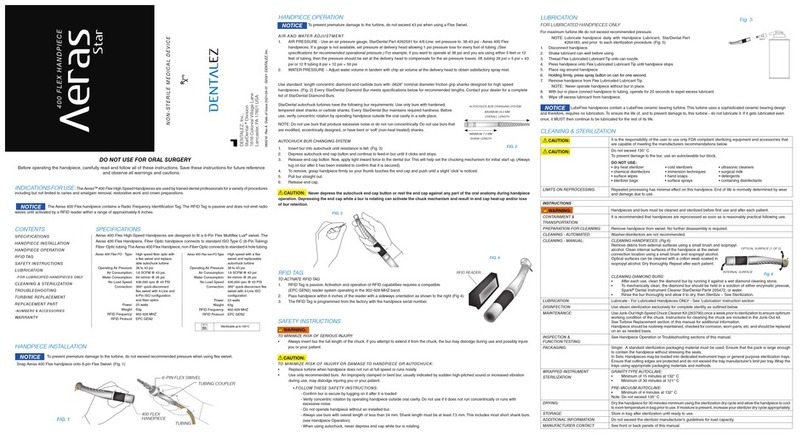

Handpiece Operation

Cleaning & Sterilization

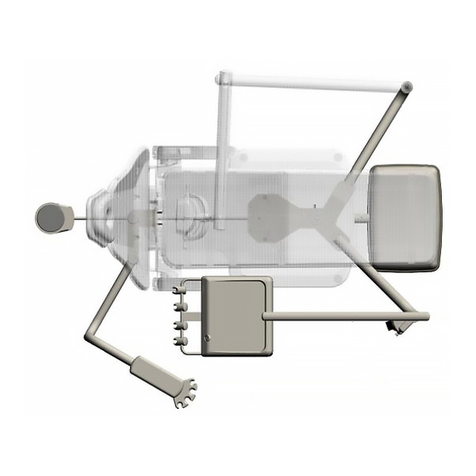

Solara QT High Speed Handpieces are designed to t a StarDental 360° quick disconnect swivel. The Solara QT connects

to standard 4-line ISO ber optic tubing and standard 4/6-line ISO ber optic tubing.

• Specications

• Handpiece Installation

• Handpiece Operation

• Safety Rules

• Lubrication - For Lubricated

Handpieces ONLY

• Cleaning & Sterilization

Contents

Type: High speed ber optic with a swivel & replaceable turbine. (Swivel sold separately.)

Operating Air Pressure: 30 to 34 psi

Air Consumption: 2.0 SCFM @ 34 psi

No Load Speed: 430,000 rpm

Connection: 360° quick disconnect swivel with 4-line ISO conguration & ber optics.

4/6 line ISO ber optic tubing.

Power: 18 watts

Weight: 32.8g

Specications (Nominal)

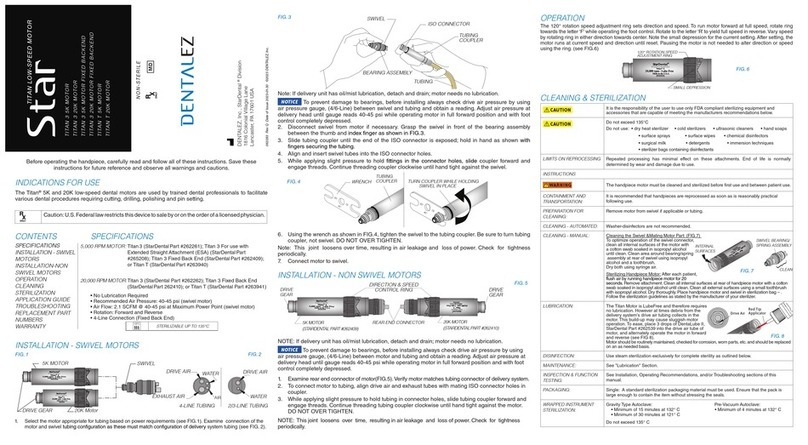

Note: This joint loosens over time, resulting in loss

of power. Check for tightness periodically.

Note: Filter air and water supplies, recommended ltration: 25 microns. Soften and deionize water. Be sure lters operate efciently.

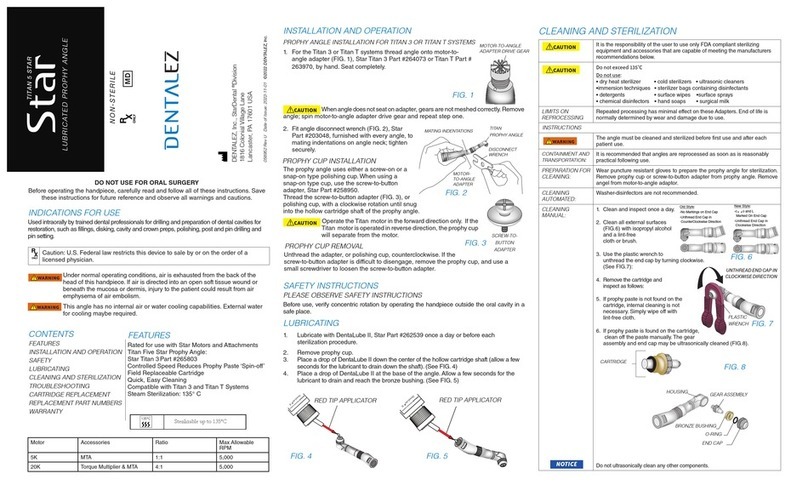

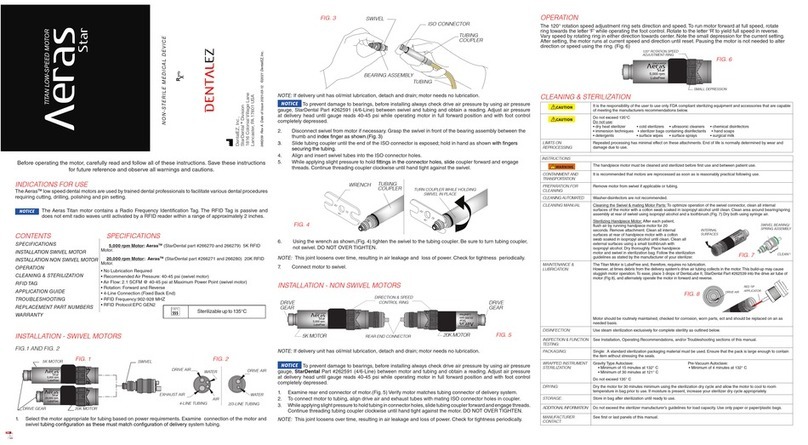

Handpiece Installation

1. Grasp the swivel in front of the bearing assembly between the thumb

and index nger as shown.

2. Slide tubing coupler until the end of the ISO connector is exposed;

hold in hand as shown with ngers securing the tubing.

3. Align and insert swivel tubes into the ISO connector holes.

4. While applying slight pressure to hold ttings in the connector holes,

slide coupler forward and engage threads. Continue threading

coupler clockwise until hand tight against the swivel.

5. Using the wrench as shown, tighten the swivel to tubing coupler

until snug. Be sure to turn tubing coupler, not swivel.

DO NOT OVER TIGHTEN. Connect handpiece to swivel.

• Troubleshooting

• Turbine Replacement

• Replacement Part Numbers

• Warranty

Sterilizable up to 135°C

135°C

Caution: Federal law restricts this device to

sale by or on the order of a dentist.

866.DTE.INFO (383.4636)

www.DentalEZ.com

065603 F DateofIssue 2019-03-31

StarDental®

1816 Colonial Village Lane

Lancaster, PA 17601 U.S.A.

Printed in the U.S.A.

©2019 DentalEZ, Inc.

Emergo Europe

Prinsessegracht 20

2514 AP The Hague

The Netherlands

EC REP

StarDental® Instruments

Solara® QT

High-Speed Handpiece

Includes LubeFree and Lubricated

Instruction Manual

0344

Non-Sterile

Medical Device

DO NOT USE FOR ORAL SURGERY

Swivel ISO Connector

Tubing

Coupler

Tubing

Bearing

Assembly

BEFORE OPERATING THE HANDPIECE, CAREFULLY READ AND FOLLOW ALL OF THESE INSTRUCTIONS.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE AND OBSERVE ALL WARNINGS AND CAUTIONS.

Indications For Use

The Solara®QT High Speed Dental Handpieces are pneumatically driven, hand-held devices intended for use by trained

dental professionals for drilling in the oral cavity. Procedures include, but are not limited to, caries removal, restorative

work and crown preparations.

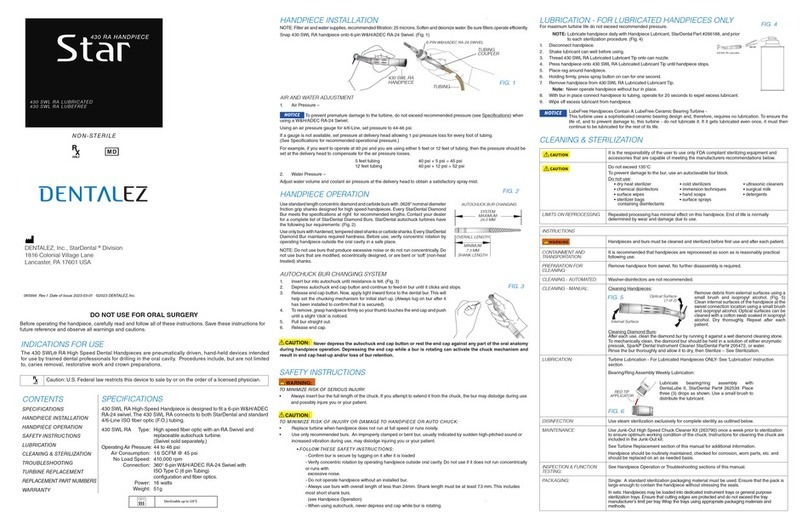

1. Air Pressure –

To prevent premature damage to the turbine, do not exceed 34 psi when using a HiFlo swivel.

Use an air pressure gauge, StarDental Part #262591 for 4/6-Line, set pressure to 30-34 psi.

If a gauge is not available, set pressure at delivery head allowing 1 psi pressure loss for every foot of tubing. (See

Specications for recommended operational pressure.)

For example, if you want to operate at 34 psi and you are using either 5 feet or 12 feet of tubing, then the pressure should

be set at the delivery head to compensate for the air pressure losses.

5 feet tubing 34 psi + 5 psi = 39 psi

12 feet tubing 34 psi + 12 psi = 46 psi

2. Water Pressure –

Adjust water volume at the delivery head to obtain a satisfactory spray stream, 30 cc/m is recommended.

3. Non-StarDental 6-pin Fiber Optic System:

If the handpiece is connected to a non-StarDental 6-pin F.O. system, consult your operator’s manual of F.O. system for

correct voltage. Non-StarDental F.O. systems must have a rated amperage output between 1.5 Amps dc and .73 Amps

dc at 3.1 Vdc. Use StarDental Part # 262962 bulb for non-StarDental F.O. systems that meet these requirements. Adjust

the voltage per instructions with the 3.1 VDC bulb.

If the non-StarDental 6-pin F.O. system has a rated amperage output of at least 1.5 Amps dc at 3.3 VDC, then the StarDental

Part #262522 bulb may be used. Adjust the voltage per instructions with the 3.3 VDC bulb.

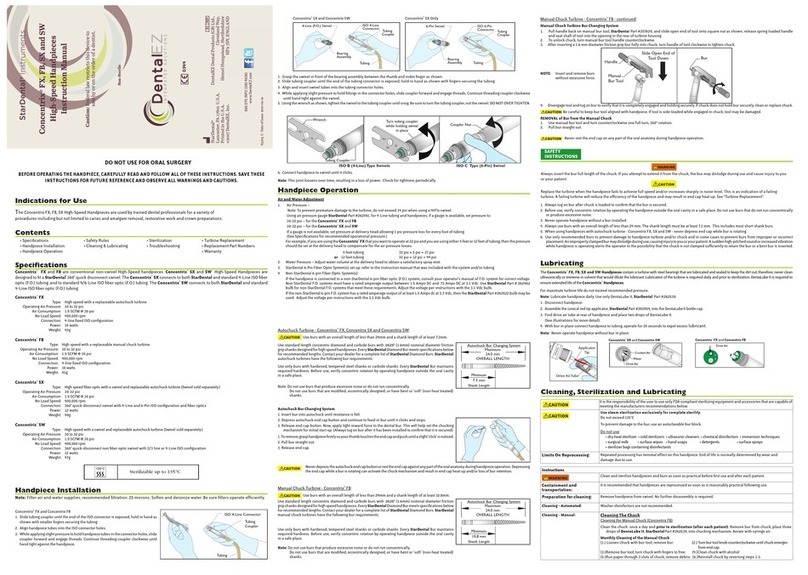

Air and Water Adjustment

NOTICE

Use standard length concentric diamond and carbide burs; all burs to have .0628"

nominal diameter friction grip shanks designed for high speed handpieces. Every

StarDental Diamond Bur meets the specications below for recommended lengths.

Contact your dealer for a complete list of StarDental Diamond Burs. StarDental

autochuck turbines have the following bur requirements:

1. To remove, grasp handpiece rmly so your thumb touches the end cap and

push until a slight ‘click’ is noticed.

2. Pull bur straight out.

3. Release end cap.

NOTE:Do not use burs that produce excessive noise or do not run concentrically.

Do not use burs that are modied, eccentrically designed, or are bent or ‘soft’ (non-heat treated) shanks.

Autochuck Bur Changing System

1. Insert bur into autochuck until resistance is felt.

2. Depress autochuck end cap button and continue to feed-in bur until it clicks

and stops.

3. Release end cap button. Now, apply light inward force to the dental bur. This

will help set the chucking mechanism for initial start up. (Always tug on bur

after it has been installed to conrm that it is secure).

Use only burs with hardened, tempered steel shanks or carbide shanks. Every

StarDental Diamond Bur maintains required hardness. Before use, verify concentric

rotation by operating handpiece outside the oral cavity in a safe place.

Never depress the autochuck end cap button or rest the end cap against any part of the oral anatomy

during handpiece operation. Depressing the end cap while a bur is rotating can activate the chuck

mechanism and result in end cap heat-up and/or loss of bur retention.

CAUTION

Autochuck Bur Changing System

Maximum

24.0 mm

OVERALL LENGTH

Minimum

7.3 mm

Shank Length

CAUTION

SAFETY

INSTRUCTIONS

WARNING

To minimize risk of serious injury:

• Always insert bur the full length of the chuck. If you attempt to extend it from the chuck, the bur may dislodge during use

and possibly injure you or your patient.

To minimize risk of injury or damage to handpiece or auto chuck:

• Replace turbine when handpiece does not run at full speed or runs noisily.

• Use only recommended burs. An improperly clamped or bent bur, usually indicated by sudden high-pitched sound or

increased vibration during use, may dislodge injuring you or your patient.

• Follow these safety instructions:

- Conrm bur is secure by tugging on it after it is loaded

- Verify concentric rotation by operating handpiece outside oral cavity. Do not use if it does not run concentrically or

runs with excessive noise.

- Do not operate handpiece without an installed bur.

- Always use burs with overall length of less than 24mm. Shank length must be at least 7.3 mm. This includes most short

shank burs. (see Handpiece Operation)

- When using autochuck, never depress end cap while bur is rotating.

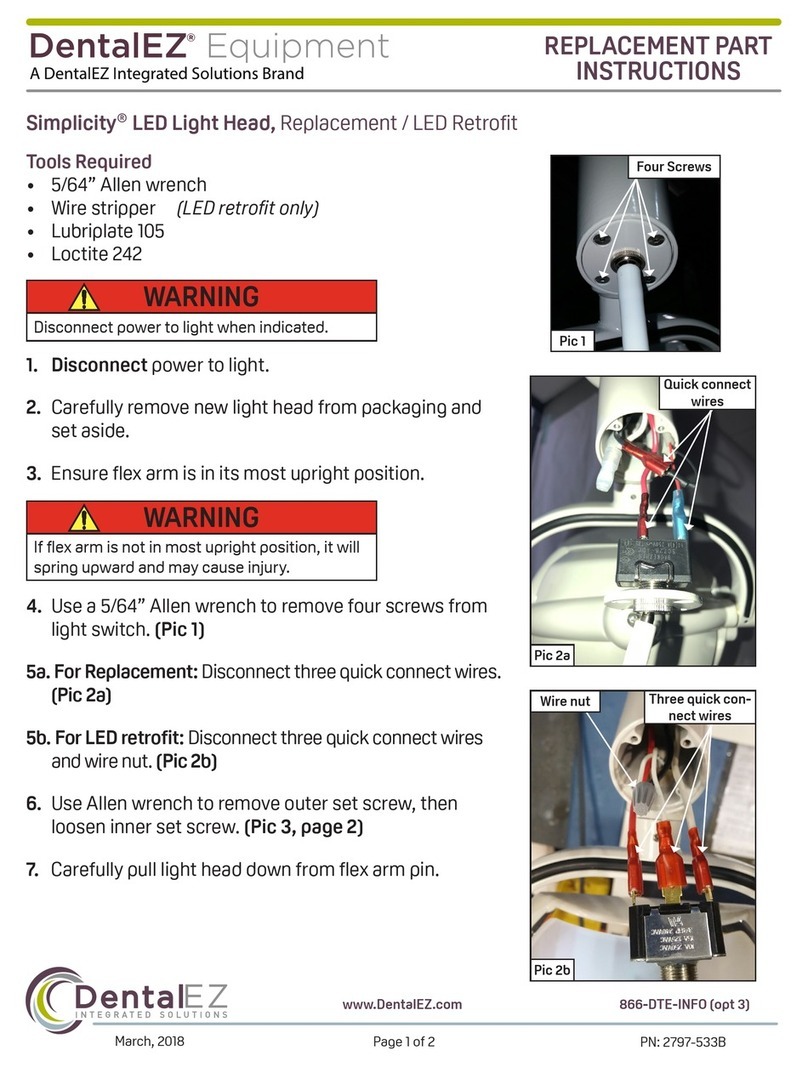

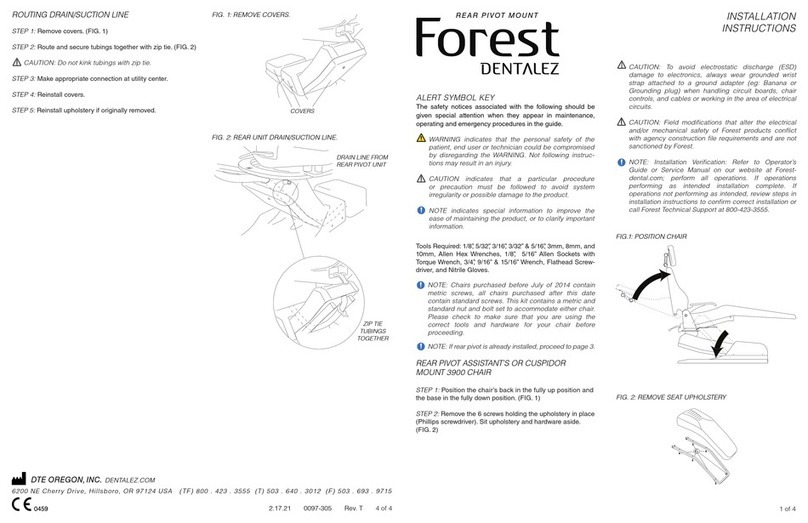

CAUTION It is the responsibility of the user to use only FDA compliant sterilizing equipment and accessories

that are capable of meeting the manufacturers recommendations below.

CAUTION Do not exceed 135°C

To prevent damage to the bur, use an autoclavable bur block.

Do not use:

• dry heat sterilizer • cold sterilizers • ultrasonic cleaners

• chemical disinfectors • immersion techniques • surgical milk

• surface wipes • hand soaps • detergents

• sterilizer bags •surface sprays

containing disinfectants

Limits On Reprocessing Repeated processing has minimal effect on this handpiece. End of life is normally determined

by wear and damage due to use.

INSTRUCTIONS

WARNING Clean and sterilize handpieces and burs as soon as practical before rst use and after each patient.

Containment and

transportation: It is recommended that handpieces are reprocessed as soon as is reasonably practical

following use.

Preparation for cleaning: Remove handpiece from swivel. No further disassembly is required.

Cleaning - Automated: Washer-disinfectors are not recommended.

Cleaning - Manual: Cleaning Handpieces:

Internal Surface

Optical Surface

(1 of 2)

Remove debris from external surfaces using a small

brush and isopropyl alcohol. Clean internal

surfaces of the handpiece at the swivel connection

location using a small brush and isopropyl alcohol.

Optical surfaces can be cleaned with a cotton swab

soaked in isopropyl alcohol. Dry thoroughly.

Repeat after each patient.

Cleaning Diamond Burs:

• After each use, clean the diamond bur by running it against a wet diamond cleaning stone.

• To mechanically clean, the diamond bur should be held in a solution of either enzymatic

presoak, Sparkl® Dental Instrument Cleaner StarDental Part# 205472, or water.

• Rinse the bur thoroughly and allow it to dry, then Sterilize – See Sterilization.

Lubrication: Lubricate - For Lubricated Handpieces ONLY - See 'Lubrication' instruction section

Disinfection: Use steam sterilization exclusively for complete sterility as outlined below.

Maintenance: Use Junk-Out High Speed Chuck Cleaner Kit (263790) once a week prior to sterilization to

ensure optimum working condition of the chuck. Instructions for cleaning the chuck are

included in the Junk-Out kit.

See Turbine Replacement section of this manual for additional information.

Handpiece should be routinely maintained, checked for corrosion, worn parts, etc. and should

be replaced on an as needed basis.

Inspection & function testing: See Handpiece Operation or Troubleshooting sections of this manual.

Packaging: Single: A standard sterilization packaging material must be used. Ensure that the pack is large

enough to contain the handpiece without stressing the seals.

In sets: Handpieces may be loaded into dedicated instrument trays or general purpose

sterilization trays. Ensure that cutting edges are protected and do not exceed the tray

manufacturer’s limit per tray. Wrap the trays using appropriate packaging materials and methods.

Wrapped Instrument

Sterilization: Gravity Type Autoclave: Pre-Vacuum Autoclave:

• Minimum of 15 minutes at 132° C • Minimum of 4 minutes at 132° C

• Minimum of 30 minutes at 121° C

Do not exceed 135° C

Drying: Dry the handpiece for 30 minutes minimum using the sterilization dry cycle and allow the

handpiece to cool to room temperature in bag prior to use. If moisture is present, increase your

sterilizer dry cycle appropriately.

Storage: Store in bag after sterilization until ready to use.

Additional information: Do not exceed the sterilizer manufacturer’s guidelines for load capacity.

Manufacturer contact: See front or back panels of this manual.

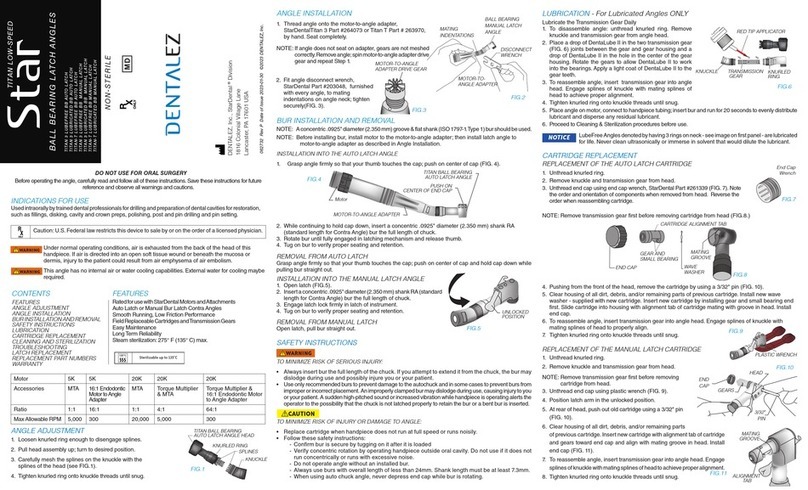

LUBRICATED Ceramic Bearing Turbine:

For maximum turbine life do not exceed recommended pressure.

Note: Lubricate handpiece daily with DentaLube

II

, StarDentalPart #262539, and prior to

each sterilization procedure.

1. Disconnect handpiece.

2. Assemble the conical red tip applicator, StarDental Part #202954, into the DentaLubeII bottle cap.

3. Find drive air tube at rear of handpiece and place three drops of DentaLube II.

(See illustrations for more detail).

Note: Never operate handpiece without bur in place.

4. With bur in place connect handpiece to tubing, operate for 20 seconds to expel excess

lubricant.

StarDental®

Instrument Solutions

Red Tip

Applicator Drive Air Tube

Water

Drive Air

Coolant

Air

Lubrication - For Lubricated Handpieces ONLY

NOTICE LubeFree Handpieces Contain A LubeFree Ceramic Bearing Turbine -

This turbine uses a sophisticated ceramic bearing design and, therefore, requires no lubrication. To ensure

the life of, and to prevent damage to, this turbine - do not lubricate it. If it gets lubricated even once, it MUST

then continue to be lubricated for the rest of its life.

Wrench

Tubing Coupler

Turn tubing coupler

while holding

swivel in place

NOTICE Any serious incident occurring from the use of this device should be reported to StarDental immediately. If incident occurred

in a EU Member State the Competent Authority must be notied.