Dentsply Sirona

Operating Instructions CEREC Guide 2

3 Product description

3.1 Description of the CEREC Guide 2

63 96 100 D3587

D3587.201.01.11.0212.2018 9

3Product description

3.1 Description of the CEREC Guide 2

CEREC Guide 2 is a precise surgical guide which is individually created

in your practice or laboratory. The manufacturing process is fast and

incurs comparatively low costs.

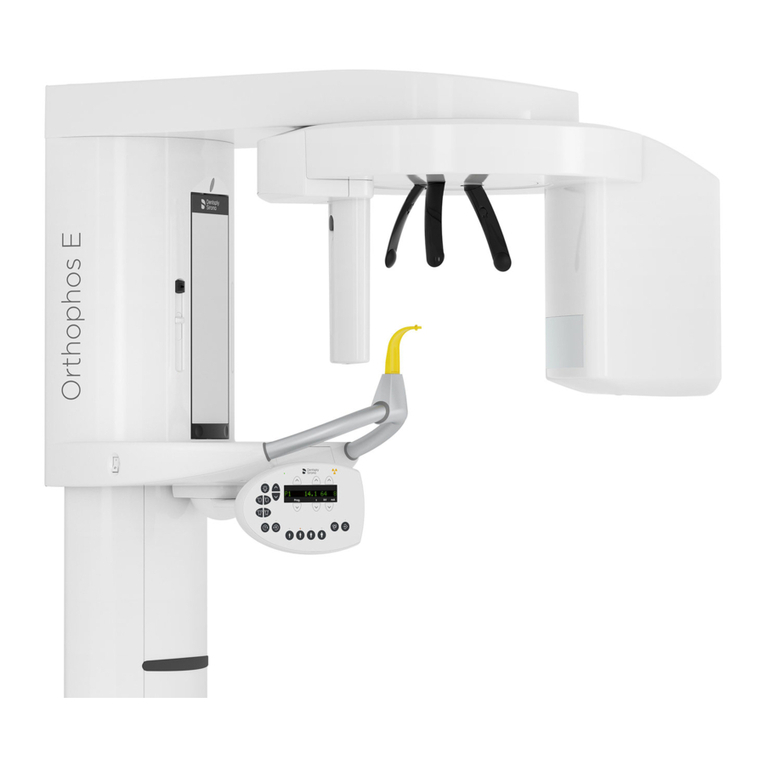

The individually produced surgical guide is part of the integrated implant

plan and surgical implementation using CAD/CAM and 3D X-ray

systems from Dentsply Sirona.

It is a prerequisite that the location of one or more implants has been

planned using the 3D X-ray scan (DVT) and that location is to be

transferred to the actual jaw. CEREC Guide 2 is a device that supports

the dentist when setting implants. CEREC Guide 2 functions as a

surgical guide, which is placed on the residual teeth or another

supporting structure in the mouth and acts as a mechanical guide for

the drills used. Together with CEREC Guide 2, drill keys are also used

as reducing bushes, which enable the use of drills with smaller

diameters.

The key steps for manufacturing and using a CEREC Guide 2 are as

follows:

1. Optical scan

An optical scan of the situation in the mouth is created (either

intraoral or using a model). A suitably large area is encompassed,

on which the drilling template can later support itself.

A restoration is designed, which initially enables the subsequent

implant planning in terms of prosthetic aspects.

This information is exported as a *.SSI file.

2. DVT exposure

A DVT scan is performed, which forms the basis for the implant

planning.

3. Implant planning

Optical scan (Import of the *.SSI file) and DVT scan are

superimposed in GALILEOS Implant using striking features, which

are present in both scans (such as the residual teeth).

The implant planning is performed based on all of this information.

Therefore the location of the guide bushing of the drill is also

defined in relation to the residual teeth (or other supporting

structures).

The planning data is exported as a *.CMG.DXD file.

4. Creating the drilling template

After importing the *.CMG.DXD file in CEREC or inLab, a drilling

template is designed, which can be placed on suitable supporting

structures and has an opening at a planned location, through which

the drill is to be fed. The single-piece template is create from

PMMA, for example by milling.

5. Surgery

The drilling template is placed in the patient’s mouth. According to

the drilling protocol of the manufacturer of the implant, different

bores with drills with different guide diameters. Drill keys are used

for this and serve as reducing bushes for the respective drill

diameter.