DeVilbiss CamAir QC3 Reference manual

Other DeVilbiss Water Filtration System manuals

DeVilbiss

DeVilbiss DAD-500 User manual

DeVilbiss

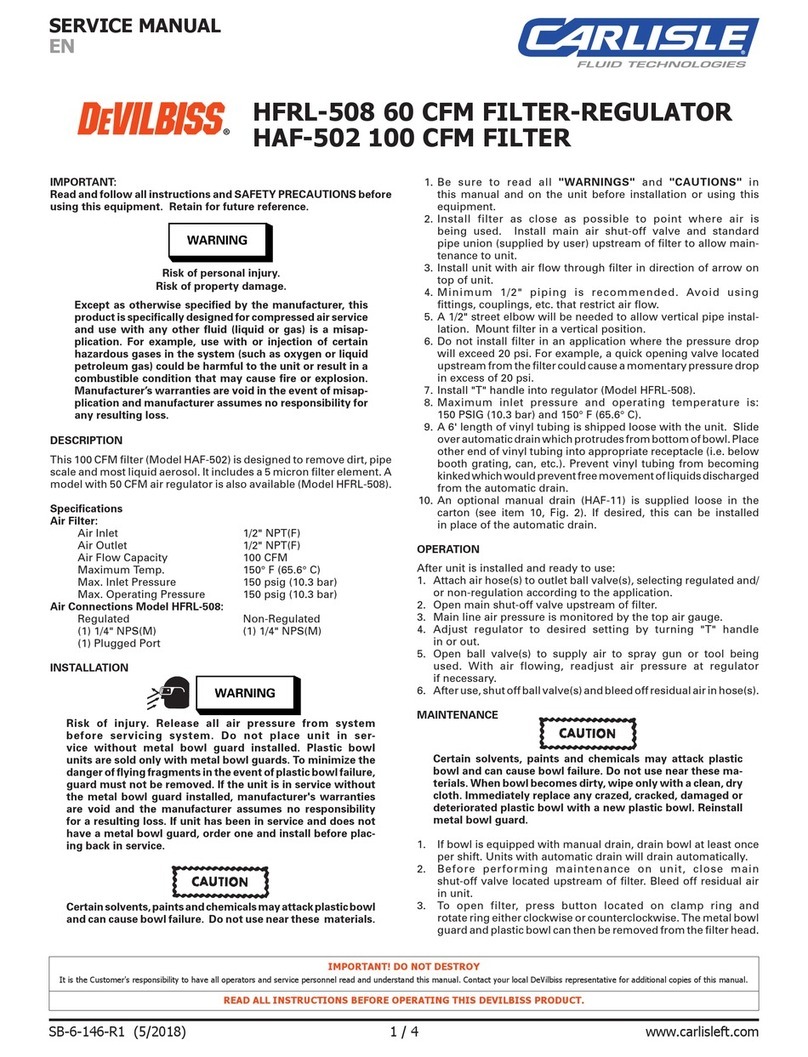

DeVilbiss HFRL-508 User manual

DeVilbiss

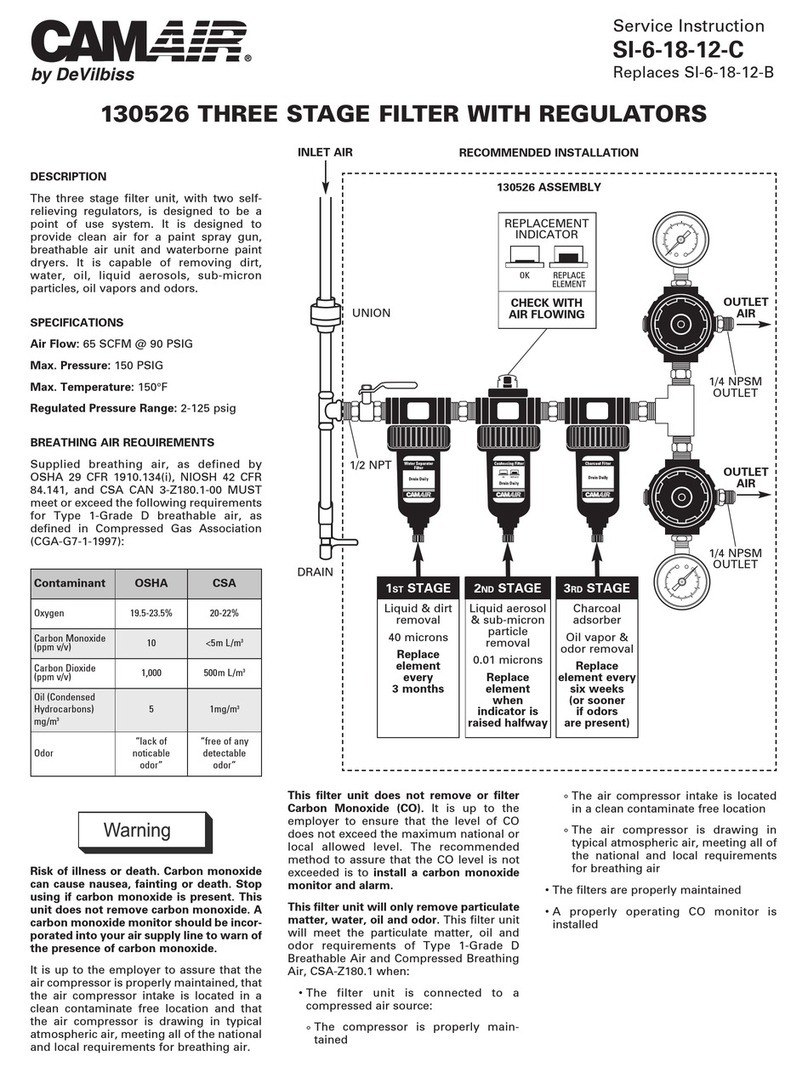

DeVilbiss 130526 Original operating manual

DeVilbiss

DeVilbiss 130524 Use and care manual

DeVilbiss

DeVilbiss DAD-503 Reference manual

DeVilbiss

DeVilbiss HAF-517 75 CFM Reference manual

DeVilbiss

DeVilbiss HAF-503 User manual

DeVilbiss

DeVilbiss HFRL-508 User manual

DeVilbiss

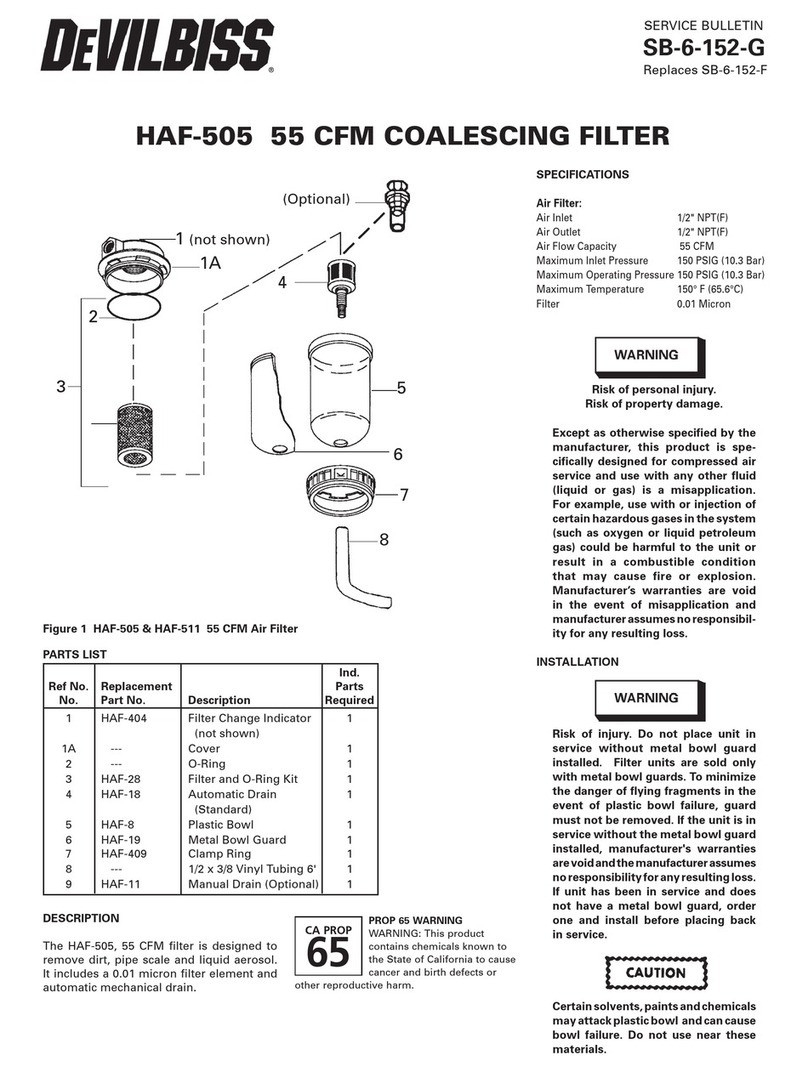

DeVilbiss HAF-505 Reference manual

DeVilbiss

DeVilbiss HFRL-508 User manual

Popular Water Filtration System manuals by other brands

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual