Page 2 SB-6-152-C

INSTALLATION(continued) OPERATION

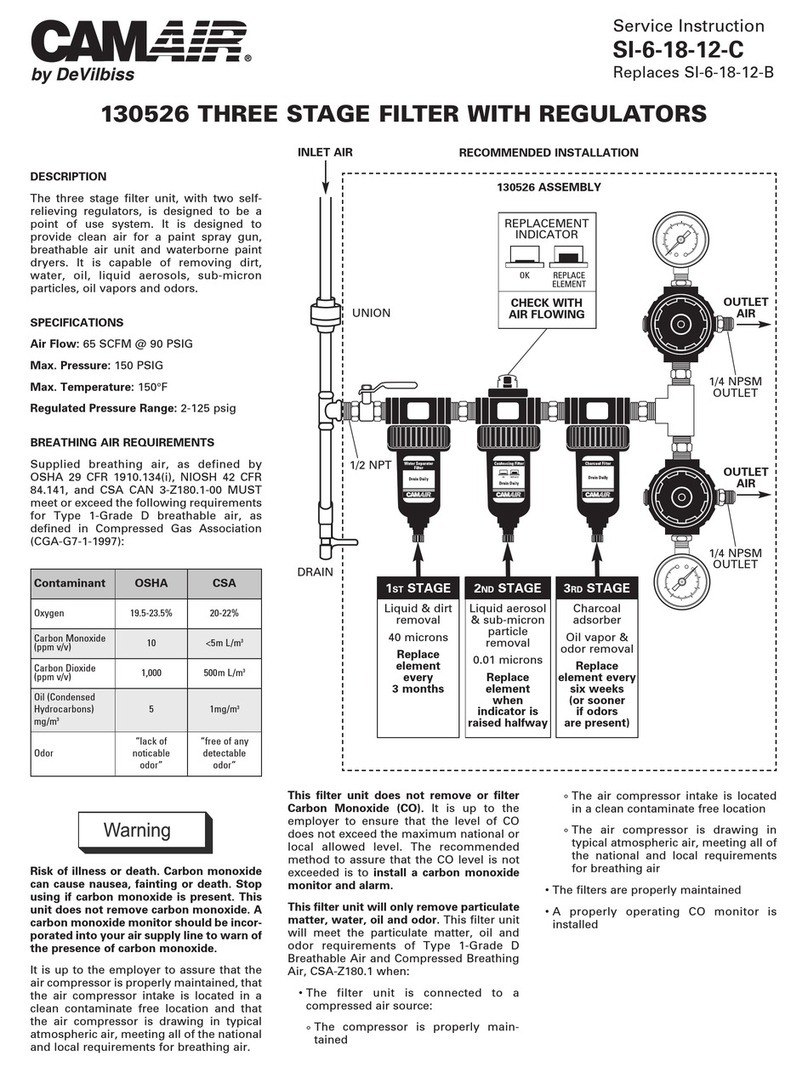

1After the unit is installed and ready to use;

2,

1. Attach air hose(s) to outlet ball valve(s),

selecting regulated and/or non-regulated

according to the application (not sup-

plied).

2. Open main shut-off valve upstream of

filter .

3. Open ball valve(s) (not supplied) to sup-

ply air to spray gun or tool being used.

4. After use, shut off ball valve(s) and bleed

off residual air in hose(s).

3.

4

Note

5

6The filter change indicator only oper-

ates when air is flowing. It will always

be green when there is no flow.

MAINTENANCE

1:==::]

Certain solvents, paints and chemi-

cals may attack plastic bowl and can

cause bowl failure. Do not use near

these materials. When bowl be-

comes dirty, wipe only with a clean,

dry cloth. Immediately replace any

crazed, cracked, damaged or dete-

riorated plastic bowl with a new

plastic bowl. Reinstall metal bowl

guard.

Be sure to read all "Warnings" and "Cau-

tions" in this manual and on the unit

before installation or using this equip-

ment.

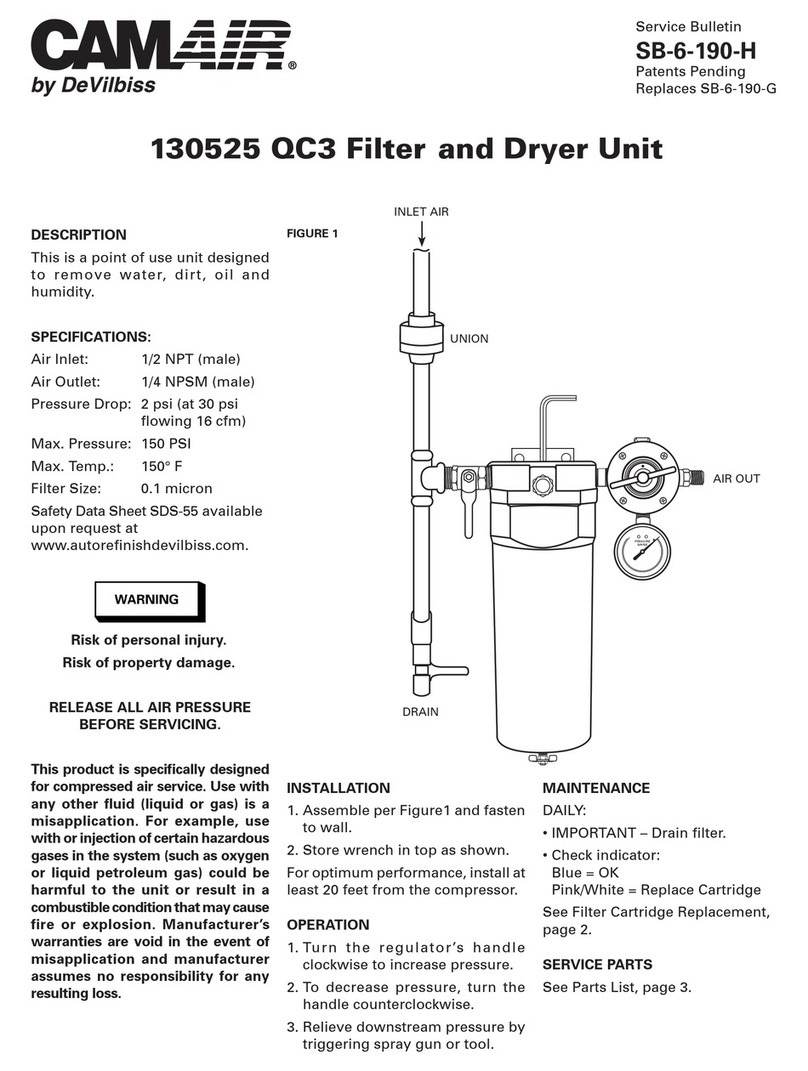

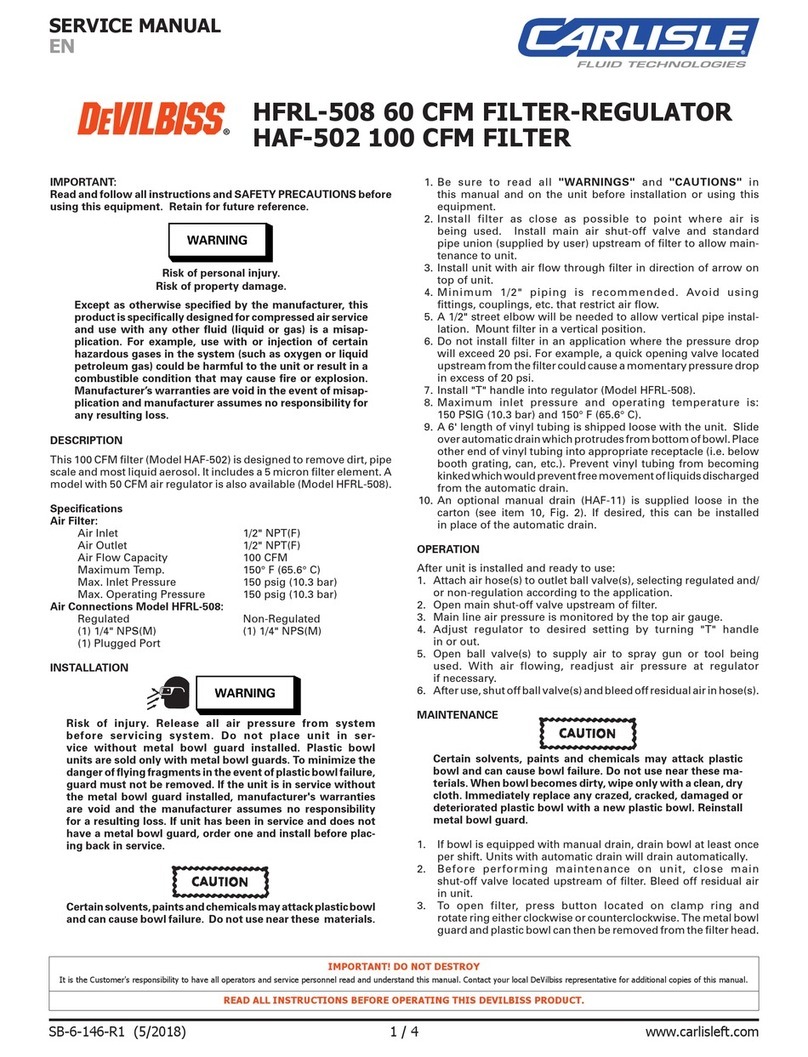

Install filter as close as possible to point

where air is being used. Install main air

shut-off valve and standard pipe union

(supplied by user) upstream of filter to

allow maintenance to unit.

Install unit with air flow through filter in

-direction of arrow on top of unit.

Minimum 1/2" piping is recommended.

Avoid using fittings, couplings, etc. that

restrict air flow.

Mount filter in a vertical position.

Do not install filter in an application

where the pressure drop will exceed 20

psi. For example, a quick opening valve

located upstream from the filter could

cause a momentary pressure drop in

excess of 20 psi.

Maximum inlet pressure and operating

temperature is: 150 PSIG (10.3 bar) and

150° F (65.6° G}.

A 6' length of vinyl tubing is shipped

loose with the unit. Slide over automatic

drain which protrudes from bottom of

bowl. Place other end of vinyl tubing

into appropriate receptable (i.e. below

booth grating, can, etc.). Prevent vinyl

tubing from becoming kinked which

would prevent free movement of liquids

discharged from the automatic drain.

An optional manual drain (HAF-11 ) can

be installed in place of the automatic

drain.

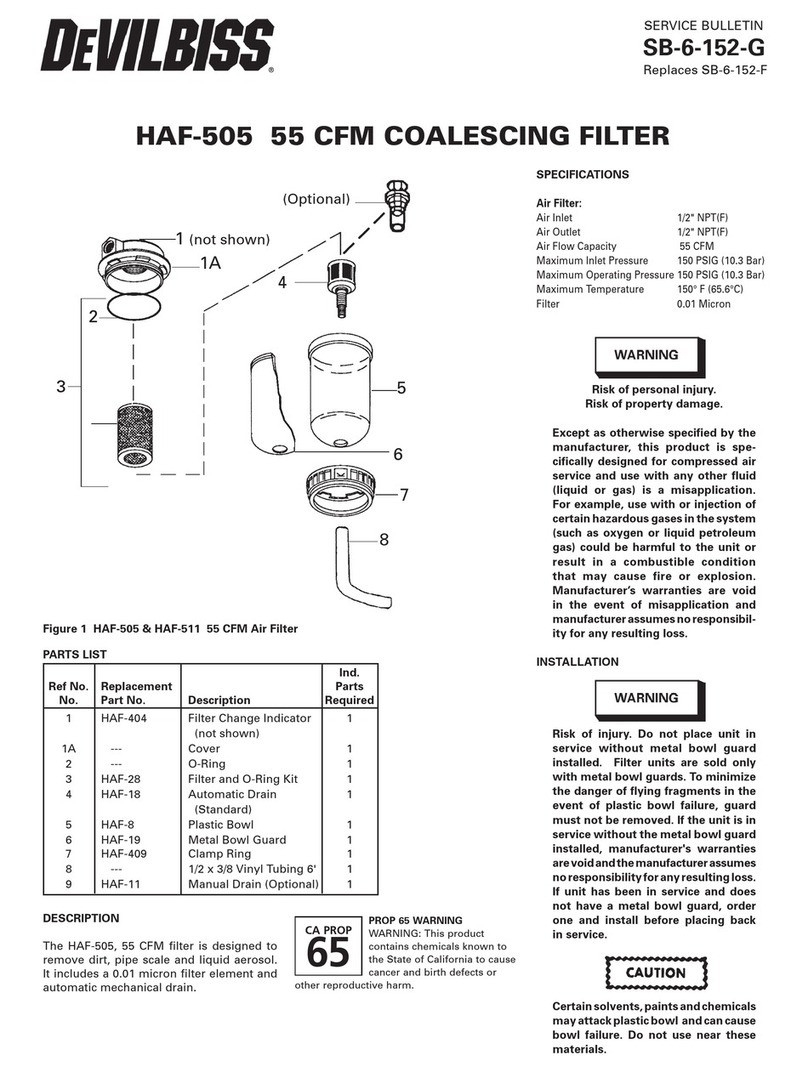

1.Before performing maintenance on

unit, close main shut-off valve located

upstream of filter. Bleed off residual

air in unit.

2. To open filter, press button located on

clamp ring and rotate ring either clock-

wise or counterclockwise while pulling

down on ring. The metal bowl guard and

plastic bowl can then be removed from

the filter head.

3. Remove the filter element by loosening

counterclockwise. Clean or replace the

filter element. Frequency of element

replacement will-depend upon air qual-

ity, air usage, and condition of the air

piping. It is recommended to check the

element change indicator daily, and re-

place when indicator turns red.

4. Inspect "0" ring for damage. Replace if

necessary.

5. Inspect plastic bowl for signs of damage

such as cracks, crazing or deterioration.

Replace if necessary. See "Caution" in

Column 2.

~]

Risk of injury. Do not place unit in

service without metal bowl guard

installed.

9.

6. Before placing unit back into service,

make sure plastic bowl and metal bowl

guard are properly installed and securely

locked in place.

7. Confirm automatic drain operates prop-

erly after unit is in operation. Refer to

Service Bulletin SB-6-149 which provides

automatic drain service information. Re-

place if necessary.

~

Risk of injury. Components under

pressure. Relieve air pressure be-

fore performing maintenance.

SERVICE BULLETIN REVISIONS

Please refer to the following chart for Part No./literature changes.

Warranty

This product is covered by ITW DeVilbiss' 1

Year Limited Warranty. See SB-1-000 which

is available upon request.

WORLDWIDE SALES AND SERVICE -www.devilbiss.com

DeVilbiss Industrial Spray Equipment

DeVilbiss has authorized distributors throughout the world. FOR TECHNICAL ASSISTANCE, CALL TOLL FREE 1-800-338-

4448 (U.S.A. ONL V).

DeVilbiss Automotive Refinishing

DeVilbiss has authorized distributors throughout the world. For equipment, parts and service, check the Yellow Pages under

"Automobile Body Shop Equipment and Supplies". FOR TECHNICAL ASSISTANCE, CALL TOLL FREE 1-800-445-3988

(U.S.A. ONL Y).