Page 2 SB-6-148-F

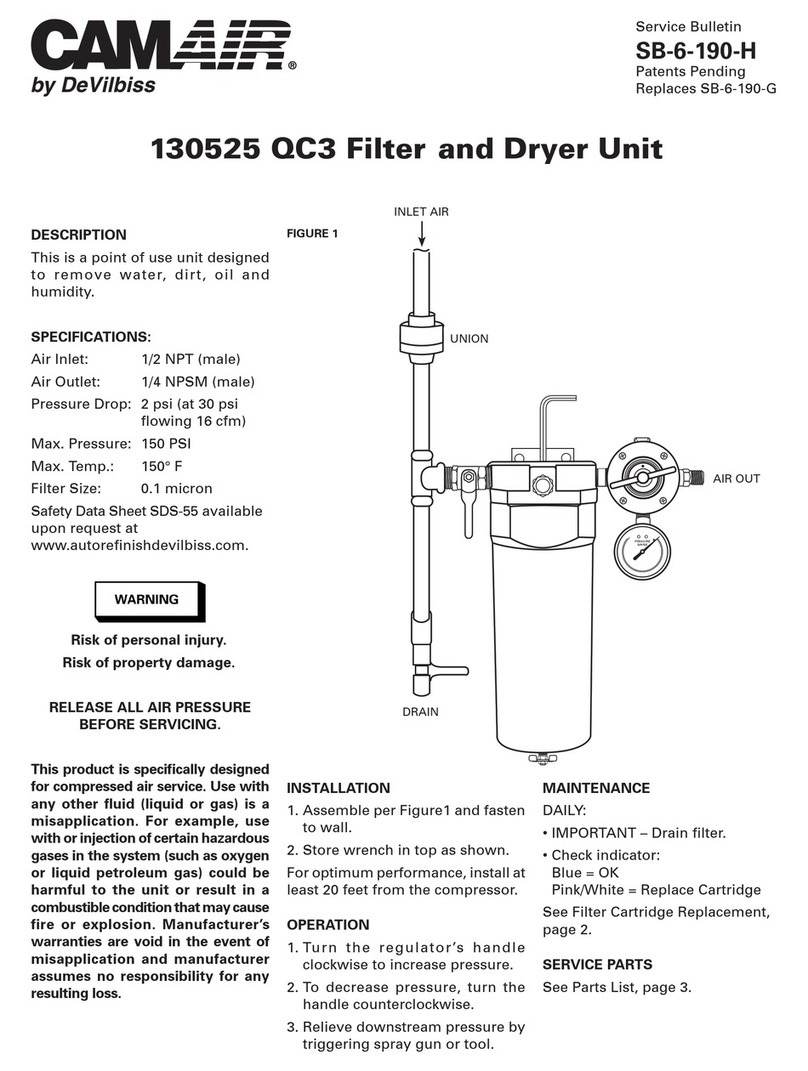

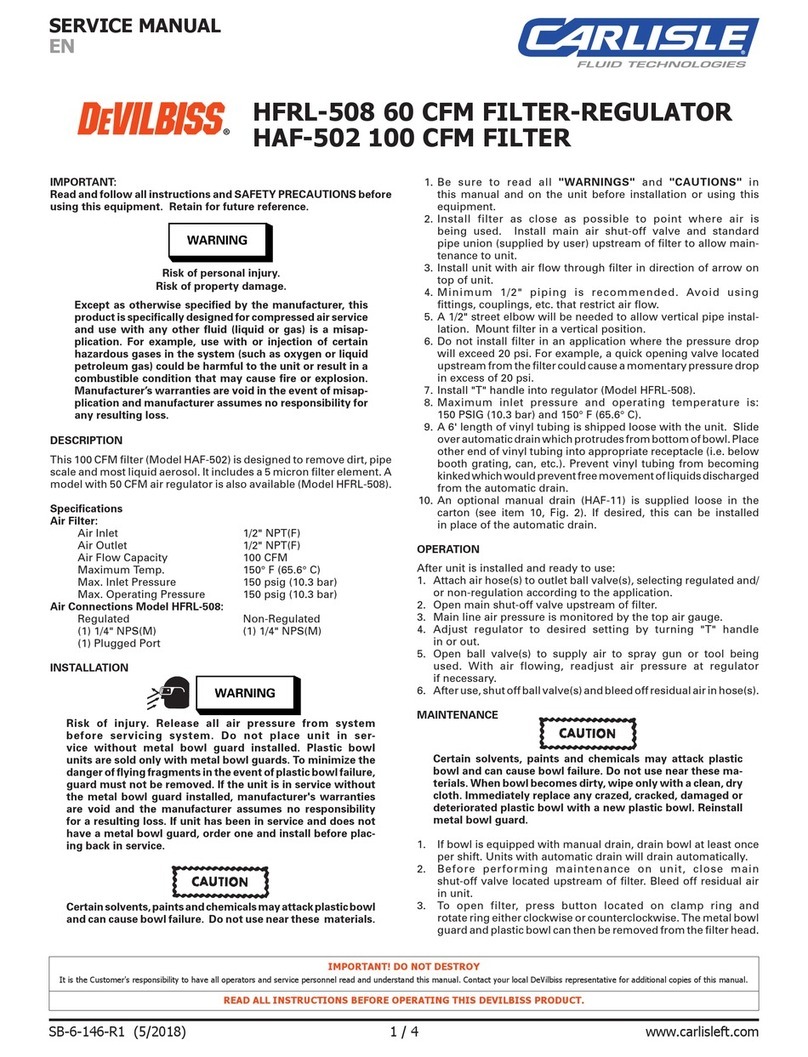

INSTALLATION

Certain solvents, paints and chemi-

cals may attack plastic bowl and

can cause bowl failure. Do not use

near these materials.

Do not place unit in service without

metal bowl guard installed. Plastic

bowl units are sold only with metal

bowl guards. To minimize the dan-

ger of flying fragments in the event

of plastic bowl failure, guard must

not be removed. If the unit is in

service without the metal bowl

guard installed, manufacturer's

warranties are void and the manu-

facturer assumes no responsibility

for any resulting loss. If unit has

been in service and does not have a

metal bowl guard, order one and

install before placing back in ser-

vice.

1. Be sure to read all "Warnings", "Cau-

tions" and "Notes" in this manual

and on unit before installing or using

this equipment.

2. Install filter as close as possible to

point where air is being used. Install

main air shut-off valve and standard

pipe union (supplied by user) up-

stream of filter to allow maintenance

to unit.

3. Install unit with air flow through filter

in direction of arrow on top of unit.

4. Minimum 3/4" piping is recom-

mended. Avoid using fittings, cou-

plings, etc. that restrict air flow.

5. The filter includes a 3/4" elbow which

allows vertical pipe installation.

Mount filter in a vertical position.

SAFETY PRECAUTIONS

This manual contains important information that ALL users should know and understand BEFORE using the equipment. This

information relates to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use

the following terms to draw your attention to certain equipment labels and portions of this manual. Pay special attention to any label

or information that is highlighted by one of these terms:

Important information - a hazard that

may cause serious injury or loss of

life.

Important information that tells how

to prevent damage to equipment, or

how to avoid a situation that may

cause minor injury.

Note

Information that you should pay spe-

cial attention to.

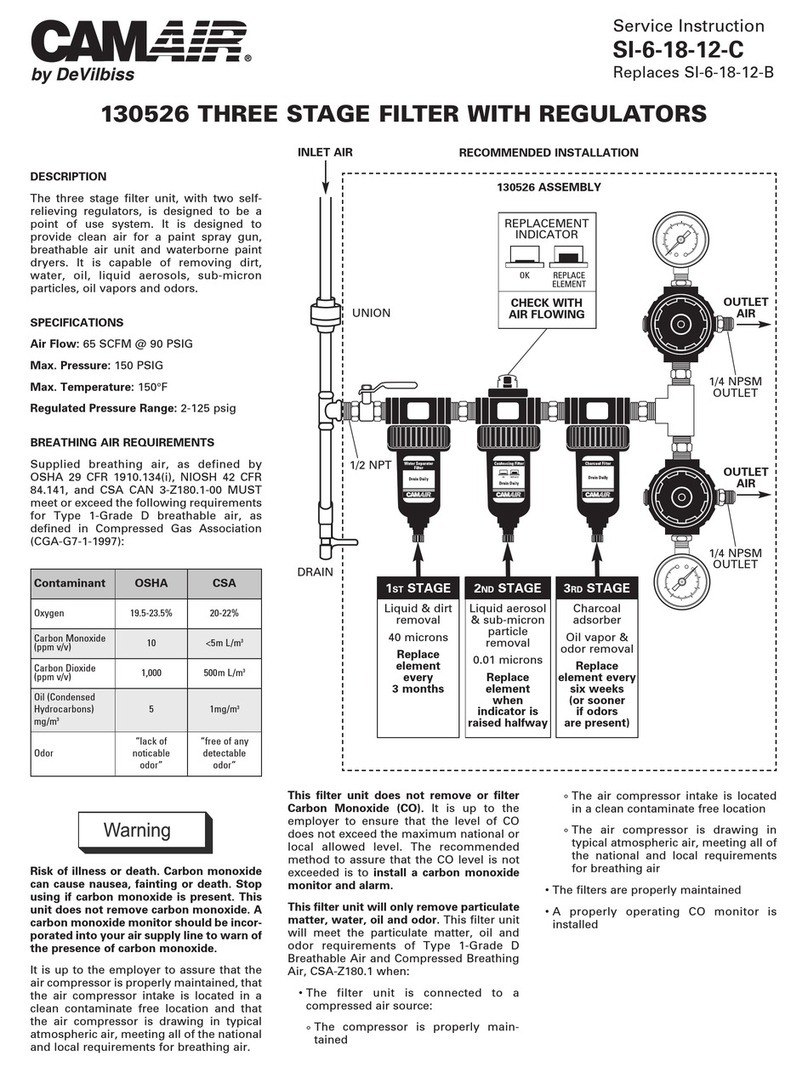

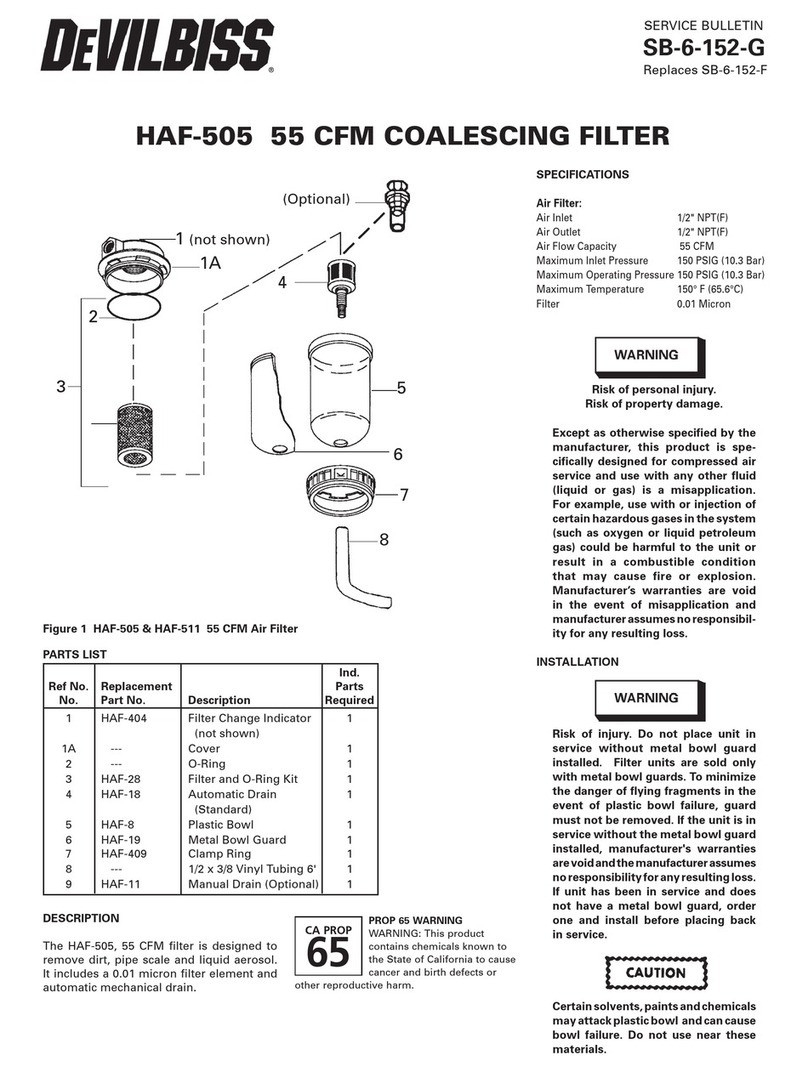

DESCRIPTION

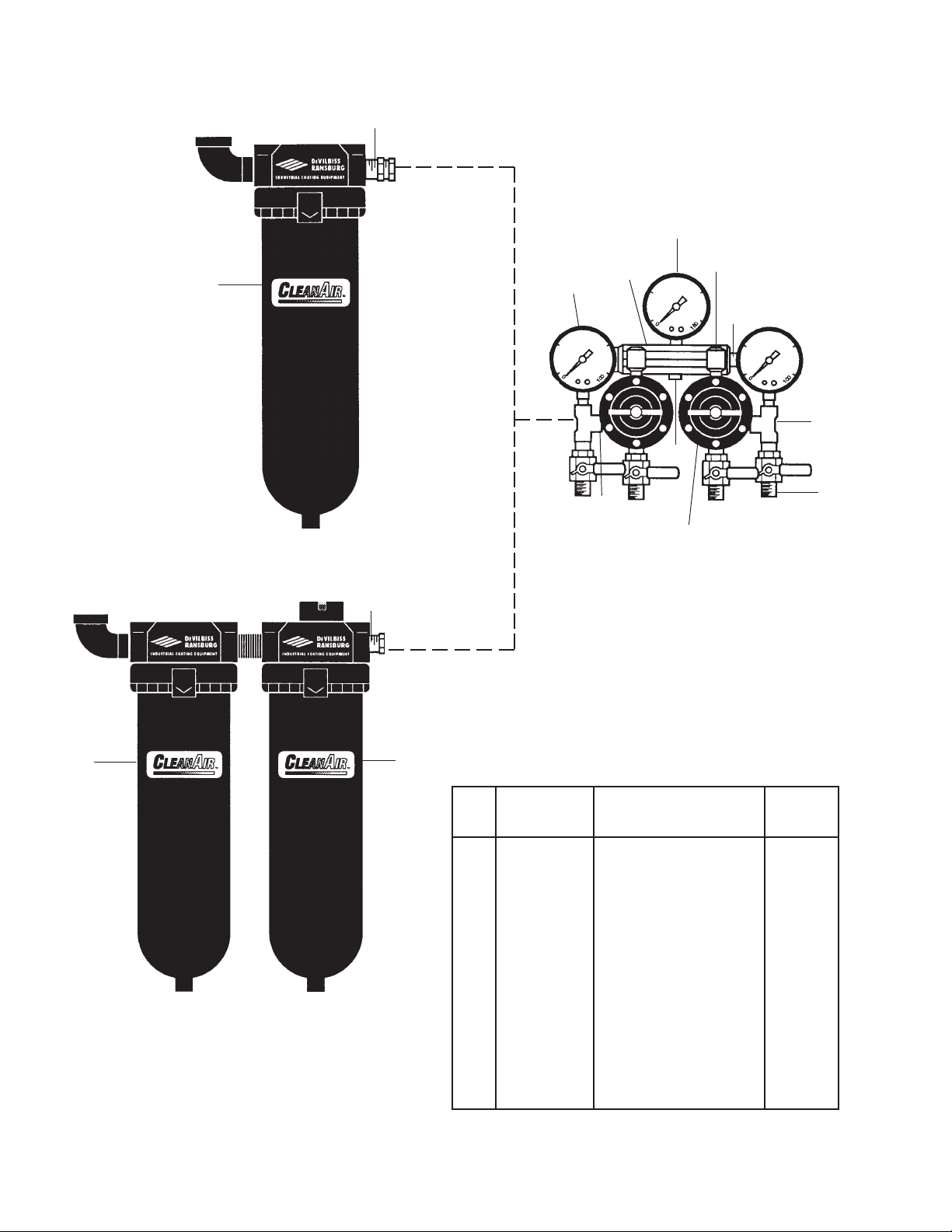

The CleanAir air control units are de-

signed to remove dirt, pipe scale, and

most liquid aerosol. The HAF-503 150 CFM

separator filter includes a 5 micron filter

element. The HAF-508 150 CFM coalesc-

ing filter includes a .01 micron filter ele-

ment. Both filters include an automatic

drain which expels liquids which accumu-

late in the filter bowl.

SPECIFICATIONS

Filter Port Sizes 3/4" NPT(F)

MaximumInletPressure 150 PSIG (10.3 Bar)

MaximumTemperature 150°F (65.6°C)

Risk of personal injury.

Risk of property damage.

Except as otherwise specified by

the manufacturer, this product is

specifically designed for com-

pressed air service and use with

any other fluid (liquid or gas) is a

misapplication. For example, use

with or injection of certain hazard-

ous gases in the system (such as

ozygen or liquid petroleum gas)

could be harmful to the unit or

result in a combustible condition

that may cause fire or explosion.

Manufacturer’s warranties are void

in the event of misapplication and

manufacturer assumes no respon-

sibility for any resulting loss.

6. Do not install filter in an application

where the pressure drop will exceed

20 psi. For example, a quick opening

valve located upstream from the fil-

ter could cause a momentary pres-

sure drop in excess of 20 psi.

7. Maximum inlet pressure and operat-

ing temperature is 150 PSIG (10.3

bar) and 150°F (65.6°C).

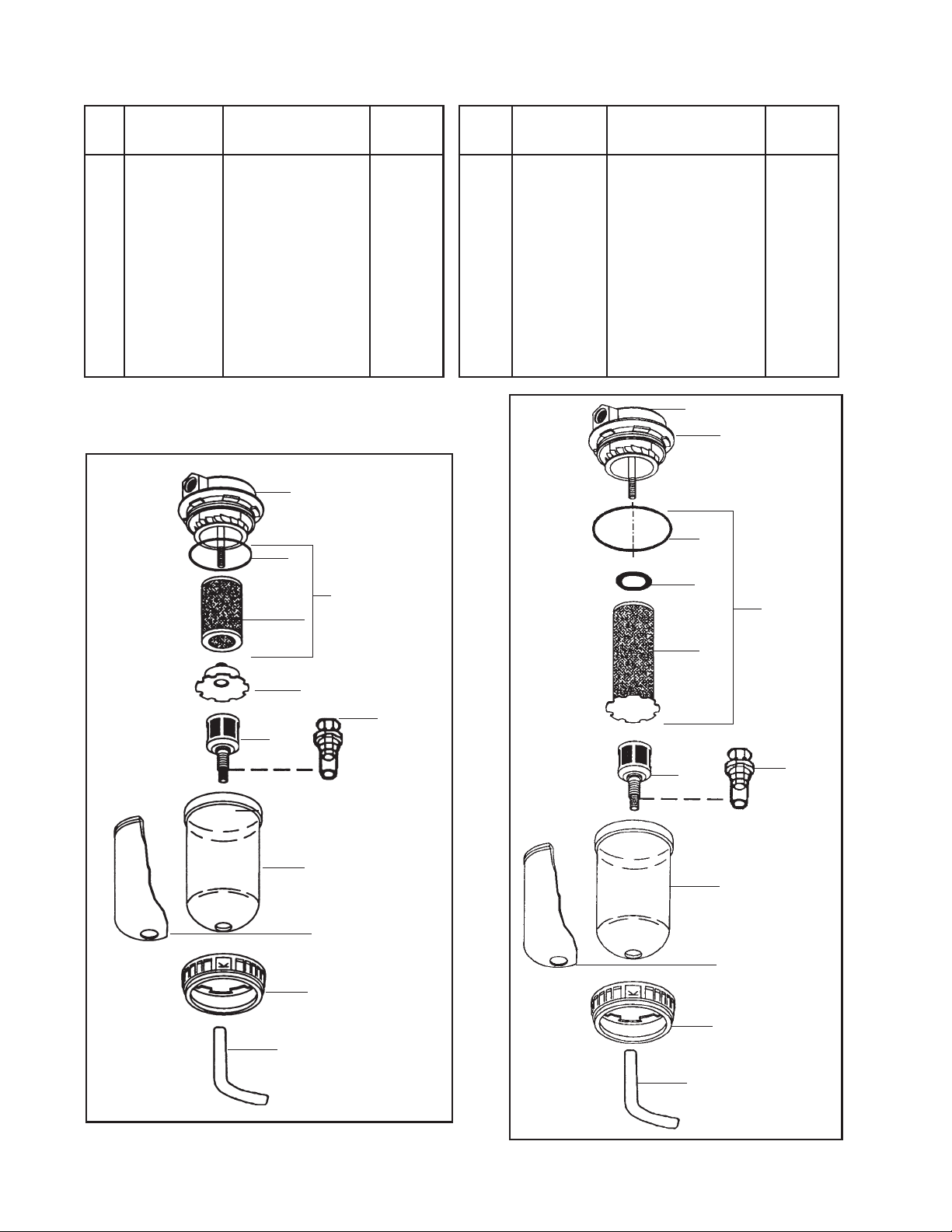

8. A 6 ft. length of vinyl tubing is

shipped loose with the unit. Slide

over automatic drain which protrudes

from bottom of bowl. Place other end

of vinyl tubing into appropriate

receptable (i.e. below booth grating,

can, etc.). Prevent vinyl tubing from

becoming kinked which would pre-

vent free movement of liquids dis-

charged from the automatic drain.

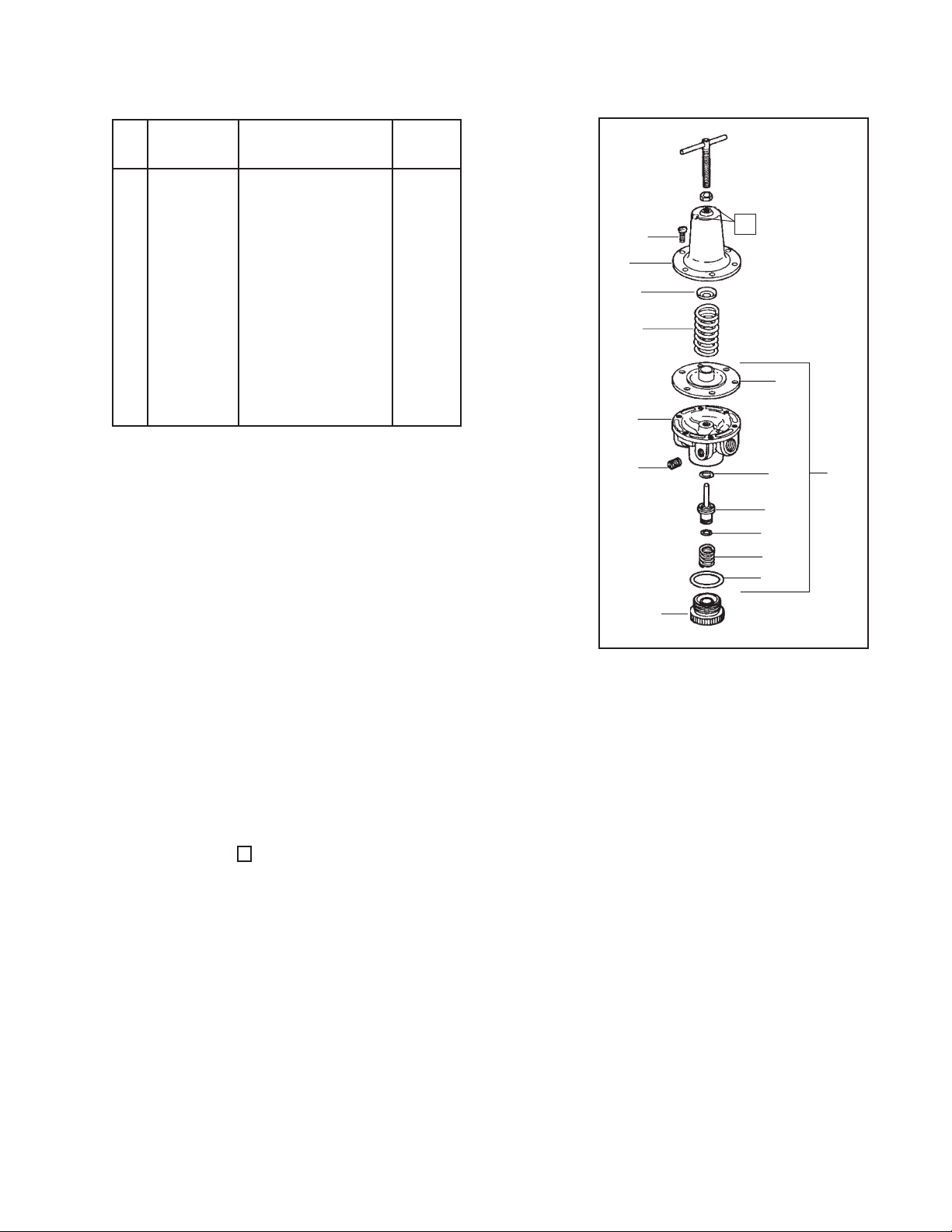

9. An optional manual drain (HAF-11) is

supplied loose in the carton (see Item

10 or 11, Fig. 4 or 5). If desired, this

can be installed in place of the auto-

matic drain.

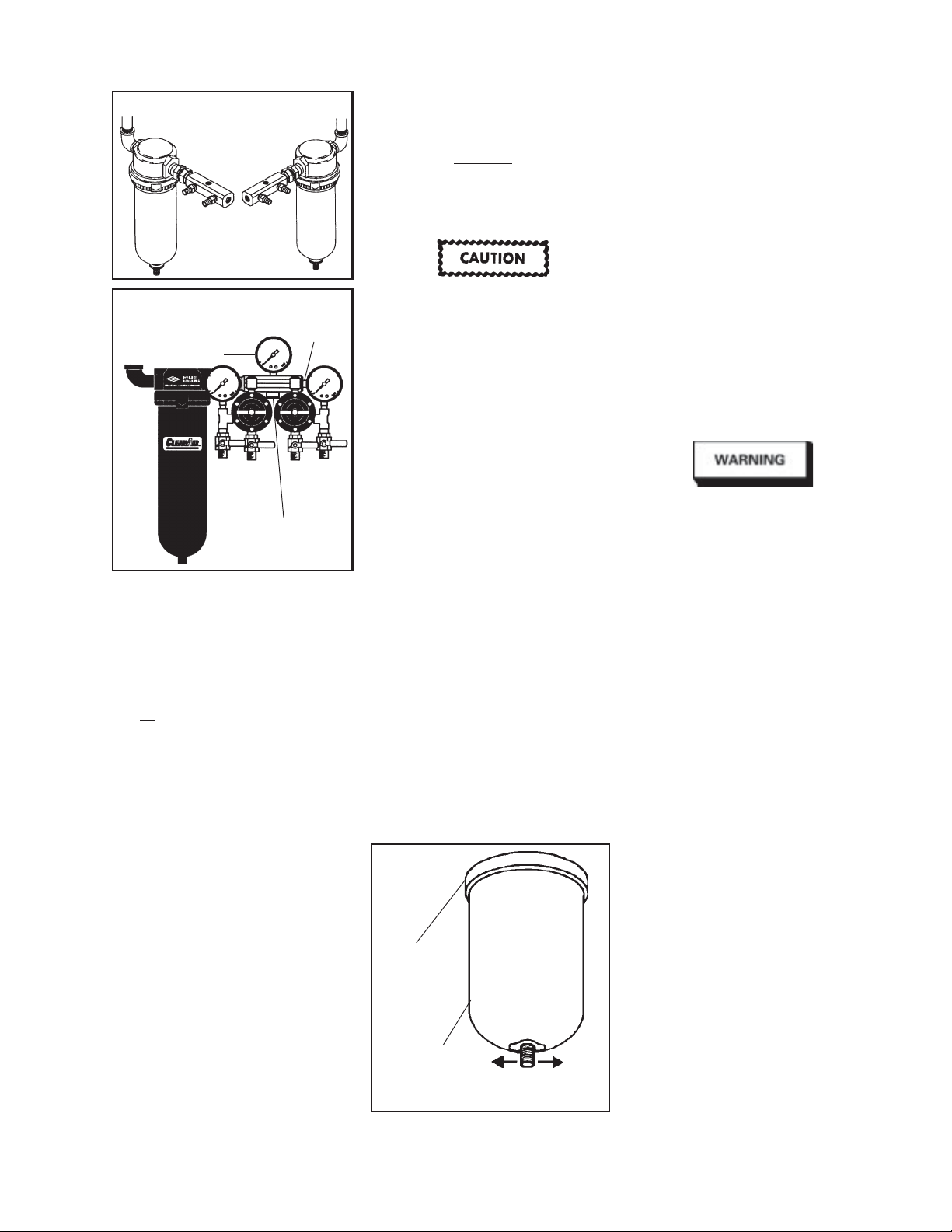

Model HFRL-511 or HFRL-513

Instructions:

In addition to Steps 1-9 above;

10. Install manifold into swivel connec-

tion on outlet of filter. Note pipe seal-

ant is not required. Orient manifold

for right or left hand operation (See

Fig. 1). Tighten swivel connection.

11. Install 0-160 psi air gauge into 1/4"

NPT(F) port in top of manifold using

pipe sealant (See Fig. 2).