DFE SteadyWeb User manual

INSTRUCTION MANUAL

STEADYWEB™

AUTOMATIC TENSION CONTROLLER

DOC 801-0783

217 Pickering Road

Rochester, NH 03867-4630 U.S.A.

For assistance, please call:

TECHNICAL SERVICE - Installations, Start-Up, Troubleshooting, Repairs, Field

Service, Returns: call 603-332-6150 and ask for Technical

CUSTOMER SERVICE - Replacement Parts, Individual Products, Questions about

Orders, Manuals: call 603-332-6150 and ask for Customer

SALES - Product Information, Systems Application Questions, and

placing orders for standard products and special systems.

Please call 603-332-6150 and ask for Sales or email to us at

Telephone: (603) 332-6150 Fax: (603) 332-3758

©1999 Dover Flexo Electronics, Inc. All rights reserved. Dover Flexo Electronics has made reasonable effort to ensure accuracy of this document.

However NO WARRANTY, whether expressed or implied, is given regarding the completeness or correctness of information in this document.

Dover Flexo Electronics shall not be liable for damages of any kind arising from the use or misuse of this document. Dover Flexo Electronics

reserves the right to make changes, additions, and deletions to this document without notice and without obligation.

READ THIS!

Your SteadyWeb™Controller has been properly configured at our factory. To install

it and start it up, it should only be necessary to use these sections of this manual:

Section 2 - Installation

Section 4 - Calibration the Tension Meter

Section 7 - Tuning for Running Stability

The other sections are for reference and for instruction if you wish to change the

configuration at some later time.

TABLE OF CONTENTS

SECTION ONE DESCRIPTION PAGE

1.0 General Description 1

1.1 Output Modules, Version of Controller 1

Pneumatic Output Module (12P) 1

High Voltage Output Module (12V) 1

0-10 Volt Compensated Output Module (12D) 1

1.2 SteadyWeb Controller Exploded View 2

1.3 Specifications 3

1.4 Standard Features

0-10 Volt Tension Output 4

4-20mA Tension Output 4

Automatic Control Mode 4

Control Voltage Selection 4

Emergency Stop 4

Manual Control Mode 4

Meter Correlation Adjustment 4

Meter Damping 4

Output Direction Selection (normal/reverse) 4

Output Meter 4

Power Voltage Selection 4

Ratio 5

Remote Tension On/Off 5

Remote Tension Set 5

Sample & Hold 5

Soft Start 5

Speed Follow 5

Speed Match 5

Status Lights 5

Tension Display 5

Transducer Voltage Selection 5

1.5 Options

220 Volt Power 6

24 Volt Output 6

45 Volt Output 6

Chassis Configuration (CC) 6

DC Tahometer Card 6

Digital Meter 6

Dual Calibration 6

Dual Transducer Input 6

Extended Range 6

Metric Air Tubing 6

Nonstandard Meter Scale 6

Pulse Tachometer Card 6

Remote Operator Devices (H6) 7

Remote Pneumatic Module 7

Remote Tension Amplifier 7

Reverse Output 7

Taper Adjustment on Front Panel 7

Taper Tension 7

Tension Limit Switch 7

1.6 Front Panel & Operator Devices 8

SECTION TWO INSTALLATION OF STANDARD UNIT

2.0 Dimensions 9

2.1 Installing the Enclosure 10

2.2 Electrical Connections 11

2.3 Electrical Connections for Options 12

SECTION THREE INSTALLATION OF H6 AND CC

CONFIGURATIONS

3.0 H6 Configuration 13

Dimensions 14

3.1 CC Configuration 15

Dimensions 15

Electrical Connections 16

SECTION FOUR CALIBRATING THE TENSION METER

4.0 Mechanical Zero 18

4.1 Calibration 18

SECTION FIVE SET-UP AND ADJUSTMENTS OF

STANDARD UNIT

5.0 Tension Zones 20

5.1 The Control Board 21

5.2 The Power Board 22

5.3 Power Voltage Selection 23

5.4 Control Voltage Selection 23

5.5 4-20mA or 0-20mA Output 24

5.6 Emergency Stop 25

5.7 High Voltage Output Module (12V only) 26

5.8 Meter Correlation 27

5.9 Meter Damping 27

5.10 Output Direction 27

5.11 Output Meter 28

5.12 Pneumatic Output Module (12P only) 28

5.13 Ratio Up/Down 29

5.14 Remote Tension Amplifier Installed? 30

5.15 Remote Tension On/Off 30

5.16 Remote Tension Set 30

5.17 Sample and Hold 31

5.18 Soft Start 31

5.19 Speed Follow 33

5.20 Tachometer Card Installed? 34

5.21 TLS Card Installed? 34

5.22 Transducer Voltage Selection 34

SECTION SIX SET-UP AND ADJUSTMENTS OF OPTIONS

6.0 220 Volt Power Input 36

6.1 24 Volt Output 36

6.2 45 Volt Output 36

6.3 DC Tachometer Card 36

6.4 Digital Meter 38

6.5 Dual Calibration 40

6.6 Dual Transducer Input 40

6.7 Extended Range 40

6.8 Pulse Tachometer Card 40

6.9 Remote Tension Amplifier 42

6.10 Taper Adjustment of Front Panel 43

6.11 Taper Tension 43

Taper by Diameter Computer 43

Taper by Rider Roll or Voltage Source 44

6.12 Tension Limit Switch (TLS) 46

SECTION SEVEN TUNING FOR RUNNING STABILITY

7.0 Introduction 49

7.1 Description of Adjustments 49

7.2 Tuning Procedure 50

7.3 Tuning the Speed Follow Function 50

SECTION EIGHT REPLACEMENT PARTS

8.0 Standard Circuit Boards 52

8.1 Optional Circuit Boards 52

8.2 Operator Devices 52

8.3 Output Modules 52

8.4 Fuses 52

8.5 Ribbon Cables 52

8.6 Relays 53

8.7 Miscellaneous 53

APPENDICES

ALocations of Standard Adjustments 54

BDIP Switch Settings 55

CBasic Set-up 58

DElectrical Connections of Standard SteadyWeb 60

EElectrical Connections of Options 61

FTransducer Electrical Connections 62

GTypical Tensions 66

HFront Board 67

ITroubleshooting 68

TERMS AND CONDITIONS OF SALE 69

INDEX 70,71

LIST OF ILLUSTRATIONS

FIGURE DESCRIPTION PAGE

1 SteadyWeb Controller - Exploded View 2

2 Front Panel and Operator Devices 8

3 Dimensions 9

4 Mounting Screw Locations 10

5 Cover Removal 10

6 Electrical Connections 11

7 Electrical Connections of Options 12

8 Remote Operator Device Configuration 13

9 Dimensions of H6 14

10 Chassis Configuration (CC) 15

11 Dimensions of CC Configuration 15

12 Electrical Connections of CC 16,17

13 Meter Access Holes 18

14 Web Path for Meter Calibration 19

15 Tension Zones 20

16 Control Board 21

17 Power Board 22

18 Power Switch 23

19 E-Stop Electrical Connections 25

20 V-OUT Module 26

21 Ratio Contact Electrical Connections 29

22 Remote Tension On/Off Button Connections 30

23 Sample & Hold Contact 31

24 Soft Start Connections 32

25 Transducer Voltage Switch 35

26 DC Tach Option Card 36

27 DC Tachometer Connections 37

28 Digital Meter Display 39

29 Digital Meter Card 39

30 Pulse Tach Option Card 41

31 Pulse tachometer Connections 41

32 Remote Tension Amplifier Electrical Connections 43

33 Taper Dia/Calc Option Card 43

34 Taper RIDER Option Card 45

35 Rider Pot. Connections 45

36 10 Volt Source Connections 45

37 TLS Option Card 46

38 TLS Reset Button Connections 47

39 TLS Relay Connections 48

40 Tuning Pots. 49

41 Standard Adjustments - Control Board 54

42 Standard Adjustments - Power Board 54

43 Standard Electrical Connections 60

44 Optional Electrical Connections 61

45 Model C, UPB Transducer Wiring 62

46 RF Transducer Wiring 63

47 TR, NW Transducer Wiring 64

48 LT Transducer Wiring 65

49 Front Board 67

1

SECTION 1 DESCRIPTION

1.0 GENERAL DESCRIPTION

The SteadyWeb tension controller automatically maintains tension of any continuous material at the

value selected by the machine operator. It consists of three basic functions:

The first function is performed by the tension amplifier. It supports all of Dover Flexo Electronics

tension transducers. (The transducers measure the actual tension in the web). It includes a regulated

power supply to excite the transducers, an amplifier to boost the transducer output signal, and a

calibration circuit to adjust the tension readout to display actual tension.

The second function is the tension regulator. It compares the output signal from the transducers with

the signal from the AUTO Set potentiometer on the front of the SteadyWeb enclosure. If there is a

difference, the regulator will either increase or decrease tension to equalize them. The tension

amplifier and the tension regulator are both located on the Control board. (See Figure 1)

The third function is performed by the output module. It accepts the output from the tension regulator

and actuates a brake, clutch, or variable speed drive system which actually creates the tension in the

web.

1.1 OUTPUT MODULES, VERSION OF CONTROLLER

Three output modules are available for the SteadyWeb controller.

A) Pneumatic output module. This is used to actuate any air operated brake or clutch. It includes a

servo valve, a pressure regulator, and an air filter. These items are fitted together into a compact

assembly which is normally installed inside the controller enclosure or optionally located remotely.

The output range is .5 to 75 psi. SteadyWeb controllers having this module are designated

"Version 12P".

B) High Voltage output module. This module uses SCR's to produce a variable voltage of up to 90

volts DC to operate any electric brake or clutch, including eddy current clutches. 45 volt and 24 volt

outputs are optional. This module is also known as the VOUT Card. SteadyWeb controllers having

this output module are designated "Version 12V".

C)0 to 10 Volt DC compensated output module. This module is in the form of a 16 pin DIP Integrated

Circuit that plugs into the Power board near the top center. It is designated U203. See Figure 17.

This output is used to control DC drives or other variable speed drive systems, usually in

intermediate tension zones. This output is isolated from ground to make it compatible with all

drives. SteadyWeb controllers having this output are designated "Version 12D".

All SteadyWeb controllers may be easily converted from one output to another if desired. There are

five locations for plug-in cards for optional features, three on the Control board and two on the

Power board. See Figures 16, 17.

2

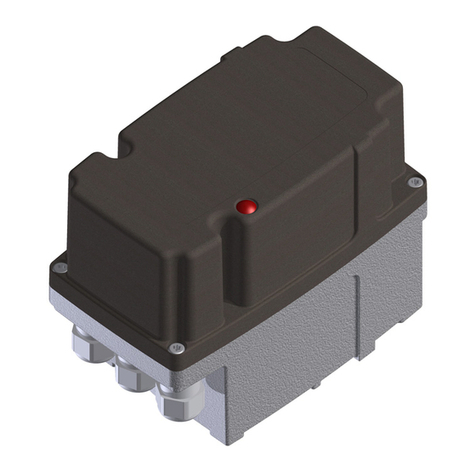

1.2 STEADYWEB CONTROLLER EXPLODED VIEW

Figure 1 - STEADYWEB CONTROLLER - EXPLODED VIEW

3

1.3 SPECIFICATIONS

POWER INPUT 12P and 12D ..... 120/240 Volts 60/50Hz single phase @ 1 Amp

12V ............ 120/240 Volts 60/50Hz single phase @ 5 Amp

OUTPUT 12P ............ 0.5to75psi(,03to5,17bar)

12V ............ 90VoltsDC,45VDC,24VDC,all@4Amp

............ 180VDC @4 Amp and 230VAC Input

12D ............ 0-10VoltsDC,compensated and isolated

TENSIONSIGNALOUTPUT .......... 0-10VoltsDC

........... 4-20MAinto500 ohm maximum load

ENCLOSURE ............ Steel,powderresinpainted,NEMA1

WEIGHT ............ 26lbs.(11,8KG)

AIRCONNECTIONS:12PIn .......... 3/8inchplastictubing(5/16",8mmoptional)

Out......... 1/4inchplastictubing(6mm)

INTERNALAIRFILTER 12P......... 5micron,1/2pintbowl,automaticdrain

TRANSDUCER SIGNAL ............ 500 mv DC per pair at rated load, 1.0 Volt with

........... Extended Range option

MATING TRANSDUCER CABLE

CONNECTORS ............ Amphenol MS3106A-10SL-3S

ZERO(TARE)RANGE ............ 95%oftransducerrating,minimum

CALIBRATIONRANGE ............ 25:1

TEMPERATURERANGE ............ 32to104 deg.F (0-40 deg.C)

SYSTEM ACCURACY ............ 1-3%typical

TENSIONMETER ............ Analog,2%,1ma,48ohm

OUTPUTRANGE ............ 0-100% Max., Min. = 0-20% of Max.

MANUALMODEOUTPUTRANGE..... 0-100%

OUTPUTRATIORANGES ........... 1:10(multiplier)and 10:1(divider)

STANDARD TENSION METER SCALES 0 - 1,5,10,25,50,100,150,250,500,1000

TENSION LIMIT SWITCH RELAY

CONTACTS(option) ............ SPDTrated@10A/30VDC,10A/250VAC

TAPER TENSION RANGE (option) ..... 0-100%

TAPER TENSION INPUTS (option)

Code TTDCT (using DC Tachs) . . . Switch selected, 3V to 250V

Code TTPT (using Pulse Tachs) . . . 300Hz to 40KHz at max. line speed

Code TTF (Roll Follower) ........ 10Kohmpot.minimum

Code TTR (external voltage) ...... 0-10VDCcoretofullroll

4

1.4 STANDARD FEATURES

SOME OF THESE FUNCTIONS REQUIRE CONFIGURING OR EXTERNAL WIRING. REFER TO

SECTION 5 FOR CONFIGURING AND SECTION 2.2 FOR WIRING.

!0-10 VOLT DC TENSION OUT. Proportional to web tension. Used as an input to other control

systems, computers or data collection devices.

!4-20mA TENSION OUT. Proportional to web tension. Used as an input to other control systems,

computers or data collection devices.

!AUTOMATIC CONTROL MODE. The controller output is determined by the difference between

web tension and the AUTO tension set knob position. The internal regulator automatically varies

the output as required to maintain set tension.

!CONTROL VOLTAGE SELECTION. Choose one of three available Control board outputs. They

are 0 to +10 VDC, 0 to -10VDC, and -10 to +10VDC. The 0 to +10VDC output operates pneumatic

(12P) and high voltage (12V) output modules when used. Any of the three outputs can be used in

the 12D version of the SteadyWeb.

!EMERGENCY STOP. Controller immediately goes to full output or zero output (selectable) upon

closure of an external contact. Normally full output is used on unwinds to stop the roll of material

quickly. Zero output is used for rewind or intermediate controllers.

!MANUAL CONTROL MODE. The controller output is determined only by the position of the

MANUAL set knob. No change occurs unless the knob is turned. Used during machine set-up or

during trouble-shooting.

!METER CORRELATION ADJUSTMENT. This causes the position of the AUTO set pot. to

correspond to the position of the needle on the analog tension meter. For example; if the AUTO

pot. is set at 4 on its dial, the tension meter would read 40% of full scale. This is important for the

proper operation of the controller.

!METER DAMPING. Eliminates vibration of the analog tension meter needle. Also minimizes flicker

of the optional digital meter.

!OUTPUT DIRECTION. Select between Normal and Reverse output. Most applications use the

Normal selection, controller output goes up when tension falls below the set level. The Reverse

selection causes output to go down when tension falls below the set level. It is used in intermediate

tension zones where the transducers are located after the nip rolls they control, and for driven

unwinds.

!OUTPUT METER. Displays the controller output, measured in 0 to 100 percent. Set 0 at left end

of scale for Version 12P, 12V and some 12D controllers. Or Set 0 at center of scale when using an

optional center-zero meter for Version 12D controllers having -10 to +10 volt outputs.

!POWER VOLTAGE SELECTION. The SteadyWeb controller is designed to operate on two ranges

of AC power; 110-120 Volts 60/50 Hz, and 220-240 Volts 60/50 Hz. A slide switch on the Power

board selects between the two.

5

!RATIO. Takes the sampled output and multiplies it (unwind applications) or divides it (rewind

applications) by a factor adjustable between 1 and 10. Used in flying splice applications to help

provide a match between controller output and roll diameter.

!REMOTE TENSION ON/OFF. Requires two momentary pushbuttons supplied by customer and

located external to the controller. Enables the machine operator to turn the controller output on and

off at the remote location and at the controller.

!REMOTE TENSION SET. Locate an AUTO Tension Set potentiometer external to the controller in

addition to the one on the front panel of the controller. Select between the two with a switch inside

the controller. Only one pot. can be active at any one time.

!SAMPLE AND HOLD. Locks the controller output at whatever level it may be when an external

contact closes, and maintains it there until the contact opens. Usually used in flying splice

applications to prevent instability during the splice. Also actuated by the RATIO function.

!SOFT START. Used on unwinds. Actuated either automatically upon a loss of tension below the

preset trip point (after an adjustable delay), immediately upon an external contact closure, or by

machine speed. Controller output is reduced to a preset low level to prevent brake lock-up when

the machine starts. When tension rises above the trip point, the controller goes back to the

automatic control mode. Does not operate in the MANUAL control mode. Actuation by machine

speed requires an optional Tachometer Card (see Options, Section 1.5)

!SPEED FOLLOW. This is a special function normally used on Version 12D SteadyWebs controlling

tension in an intermediate zone (see Tension Zone drawing, Section 5.0, page 20) or surface

driven rewinds and unwinds. Versions 12P and 12V can also use it if they are controlling a clutch

which has a constant input speed. In any case, the controller must be equipped with an optional

DC Tach card or Pulse Tach card.

The Control board contains a regulator circuit, separate from the tension regulator, that accepts a

line speed signal and, optionally, a nip roll speed signal. The line speed signal causes the output of

the controller to follow (go up and down with) line speed. The output of the tension regulator then

trims the follower output as needed to maintain set tension.

The follower method described above is recommended over the Speed Match method for most

applications because it is less affected by tachometer drift, is easier to set up and its adjustment is

less critical, and will not result in a run-away condition if the nip roll speed signal is lost.

!SPEED MATCH. The same as Speed Follow above, except that the nip roll speed input is also

used. In this case, the nip roll is speed-regulated and the tension regulator trims the roll speed.

!STATUS LIGHTS. Show that particular functions are active when lights are illuminated.

!TENSION DISPLAY. Web tension is displayed on an analog meter which is calibrated to read out

total tension in pounds, newtons, kilograms, or any other desired units. A digital meter is optional.

!TRANSDUCER VOLTAGE SELECTION. Choose between 5VDC and 10VDC excitation for the

tension transducers. 5VDC is standard. 10VDC is used only for the extended range option.

6

1.5 OPTIONS (The option code is shown in parentheses)

SOME OF THESE OPTIONAL FUNCTIONS REQUIRE CONFIGURING OR EXTERNAL WIRING.

REFER TO SECTION 6 FOR CONFIGURING AND SECTION 2.3 FOR WIRING.

!220 VOLT POWER (220V). 220 volt 50/60 Hz power input.

!24 VOLT OUTPUT (24V). For Version 12V only. Factory-installed option with 220V power.

!45 VOLT OUTPUT (45V). For Version 12V only.

!CHASSIS CONFIGURATION (CC). No cover or front panel on enclosure. Customer supplies all

operator devices. Controller must be installed inside customer's enclosure.

!DC TACHOMETER CARD (DCT). Takes the voltage output from one or two DC tachometers and

scales it to 0-10 volts DC. This card is required for the Taper Tension (TTDCT) option, the version

of Soft Start which is actuated by machine speed, and the Speed Follow function. This card plugs

into the Power Board.

!DIGITAL METER (DM). 4 full digits, red 1" high LED's with over and under range indicators. The

maximum range is 0000 to 9999. An over-range indicator lights at values over 9999, and an under-

range indicator lights at values below 0. Can be read from further away than the analog meter. Up

to 2 decimal places.

!DUAL CALIBRATION (DC). Two meter scales for the standard analog tension meter and/or two

running-stability setups. The meter scales may have any ratio, limited only by the range of the

transducers. Used in those cases in which a wide range of materials having very wide tension

requirements are being run.

!DUAL TRANSDUCER INPUT (DTI). Controller receives two separate tension signals, one from

each of two sets of transducers. Used when a very wide range of tensions must be controlled. A

switch on the front panel selects the tension signal to use. The option card plugs into the left-hand

option socket on the Power board. There are no adjustments on this card. The Dual Calibration

option (DC) is required.

!EXTENDED RANGE (XR). The transducers are excited by 10 volts instead of the standard 5 volts.

Used for low tension applications. The transducers must also have the XR option.

!METRIC AIR TUBING (8MM). For Version 12P only. Air fitting for use of 8mm diameter air supply

tubing in place of the standard 3/8 inch tubing.

!NONSTANDARD METER SCALE (NMS). Any nonstandard analog meter scale. Either single or

dual scale. See Specifications, page 3, for standard scales.

!PULSE TACHOMETER CARD (PT). Takes the pulse output from one or two rotary encoders, AC

tachometers or other types of pulse generators and converts and scales it to 0-10 volts DC. This

card is required for the Taper Tension (TTPT) option, the version of Soft Start which is actuated by

machine speed, and the Speed Follow function. This card plugs into the Power Board.

7

!REMOTE OPERATOR DEVICES (H6). No cover on enclosure. Front panel attached to controller

via a 6'(length optional) cable. Allows front panel to be installed in customer's control panel and

controller to be installed inside.

!REMOTE PNEUMATIC MODULE (2E). For Version 12P only. Allows servo valve to be installed

close to the brake/clutch while the controller is located elsewhere.

!REMOTE TENSION AMPLIFIER (RTA). The internal tension amplifier is bypassed and the tension

signal is provided by an external remote device such as the TI7. This allows use of special

indicator functions, such as intrinsic safety, which are not available in the SteadyWeb controller.

!REVERSE OUTPUT (RO). Controller output goes up when tension exceeds the set point. This is

the reverse of normal, when output goes down upon excess tension. Used in intermediate tension

zones where the transducers are located after the nip rolls they control. NOTE: No additional

wiring connections or components are needed to use the Reverse Output feature. It is selected by

a switch on the Control board. See section 5.10 for setup.

!TAPER ADJUSTMENT ON FRONT PANEL (XTA). Instead of inside controller.

!TAPER TENSION. For rewind applications. Causes tension to decrease as roll diameter

increases. Helps produce a better quality roll by eliminating telescoping, crushed cores, too tight or

too loose rolls. Two methods are available, diameter computer and rider roll. The diameter

computer method requires machine speed and roll speed signals from the optional DC Tachometer

Card or the Pulse Tachometer Card. The rider roll method requires a follower roll in contact with

the rewinding roll, or some other roll-sensing device such as a sonic rangefinder to detect the roll

diameter. The device must have a 0-10 Volt DC output. Taper is adjustable from 0 to 100%. The

taper circuitry is located on a card which is plugged into the Control Board. Here is a list of the

different types of taper circuits available:

(TTDCT) DC Tachometers used for speed signals.

(TTPT) Pulse Tach generators used for speed signals.

(TTF) Roll Follower or external 0-10VDC source used.

!TENSION LIMIT SWITCH (TLS). Provides relay contact closure at preset tension levels,

either high or low. Usually used as a web break detector. The electronic circuitry is located

on a card which is plugged into the Control Board. The relay is located on the Power

Board.

8

1.6 FRONT PANEL AND OPERATOR DEVICES

Figure 2 - FRONT PANEL and OPERATOR DEVICES

9

SECTION 2 INSTALLATION

2.0 DIMENSIONS

ABCDEFGHJKL

inch 12.44 10.42 7.75 1.42 2.41 .24 11.78 9.41 10.54 4.71 .42

mm 316 265 197 36 61 6 299 239 268 120 11

Note: Allow 5" (127mm) clearance on the left side for the controller to open completely.

FRONT SIDE BACK

REMOTE PNEUMATIC ASSEMBLY DIMENSIONS

ABCDEFG

inch 2.0 4.5 8.0 3.0 6.0 2.0 .56

mm 51 114 203 76 152 51 14

Figure 3 - DIMENSIONS

10

2.1 INSTALLING THE ENCLOSURE

Select a location on the machine frame or a wall that will be convenient for the machine

operator to operate the controller and to see the tension meter easily. Be sure the location is

free of vibration, and is dry and clean. Take care to choose a place that the controller won't

be struck and damaged by anything or anyone.

The enclosure is fastened to the mounting surface you have chosen by two socket head cap

screws. Install the screws in the mounting surface as shown below. Leave them loose about

6 turns. Position the keyholes in the back panel of the enclosure over the screws and slide it

down until it locks in place. The cover must be removed to tighten the mounting screws. (See

Figure 5)

Figure 4 - MOUNTING SCREW LOCATIONS

Figure 5 - COVER REMOVAL

11

After removing the cover, swing the front panel out by first loosening the two screws on the right side

top and bottom corners 1/4 turn CCW. Use a hex wrench to tighten the two enclosure mounting

screws.

2.2 ELECTRICAL CONNECTIONS

Refer to the drawing below for electrical connections. If your controller has any optional equipment,

refer to Section 2.3 or Appendix D of this manual for the appropriate connections. TB201, TB203 and

TB204 are located on the Power Board.

Figure 6 - ELECTRICAL CONNECTIONS

NOTE: The tension transducers are usually connected to the controller by two 3 pin Amphenol

connectors mounted on the bottom of the enclosure. However they may be hard-wired

directly to the terminal strips as shown above, if desired.

12

2.3 ELECTRICAL CONNECTIONS OF OPTIONS

Figure 7 - ELECTRICAL CONNECTIONS OF OPTIONS

Table of contents

Other DFE Controllers manuals

Popular Controllers manuals by other brands

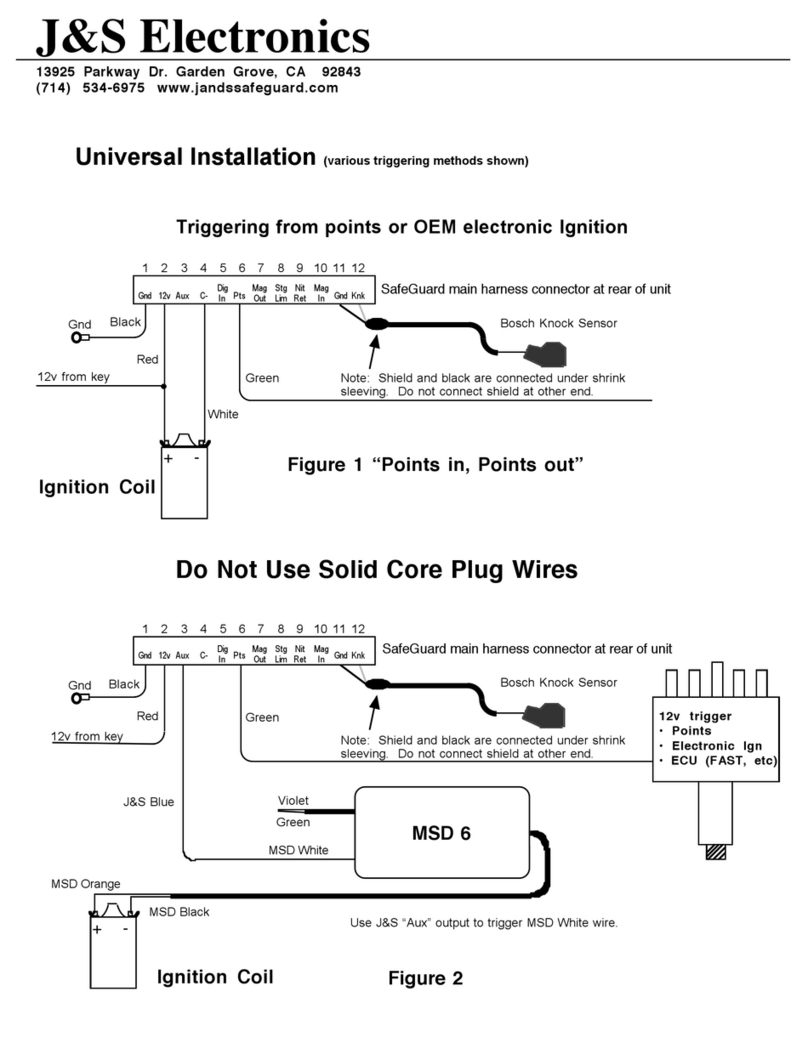

Jands

Jands SafeGuard installation guide

IFM Electronic

IFM Electronic ecomat 100 R 360 Mounting and installation instructions

Emerson

Emerson Bettis RTS FQ Series operating manual

BACHMANN EUROPE Plc

BACHMANN EUROPE Plc 36-565 operating instructions

inVENTer

inVENTer iV14-Zero sMove operating instructions

Beckett

Beckett AquaSmart manual