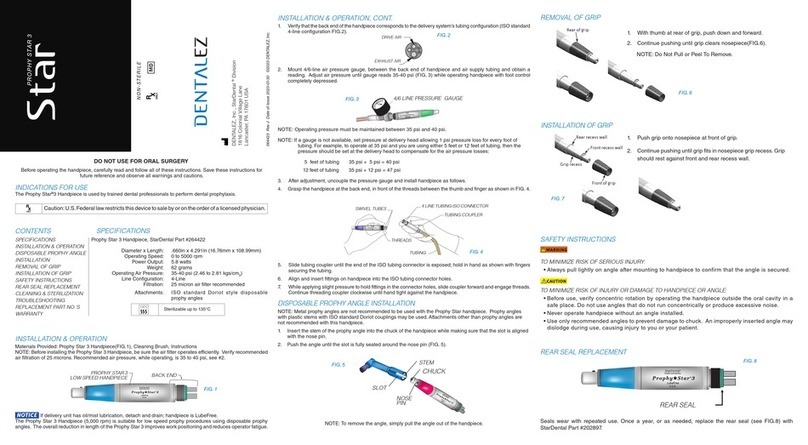

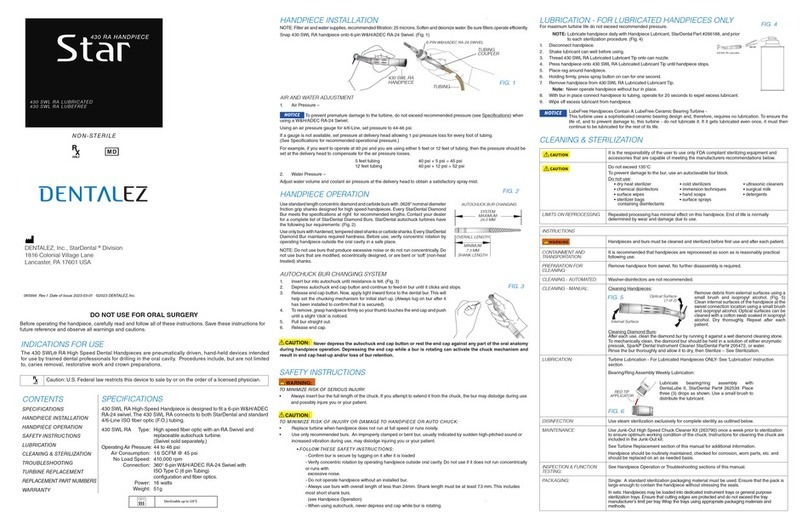

3. Carefully mesh the splines on the angle with the splines of the Motor-to-Angle Contra-Angle

Attachment (see FIG 8).

4. Tighten knurled ring onto threads until snug.

5. Install bur according to the angle’s instruction manual.

7LWDQ(

USP/XEH)UHH

0DGHLQ WKH86$

-;;;;;

6WDU 'HQWDO

SPLINES

ANGLE

MOTOR-TO-ANGLE

CONTRA-ANGLE ATTACHMENT

TITAN-E MOTOR

TRANSMISSION GEAR

CAUTION

When angle does not seat on attachment, gears are not meshed correctly. Remove

angle; spin angle transmission gear and repeat Step 3.

Titan E

®

StarDental

®

INTERNAL

SURFACES

SWIVEL BEARING/

SPRING ASSEMBLY

CLEAN

StarDental®

Instrument Solutions

StarDental®

Instrument Solutions

7LWDQ (

6WDU'HQWDO

7LWDQ (

6WDU'HQWDO

Drive

Air

RED TIP

APPLICATOR

TROUBLESHOOTING

Problem: LACK OF POWER

Cause: Air pressure

Correction: Verify proper handpiece air pressure. Refer to Installation.

Cause: Crimped tubing

Correction: Straighten tubing inside and outside delivery head.

Cause: Swivel not threaded fully onto tubing

Correction: Refer to Installation.

Cause: Brittle motor or swivel silicone rubber seal

Correction: Replace silicone rubber seal for 2/3-line swivel with StarDental Part #203103

and 4-line with StarDental Part #202897.

Cause: Swivel O-rings worn

Correction: Replace swivel O-rings, StarDental Part #259884.

Cause: Debris build-up in handpiece

Correction: Clean handpiece. Refer to Cleaning.

Problem: SWIVEL WILL NOT DISENGAGE FROM HANDPIECE

Cause: Build-up of debris

Correction: Place 3 drops of DentaLube II, StarDental Part #262539, into the swivel/tubing

connector. Rotate swivel to circulate lube. Disengage handpiece. Contact dealer

if unable to disengage swivel. To prevent reoccurrence, refer to Cleaning.

Note: If a problem persists, contact dealer for further assistance or contact StarDental technical

service at 1-866-DTE-INFO.

Silicone Rubber Seal, 4-Line (Pkg. of 3).......................202897 ........................................202897

DentaLube II .................................................................262539 ........................................262539

ACCESSORIES

Swivel, Motor 2/3-Line ..................................................260152......................................... 260152

Swivel, Motor 4-Line .....................................................260144......................................... 260144

LubeFree Ball Bearing Auto Latch Angle ......................264146

LubeFree Ball Bearing Manual Latch Angle .................262738

LubeFree Ball Bearing Autochuck Friction Grip Angle.......264151

Ball Bearing Auto Latch Angle ......................................264182

Ball Bearing Manual Latch............................................259005

Ball Bearing Autochuck Friction Grip Angle ..................264149

CLEANING & STERILIZATION

CAUTION It is the responsibility of the user to use only FDA compliant sterilizing

equipment and accessories that are capable of meeting the manufacturers

recommendations below.

CAUTION Do not exceed 135°C

Do not use: • dry heat sterilizer • cold sterilizers • ultrasonic

cleaners • hand soaps • surface sprays • surface wipes •

chemical disinfectors • surgical milk • detergents •

immersion techniques

• sterilizer bags containing disinfectants

LIMITS ON REPROCESSING Repeated processing has minimal effect on these attachments. End of life

is normally determined by wear and damage due to use.

INSTRUCTIONS

The handpiece motor must be cleaned and sterilized before first use and

between patient use.

CONTAINMENT AND

TRANSPORTATION:

It is recommended that handpieces are reprocessed as soon as is reasonably

practical following use.

PREPARATION FOR

CLEANING:

Wear puncture-resistant gloves and protective eye wear. After each patient,

flush air by running handpiece motor for 20 seconds. Remove motor from

swivel if applicable or tubing.

CLEANING - AUTOMATED: Washer-disinfectors are not recommended.

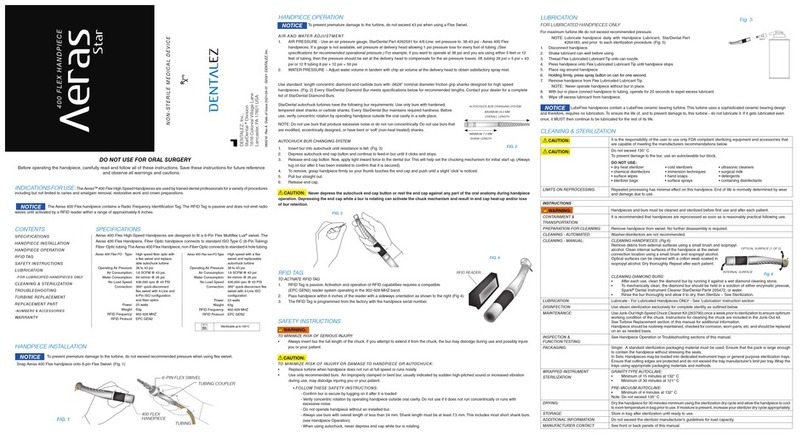

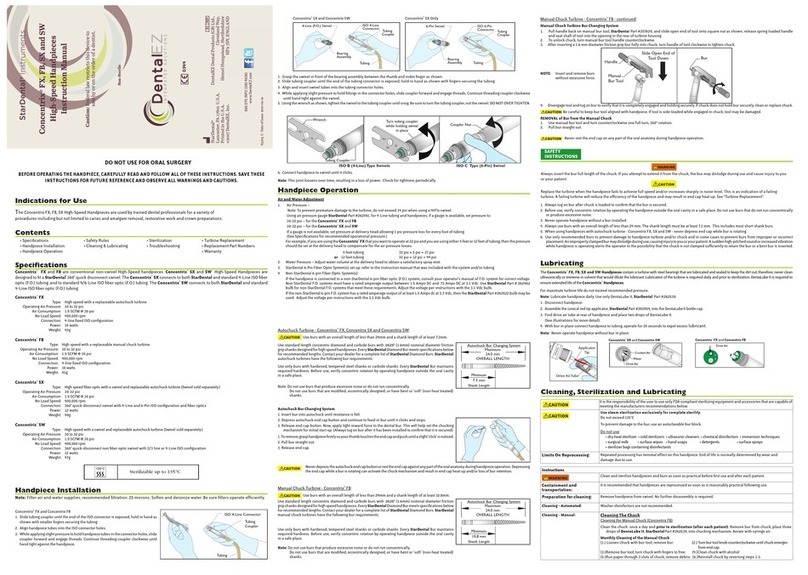

CLEANING - MANUAL: The Titan E Motor is LubeFree and, therefore, requires no lubrication.

At times debris from the delivery system’s drive air tubing collects in the

motor. This build-up may cause sluggish motor operation. To ease, place 3

drops of DentaLube II, StarDental Part #262539 into the drive air tube of

motor (FIG 9), and alternately operate the motor in forward and reverse.

CLEANING THE SWIVEL, THE MATING MOTOR PART

Clean all internal surfaces at rear of handpiece motor with a cotton swab

soaked in isopropyl alcohol until clean (FIG. 10).

Clean all external surfaces using a small toothbrush with isopropyl alcohol.

To optimize operation of the swivel connector, clean all internal surfaces of

the motor with a cotton swab soaked in isopropyl alcohol until clean. Clean

area around bearing/spring assembly at rear of swivel using isopropyl

alcohol and a toothbrush. Dry both using syringe air.

MAINTENANCE

&LUBRICATION:

The Titan-E Motor is LubeFree and, therefore, requires no lubrication. Motor

should be routinely maintained, checked for corrosion, worn parts, etc. and

should be replaced on an as needed basis.

FIG. 8

FIG. 9

FIG. 10

DISINFECTION: Use steam sterilization exclusively for complete sterility as outlined below.

INSPECTION & FUNCTION

TESTING:

See Installation, Operating Recommendations, and/or Troubleshooting

sections of this manual.

PACKAGING: Single: A standard sterilization packaging material must be used. Ensure

that the pack is large enough to contain the item without stressing the seals.

WRAPPED INSTRUMENT

STERILIZATION:

Gravity Type Autoclave: Pre-Vacuum

Autoclave:

• Minimum of 15 minutes at 132° C • Minimum of 4

minutes at 132° C

• Minimum of 30 minutes at 121° C

Do not exceed 135° C

DRYING: Dry the motor for 30 minutes minimum using the sterilization dry cycle and

allow the motor to cool to room temperature in bag prior to use. If moisture

is present, increase your sterilizer dry cycle appropriately.

STORAGE: Store in bag after sterilization until ready to use.

ADDITIONAL INFORMATION: Do not exceed the sterilizer manufacturer’s guidelines for load capacity. Use

only paper or paper/plastic bags.

MANUFACTURER CONTACT: See first or last panels of this manual.

WARNING

REPLACEMENT PART NUMBERS

ALWAYS INSIST ON STARDENTAL PARTS FOR BEST PERFORMANCE.

DESCRIPTION

TITAN T

ITEM NUMBER

TITAN 3

ITEM NUMBER

LIMITED WARRANTY

O-Rings and Seals are specifically excluded from this warranty.

DENTALEZ warrants the Titan E Low-Speed Handpiece Motor for 1 year from the date of

purchase*.

Please note the following additional terms of our warranty policy:

• Warranty covers manufacturing defects only and does not cover defects resulting from abuse,

accidents, misuse, improper handling, cleaning, care or maintenance or the failure to follow

or observe our operating/use, maintenance and/or installation instructions. Damage resulting

from the use of chemicals, cleaners, disinfectants or sterilization is not covered under this

warranty nor is normal wear and tear. Failure to use authorized parts or an authorized repair

facility voids this warranty.

• Liability is limited to repair or replacement of the defective part(s) or products at our sole

discretion. All other liabilities, in particular liability for damages, including, without limitation,

special, exemplary, consequential or incidental damages are excluded

• THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. NO EMPLOYEE, REPRESENTATIVE OR DEALER IS AUTHORIZED

TO CHANGE THIS WARRANTY IN ANY WAY OR TO GRANT ANY OTHER WARRANTY.

*Provided conditions in warranty are met.

WARRANTY REGISTRATION

Please visit the website below to register your StarDental product. This will ensure proper registration and prompt and accurate

service should any of your purchases need evaluation or repair during the warranty period.

StarDental Products: WWW.DENTALEZ.COM/warranty

FOR NEW PRODUCTS, MANUALS AND TECHNICAL INFORMATION, CALL

1-866-DTE-INFO OR VISIT OUR WEB SITE @ WWW.DENTALEZ.COM

IMPORTANT NOTICE ABOUT RETURNING PRODUCT TO DENTALEZ INC.

Anyone wishing to return any DENTALEZ Inc. product to a DENTALEZ facility MUST obtain the proper RETURN AUTHORIZATION

NUMBER from the Customer Service Department.The RA Number must appear clearly marked on both the outside and inside of

the returned product carton. When calling for a return authorization number you will be asked to provide the following information:

To Obtain A

Return Authorization

Number Call

1-866-DTE-INFO

1. Product Name, Model Number or Part Number

2. Serial Number of Product

3. Dealer Return Purchase Order Number

4. Reason For Return

5. Copy of Invoice Showing Purchase

Items will be evaluated. Return Authorization Number is not a guarantee for credit. Your cooperation with this procedure will

help us expedite processing of any returns.

TITAN E LOW-SPEED MOTOR