Run or Action Mode

Animation

Description

50/50 Color 1 is displayed on 50% of every segment and Color 2 is displayed on the other 50% of every segment at the defined color intensities

and segment shift

50/50 Rotate Color 1 is displayed on 50% of every segment and Color 2 is displayed on the other 50% of every segment while rotating at the defined

speed, color intensities, rotational direction, and segment shift

Chase Color 1 is displayed as a single spot against the background of Color 2 while rotating at the defined speed, color intensities, rotational

direction, and segment shift

Intensity Sweep Color 1 repeatedly increases and decreases intensity between 0% to 100% on every segment at defined speed and color intensity

Scroll Color 1 fills two segments and those segments move in one direction up or down against the background of Color 2 at the defined speed,

color intensities, and rotational direction

Bounce Color 1 fills two segments and those segments move up and down between the top and bottom of the tower against the background of Color

2 at the defined speed, color intensities, and rotational direction

Color Spectrum The tower light scrolls through the 14 predefined colors with a different color on each segment at the defined speed, Color 1 intensity, and

rotational direction

Advanced Mode—Use Advanced Mode to set the value range, thresholds, colors, intensities, flash speeds, and animation types for

PWM, PFM, Counter, and Timer control inputs.

Advanced Mode

Parameters Description

Control Type

PWM (Pulse Width Modulation): Apply a square wave signal to the PWM/PFM Input and vary the duty cycle from 0 to 100%

to set value. The signal must use a constant frequency between 100 to 10,000 Hz.

PFM (Pulse Frequency Modulation): Apply a square wave signal to the PWM/PFM Input and vary the frequency from 100 to

10,000 Hz to set the value. The signal must use a constant duty cycle from 10 to 90%.

Counter: Apply a single pulse to the Counter Input to change the value by 1. Apply a single pulse to the Reset Input to set the value to

the starting value, if enabled. The pulse signal must last a minimum of 16 ms; the value changes on the leading edge.

Timer: Apply constant power to the tower to change the value by 1 every 1 second. Use a constant on or off signal on the Timer Run

Input to start and pause the timer, respectively, if enabled. Apply a pulse to the Reset Input to set the value to the starting value, if

enabled. The pulse signal must last a minimum of 16 ms; the value changes on the leading edge.

Subsegment Style If the value is a partial percentage of a segment, select if segment will be on steady or analog dimmed to the partial percentage

Start From Top: The value decreases from the maximum value

Bottom: The value increases from the minimum value

Reset Input Apply a pulse signal to the Reset Input to set the value to the starting value, if enabled. The pulse signal must last a minimum of 16 ms.

Threshold Dominance Dominant: All segments display the active threshold color

Non-Dominant: Segments display their defined threshold color

Threshold Type:

Background A defined color and intensity is displayed on segments that are not active

Threshold Type: Base A defined animation state is displayed on segments that are not defined within a threshold

Threshold Type

≤: The animation state is displayed on the segments that are less than or equal to the defined threshold

≥: The animation state is displayed on the segments that are greater than or equal to the defined threshold

Disabled: The threshold is disabled

Global Parameters and

Advanced Settings Description

Orientation Standard: The tower base is down

Upside Down: The tower base is up

Background Color A defined color and intensity is displayed on segments that are not active

Animation Sync On: Segment animations align when any input state changes

Off: Segment animations will not be synchronized

Auto Restart On: The counter and timer will reset to the starting value after reaching the end value

Off: The counter and timer will stop at the ending value

Timer Run Input Use a constant on or off signal on the Timer Run Input to start and to pause the timer, respectively, if enabled

PFM/PWM Filter Level

Smooths the input signal by varying the sample size

Low: The sample size is short and changes to the input signal are more noticeable

High: The sample size is long and changes to the input signal are less noticeable

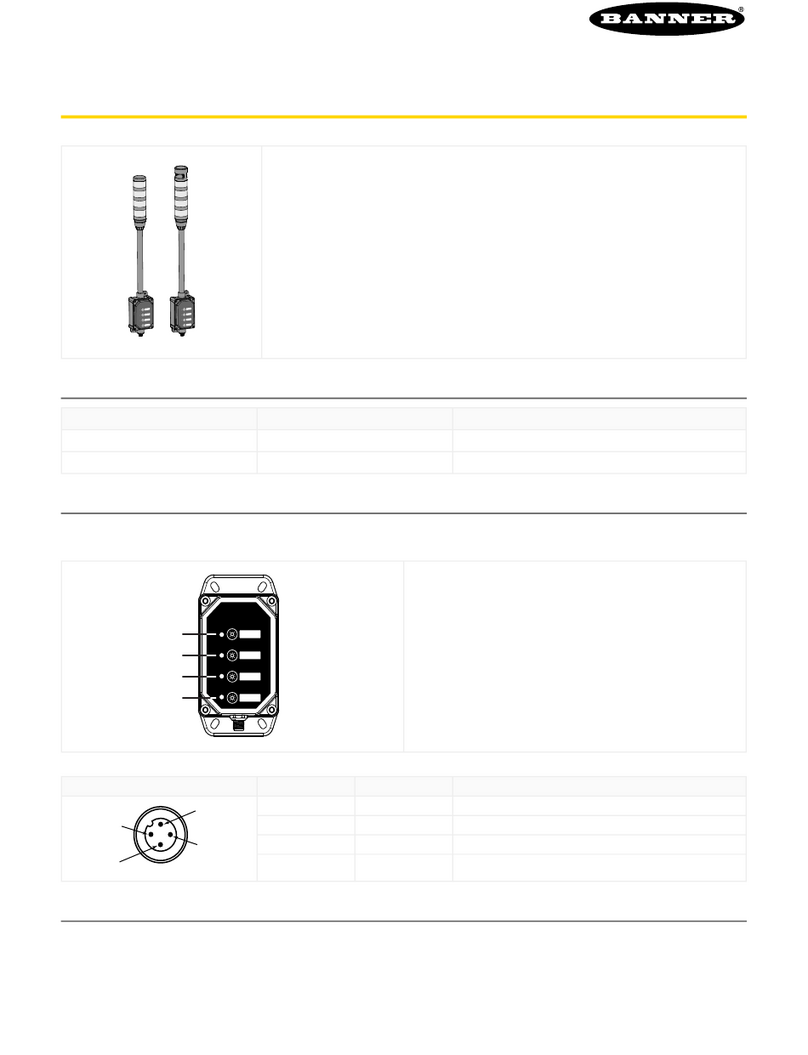

TL50 Pro Tower Light

4 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 209142 Rev. D