DEUTZ-FAHR SwatMaster 7131 EVO User manual

SwatMaster 7131 EVO

Operating manual

Edition 11/2006

Date printed 12.2006

Language EN

Implement number 5001 -

Type / series 6962/16

Document number VF16643769

All manuals and user guides at all-guides.com

Identification of the implement

Your dealer requires some information about your implement in order to be able to help you as quickly as

possible.

Please enter the information here.

Designation

Working width

Weight

Implement

number

Accessories

Address of

the supplier

Manufacturer's

address

Kverneland Group Gottmadingen N. V. of Germany owns the copyright and right of exploitation. Reproduction, transfer to other media, translation

or the use of extracts or parts of this manual without the explicit permission of Kverneland, is not permitted. All rights reserved. The contents of

this operating manual are subject to change without notice. The right to technical revision is reserved.

SwatMaster 7131 EVO

Kverneland Group Gottmadingen N.V.

Industriepark 312

78244 Gottmadingen

Germany

Tel.: +49 7731 788 - 0

7.10 metres

All manuals and user guides at all-guides.com

Table of contents

3

Tabl e of conten ts

Preliminary information ..................................4

Target group for this operating manual 4

Meaning of the symbols 4

Safety................................................................5

For your safety 5

Who is allowed to operate the implement 6

Coupling 6

Driving on the road 8

Initial operation 9

Uncoupling the implement 10

Care and Maintenance 10

Further regulations 11

Familiarise yourself with the device............12

Area of application of the implement 12

Features of the implement 12

Component designations 13

Specifications 14

Delivery and assembly..................................17

Checking the scope of supply 17

Coupling the implement................................18

General 18

Coupling to the lift link drawbar 18

Coupling to the pending attachment 19

Coupling the cardan shaft 20

Wheel wedges 20

Rip chain for USA and Canada 20

Connections 21

Preparing for operation.................................23

Safety 23

Working depth 24

Stabiliser [+] 25

Raking wheel pitch 26

Tine anti-loss device [+] 26

Driving on the road........................................27

Safety 27

Prior to travel on public roads 27

Road transport 32

Preparations on the field ..............................33

Safety 33

General 33

Swath deposit 34

Attaching the tine support 38

Pulling out the guard 38

Swath former, rear 39

Swath former, front [+] 41

Operation........................................................42

Safety 42

General 43

3-way ball valve 43

Swathing 44

Cleaning and care ......................................... 46

Safety 46

Cleaning 46

Care 46

Parking and storage...................................... 47

Safely setting down the implement 47

General 47

After the end of the season 47

Maintenance................................................... 48

For your safety 48

General 50

Screw connections 52

Lubrication points for grease lubrication 53

Lubricating the cardan shafts 54

Adapting the cardan shaft 55

Filling volumes 56

Tyres 56

Hydraulic 56

Accessory equipment ................................... 57

Tine anti-loss device 57

Tandem axles 57

Roller feelers 57

Lift link drawbar 57

Front swath former 58

Height adjustable sustainer 58

Fault................................................................ 59

Circuit diagrams............................................ 60

Hydraulic circuit diagram 60

Lighting circuit diagram 61

Disposal ......................................................... 62

EC Conformity Declaration........................... 63

in conformity with the

EC Directive 98/37/EC 63

Index ............................................................... 64

All manuals and user guides at all-guides.com

4

Preliminary information

Prel imi nary informat ion

Target group for

this operating ma-

nual

This operating manual is directed at trained farmers and individuals

who are otherwise qualified to perform agricultural activities and who

have received instruction on the handling of this implement.

For your safety

Familiarise yourself with the contents of this operating manual before

assembly or initial operation of the implement. In this way, perfor-

mance and work safety are optimised.

The employer should:

All personnel are to be regularly instructed on the use of the imple-

ment, at least once annually, in accordance with the regulations of

section 1 of the trade's mutual indemnity association. Untrained or un-

authorised persons are not allowed to use this implement.

Training

Your dealer will provide instruction on operation and care of the imple-

ment.

Meaning of the

symbols

In order to make this manual clear and easy to read, we have used va-

rious symbols. They are explained below:

•

A dot accompanies each item in a list

> A triangle indicates operating functions which must be performed

→

An arrow indicates a cross-reference to other sections of this ma-

nual

[+] A plus sign indicates an add-on item of equipment, which is not

included in the standard version.

N

OTE

The term, “Note” indicates tips and notes on operation.

The screwdriver indicates tips during assembly or adjustments.

The warning triangle indicates important safety instructions. Failure

to observe these safety instructions can result in:

•

Coarse defects in the operability of the implement

•

Damage to the implement

•

Personal injury or accidents.

0

A star indicates examples that assist understanding of the instruc-

tions.

All manuals and user guides at all-guides.com

Safety

5

Safety

For your safety

This chapter contains general safety instructions. Each chapter of the

operating manual contains additional specific safety instructions

which are not described here. Observe the safety instructions

•

in the interest of your own safety,

•

in the interest of the safety of others, and

•

to ensure the safety of the implement.

Numerous risks can result from handling agricultural implements in

the wrong way. Therefore, always work with special care and never

under pressure.

The employer should:

At regular intervals inform those who work with the implement about

these safety instructions and the

statutory regulations.

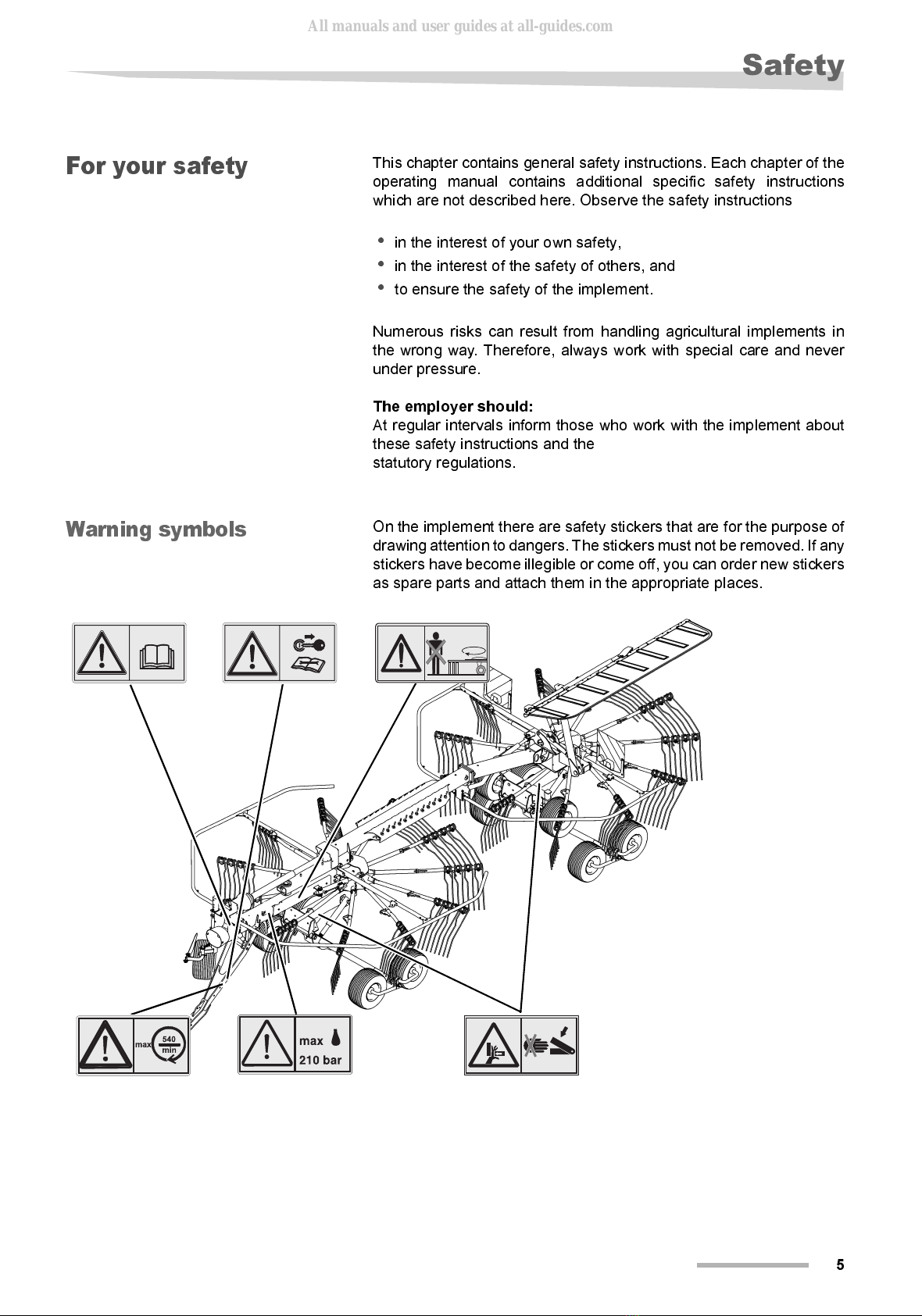

Warning symbols

On the implement there are safety stickers that are for the purpose of

drawing attention to dangers. The stickers must not be removed. If any

stickers have become illegible or come off, you can order new stickers

as spare parts and attach them in the appropriate places.

All manuals and user guides at all-guides.com

6

Safety

Meaning of warning sym-

bols

Read the operating manual

Read and observe the operating manual and the safety regulations

prior to initial operation!

Switch off the engine

Perform all maintenance, repair and adjusting work only when the im-

plement is at a standstill.

Keep your distance

Keep your distance from the rotating raking wheel. When the wheel ra-

ke is in operation nobody is allowed in the immediate vicinity of the im-

plement!

Maximum cardan shaft speed 540 rpm

The prescribed maximum cardan shaft speed of 540 rpm must not be

exceeded.

Risk of crushing

Never reach into the zone where there is a risk of getting crushed as

long as any parts there are able to move.

Maximum hydraulic pressure 210 bar

The hydraulic pressure of the tractor on the implement's hydraulic sy-

stem must not exceed 210 bar.

Who is allowed to

operate the imple-

ment

Only qualified personnel

Only qualified persons who have been informed of the dangers asso-

ciated with handling the implement are permitted to operate, service

or repair the implement. As a rule, such persons are trained and ex-

perienced in agricultural work or have been thoroughly trained in a si-

milar fashion.

Coupling

Increased risk of injury

When coupling the implement to the tractor, there is an increased risk

of injury. Therefore:

•

secure the tractor against rolling away, shut off the engine and take

out the ignition key

•

never stand between the tractor and the implement during coupling

•

when hitching onto the lift link drawbar fix the lower link laterally

and lock the three-point power lift against lifting and lowering.

•

lock the cardan shaft securely to the PTO shaft end of the tractor

and implement

If this is not complied with, the consequence can be damage to the im-

plement and even life-threatening injuries.

All manuals and user guides at all-guides.com

Safety

7

Cardan shaft

Use only the cardan shafts prescribed by the manufacturer and read

the attached operating manual attentively. Adapt the length of the car-

dan shaft as required. The wrong cardan shaft lengths can cause da-

mage to the implement and injuries to personnel.

Check and fix the cardan shaft guard

The rotating cardan shaft is protected by the cardan shaft guard. En-

sure that the guard is not damaged. Fix the cardan shaft guard by con-

necting the chains on the implement and tractor faces. Unguarded

cardan shafts can cause life-threatening injuries.

Maximum cardan shaft speed 540 rpm

The prescribed maximum cardan shaft speed of 540 rpm must not be

exceeded. Higher rpm's can cause damage to the implement.

Hydraulic connection at zero pressure only

Only connect hydraulic tubes to the tractor hydraulic system if the trac-

tor and implement hydraulic system is depressurised. A pressurised

hydraulic system can trigger unforeseeable movements on the imple-

ment.

High pressures in the hydraulic system

The hydraulic system is under high pressure. Regularly check all

pipes, hoses and bolted connections for leaks and externally visible

damage. Only use suitable agents when looking for leaks. Eliminate

damage immediately. Escaping fluid may result in injuries and fires.

Seek medical attention immediately if injuries occur.

Colour-coded hydraulic connections

To avoid operating errors, the plug sockets and plugs of the hydraulic

connections between the tractor and implement are colour coded.

Wrongly connected hydraulic hoses can trigger unforeseen move-

ments on the implement.

All manuals and user guides at all-guides.com

8

Safety

Driving on the road

Make sure that the condition of the implement conforms to traffic

regulations.

The implement must conform to current national traffic regulations if

you intend to drive it on public roads. This includes, for example:

•

Lights, warning equipment and guard devices are installed

•

Compliance with the permissible transport widths and weights, ax-

le loads, tyre loadbearing capacities, laden weights and national

speed restrictions

•

Compliance with the maximum permissible transport speed of

40 km/h.

If this is not complied with, the driver and keeper of the vehicle are lia-

ble.

Close the ball valve

Close the ball valve before driving on the road. If the ball valve is open

and there is an operating error, the implement can drop. This can cau-

se damage to the implement.

Check tyre pressure

Check tyre pressure regularly. The wrong tyre pressure will reduce the

service life of a tyre and can cause unstable driving properties and ac-

cidents.

Check the pin connection

The hitch pin must be in perfect condition, there must be no signs of

wear and it must be properly secured. Otherwise coupled implements

are able to detach themselves.

Check remote cord for the quick release coupling

Remote cords must hang loose and must not, when in their lowered

position, release the couplings of their own accord. Coupled imple-

ments can otherwise detach themselves independently from the trac-

tor's lower link arm.

No riding on the implement

Neither personnel nor objects are allowed to be transported on the im-

plement at any time. Riding on the implement is hazardous and strictly

prohibited.

Altered driving and braking performance

The driving and braking performance are altered when the implement

is attached to the tractor. Take the width and balancing weight of the

implement into consideration, especially on sharp bends. A driving

style which is not adapted to road conditions can cause accidents.

Adapting the speed

In the event of bad road conditions and excessive speed very high

forces can occur that subject the material of the tractor and of the im-

plement to high loads or to an overload. It is therefore important to ad-

just your speed to the road conditions. A driving style which not adap-

ted to road conditions can cause accidents.

All manuals and user guides at all-guides.com

Safety

9

Initial operation

The implement should not be put into operation for the first time

until the user has been trained to use it.

The implement must not be used for the first time until an instruction

lesson has been given by employees of the distribution associates,

company representatives or employees of the

manufacturer. If initial operation is performed without instruction, da-

mage to the implement can be caused by operating errors and acci-

dents can occur.

Ensure that the implement is in perfect working condition.

Do not operate the implement unless it is in perfect working condition.

Check all important components and replace any defective compon-

ents before starting the implement. Defect components can cause da-

mage to equipment and injury to persons.

Do not remove the protective equipment.

The guard devices must not be removed or by-passed. Check all

guard devices before starting the implement. Unguarded parts of the

implement can cause serious or fatal injuries.

No riding on the implement

Neither personnel nor objects are allowed to be transported on the im-

plement at any time. Riding on the implement is hazardous and strictly

prohibited.

Make sure the immediate vicinity is clear

Before starting, unfolding and commencing operation, check the sur-

rounding area of the implement. Make sure the operator has an ade-

quate view of the work area. Do not begin work until the immediate

vicinity is cleared of any persons or objects. Life-threatening injuries

can occur.

Retighten all nuts, bolts and screws

Nuts, bolts and screws should be checked at regular intervals and

tightened if necessary. Screws can work loose through the use of the

implement. The consequence can be damage to the implement and

accidents.

What to do in the event of a malfunction

In the event of a malfunction, shut down and secure the implement im-

mediately. The malfunction may be eliminated immediately, or your

dealer must be assigned the task. Continued operation of the imple-

ment can cause damage and accidents.

All manuals and user guides at all-guides.com

10

Safety

Uncoupling the im-

plement

Increased risk of injury

There is an increased risk of injury when uncoupling the implement

from the tractor. Therefore:

•

Secure the tractor against rolling away, switch off and take out the

ignition key

•

Never stand between the tractor and the implement during uncou-

pling.

•

Ensure that the implement is standing on a flat and stable surface

•

Ensure that the parking leg is securely locked

•

Set the cardan shaft down on the mounting provided

•

Secure the implement against rolling away (use wheel wedges)

•

Do not disconnect the hydraulic hoses until the hydraulic system is

unpressurised on both the tractor and implement faces

If this is not complied with, the consequence can be serious or fatal

injuries.

Care and Mainte-

nance

Follow the care and maintenance chart

Observe prescribed intervals for maintenance checks and inspections

specified in the operating manual. If these intervals are not complied

with, damage to the implement and accidents can be caused.

Only use OEM replacement parts (original equipment manufac-

turers).

Many components have special properties that are decisive for the

stability

and operability of the implement. Only spare and wear parts

supplied by the manufacturer have been tested and cleared. Using

other products may lead to malfunctions or reduce safety of operation.

The use of non-OEM replacement parts renders the manufacturer's

guarantee null and void and frees the manufacturer from all liability.

When performing care and maintenance work:

•

Switch off the cardan shaft drive

•

Depressurise the hydraulic system

•

Whenever possible, uncouple the tractor

•

Switch off the tractor and withdraw the ignition key

•

Make sure the implement is standing safely. Provide additional

supports as required

•

Do not use parts of the implement to climb onto it; use only secure

steps, ladders or other means of access

•

Secure the implement against rolling away (use wheel wedges)

Only if these regulations are complied with is safety ensured during

care and maintenance work.

Turn off the electrical supply

Prior to carrying out work on the electrical system, disconnect it from

the power supply. Equipment under electrical power can cause dama-

ge to equipment and injury to persons.

All manuals and user guides at all-guides.com

Safety

11

Replace hydraulic tubes

Hydraulic tubes can age without this being externally visible. We the-

refore recommend replacing the hydraulic hoses every six years. De-

fective hydraulic lines can lead to severe or fatal injuries.

Caution when cleaning with a high-pressure cleaner

The implement can be cleaned using either water or a steam jet. Cle-

an the bearings, plastic parts and hydraulic hoses using low pressure

only. Excessive pressure can damage these parts.

No corrosive washing additives

Do not use any corrosive washing additives for cleaning. The bright

metal surfaces can get damaged.

Prior to

carrying out

welding work

Before performing any electrical welding work on the uncoupled im-

plement, disconnect the tractor's battery and the alternator. This will

avoid damaging the electrical system.

Tighten the screw connections

Retighten any loosened screw connections after care and mainte-

nance work. Serious personal injuries and damage to property can be

caused by loose screw connections.

Further regulati-

ons

Observe the regulations

In addition to those listed above, please observe the following safety

instructions:

•

Accident-prevention regulations

•

Generally recognised safety regulations, occupational health re-

quirements and road traffic regulations

•

Instructions given in this operating manual

•

Regulations pertaining to operation, maintenance and repair.

All manuals and user guides at all-guides.com

12

Familiarise yourself with the device

Fam iliarise yourself with the de vice

Area of application

of the implement

The implement is a two-wheel rake, which is suitable only for the ra-

king together of mowed stalk-type vegetation (for example, hay or

straw). By hydraulic adjustment of the two raking wheels the crop can

be deposited in a swath or in two individual swaths.

Proper use

Any other use extending beyond this, for example, for silo distribution,

any form whatsoever of soil preparation, road sweeping or for the

transmission of power to other implements is not an intended use. The

manufacturer and dealer are not liable for damage caused by impro-

per use. Improper use is solely at the risk of the user.

Features of the im-

plement

Versatility - for a single swath or two individual swaths

This rake meets all the requirements of modern fodder heaping tech-

nology, no matter whether a 12.5 m wide double swath has to be pro-

vided for a high-output fodder harvesting implement or small swaths

for the hay harvest. The rake can be pulled by tractors of 30 kW or mo-

re by the pending attachment, hitch or lift link drawbar.

Extensive equipment

The implement is equipped with low-maintenance gearboxes and

11 rotating arms on the front and rear raking wheel. Excellent raking

quality is achieved thanks to the bent prongs. Each raking wheel can

be equipped optionally with tandem axles with 18“ wheels.

Together with the "TerraLink" support these ensure excellent following

of the ground contour.

Flexible due to the swivelling rear raking wheel

The facility for lateral outward slewing of the rear raking wheel to the

left or right offers many usage options.

All manuals and user guides at all-guides.com

Familiarise yourself with the device

13

Easy changeover from operating to transport position

The rake is easily changed over from operating to transport position.

Hydraulic cylinders lift the rake into transport position and the swath

former folds up hydraulically to maintain the transport width of less

than 3.0 m with the tine arms attached. If a smaller transport width is

required, the tine arms can be removed, fixed in parking position and

the guard can be pushed in.

50 centimetre lift-out height

For road transport and at headlands the implement can be quickly lif-

ted out by roughly 50 centimetres. For working, lower the wheel rakes

hydraulically from transport position back to working position.

Component desi-

gnations

Support arm

Drawbar Drawbar cylinder Axle support

Chassis cylinder

Cardan shaft

Articulated arm

Cross beam

Swath former

Pivoting cylinder

Raking wheel arm

Tine support

Tandem axle

Raking wheel gear

Slewing gear

All manuals and user guides at all-guides.com

14

Familiarise yourself with the device

Specifications

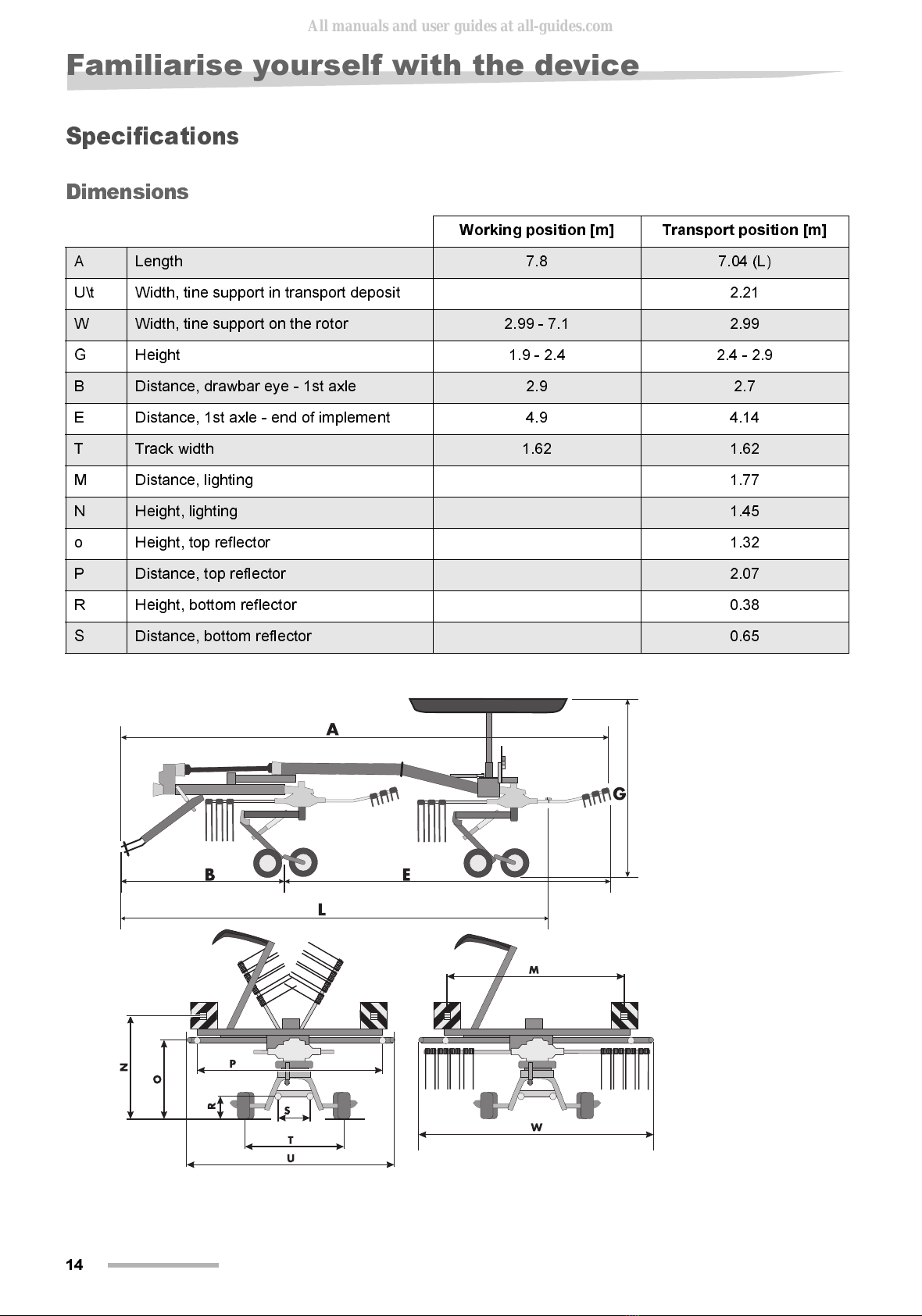

Dimensions

Working position [m] Transport position [m]

ALength 7.8 7.04 (L)

U\t Width, tine support in transport deposit 2.21

WWidth, tine support on the rotor 2.99 - 7.1 2.99

G Height 1.9 - 2.4 2.4 - 2.9

BDistance, drawbar eye - 1st axle 2.9 2.7

E Distance, 1st axle - end of implement 4.9 4.14

TTrack width 1.62 1.62

M Distance, lighting 1.77

NHeight, lighting 1.45

o Height, top reflector 1.32

PDistance, top reflector 2.07

R Height, bottom reflector 0.38

SDistance, bottom reflector 0.65

All manuals and user guides at all-guides.com

Familiarise yourself with the device

15

Weights

Tractor equipment

required

Operating position Transport position

Gross weight 1393 kg 1393 kg

Load supported on the stabiliser 150 kg 160 kg

Axle load of 1st axle 633 kg 663 kg

Axle load of 2nd axle 610 kg 570 kg

Output / connections

Minimum output of the tractor 30 kW

Lighting power supply 12 V, 7-pin plug socket ISO 1724

Hydraulic connections 1 x double acting / 1 x single acting

Hydraulic pressure 150 - 210 bar

Cardan shaft speed 540 rpm

Lift link drawbar Fixable in height and laterally

Pending attachment Standard

All manuals and user guides at all-guides.com

16

Familiarise yourself with the device

Equipment of the im-

plement

Swath deposit

Swath former for rear raking wheel Standard

Swath former for front raking wheel [+]

Raking wheels / raking wheel arms / tines

Number of raking wheels 2

Number of arms per raking wheel 11

Number of tines per raking wheel arm 4

Tine arms removable Standard

Raking wheel precision height adjustment Mechanical

Hydraulically liftable swath former Standard

Tine anti-loss device [+]

Wheels

Single axles 18 x 8.50-8

Stabiliser [+] 18 x 8.50-8

Tandem axles [+] 18 x 8.50-8

Roller feelers [+] 18 x 8.50-8

Safety accessories

Lighting Standard

Warning signs Standard

Cardan shaft - double wide-angle cardan shaft Standard

All manuals and user guides at all-guides.com

Delivery and assembly

17

Deli very and assembl y

Checking the

scope of supply

Wheel rake

The implement is delivered fully assembled. If any parts of the imple-

ment have not been assembled, please contact your dealer.

Do not perform any assembly work yourself

Do not perform the assembly work yourself. The following points are

required to be met for the implement to be in proper condition:

•

observance of a sequence of work steps

•

Compliance with tolerances and torques

•

Knowledge of work safety during assembly

N

OTE

If parts are missing or have been damaged during transportation,

please submit a complaint immediately to your dealer, importer or the

manufacturer.

All manuals and user guides at all-guides.com

18

Coupling the implement

Coupl ing the im plement

Increased risk of injury

When coupling the implement to the tractor, there is an increased risk

of injury. Therefore:

•

Secure the tractor in such a way that it cannot roll forwards or back-

wards

•

never stand between the tractor and the implement during coupling

•

Actuate the three-point power lift system slowly and carefully.

If this is not complied with, the consequence can be serious or fatal

injuries.

General

The implement is equipped ex-factory for coupling to the pending at-

tachment or lift link drawbar.

Genuine socket pins from the manufacturer

Use only genuine socket pins from the manufacturer. These have the

required strength. Other pins can break. The consequence can be da-

mage to the implement or an accident.

> Fit the wheel rake by means of socket pins to the lift link drawbar

or pending attachment

> Secure the socket pin with a safety splint

Coupling to the lift

link drawbar

Lock the height adjustment of the lower link

Lock the height adjustment of the lower link Comply with the tractor

operating manual. Accidental lifting of the lower links complete with

the lift link drawbar can destroy the cardan shaft.

Lock the lateral setting of the lower links.

Fix the lower links after coupling the implement. Lateral free move-

ment of the lower links causes unstable drive properties during trans-

port journeys and can cause accidents.

> Fix the lower link height to a distance of roughly 400 mm from the

ground.

N

OTE

The working depth is set via the two chassis, the drawbar cylinder or

the stabiliser [+].

→

Chapter »Preparing for operation«, section »Working depth«, page

24

Safety splint

Socket pin

All manuals and user guides at all-guides.com

Coupling the implement

19

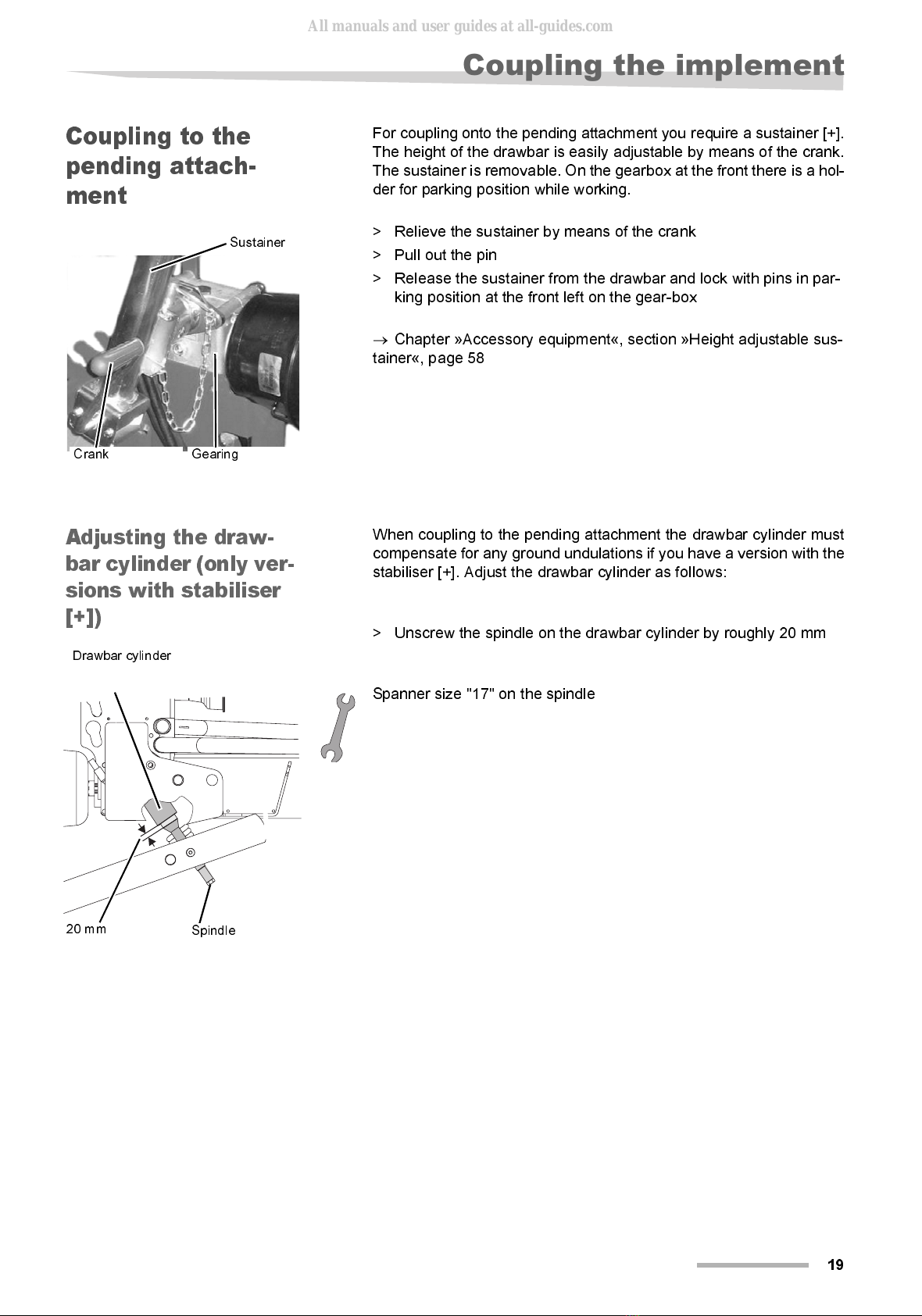

Coupling to the

pending attach-

ment

For coupling onto the pending attachment you require a sustainer [+].

The height of the drawbar is easily adjustable by means of the crank.

The sustainer is removable. On the gearbox at the front there is a hol-

der for parking position while working.

> Relieve the sustainer by means of the crank

> Pull out the pin

> Release the sustainer from the drawbar and lock with pins in par-

king position at the front left on the gear-box

→

Chapter »Accessory equipment«, section »Height adjustable sus-

tainer«, page 58

Adjusting the draw-

bar cylinder (only ver-

sions with stabiliser

[+])

When coupling to the pending attachment the drawbar cylinder must

compensate for any ground undulations if you have a version with the

stabiliser [+]. Adjust the drawbar cylinder as follows:

> Unscrew the spindle on the drawbar cylinder by roughly 20 mm

Spanner size "17" on the spindle

Crank Gearing

Sustainer

Spindle

20 mm

Drawbar cylinder

All manuals and user guides at all-guides.com

20

Coupling the implement

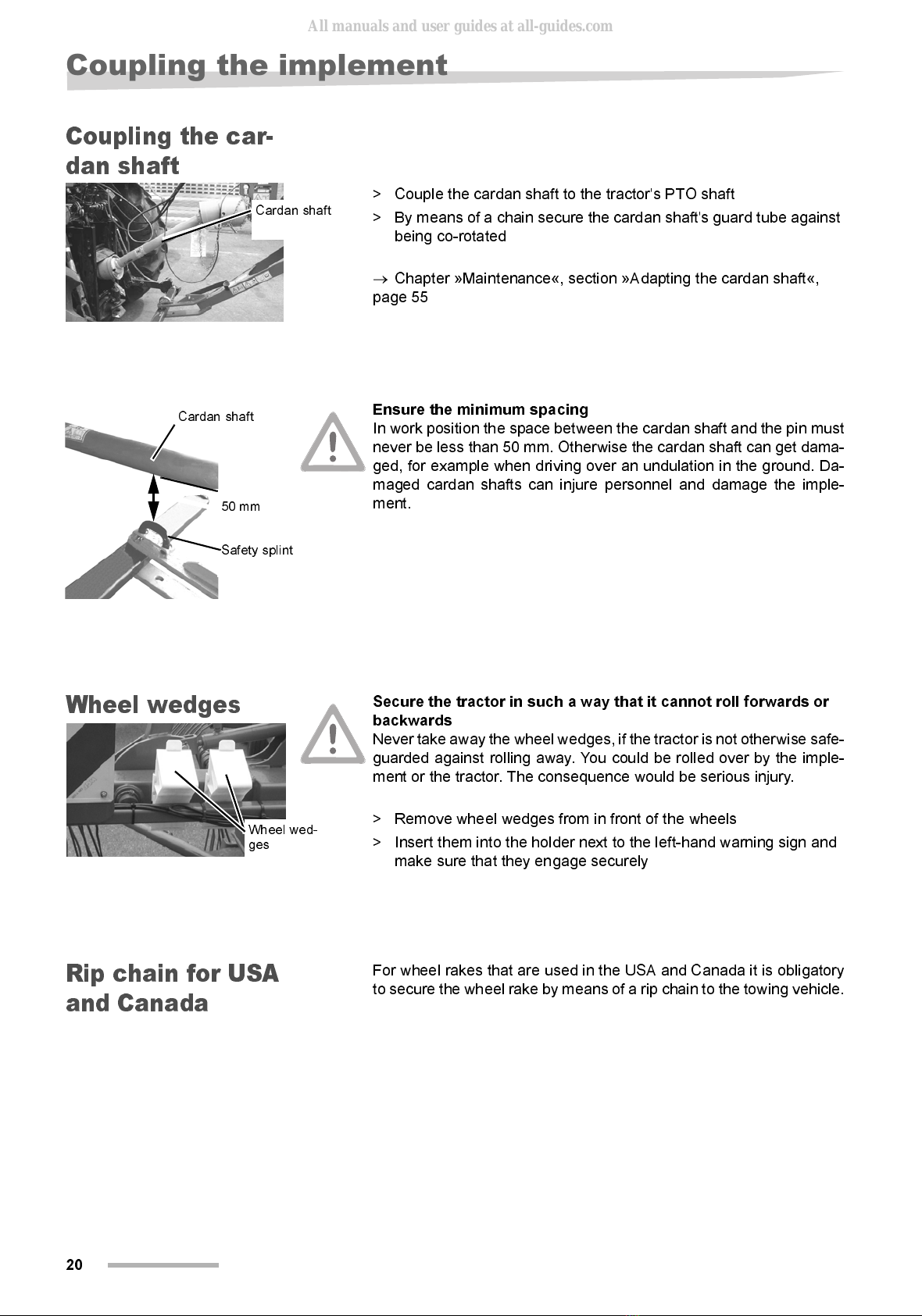

Coupling the car-

dan shaft

> Couple the cardan shaft to the tractor's PTO shaft

> By means of a chain secure the cardan shaft's guard tube against

being co-rotated

→

Chapter »Maintenance«, section »Adapting the cardan shaft«,

page 55

Ensure the minimum spacing

In work position the space between the cardan shaft and the pin must

never be less than 50 mm. Otherwise the cardan shaft can get dama-

ged, for example when driving over an undulation in the ground. Da-

maged cardan shafts can injure personnel and damage the imple-

ment.

Wheel wedges

Secure the tractor in such a way that it cannot roll forwards or

backwards

Never take away the wheel wedges, if the tractor is not otherwise safe-

guarded against rolling away. You could be rolled over by the imple-

ment or the tractor. The consequence would be serious injury.

> Remove wheel wedges from in front of the wheels

> Insert them into the holder next to the left-hand warning sign and

make sure that they engage securely

Rip chain for USA

and Canada

For wheel rakes that are used in the USA and Canada it is obligatory

to secure the wheel rake by means of a rip chain to the towing vehicle.

Cardan shaft

50 mm

Cardan shaft

Safety splint

Wheel wed-

ges

All manuals and user guides at all-guides.com

Other manuals for SwatMaster 7131 EVO

1

Other DEUTZ-FAHR Farm Equipment manuals

Popular Farm Equipment manuals by other brands

New Leader

New Leader NL450 Assembly/operators/parts manual

Raven

Raven AutoBoom XRT installation manual

Opico

Opico Air 8 Electronic operating instructions

TKS

TKS 3742 Operator's manual

Kverneland

Kverneland 608 Operator's manual

greenhouse sensation

greenhouse sensation Hydropod Assembly and maintenance instructions