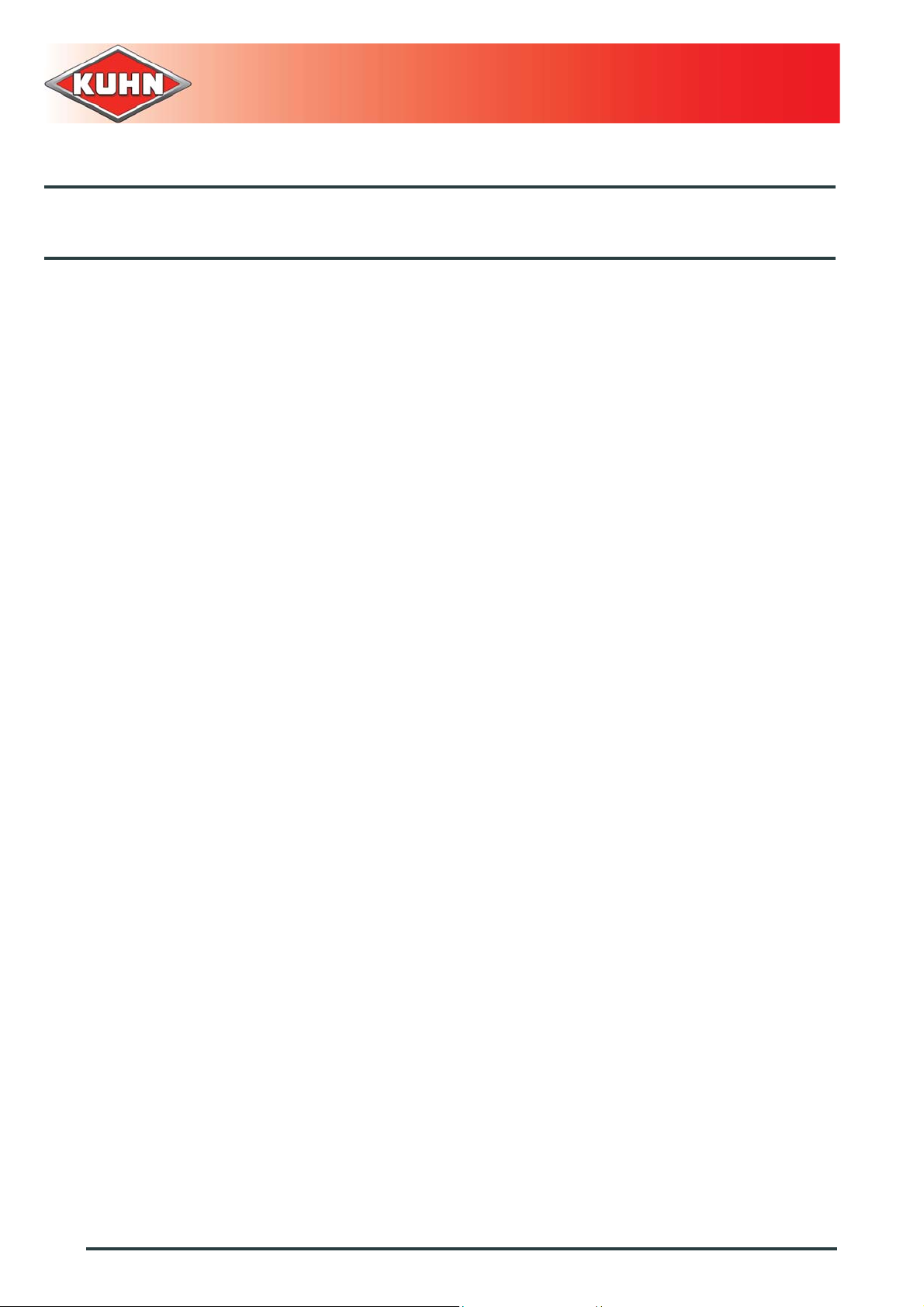

MERGE MAXX 950

62. - Contents

KN233BGB_C

Merger

6.4.7 Pneumatic braking connections (depending upon specification)...................................... 50

6.4.8 Electrical connections....................................................................................................... 52

6.4.9 Primary PTO shaft............................................................................................................52

6.4.10 Adjusting the machine ......................................................................................................55

6.4.11 Uncoupling the machine...................................................................................................55

6.4.12 Handling ........................................................................................................................... 57

7. Instructions for transport ............................................................................................58

7.1 Putting the machine into transport position....................................................................................58

7.1.1 If the work units are distant............................................................................................... 59

7.1.2 If the work units are close.................................................................................................60

7.2 Conformity with the road regulations ............................................................................................. 61

7.3 Machine transport using transport means ..................................................................................... 62

8. Instructions for work....................................................................................................63

8.1 Putting the machine into work position .......................................................................................... 63

8.2 Adjustments in working position.....................................................................................................65

8.2.1 Adjusting the pick-up working height................................................................................ 66

8.2.2 Adjustment of the windguard aggressiveness.................................................................. 67

8.2.3 Ground pressure adjustment of the side pick-ups............................................................ 68

8.2.4 Flow control valve (Conveyor).......................................................................................... 69

8.2.5 Adjustment of the time delay when inverting the conveyor belt direction of rotation........69

8.3 Machine use .................................................................................................................................. 69

8.3.1 Drive speed ......................................................................................................................71

8.3.2 Selecting the windrow delivery mode ............................................................................... 71

8.3.3 Putting the machine in headland turn position.................................................................. 78

8.3.4 Adjusting the headland turn height................................................................................... 83

8.3.5 Use in deteriorated mode ................................................................................................. 83

9. Optional equipment......................................................................................................84

9.1 1 3/8’’ - 6 spline pto shaft............................................................................................................... 84

9.2 1 3/8’’ - 21 spline pto shaft............................................................................................................. 84

9.3 Quick hitch..................................................................................................................................... 84

9.4 Wide wheels .................................................................................................................................. 84

9.4.1 Technical specifications....................................................................................................85

9.5 Mudguard....................................................................................................................................... 85

9.6 Windrow curtain............................................................................................................................. 85

9.6.1 Safety ............................................................................................................................... 86

9.6.2 Putting into service ........................................................................................................... 86

9.6.3 Adjust windrow curtain position ........................................................................................ 87

9.6.4 Instructions for transport................................................................................................... 88

9.6.5 Instructions for work ......................................................................................................... 88