Page 2 SB-6-155-B

OPERATION

After the unit is installed and ready to use;

1. Attach air hose(s) to appropriate outlets (ball

valve not included).

2. Open main shut off valve upstream of filter.

3. Open appropriate ball valves or attach hoses to

supplied air respirator and/or air tools.

4. After use, shut off ball valve(s) and bleed off

residual air in hoses.

Note

The filter change indicator only operates when

air is flowing. It will always be green when there

is no flow.

MAINTENANCE

Risk of injury. Components under pressure.

Relieve air pressure before performing main-

tenance.

1. Before performing maintenance on unit, close

main shut-off valve located upstream of filter.

Bleed off residual air in unit.

2. To open filter, press button located on clamp ring

and rotate ring either clockwise or counterclock-

wise while pulling down on ring. The metal bowl

guard and plastic bowl can then be removed

from the filter head.

3. Frequency of element replacement will depend

upon air quality, temperature, air usage and con-

dition of the air piping. It is recommended to

change the element when it no longer removes

odors or when the red indicator is visible. Remove

the filter element by loosening counterclockwise.

4. Inspect o-ring for damage. Replace if necessary.

5. Inspect plastic bowl for signs of damage such as

cracks, crazing or deterioration. Replace if neces-

sary. See "Caution" above.

6. Before placing unit back into service, make sure

plastic bowl and metal bowl guard are properly

installed and securely locked in place.

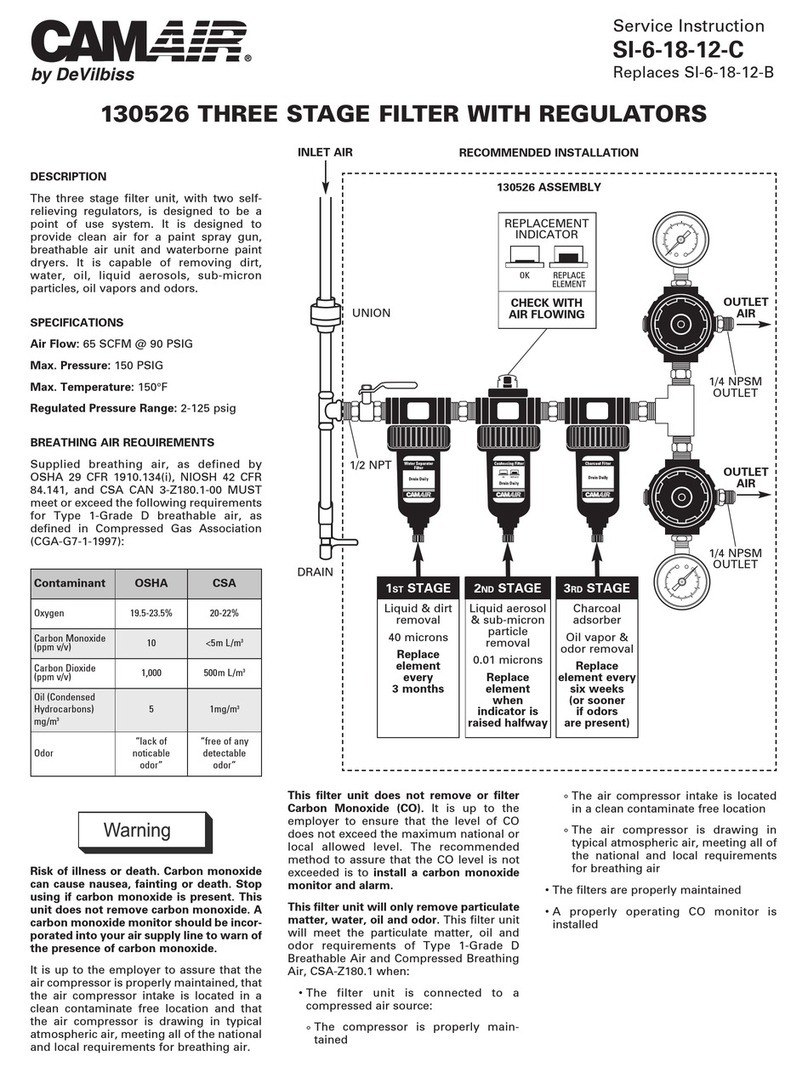

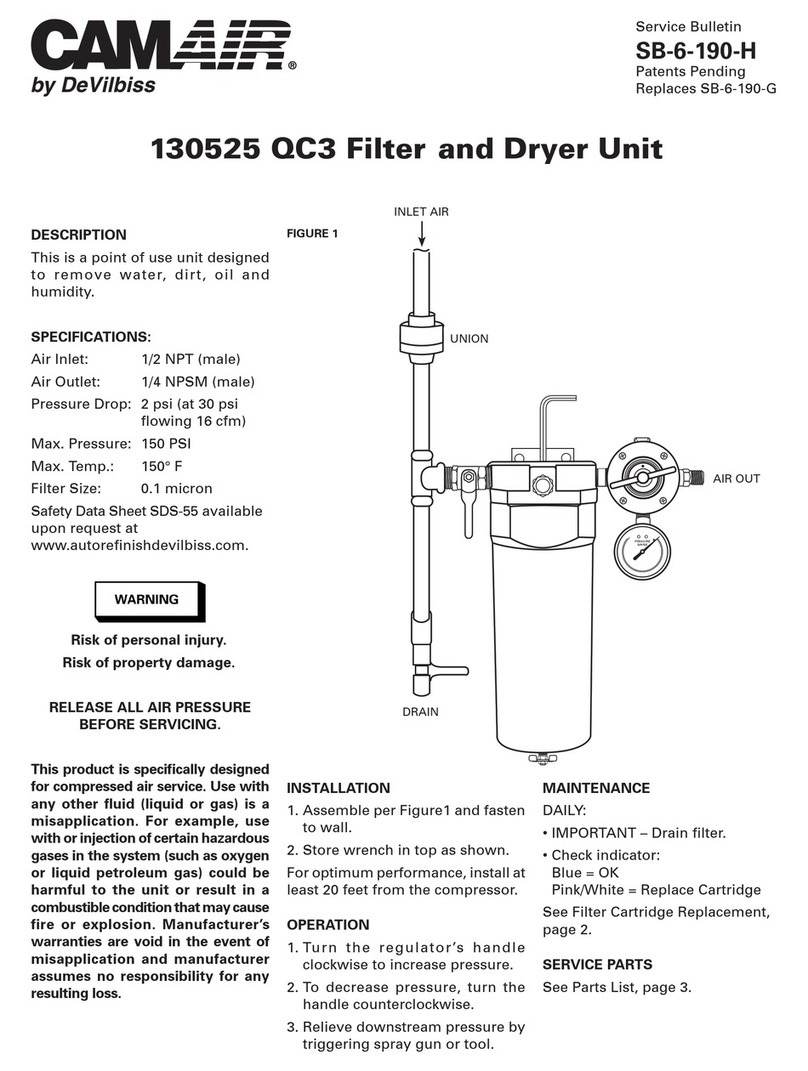

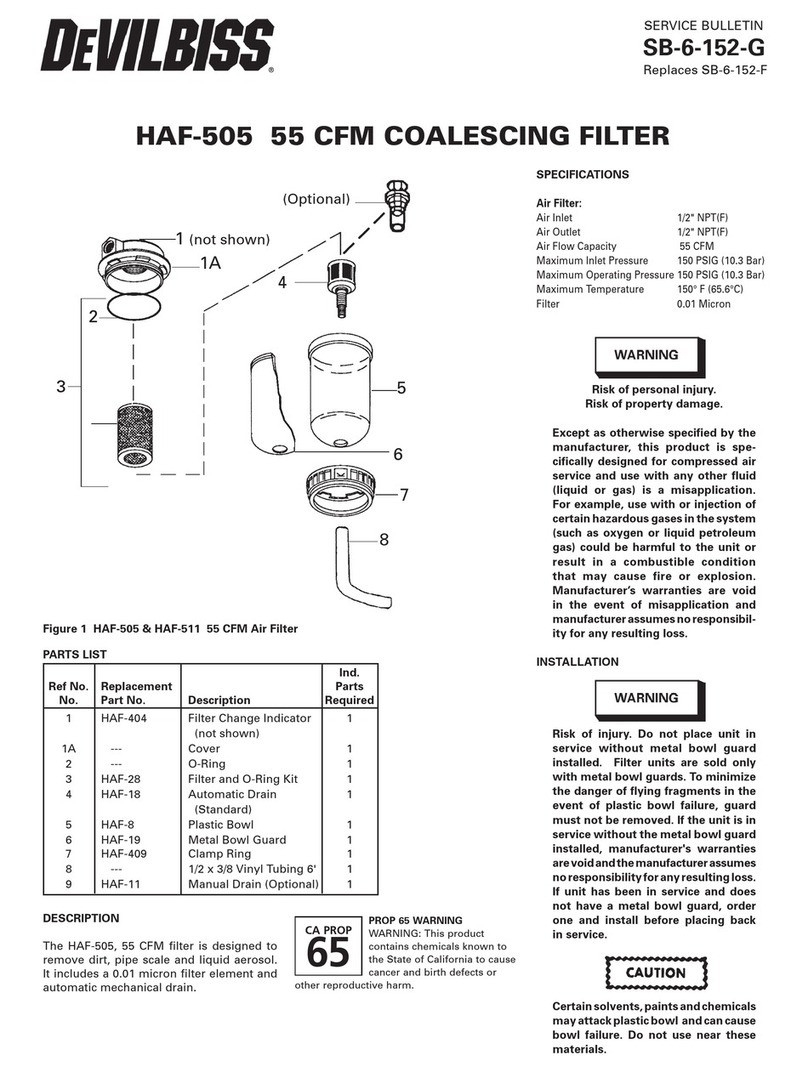

DESCRIPTION

This 75 CFM filter is designed to remove oil vapor,

hydrocarbons and odors from a compressed air sys-

tem. It includes a .003 ppm/wt. aerosol filter element

and manual drain.

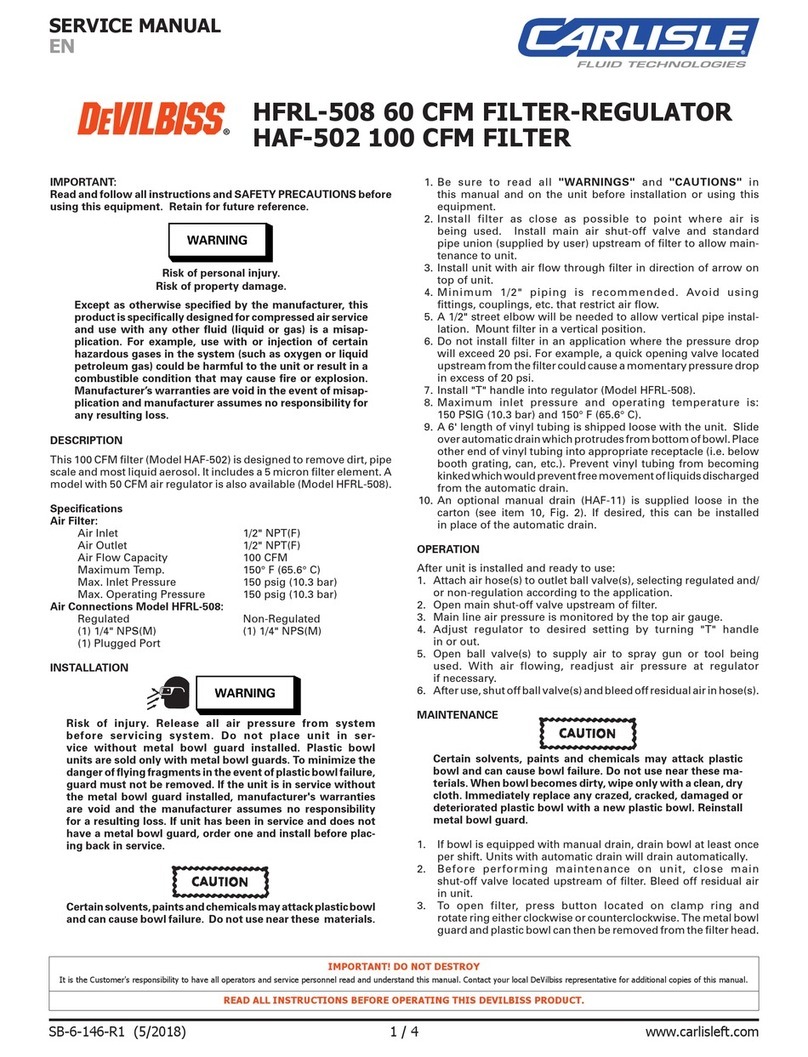

INSTALLATION

1. Be sure to read all "Warnings" and "Cautions" in

this manual and on the unit before installation or

using this equipment.

2. Install filter as close as possible to point where air

is being used. Install main air shut-off valve and

standard pipe union (supplied by user) upstream

of filter to allow maintenance to unit.

3. An appropriate coalescing filter must be located

upstream of the charcoal filter. Failure to due so

will result in the element becoming quickly satu-

rated and ineffective. We recommend a DeVilbiss

HAF-505 or HAF-515 Coalescing Filter.

4. Install unit with air flow through filter in direction

of arrow on top of unit.

5. Minimum 3/4" piping is recommended. Longer

pipe size will be required for high flow rates.

Avoid using fittings, couplings, etc. that restrict

air flow.

6. Mount filter in a vertical position.

7. Do not install filter in an application where the

pressure drop will exceed 20 psi. For example, a

quick opening valve located upstream from the

filter could cause a momentary pressure drop in

excess of 20 psi.

8. Maximum inlet pressure and operating tempera-

ture is: 150 PSIG (10.3 bar) and 150° F (65.6° C).

ACCESSORY

HAF-407 Bracket Assembly Kit – Used with HAF-502, HFRL-

508, HAF-505, HAF-517, HAF-518 and 13-0041 (HAF-500).

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Sales and Service: www.devilbiss.com

DeVilbiss

DeVilbiss has authorized distributors throughout the world. For technical

assistance or the distributor nearest you, see listing below.

U.S.A./Canada Customer Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-800-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-888-246-5732

DeVilbiss Automotive Refinishing

DeVilbiss has authorized distributors throughout the world.

For equipment, parts and service, check the Yellow Pages

under “Automotive Body Shop Equipment and Supplies.”

For technical assistance, see listing below.

U.S.A./Canada Customer Service Office:

11360 S. Airfield Road, Swanton, OH 43558

Toll-Free Telephone: 1-800-445-3988 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-445-6643

6/14 © 2014 DeVilbiss All rights reserved. Printed in U.S.A.