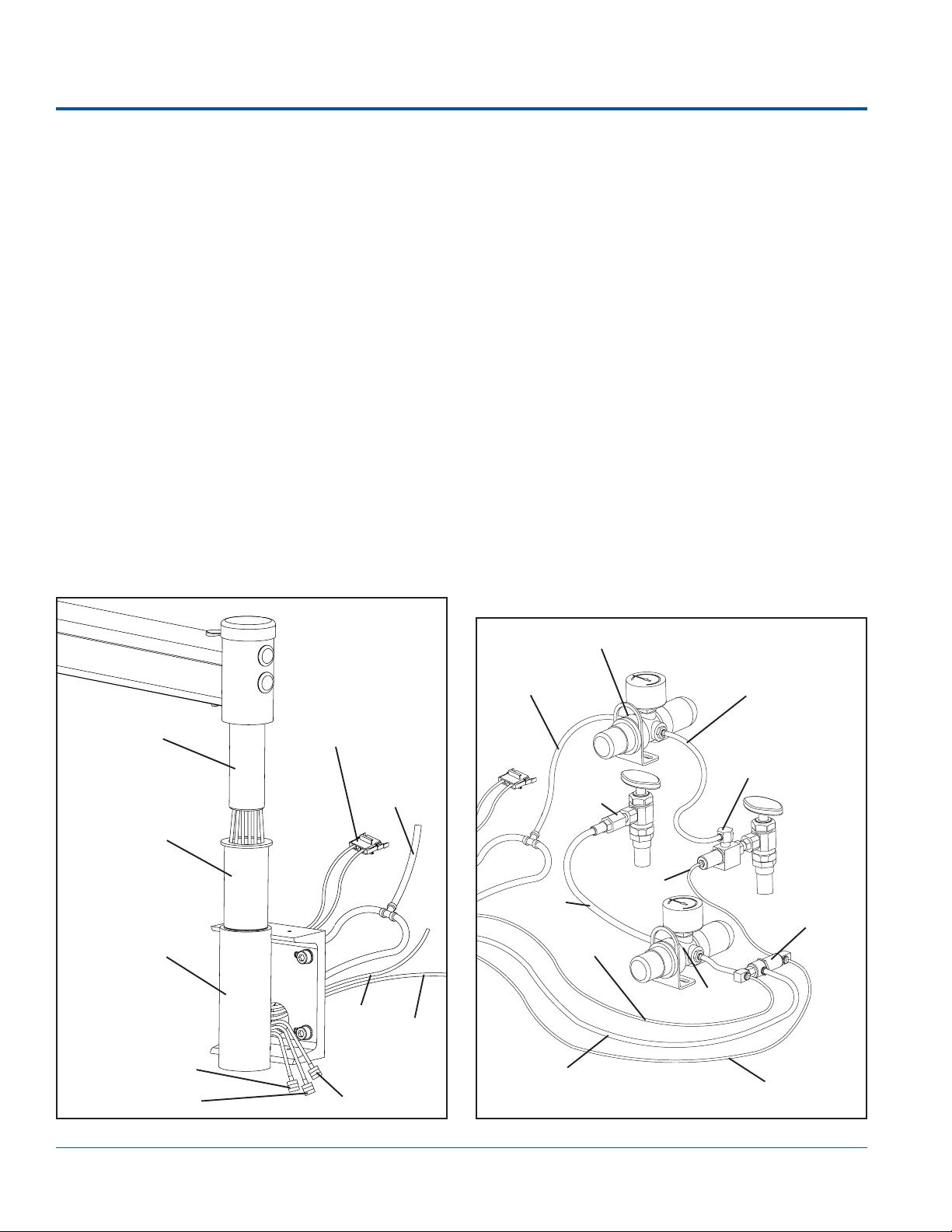

Air Pressure

Air pressure to each handpiece can be adjusted to the

manufacturer's specifications by followin the air

pressure instructions in Section IV Testin , Page 17.

NOTE: These procedures must be done while:

The master switch is in the ON position,

The handpiece is out of its holder and

The foot control is fully depressed.

NOTE: When making necessary air pressure adjust-

ments, refer to the air pressure gauge located at the front

of the delivery head to check the approximate amount

of air pressure delivered to the handpiece.

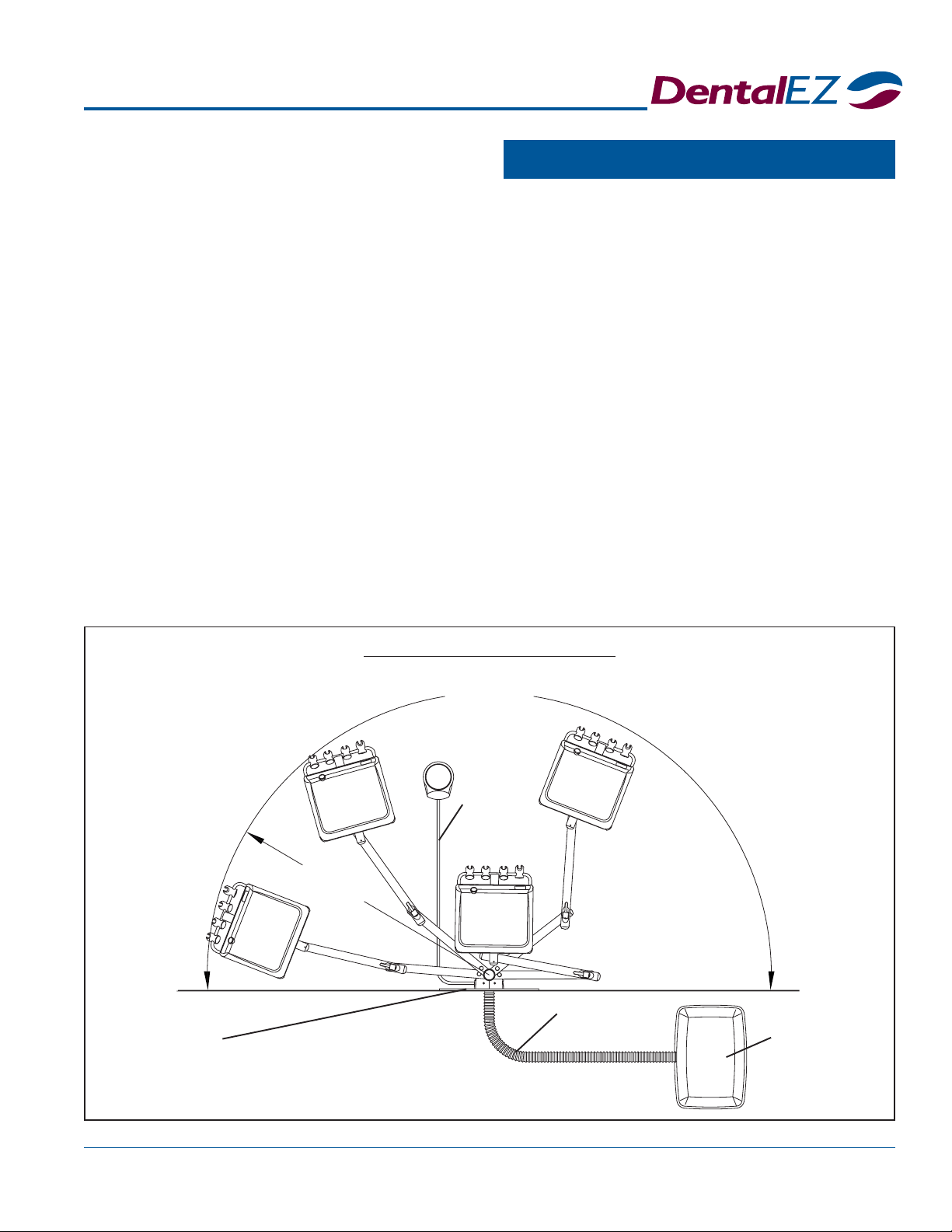

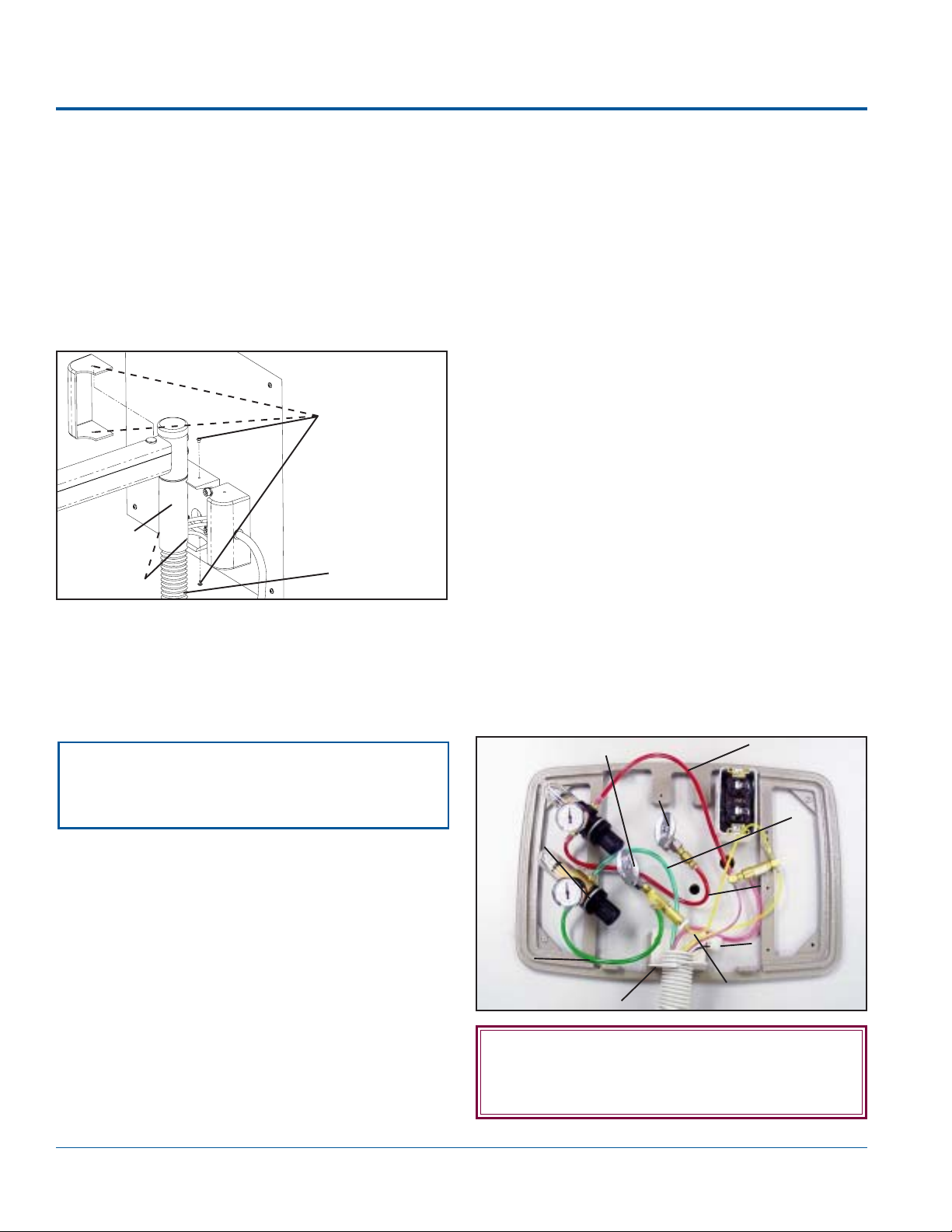

Flush System

It is recommended that the tubin of each handpiece

used be flushed after each patient.

1. Hold the handpiece tubin over a sink or

open vacuum line.

2. While facin the front of the unit, move the

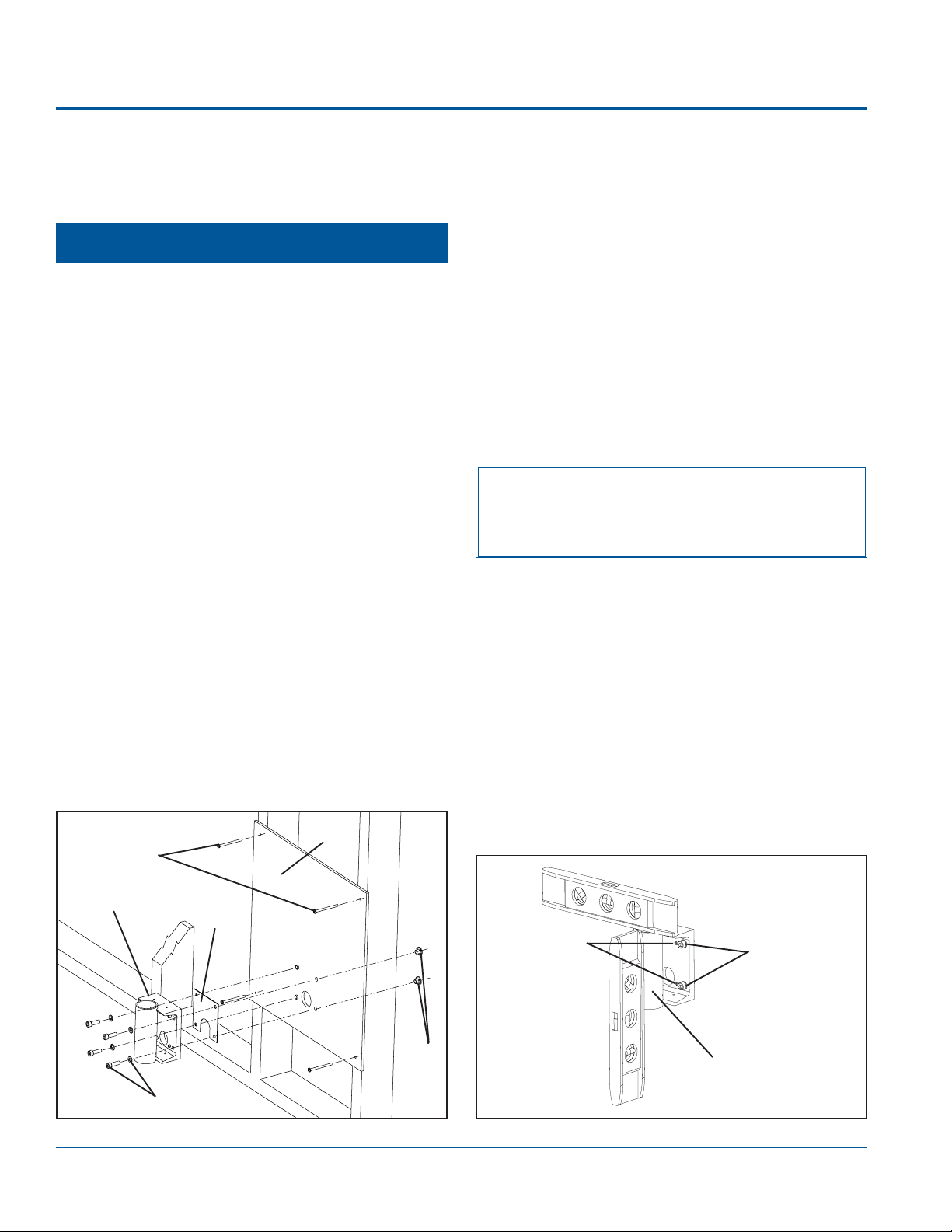

Foot Control

A li ht pressure on the

foot control disk causes a

slow speed.

Full pressure on the disc

causes the handpiece to

operate at full speed.

NOTE: The coolant water

Syringe

Chipblower (Optional)

Fiber Optics (Optional)

The speed of the handpiece is controlled by depress-

in the disk located on the foot control.

spray ON/OFF function is also controlled by using

the toggle valve on the foot control as described above.

The syrin e is desi ned to deliver air or water, or a

mixture of air and water, as required.

To deliver water only, press the button on the

syrin e marked with a water drop symbol.

For air only, press the button on the syrin e with

no markin .

To et a spray mixture of air and water, press

both buttons simultaneously.

NOTE: Air and water flows are factory preset.

This feature is used to blow debris away from the

cuttin site by creatin an air blast throu h the hand-

piece without causin the burr to rotate. To operate

the chip blower, depress and hold down the valve on

the upper ri ht of the foot control.

The fiber optics control is automatically activated by

operatin the handpiece usin the foot control.

NOTE: When the foot control is released, the fiber

optics light will stay on for approximately ten seconds to

allow inspection of the cutting site.

delivery head,

to the left

and hold it

there for 20

seconds.

NOTE: Flushing the water line in the handpiece can

be done by operating the FLUSH toggle valve while

either fully depressing or not depressing the foot control.