DeVilbiss JGHV User manual

Other DeVilbiss Paint Sprayer manuals

DeVilbiss

DeVilbiss MBC-ZINC Reference manual

DeVilbiss

DeVilbiss KB II Reference manual

DeVilbiss

DeVilbiss COBRA 3C User manual

DeVilbiss

DeVilbiss FLG-P5-14 User manual

DeVilbiss

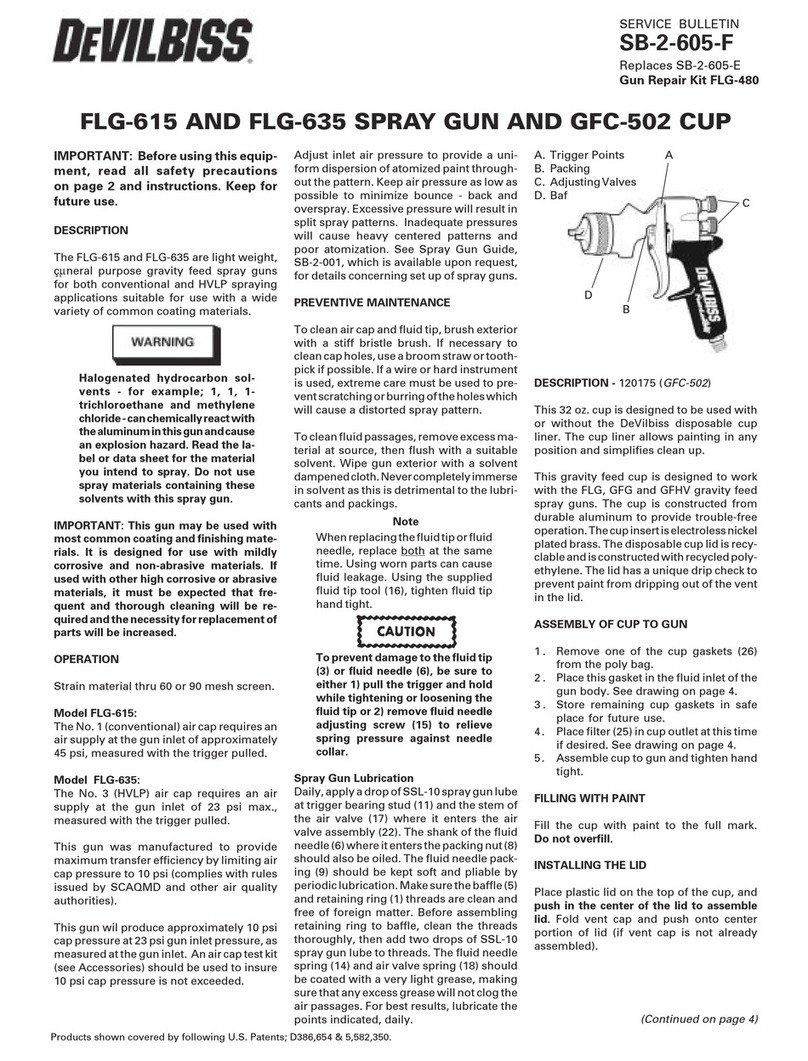

DeVilbiss FLG-615 User manual

DeVilbiss

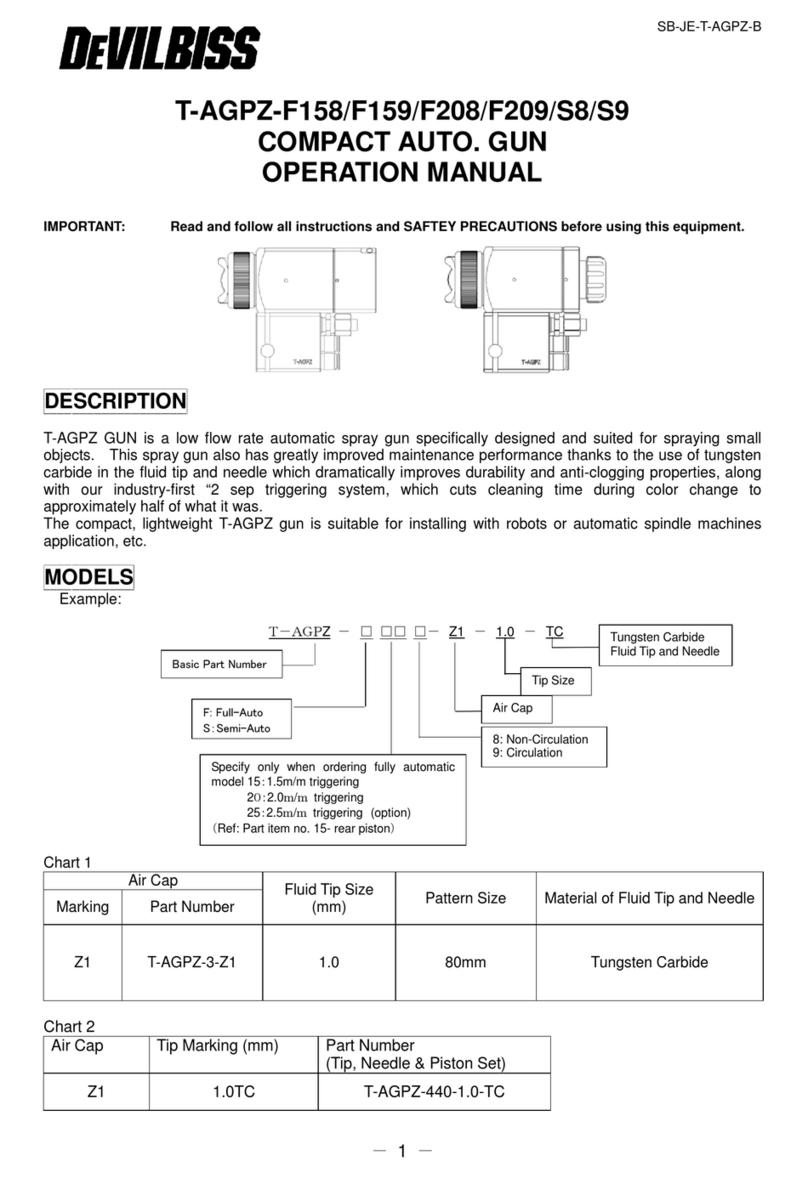

DeVilbiss T-AGPZ-F158 User manual

DeVilbiss

DeVilbiss FUN-600G Reference manual

DeVilbiss

DeVilbiss GTI User manual

DeVilbiss

DeVilbiss JGX-502 User manual

DeVilbiss

DeVilbiss Compact Series User manual

DeVilbiss

DeVilbiss FLG-692 User manual

DeVilbiss

DeVilbiss JGA-635G Reference manual

DeVilbiss

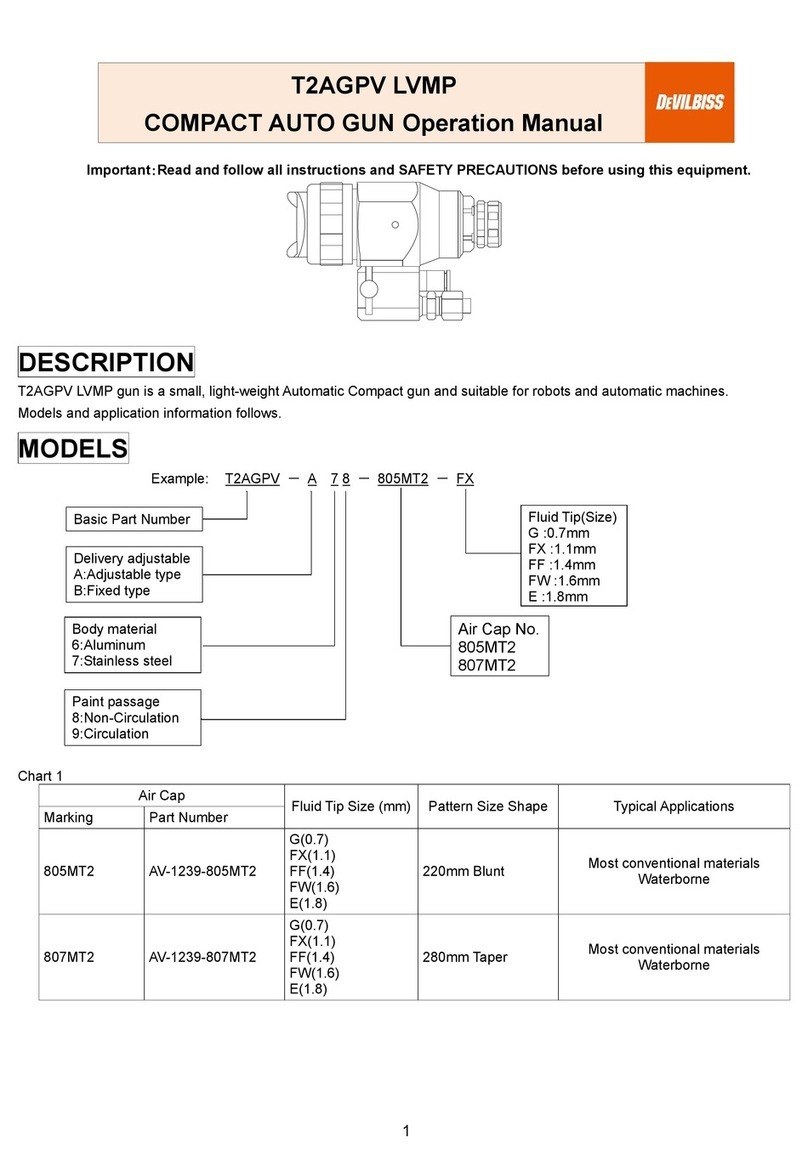

DeVilbiss T2AGPV LVMP Series User manual

DeVilbiss

DeVilbiss SRI-2-12-K User manual

DeVilbiss

DeVilbiss AGN-502 User manual

DeVilbiss

DeVilbiss HVLP Gravity Feed Spraygun User manual

DeVilbiss

DeVilbiss MSV-531-28FF Reference manual

DeVilbiss

DeVilbiss FLG-P5-14 User manual

DeVilbiss

DeVilbiss AG360 Series User manual

DeVilbiss

DeVilbiss MBC-510 Reference manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual