SB-2-001-F Page 5

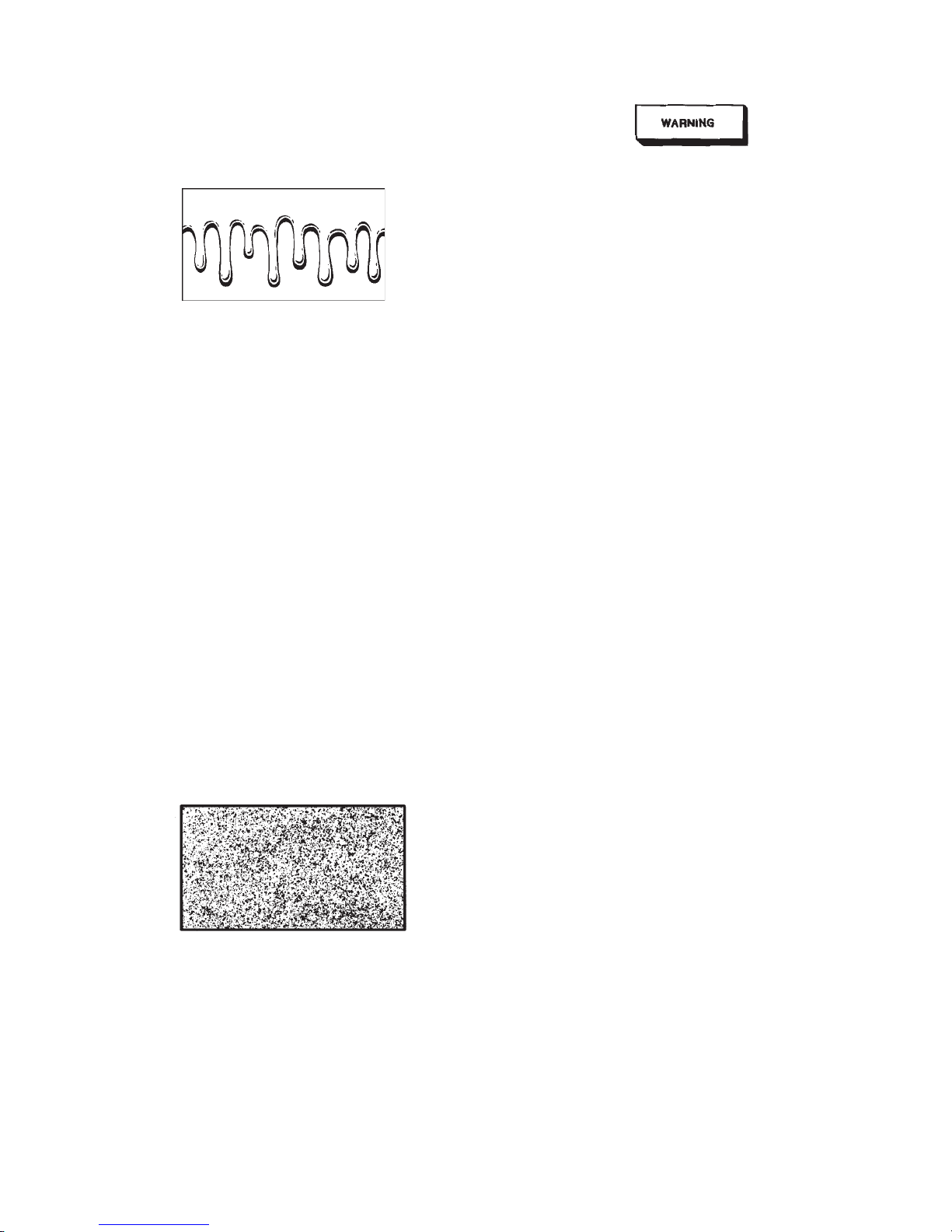

Figure 10 Horizontal Test Pattern with Even Mate-

rial Distribution

If the pattern produced by the above test appears

normal,rotatetheaircapbacktoanormalspraying

position and begin spraying (Example - a normal

pattern with a #9000 air cap will be about 9" long

whenthe gun is held 8"from the surface.) With the

fluid adjusting screw open to the first thread and

the air pressure set at approximately 30 psi, make

afewtestpasseswiththegunonsomecleanpaper.

Move the gun faster than usual when spraying the

test passes. If there are variations in particle size -

specks and/or large globs, the paint is not atomiz-

ing properly (See Figure 12). If the paint is not

atomizingproperly,increasetheairpressureslightly

and make another test pass. Continue this se-

quence until the paint particle size is uniform.

If the pattern seems starved for material and the

fluid adjusting screw is open wide (to the first

thread), the atomization air pressure may be too

high,orthematerialmaybetooheavy.Recheckthe

viscosity or reduce the air pressure.

If the material is spraying too heavily and sagging,

reduce the material flow by turning in the fluid

adjusting screw (clockwise).

Figure 11 Pattern with Uneven Particle Size

Pressure Feed Components

Apressurefeed system consists of a pressurefeed

spray gun, pressure feed tank, cup or pump, an air

filter/regulator,appropriate airandfluid hosesand

anaircompressor.

Connecttheairhosefromtheairregulatortotheair

inlet on the gun. Connect the mainline air hose to

the air inlet on the tank, cup or pump.

To avoid hazardous bursting or equipment

damage, do not exceed the container's maxi-

mum working pressure.

Connect the fluid hose from the fluid outlet on the

tank or pump to the fluid inlet on the gun.

Openspreaderadjustmentvalveformaximumpat-

ternsize. Openfluidadjustmentscrewuntilthefirst

threadis visible.

Shut off atomization air to the gun. Set the fluid

flow rate by adjusting the air pressure in the mate-

rialcontainer.Useabout6psiforaremotecupand

about 15 psi for a 2-gallon, or larger, container.

Adjust the fluid flow in the following ways:

Remove the air cap. With atomization air off, pull

thetrigger,flowingmaterialintoaclean,graduated

container for 10 seconds. Measure the amount of

material which flowed in that time and multiply

times6(orflowfor30secondsandmultiplytime2).

This is the fluid flow rate in ounces per minute. For

standard finishing, it should be about 14 to 16

ounces per minute. If the flow rate is less than this,

increase the air pressure in the container and re-

peat.

When the flow rate is correct, reinstall the air cap.

Iffluidpressureatthetank,cuporpumpexceeds20

psi, the next larger fluid tip size should be used.

Turn the atomizaton air to about 30 psi at the gun.

Spray a fast test pattern on a clean sheet of paper

and check the consistency of the particle size.

Increase or decrease the air pressure until even

particle size is achieved.

Spray a horizontal test pattern holding the trigger

openuntilthematerialbeginstorun. Paintdistribu-

tionacrossthefullwidthofthepatternshouldbethe

same (adjust with fan pattern adjustment). If it

cannot be adjusted, there may be a problem with

either the air cap or the fluid tip which must be

corrected. Refer to the Troubleshooting Section.

Hints for good spray technique.

Hold gun perpendicular 6" to 8" (HVLP guns) or 8"-

10" (suction, gravity or pressure conventional feed

guns) to surface being sprayed.

Don'ttiltthe gun in anydirection.Thiswillresult in

unevenpaint build causing runs and sags.

Triggergunjustbeforetheedgeofthesurfacetobe

sprayed.Thetriggershouldbeheldfullydepressed

andthegunmovedinonecontinuousmotion,until

theotheredgeof theobjectisreached.Releasethe

triggerbutcontinuethemotionforafewinchesuntil

it is reversed for the return stroke.

If distribution is not even, there is a problem with

either the air cap or the fluid tip. Refer to the

TROUBLESHOOTINGsectionforexamplesoffaulty

patterns to help diagnose the problem.