Dialight DuroSite User manual

9100127275499 REV A

Dialight, 1501 Route 34 South, Farmingdale, NJ, USA 07727

Tel: 732 919 3119 Fax: 732 751 5778 www.dialight.com

DuroSite®Emergency Stainless Steel LED Linear Luminaire for industrial areas

Important information:

These instructions contain safety information, read and follow them carefully. Dialight will not accept any

responsibility

for

injury, damage or loss which may occur due to incorrect installation, operation or maintenance

Operating

Instructions

Languages

Page Number

English

5 - 6

Stainless Steel

9100127275499 REV A

Dialight, 1501 Route 34 South, Farmingdale, NJ, USA 07727

Tel: 732 919 3119 Fax: 732 751 5778 www.dialight.com

DuroSite®Emergency Stainless Steel LED Linear Luminaire for industrial areas

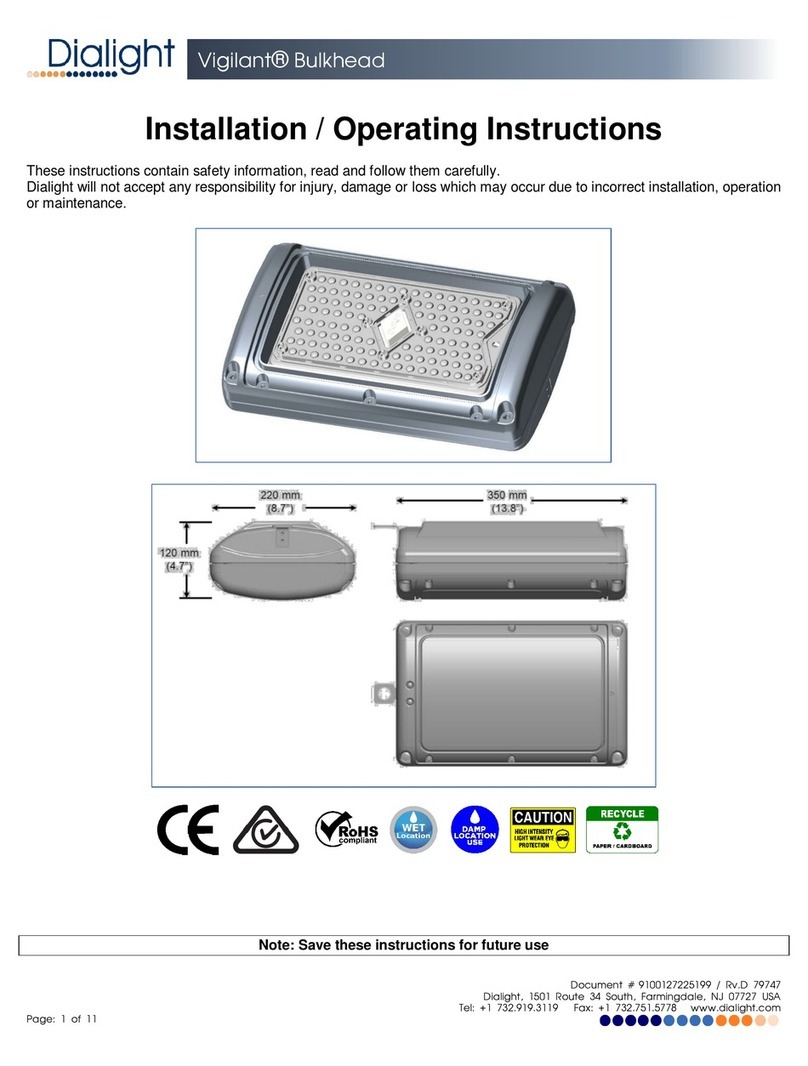

Dimensions in mm

Tightening Torques

End cover screws 1.9Nm

Bracket fixing screws 2 Nm

9100127275499 REV A

Dialight, 1501 Route 34 South, Farmingdale, NJ, USA 07727

Tel: 732 919 3119 Fax: 732 751 5778 www.dialight.com

DuroSite®Emergency Stainless Steel LED Linear Luminaire for industrial areas

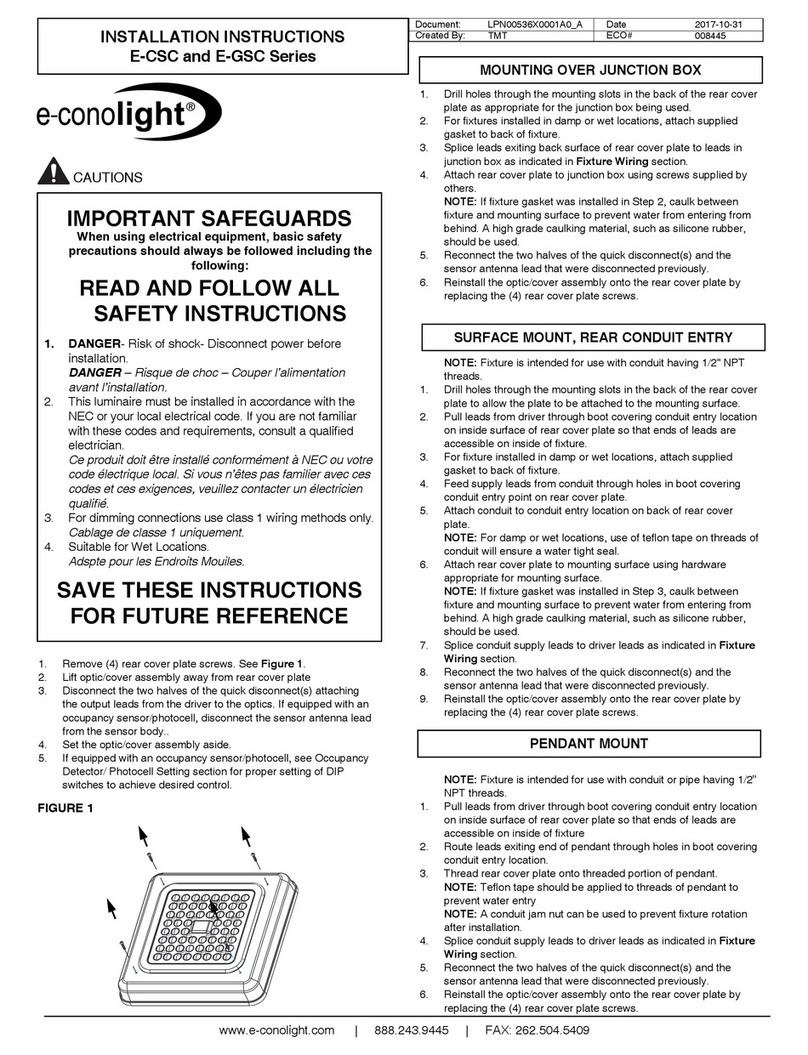

THRU CABLE 2,5MM²

THRU CABLE 1,5MM²

9100127275499 REV A

Dialight, 1501 Route 34 South, Farmingdale, NJ, USA 07727

Tel: 732 919 3119 Fax: 732 751 5778 www.dialight.com

DuroSite®Emergency Stainless Steel LED Linear Luminaire for industrial areas

Tightening Torques

End cover screws 1.9Nm

Optional Safety Rope

9100127275499 REV A

Dialight, 1501 Route 34 South, Farmingdale, NJ, USA 07727

Tel: 732 919 3119 Fax: 732 751 5778 www.dialight.com

DuroSite®Emergency Stainless Steel LED Linear Luminaire r industrial areas

Conformity with Standards

This equipment conforms to the standards specified in

the Declaration of Conformity.

It has been designed, manufactured and tested in

accordance with BS EN 9001.

2004/108/EC:EC Directive for electromagnetic

compatibility.

Equipment Application

This lighting equipment is intended for use in an

industrial area.

The product can be used inside or outside to

illuminate industrial areas

Mounting the Luminaire

Assemble the mounting bracket to the luminaire with 2 off

M8 x 1.25 by 16mm bolts. Torque specification: 2.0 Nm

maximum.

Installation

Ensure that the mains voltage supply is disconnected

before connecting the luminaire. Install the

equipment in accordance with the manufacturer’s

instructions as well as any other applicable electrical

codes.

Always transport and store the equipment in its original

packaging and keep in a dry location.

When unpacking check for any cracks or damage in the

housing, end covers and lens. If in doubt, do not install!

All EL and ELE luminaires come complete with through wire

capabilities and as such, the mains can enter the luminaire

from either end. All EL and ELE luminaires come with two

entry points at each end to allow for mains in, switched live

in and through wires out on separate cables if required.

Opening the terminal tray

To open the tray, completely remove the two 4mm HEX

socket screws at either the emergency module end or the

luminaire end. Once these are removed, the tray can be

slid out exposing the terminal block. The terminal blocks are

mounted to the front sides of the trays (where the front side

is the light output side) This gives easy access to the

terminals when the luminaire is mounted in position.

The terminal tray is captive and will not fall out when slid

open to its max position.

The terminal tray slides back into position once the wires are

connected to the terminal block (See Electrical

connections on Page 3). The gear tray should be slid back

with care ensuring no cables or wires are overstressed or

trapped. When replacing the end covers, ensure the seals

are clean and undamaged. If the covers are not fully in

place the screws may be difficult to engage and can be

cross-threaded. Do not allow any cables to be trapped by

the end covers or terminal tray. Ensure that all wires are

clear from the screw entry points.

The cable glands used with this fixture must be rated

IP66/67 or better to maintain the protection level of the

luminaire. A locknut is required for each cable gland to

ensure they are securely fastened to the end covers.

Cable gland with O-ring min. thread length C = 10mm.

P= M20 x 1,5mm

P= M25 x 1,5mm (add 4

suffix to part code)

The cable used must be suitable for the site application

and/or the site requirements.

When assembling the cable entries for the mains

connection, always observe the manufacturers

specifications for the glands used.

Note:- This fixture is supplied with one dust cap. Unused

cable entries must be closed off with blanking

plugs or stoppers to maintain the IP rating. (3 supplied).

The cable entries should be securely tightened to ensure

that the minimum protection rating is achieved. The cable

entry should be rated to minimum of IP66 / IP67 to maintain

the protection level of the fixture.

Do not over tighten as the protection rating may be

compromised. Always refer to gland manufacturers data

for torque settings.

Electrical Connections

The terminal block is suitable for multi-stranded and single

core cables up to a maximum of 4mm², strip length 10mm

The LIVE 1, LIVE 2, NEUTRAL and EARTH connections are

clearly marked on the terminal block or label.

When terminating the conductors, the insulation of the

conductors shall reach up to the terminal block. The

conductor itself shall not be damaged. The connectable

minimum and maximum conductor cross sections shall be

observed (see technical data box).

The L1 connection is a permanent live feed. It powers the

main normal mode operation, battery charger and is used

to activate emergency mode. The L2 connection is a

switched live feed to control the luminaire normal mode on

or off. It is a signal input that consumes negligible current.

Single Luminaire Electrical Connections:-

Push down at the ‘cross point’ on the terminal block, insert

correct cable and release, ensuring the cable has been

securely retained.

Loop Through Electrical Connections:-

Connect incoming cable as above then connect the

outgoing cable to the associated adjoining connection to

pass to the next luminaire.

3 phase connection

Connect the designated load phase (e.g. L1) to L on the

terminal block and the other 2 phases for loop thru L2 / L3

respectively to the terminal block as shown in the diagram

ONLY SINGLE CABLES TO BE USED ON EACH TERMINAL ENTRY

POINT.

The improper installation, operation, or maintenance of

these luminaries may result in the invalidation of the

warranty.

Use the dimensions in Section 1 provided to locate the

luminaire into the desired position.

Maximum screw / bolt size M8 x 16 (screws are supplied with

the mounting hardware and are supplied separately).

Battery

A 3.6V 10Ah (part ref ELX-BATT-KIT) is provided with both the

35W and 70W versions. The 10Ah battery is mounted on a

completely removable tray which only requires removing

when battery pack replacement is required. To remove the

battery tray, DISCONNECT the 2-pole battery connector

and loosen the battery tray retaining screw. The screw is

retained to the tray, un-hook the tray to remove the battery

pack.

Safety Instruction:

The installation, operation and

maintenance must be carried out

by a suitably trained electrician.

• The technical data indicated on the

LED luminaires are to be observed.

• Changes of the design and

modifications to the LED luminaire

are not permitted

• Observe the national electrical

safety rules and regulations during

installation.

• No user serviceable parts inside.

• Only the battery pack is field

replaceable

9100127275499 REV A

Dialight, 1501 Route 34 South, Farmingdale, NJ, USA 07727

Tel: 732 919 3119 Fax: 732 751 5778 www.dialight.com

DuroSite®Emergency Stainless Steel LED Linear Luminaire r industrial areas

Battery and Micro-switch interlock

The driver electronics along with the micro-switch interlock

shut down all battery related circuits when the battery-side

end cover is withdrawn.

Closing the LED Luminaire

Remove any foreign bodies from the fixture

Pay attention when closing the terminal tray fitting to the

enclosure; make sure the seals are clean and undamaged.

Do not allow any cables to become trapped between the

end cover and the enclosure.

Tighten both 4mm HEX socket screws evenly to the

specified torque and re-check.

Taking into operation

Prior to operating, check the luminaire for its correct

installation in compliance with these operating instructions

and other applicable regulations.

Attention: Only fully certified equipment may be put into

operation.

Improper installation and operation of this luminaire may

invalidate the warranty.

Upon applying power, confirm the operation of battery

circuits by observing the green status LED located at the

end of the led strip. The green status LED will light only if all

of the below conditions are met:

-The terminal tray is properly closed, activating

the micro-switch

-The battery is connected

-The battery is charging and within acceptable

voltage limits

If the green Status LED is not lit with power applied to the L1

feed, disconnect power and rectify any faults.

In Service, Battery Charging and Condition Monitoring

When power is applied (initially or after an outage), the

battery will be charged for 36 hours. Thereafter, in order to

maximise battery life while maintaining emergency

capacity, the battery charging operates for 1 minute in

every hour.

The battery is continually monitored for voltage limits and

charge current acceptance (during charge pulses). If the

mains power supply is interrupted, the fixture will switch to

emergency mode operation at reduced light output.

Expected emergency mode duration exceeds 3 hours at

-20°C and far exceeds 3hrs at higher ambient

temperatures.

If, during an emergency mode cycle, the battery capacity

has deteriorated to the point that 3 hours is not achieved,

then when power is restored this battery “failure” will be

signalled by flashing the green status LED once every 7-8

seconds. The fault indication will be automatically reset

when a successful charge/discharge cycle is completed.

Conditions for use:

The supply to the Luminaire must include a fuse which is

capable of interrupting a 1.5kA short circuit current.

When used with steel wired armoured or braided cable the

basket weave armour or braid is unable to carry the cable

load without fracture. Therefore the cable must be

clamped and cleated to prevent pulling on the cable

being transmitted to the cable terminations.

Improper installation and operation of this luminaire may

invalidate the warranty.

For maximum long term reliability and light output, the

luminaire must be installed in free air.

Inspection

Within the scope of maintenance or inspection routine the

following should be included:

- Protective hoses covering the connection cables.

- Cable entries must be free of corrosion.

- Perform visual mechanical and electrical inspections on a

regular basis. We recommend routine checks to be made

on a yearly basis. Frequency of use and environment should

determine this. It is recommended to follow an Electrical

Preventive Maintenance Program as described in NFPA

70B: Recommended Practice for Electrical Equipment.

- The lens should be cleaned periodically as needed to

ensure continued photometric performance. Clean the lens

with a damp, non-abrasive, lint free cloth. If not sufficient,

use mild soap or a liquid cleaner.

- Inspect the luminaire to ensure that it is free of any

obstructions or contamination (i.e. excessive dust build up).

Clean with a non-abrasive cloth if needed.

Repairs / Overhaul / Modification

Any unforeseen repairs or overhaul may only be carried out

with genuine Dialight spare parts.

Should the luminaire enclosure be damaged, only a full

luminaire replacement will be permitted. In case of doubt,

the equipment should be returned to Dialight for

inspection/repair.

Modifications to the device or changes of its design are not

permitted.

This equipment must be operated according to the

intended purpose in a perfect and undamaged condition.

Ordering Spare Parts

Replacement Batteries

Dialight Part Number ELX-BATT-KIT

(3.6V 10Ah Ni-MH battery pack)

Should any unforeseen spares be required then please

contact Dialight for availability.

Disposal Recycling

When the battery is disposed of, the respective national

regulations on waste disposal should be observed.

WEEE (Waste electrical & electronic equipment) registration

number WEE/DC2678RY.

Technical Data:

Rated Input

Voltage:

230/240 VAC 50/60 Hz

Typical Running Current:

35W:

150mA at 230V AC

70W:

300mA at 230V AC

Typical Inrush Current @ 230VAC:

35W:

4A for 50µs

70W:

1.6A for 0.5ms

Operating Temp.

-20°C to +60°C

Housing:

Marine Grade 316

Stainless Steel IP66/67

Dimensions:

See diagram page

Cable Entries:

Standard 2 OFF M20 x 1.5mm

both ends

(Other entry options)

Terminal block:

Standard: 4-way, max. 4mm²

3-Phase: 7-way, max. 4mm²

Through cable:

Standard: 3 x 1,5 mm²

3-Phase: 7 x 2,5 mm²

3-Phase: 7 x 2,5 mm²

Tightening

Torques:

See diagram page

Weight:

35W:

8.9Kg

70W

13.7Kg

Battery Capacity:

10Ah 3.6VDC NiMH

Table of contents

Other Dialight Lighting Equipment manuals

Dialight

Dialight VIGILANT Series User manual

Dialight

Dialight Vigilant User manual

Dialight

Dialight L-856 Manual

Dialight

Dialight Reliant User manual

Dialight

Dialight VIGILANT Series User manual

Dialight

Dialight Vigilant Bulkhead Guide

Dialight

Dialight HBXREF22 User manual

Dialight

Dialight HBXW3SSL304FT User manual

Dialight

Dialight SAFESITE LSD3C4M2P Manual

Dialight

Dialight SafeSite User manual