Dialight L-856 Manual

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporat ion 1501 Route 34 South Farmingdale NJ 07727

Tel: 732.919.3119 Fax: 732.751.577 8 Web: www.dialight.com

INSTALLATION AND MAINTENANCE MANUAL

FOR

L-856 / L-864 High Intensity Strobe

D266-A57-CTR-AC

(Base Controller)

D266-A57-270 (Power Supply and Flash Head)

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 2 of 40

CONTENTS PAGE

Notice and Warnings --------------------------------------------------------------------------------- 3

Product Overview-------------------------------------------------------------------------------------- 4

Terminology --------------------------------------------------------------------------------------------- 6

Getting Started ----------------------------------------------------------------------------------------- 7

Section 1.0: Tower Preparation------------------------------------------------------------------ 7

Section 2.0: Choosing a circuit breaker ------------------------------------------------------- 8

Section 3.0: Base Controller Preparation ---------------------------------------------------- 9

Section 4.0: Photocell Installation -------------------------------------------------------------11

Section 5.0: OB or L810 Connections ---------------------------------------------------------12

Section 6.0: Sync Input (with Optional GPS Hardware) --------------------------------12

Section 7.0: Sync Output (with Optional GPS Hardware)------------------------------13

Section 8.0: AOL Enable / Disable -------------------------------------------------------------13

Section 9.0: Adding Additional Interfaces --------------------------------------------------13

Section 10.0: Photocell Validation-------------------------------------------------------------14

Section 11.0: Initial Power Supply Preparation -------------------------------------------15

Section 12.0: Power Supply Addressing ----------------------------------------------------16

Section 13.0: Power Supply Cable Definition & DC Connections-------------------18

Section 14.0: Flash Head Communication Connections-------------------------------22

Section 15.0: Other Power Supply Preparation -------------------------------------------22

Section 17.0: Mounting Power Supply Enclosures --------------------------------------25

Section 18.0: Mounting Flash Heads----------------------------------------------------------27

Section 20.0: System Power Up ----------------------------------------------------------------31

Section 21.0: Alarm Relays-----------------------------------------------------------------------31

Section 22.0: Additional Information ----------------------------------------------------------33

Section 23.0: Troubleshooting-------------------------------------------------------------------33

Section 24.0: System Specifications-----------------------------------------------------------38

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 3 of 40

Notice and Warnings

This manual contains important information regarding the proper installation, operation, and

maintenance of this product. Before using the product, read and understand all instructions,

cautions, and warnings; as well as all of the labels affixed to the product. Failure to do so

could result in personal injury or damage to the equipment, and/or void the product warranty.

FAILURE TO LEAVE THE ENCLOSURES FREE FROM DEBRIS UPON COMPLETION OF

INSTALLATION MAY CAUSE SHORT CIRCUITS AND VOID THE SYSTEM WARRANY.

FAILURE TO TIGHTEN DOWN CLAMP WASHERS WILL MAKE INTERNAL COMPONENTS

VULNERABLE TO SURGE OR LIGHTNING DAMAGE AND VOID THE SYSTEM WARRANY.

FAILURE TO PROPERLY BOND THE EARTH GROUND WIRE TO THE JUNCTION BOX WILL

RESULT IN EVENTUAL LIGHTNING DAMAGE OF THIS SYSTEM.TO AVOID WARRANTY

NULLIFICATION,FOLLOW ALL DIRECTIONS IN THEIR ENTIRETY.

CAUTION:PHOTOCELL ONLY TO BE CONNECTED TO MONITOR BOARD USING

TERMINAL BLOCKS PROVIDED

WARNING:FAILURE TO PROPERLY BOND THE FLASH HEADS AND POWER SUPPLY

ENCLOSURES TO THE TOWER STRUCTURE WILL RESULT IN EVENTUAL LIGHTNING

DAMAGE OF THIS SYSTEM.THE SYSTEM’S WARRANTY SHALL BE VOID IF ALL FLASH

HEADS AND POWER SUPPLY ENCLOSURES ARE NOT PROPERLY BONDED TO THE TOWER

STRUCTURE.TO AVOID WARRANTY NULLIFICATION,FOLLOW ALL DIRECTIONS IN

THEIR ENTIRETY.

CAUTION:NEVER LOOK AT THE FRONT OF A FLASH HEAD WHILE THE SYSTEM IS

ENERGIZED.THE FLASH HEAD COULD START FLASHING CAUSING TEMPORARY

BLINDNESS WHICH WOULD BE DANGEROUS AT HIGH ELEVATIONS.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 4 of 40

FAILURE TO SET UP SYSTEM CORRECTLY DURING START UP WILL RESULT IN THE

TOWER HAVING TO BE CLIMBED AGAIN TO PERFORM TROUBLESHOOTING.

DIALIGHT CORPORTATION DOES NOT WARANTEE THE HIGH INTENSITY SYSTEM WHEN

USING IT WITH A TEMPORARY POWER SOURCE.

DIALIGHT CORPORTATION DOES REQUIRE PICTURES OF THE INSTALLATION FOR

COMMISIONING PURPOSES.FAILURE TO DO WILL VOID ALL ALL WARRANTIES.

THE SITE MANAGER OR OWNER MUST SUPPLY RECENT PICTURES OF THE STRUCTURE

TO ENSURE ACCURACY OF THE LIGHTING SYSTEM AND HARDWARE SUPPLIED.

ADEQUATE WIRING GAUGES AND BREAKER SIZES ARE THE RESPONSIBILITY OF THE

SUPPLIER OF THE SYSTEM.

SPECIAL CONSIDERATIONS ARE REQUIRED FOR INSTALLING ON HOT AM TOWERS.

CONTACT THE SUPPLIER OF THE SYSTEM WHEN IN DOUBT.

AC INPUT TOLERANCES ARE A MAXIMUM OF +/-10% OF THE NOMINAL VOLTAGES

SHOWN IN THE MANUAL

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 5 of 40

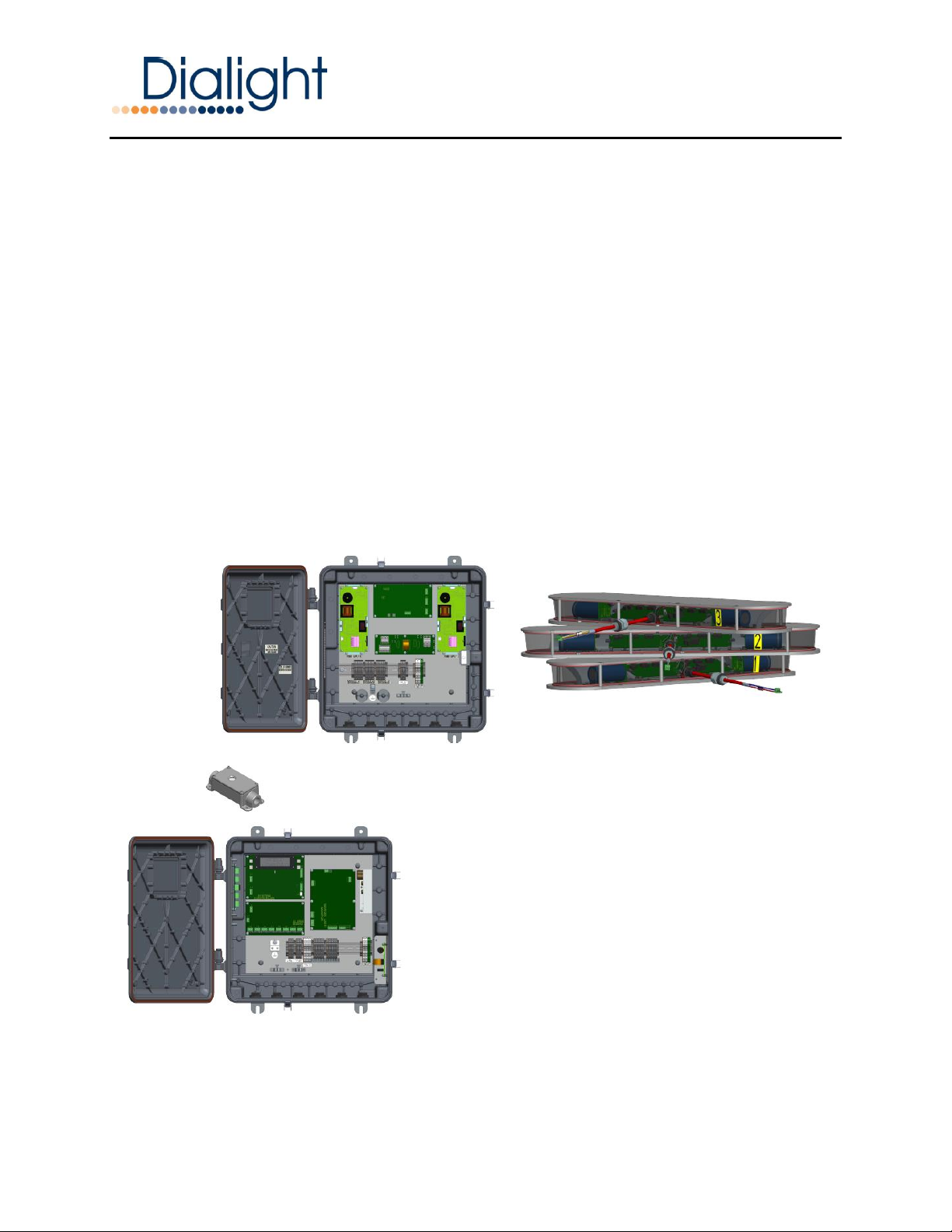

Product Overview

The Dialight L-856 / L-864 High Intensity White / Red Strobe System, herein referred

to as the System, is designed to for the lighting of tall structures such as television and radio

towers, chimneys, cooling towers, tall buildings, wind generators and other obstructions to

aerial navigation, per specification by the FAA.

This product uses LED technology within each Flash Head to produce white strobe

light. Unlike conventional xenon flashtube technology, little or no maintenance is required

during the lifetime of this System. Working voltages within this System never exceed 200

Volts DC. Therefore by significantly lowering the working voltage with respect to Xenon white

strobes, this System represents an advance in obstruction lighting safety and efficiency.

One Base Controller Enclosure is required to enable the System regardless of system

scale. For example a System with three Flash Heads and a System with eighteen Flash

Heads both need the same Base Controller Enclosure to operate.

With the use and proper setup of the Base Controller each of the below systems can

be configured through the LCD display.

White Only System

The System may comprise up to eighteen L-856 High Intensity White Strobe Flash

Heads; each with a corresponding Power Supply Enclosure, e.g. one Power Supply

Enclosure per Flash Head. The Flash Heads are typically distributed as three per level on up

to six levels, for a maximum of eighteen Flash Heads.

Red/White System

The System may comprise up to eighteen L-856/864 High IntensityWhite Strobe Flash

Heads which have the RED L-864 included in each of the LED modules. Each has a

corresponding Power Supply Enclosure, e.g. one Power Supply Enclosure per Flash Head.

The Flash Heads are typically distributed as three per level on up to six levels, for a maximum

of eighteen Flash Heads. L810 Marker Lights are also monitored through the base controller.

AOL Strobe

Additionally, one L-864/L-865 Medium Intensity Strobe may be integrated into the

system as an Antenna Obstruction Light (AOL). The Base Controller will synchronize,

monitor, and control the entire System, as well the Antenna Obstruction Lights.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 6 of 40

Terminology

The following definitions apply to the System:

L856

FAA classification of a flashing white High Intensity Obstruction Light, 40 FPM

L864

FAA classification of a flashing Red Medium Intensity Obstruction Light, 20-30 FPM

L810

FAA classification of a Red Steady Burning Obstruction Light

Base Controller

Master Control Cabinet

LCD Screen

Liquid Crystal Display; forty character module

Micro Board

Printed circuit board with onboard micro controller

Relay Board

Provides 8 external connections for alarm status and monitoring

Alarms

Alarm faults that need to verified and corrected, NOTAM must be reported

Events

Events are notice to the site manager that an “event” occurred but has NOT caused

an alarm. I.E. power on, Power Supply was turned off. These are also used to

troubleshoot alarms.

Power Supply

Enclosure mounted to the tower controlling the individual Flash Head

Dip Switches

Located in Power Supplies to assign addresses to Flash Heads

Flash Head

The 3 individual Flash LED Modules mounted together

Flash “LED” Module

The individual module numbered 1, 2or 3 containing the LED’s and reflectors

PEC Mode

Flash intensity based on outdoor ambient light condition

Heartbeat

Blinking LED which indicates a Micro Board is healthy. NOTE: Located in both the

Base Controller and Power Supply

Red System

When properly configured through the main micro provides RED at night operation

AOL

Antenna Obstruction Light, also can be added through the Base Controller

Synchronization

All lights flash simultaneously to the human eye

Communication

RS485 signals between Controller, Power Supply and Flash Head

25% Failure

Alarm occurs when greater than 25% of a single Flash Head is out, monitors for

both in Red operation and white operation

The System

The lighting, hardware, wiring and any other materials required for installing the

system.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 7 of 40

Getting Started

Carefully unpack and take inventory of all system components before beginning the

following steps. Flash Heads and Power Supply Enclosures come in separate boxes. They

must be paired together and laid out in a clean work area.

Parts Typically Supplied:

1: 1 Base Controller

2: 3 or More LED Flash Heads (Consisting of 3 modules factory secured together)

3: 3 or More Flash Head Power Supply enclosures

4: Spare Parts Kit(s)

5: This manual

6: Quick start Manual (For configuring the Base Controller)

NOT Supplied with this Manual is the site specific wiring diagram. This is supplied by the

seller of the system.

Section 1.0: Tower Preparation

It is recommended that the tower on which the System is to be installed be inspected

prior the installation.

1: If using existing junction boxes, they should be opened and checked for leaks.

2: If re-using wiring from an existing system it must be checked at this time for ratings, breaks,

oxidation and other damage that could cause electrical issues during the installation and

operation. Failures in the wiring during or after the installation are the responsibility of the Site

Manager and the owner of the structure.

NOTE: It is recommended that any reused existing cable has the bare wire cut far enough

back to expose clean copper. If this is not possible then the cabling MUST be replaced.

3: The Dialight High Intensity system uses RS485 for communications. The signal integrity,

ratings and wire gauge should be verified before installing this system.

4: The Base Controller and Power Supply enclosures have terminal blocks for AC wiring that

can accept up to 8 gauge (8AWG) wires.

NOTE: Do not use less than 14 gauge (14AWG) mains cord for powering the system. Refer

to electrical specifications below for further details.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 8 of 40

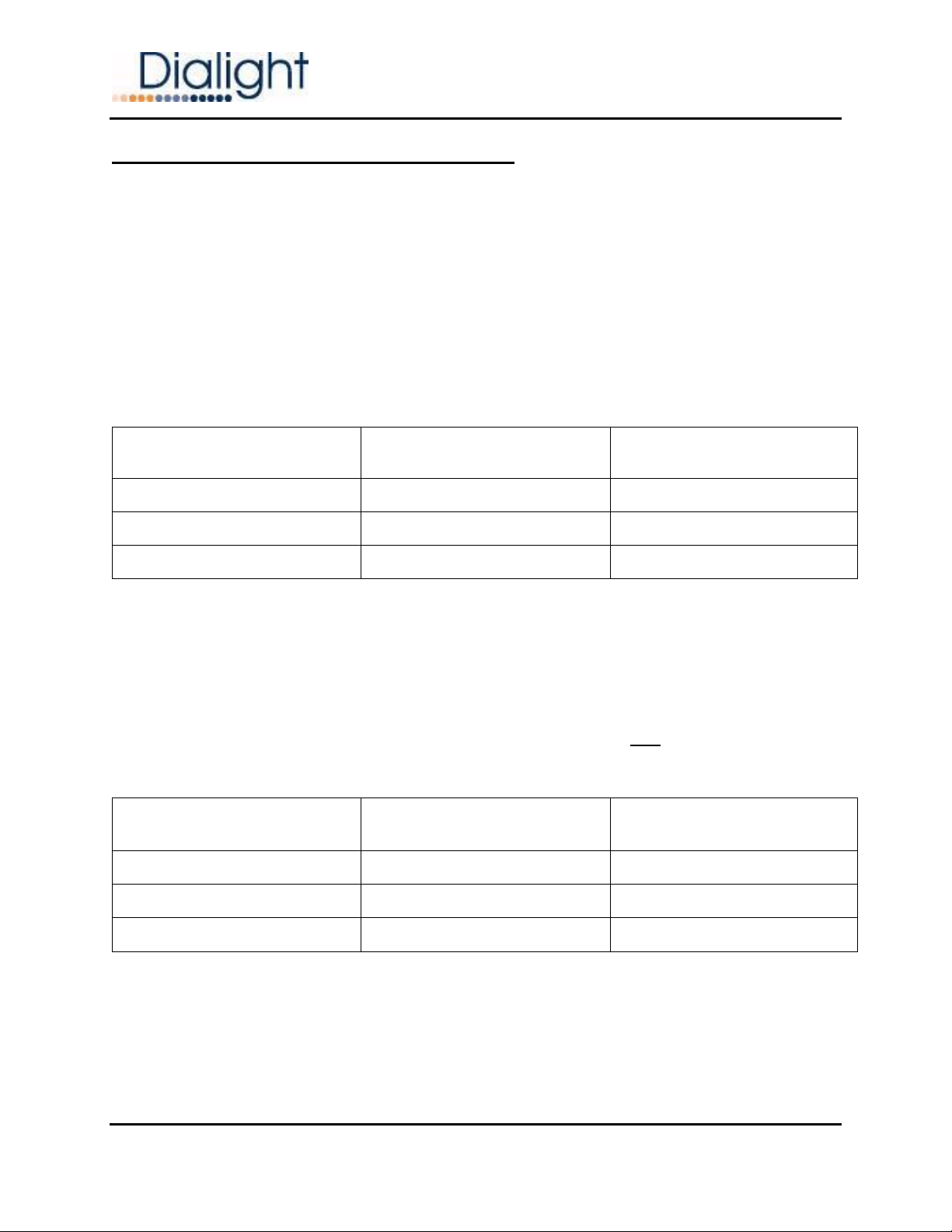

Section 2.0: Choosing a circuit breaker

Also refer to the wiring diagram that is sent with the cables and hardware for site

specific information. This information is required to be sent by the system provider or the

hardware provider.

For the purpose of sizing tower conductor gauges and circuit breakers follow the table

and formula below. Input current is inversely proportional to supply voltage, so low supply

voltages result in higher input currents. It is the responsibility of the system supplier to

calculate the required cable gauges and breaker sizes.

All tolerances are +/- 10% from nominal voltages shown below.

Measurements are actual measurements and not scaled in any matter

Nominal Supply Voltage /Freq

(VAC)/Hz

RMS Current (A) per Flash

Head

Peak Current (A) per Flash

Head

208 / 60Hz

1.12

2.18

240 /50Hz

.96

1.98

277 /60Hz

.87

1.68

Table 1 - High Intensity Strobe Current Ratings

Find the voltage you are planning to run the System in the table above; then multiply

the number of Flash Heads on the System times the RMS current to find the total operating

current. Also multiply the number of Flash Heads on the System times the peak current to

find the total peak current.

If using a Dialight DR1W strobe as an AOL, then you must add the current of the AOL

to the total calculated below if the AOL is to be powered off the same breaker.

Nominal Supply Voltage

(VAC)

RMS Current (A) for AOL

Peak Current (A) for AOL

208

0.8

1.3

240

0.50

0.8

277

0.50

0.8

Table 2 - AOL (D1RW) Current Ratings

WARNING:The above tables arefor individual Flash Heads and the AOL. The system power

requirements must be calculated.

WARNING: It is recommended that no more than 80% of the breaker rating is used.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 9 of 40

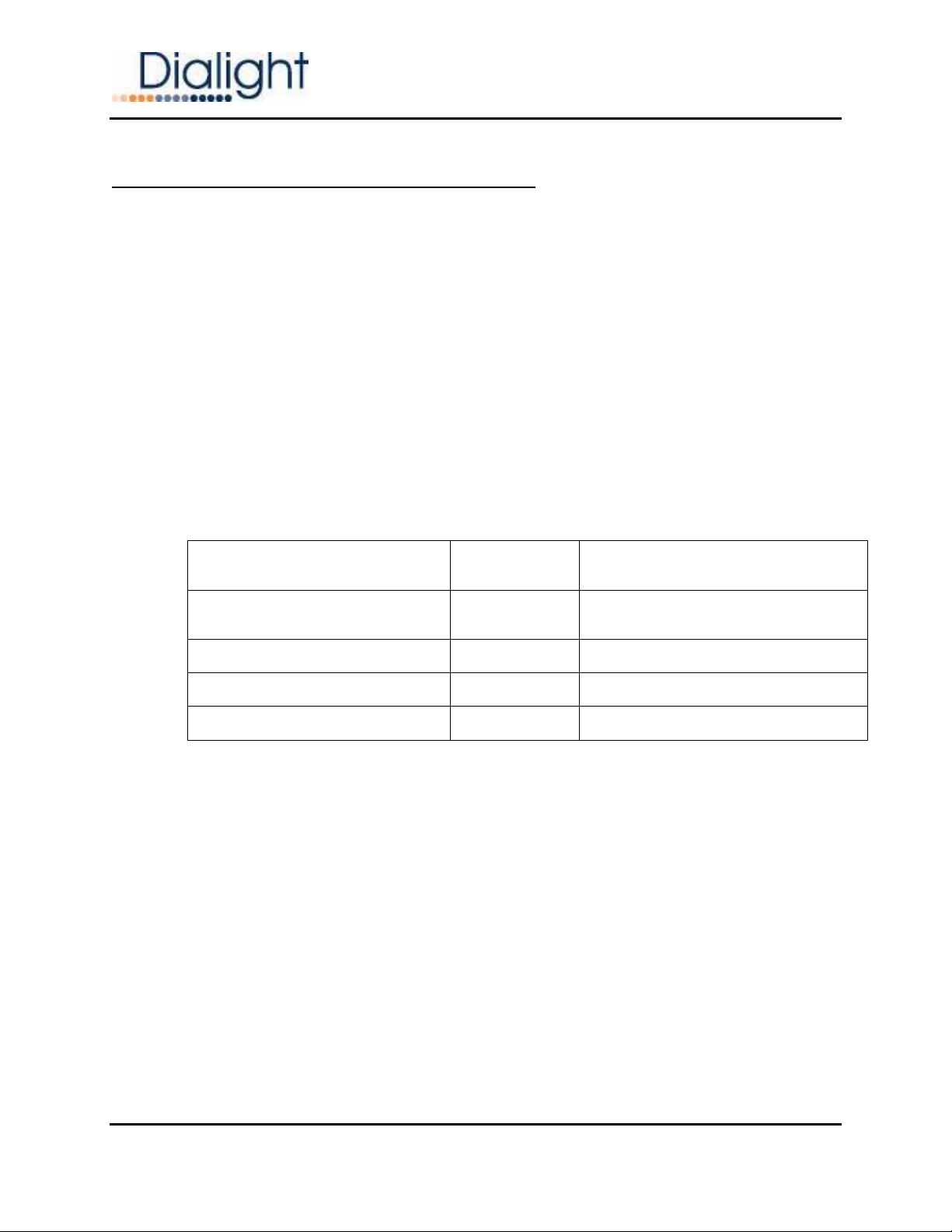

Section 3.0: Base Controller Preparation

The Base Controller should be permanently mounted in a location which has easy

access for inspections or upgrades.

The Base Controller can be energized from the same circuit breaker as the Power

Supply Enclosures, or it can be run from a different voltage or breaker. In the case of different

voltages and breakers, it is recommended that the Power Supplies be powered up first, then

the Base Controller. This will only be required during the installation process and configuring

the system. Thus it is preferred that the Base Controller be on its own breaker.

Base Controller Electrical Parameters:

NOTE: This is only for the High Intensity Base Controller

NOTE: Only the Base controller can run from 120Vac

WARNING: Power Supplies/Flash Heads can NOT properly operate from 120VAC.

Nominal Supply Voltage

(VAC) Hz

Watts

Information

120 +/-10% Max 50/60Hz

6.5

Can only be used if Controller

has its own power

208 +/-10% Max 50/60Hz

6.5

240 +/-10% Max 50/60Hz

6.5

277 +/-10% Max 50/60Hz

6.5

Table 3 - AOL (D1RW) Base Controller Electrical Parameters

The following steps are recommended for a successful installation:

The Base Controller can be mounted to any sufficient location the installer/electrician

sees fit. The dimensions are given below. If the Base Controller is to be mounted to an exterior

structure such as the tower, then special grounding considerations must be adhered to avoid

voided warranties. See Section 17.0 for further details.

For exterior mounting it is suggested that the conduit or glands be mounted on the

bottom of the enclosure using holes provided by Dialight to ensure a weather tight seal for

the life of the product.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 10 of 40

NOTE: If there is a possibility of water or condensation entering through the conduit or cables,

the installer must take all necessary precautions to prevent water entering the enclosure.

Failure to do so will void all warranties. Cable loops and drain plugs must be added to the

system as seen fit. If in doubt, please contact www.dialight.com or the system provider.

For cable loops it is suggested that a minimum of 3 to 4 loops with a diameter of 12

inches are used.

Drain plugs should be located at the bottom of any conduit run and or at the lowest

point of the conduit run.

For horizontal conduit runs it is required that the conduit be tilted or angled toward

junction boxes that have drain plugs. Conduit should not tilt downwards to un-drained

enclosures or to breaker panels.

Refer to the Quick Start Manual for information regarding connection of AC power and

RS485 Communications.

Spacing of the mounting tabs is shown below:

Open the Base Controller enclosure and set aside any spare parts bags.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 11 of 40

NOTE: Some spare parts included in this bag may be required for the fixtures being

mounted on the structure

Section 4.0: Photocell Installation

NOTE: See the Photocell manual included in itspackaging box for connections and additional

information.

Cable Requirements:

NOTE: The connection cord to the photocell is required to be 3 conductors of 18 to 14

gauge stranded wire. Refer to structure’s wiring diagram supplied with the hardware kit.

A separate ¾” conduit must be run for the Photocell to connect to the Base Controller.

A single Photocell is required for transitioning between day, twilight and night modes. The

Photocell is pre-calibrated to the correct trigger light intensity. No additional adjustments are

required.

When mounting, it is important to orientate the Photocell so that it faces north with no

obstructions. The Photocell is powered by the Base Controller through the Monitor Board

and no additional power is required as shown below.

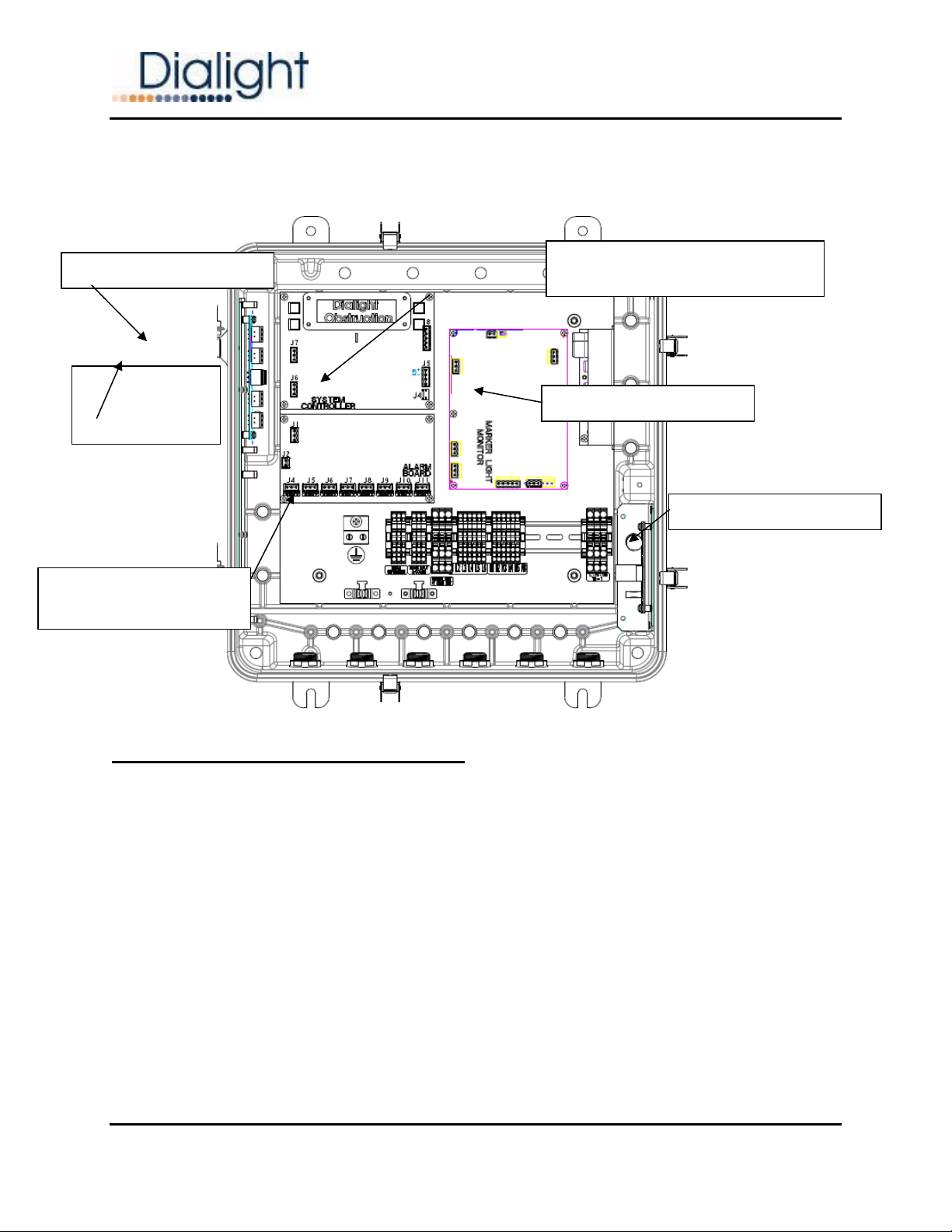

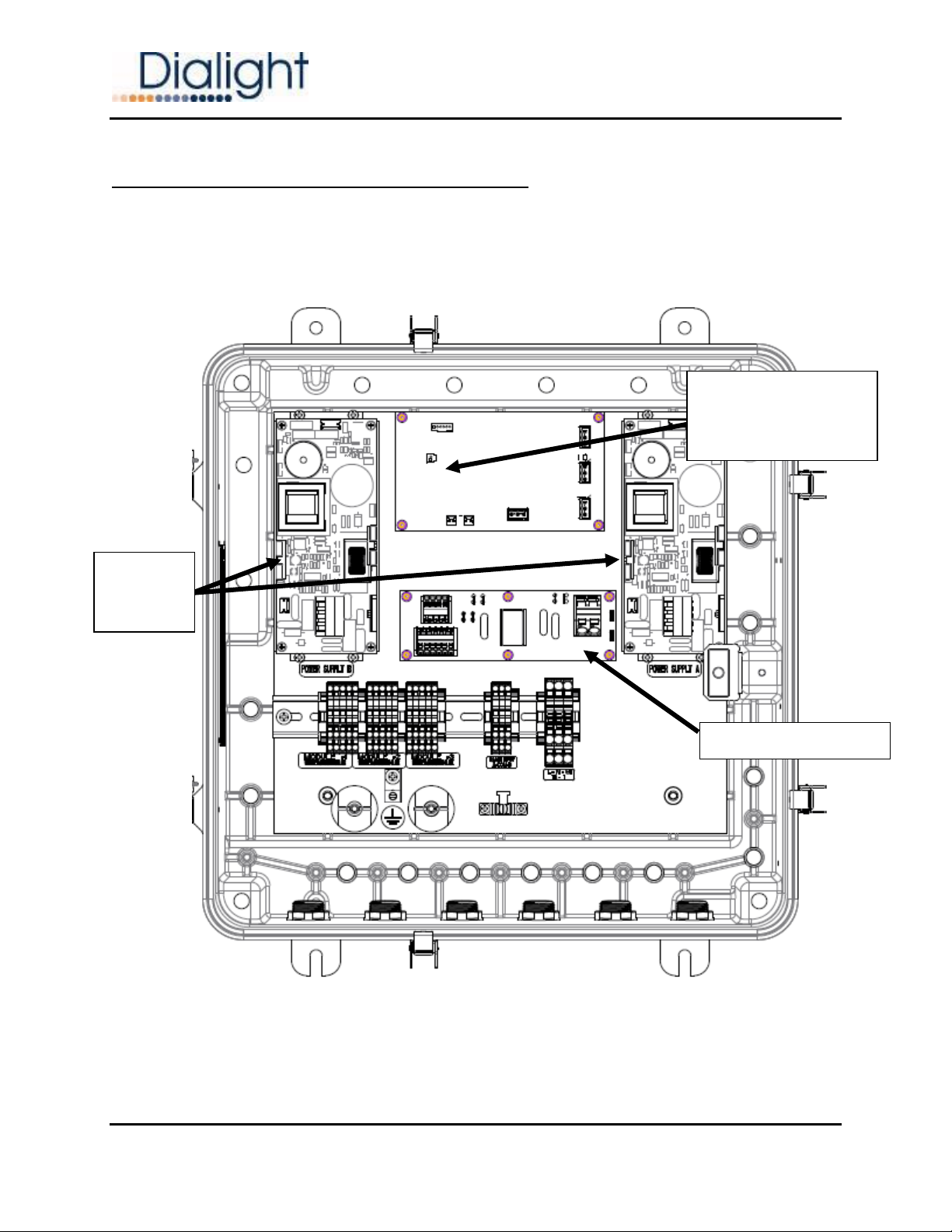

Dry Contact Relay

Board

RS485

Junction Board

Filter / Surge Board

48V Power Supply

L810 Monitor & Photocell

Control Board

Main Controller Board

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 12 of 40

NOTE: Only Dialight Photocells can be used with this system

NOTE: Additional Photocell relay testing will be included in Section 10.0 of this manual.

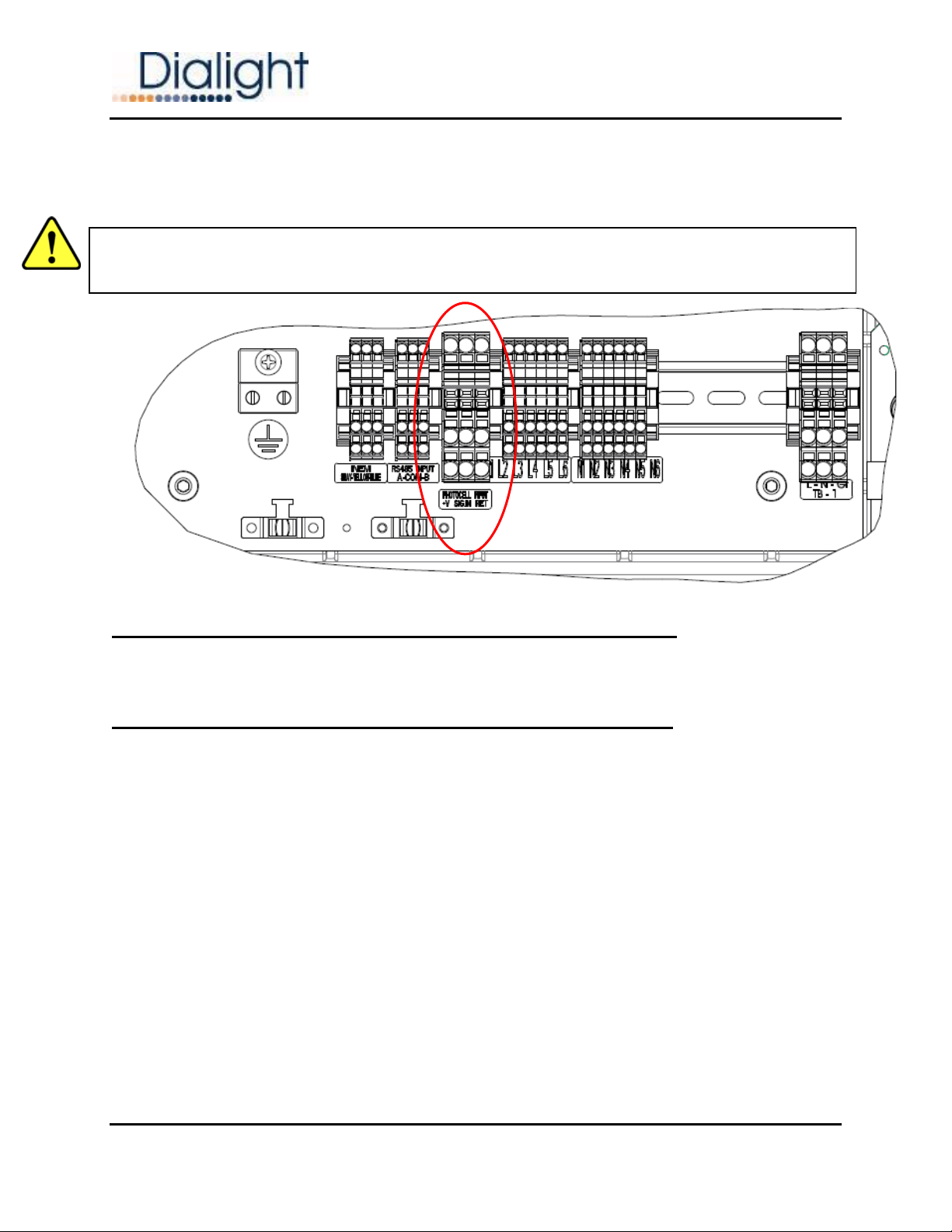

CAUTION:PHOTOCELLS ARE TO BE CONNECTED TO J4 OF THE MONITOR BOARD ONLY

USING THE DIN RAIL TERMINAL BLOCKS IN THE CONTROLLER ENCLOSURE

Section 5.0: RED Side lights (OB) or L810 Connections

Refer to Quick Start manual for instructions to calibrate and connect side lights to the

System.

Section 6.0: Sync Input (with Optional GPS Hardware)

This connection will synchronize the System with either a GPS controller or another

local Base Controller. The contact looks for a pulsed signal with a period of 1,500

milliseconds, where the leading edge to falling edge of the pulse is greater than 100

milliseconds. This will trigger forty flashes per minute synchronized with the other system’s

output.In order for the system to work with a GPS controller the Base Controller must be

configured through the “config” setup screens. See the Quick Start Manual for details and set

up.

NOTE: The maximum distance between the Base Controller and the device receiving the

sync signal is 50 feet. If longer distances are required please contact www.dialight.com.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 13 of 40

NOTE: Be sure the GPS antenna is located at an adequate height and does not have

obstructed views of the sky when selecting a location.

Section 7.0: Sync Output (with Optional GPS Hardware)

This connection will synchronize the System to another local Base Controller. The

contact generates a pulsed signal with a period of 1,500 milliseconds, where the leading edge

to falling edge of the pulse is approximately 100 milliseconds.

The System generates this output in all operational modes after startup.

This connection would be typically used when 2 structures are situated side by side and

requires both structures to flash simultaneously.

NOTE: 2 Base Controllers are required for this option

NOTE: If a single Base Controller is used then the RS485 or a sync cable can be ran between

structures. There are no further details in this manual for this connection, please contact

www.dialight.com for connections, maximum distances and more information.

Section 8.0: AOL Enable / Disable

An AOL light can be added to the System at anytime by way of RS485

communications. By connecting RS485 from the AOL Power Supply to the last junction box

and the Base Controller configured for the AOL, the system then will control the AOL.

WARNING: The AOL must be an approved Dialight version or delivered from one of their

partners.

WARNING: Refer to the AOL instruction manual for wiring and mounting.

To enable the use of an AOL requires configuration through the config screen. See the Quick

Start Manual for setup.

Section 9.0: Adding Additional Interfaces

If at a later date an AOL is required for the structure that has this system already

installed then just the AC connection and a link in to the RS485 bus is required for connecting.

Once installed the Base Controller requires configuring for AOL. Only a single AOL can be

added to the system. Multiple AOL’s can not be added. The AOL must be fed from the same

AC power source as feeding the lights.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 14 of 40

Section 10.0: Photocell Validation

Perform the following to make sure the Photocell is correctly connected and controlling the

System mode.

1. NOTE: This can be done as a stand alone test; no Flash Heads are required to be

powered.

2. Turn on the Base Controller, and using the up/down arrows go to the “alarm screen”

3. On the Monitor Board confirm LED Photo_Fault is not lit.

If the LED is lit RED then the Photocell is not being detected and wiring and

connections must be confirmed before continuing the testing of the Photocell.

4. Remove the Phoenix connector that connects the 3 wires that go to the Photocell.

Located on the Monitor Board J4.

5. The status alarm must go from “normal” to alarm and by selecting the “ent” button the

last alarm will be PEC lost “act”.

6. A red LED labeled LED Photo_Fault on the monitor board will be turned on this

indicates there is no Photocell detected.

7. Re-install the Photocell J4 and the LED will be turned off and then by pressing the up

arrow the next entry will be PEC lost “Clr” which means the Photocell is detected.

For testing the actual operation of the Photocell it is required that the Photocell be

covered to indicate night mode operation.

NOTE: Since twilight mode is triggered between day and night mode, only day and night

mode are required to be tested to ensure proper operation of the Photocell.

1: With the Base Controller powered on, using the up/down arrows select the Mode screen.

2: Verify the present mode which will be day, twilight or night

NOTE: If the present mode is not shown it is due to the connections of the Photocell not being

correct.

3: If the System mode is day then simply covering the Photocell with a glove will change the

state of the Photocell to twilight then night.

NOTE: There is a factory default setting of approximately 1 minute before switching modes.

If the system mode is shown as night then a flash light focused on the Photocell can be used

to change the state of the system to day.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 15 of 40

WARNING: If Flash Heads are connected then the structure will go to 270,000cd day mode

and changing back has a 1 minute delay.

WARNING: If the Photocell is removed or not connected properly all Flash Heads will operate

in night mode based on if the system is set for red night or white night.

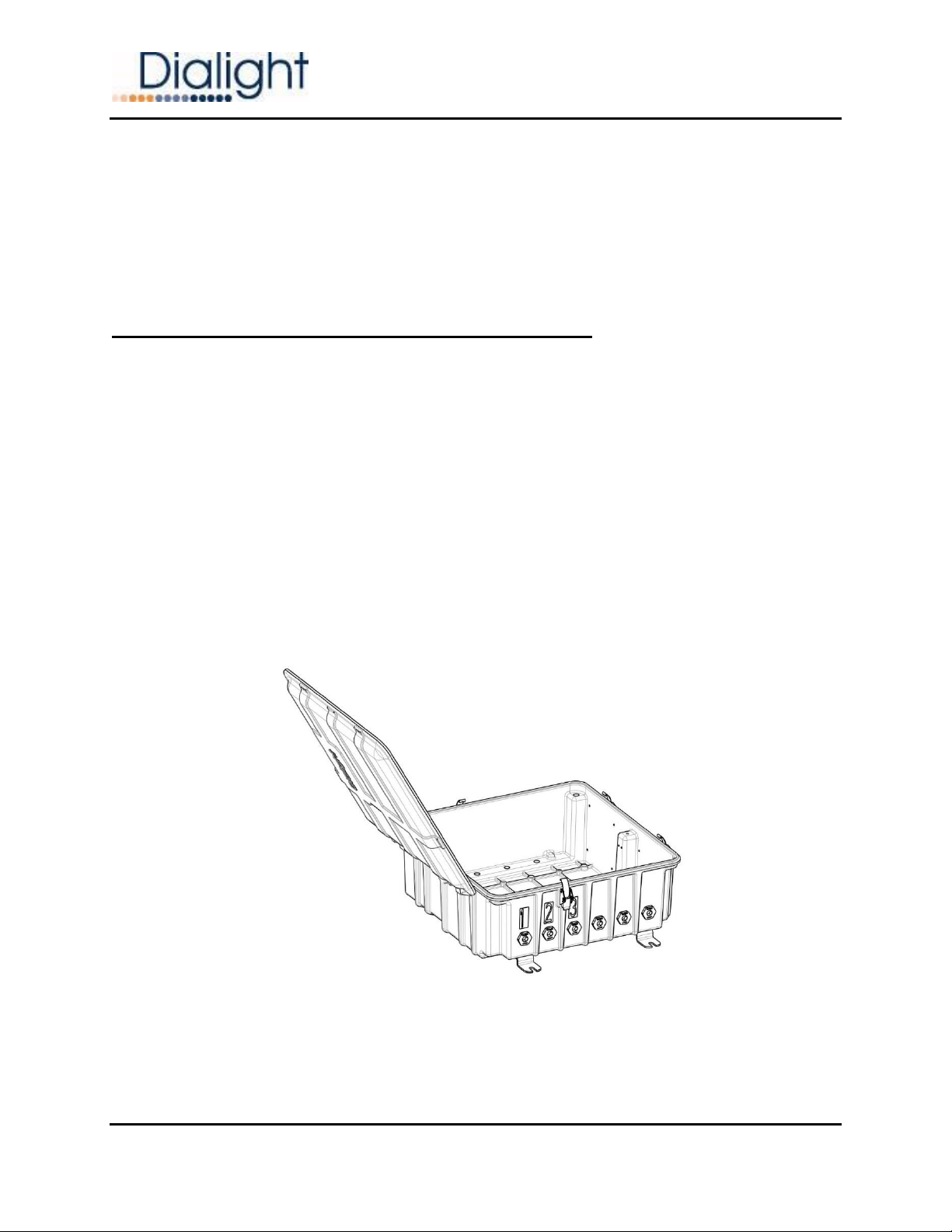

Section 11.0: Initial Power Supply Preparation

The Power Supply Enclosure requires the most field wiring and should be configured

and reviewed before being brought up the tower.

At the bottom of the enclosure there are six factory installed holes. 3 of these

are for connection to the Flash Head and 1 for AC mains and RS485 communications

cable. The AC and RS485 can be run together and must be in seal tight or conduit.

Unused holes must remain plugged to maintain ingress protection ratings.

NOTE: If for some un-foreseen reason additional holes are required for the

installation. Contact the seller of the system or Dialight for instructions.

NOTE: The AC and RS485 can be run together and must be in seal tight or conduit.

The enclosure comes with mounting tabs that are to be joined to the body of the

tower.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 16 of 40

Section 12.0: Power Supply Addressing

Open the enclosure and orientate your view to match the illustration shown below. On

the Micro Board there is a DIP switch array designated as SW1. This is the addressing switch

used to identify this Power Supply Enclosure / Flash Head on the system.

P/S Micro Board

DIP switch SW1 for

setting addresses of

the Power Supply

Filter/Surge Board

150V

Power

Supplies

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 17 of 40

The default factory address is 1. One of the Power Supply Enclosures must be

set as address 1. The addresses of all other Power Supply Enclosures must be

changed. The inside of the enclosure will have a sticker showing all the possible

address positions for switch SW1.

WARNING: No two Power Supplies can have the same address setting.

If duplicate settings are made then configuration errors will be shown in the event

log. Flip the DIP switches on SW1 to match the desired address for that Power

Supply location, as shown below, and then immediately mark the inner label with an

Xin permanent marker as to which address was set. The enclosure should be closed

up tightly before being lifted to the mounting location. Therefore before mounting the

address should also be written on the outside of the enclosure with a grease pencil

or marker.

NOTE: Typical installations are that Power Supply #1 is located on the lowest level

and mounted to the Northern most leg. Looking down from the top of the structure

counting clockwise the next is 2 and the next is 3. So that above #1 is #4 and above

that is #7 and so one.

NOTE: This is required unless the Site manager wants something different than the

above states.

NOTE: Refer to the below and section 23.0 for additional information.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 18 of 40

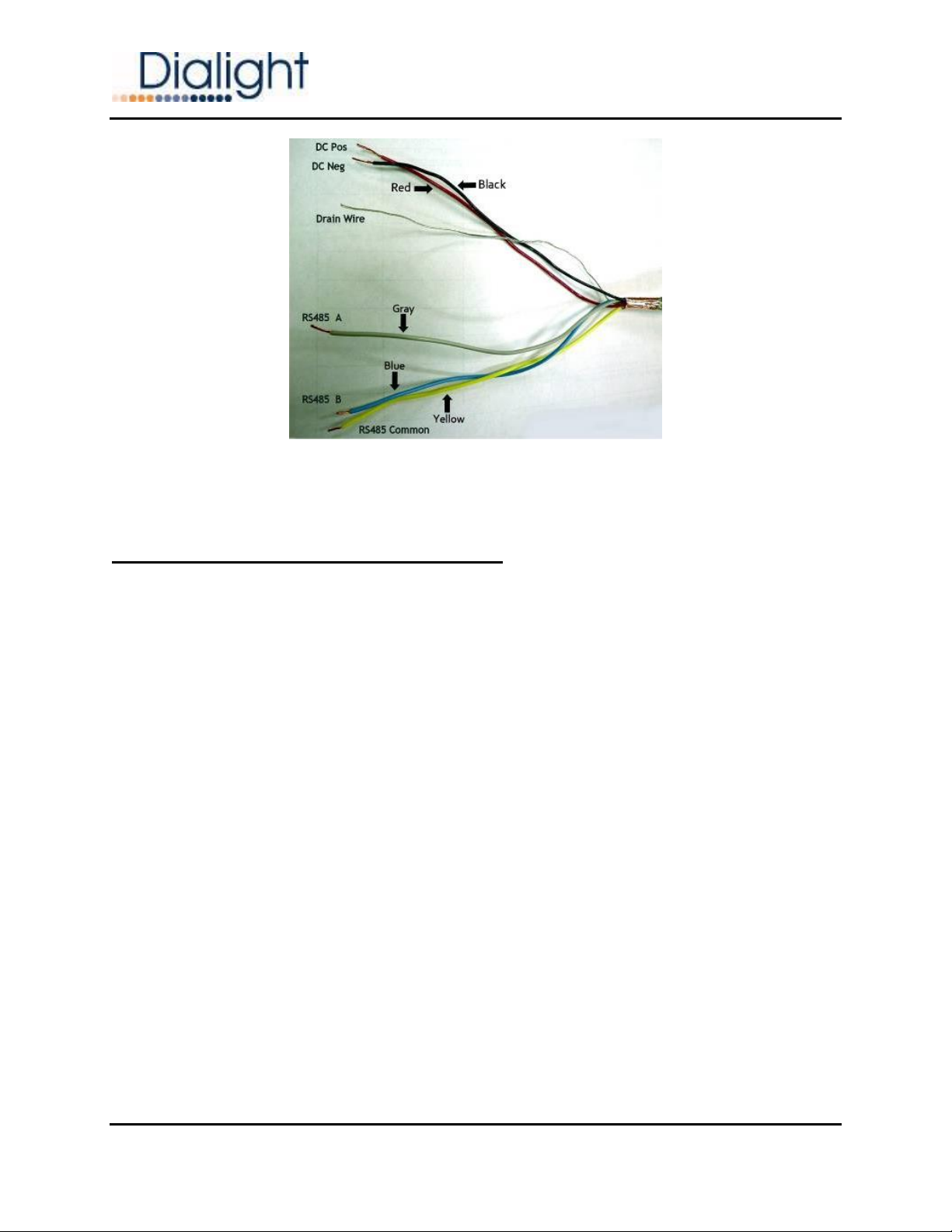

Section 13.0: Power Supply Cable Definition & DC Connections

The Flash Head cable is supplied factory installed into each of the modules that make

up the Flash Head.

Connect the Flash Head cables to the Power Supply Enclosure so that the electrical

connections can be tested on the ground. Each of three red cables should be passed through

a corresponding cable grip. All cables and cable grips are numerically labeled for easy match

up. The ends of each cable have been prepared for connections within the enclosure. The

triad of blue, yellow, and gray wires is for communication. The pair of black and red wires is

for DC power from the Power Supply Enclosure to the Flash Head. Do not alter the length of

these wires or attempt to cut back or modify the exposed braided shield. The picture below

shows the prepared cable end.

Level 1

Level 3

Level 4

Level 5

Level 6

Level 2

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 19 of 40

NOTE: The cable grip has been pre installed on to the cable. The nut must first be removed

after securing the cable grip to the enclosure.

Land the exposed braid underneath one of two large clamp washers (whichever one which

lines up with that cable grip position). Two cable braids can be landed side by side on the

clamp washers as shown below. Pull enough of the cable length through to reach all

connections before tightening down the washers.

FAILURE TO PROPERLYTIGHTEN DOWN CLAMP WASHERS WILL MAKE INTERNAL

COMPONENTS VULNERABLE TO SURGE OR LIGHTNING DAMAGE AND VOID THE SYSTEM

WARRANY

NOTE: If the Red and Black wires need to be cut and re stripped then ¾”of insulation

should be removed. The wires must be neatly twisted before inserting in to the terminal

blocks.

Document: 9100-127-2905-99

Revision B

Release Date: 1/23/2017

Dialight Corporation 1501 Route 34 South Farmingdale, NJ 07727

Tel: 732.919.3119 Fax: 732.751.5778 Web: www.dialight.com

Page 20 of 40

Steps for inserting the Red and Black wires:

The DC power wiring needs to be terminated on the DIN rail terminal blocks connected

to J2 of the Filter / Surge board as shown in Figure xx below. The DIN rail terminal blocks are

labeled appropriately for each module.

NOTE: Module #1 gets connected to pins 1 and 2 of J2 (left), Module #2 gets connected to

pins 3 and 4 of J2 (middle), & Module #3 gets connected to pins 5 and 6 (right).

NOTE: It is recommended that each Red and Black wire gets twisted on the exposed copper

before inserting into the terminal block.

Use a small flathead screwdriver to terminate by inserting the blade in to the slot and

easily lifting the screwdriver, then inserting the wire. The wire must go in easily and must not

be forced into the terminal bock.

If it is forced then the wire should be removed re-twisted and inserted again.

NOTE: Tug on these connections to ensure the wire ends were landed properly.

Drain wires from all three Module cables must be terminated on the grounding bus. This

connection is for lightning / surge protection and should be double checked like all other

wiring discussed above. Since the drain wire is a bare wire, extra attention should be placed

on routing these connections neatly.

Other manuals for L-856

2

This manual suits for next models

3

Table of contents

Other Dialight Lighting Equipment manuals

Dialight

Dialight DuroSite User manual

Dialight

Dialight Vigilant User manual

Dialight

Dialight HBXW3SSL304FT User manual

Dialight

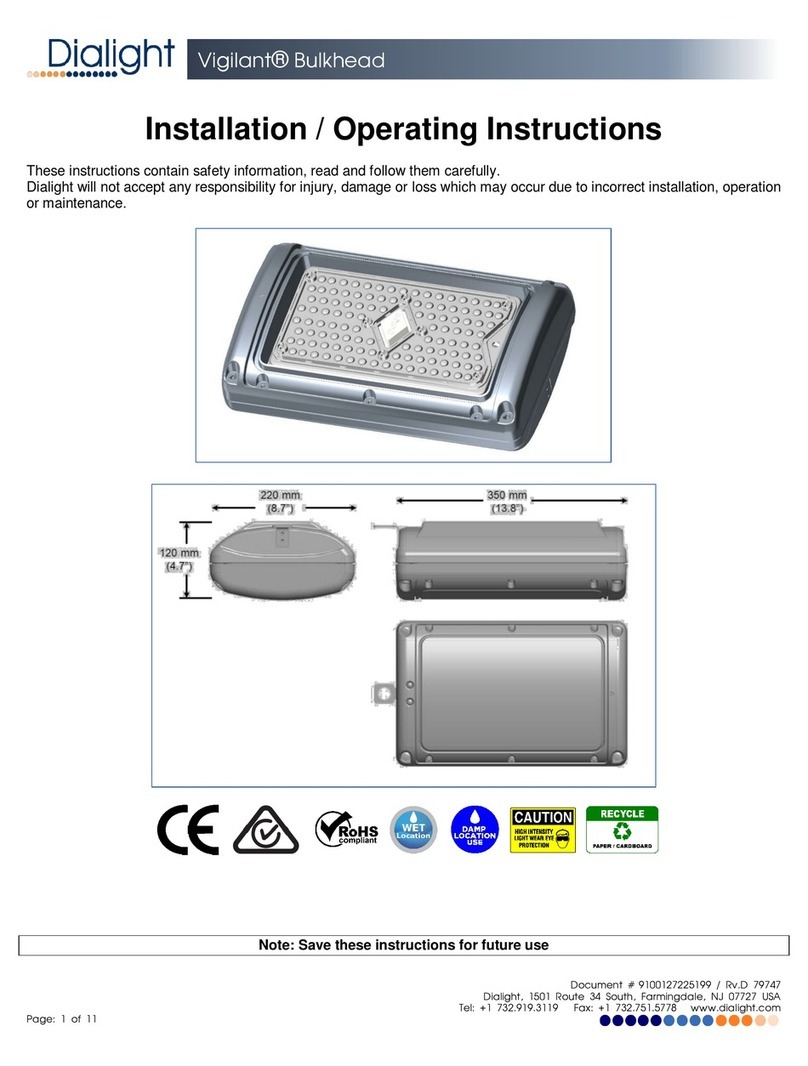

Dialight Vigilant Bulkhead Guide

Dialight

Dialight L-856 Troubleshooting guide

Dialight

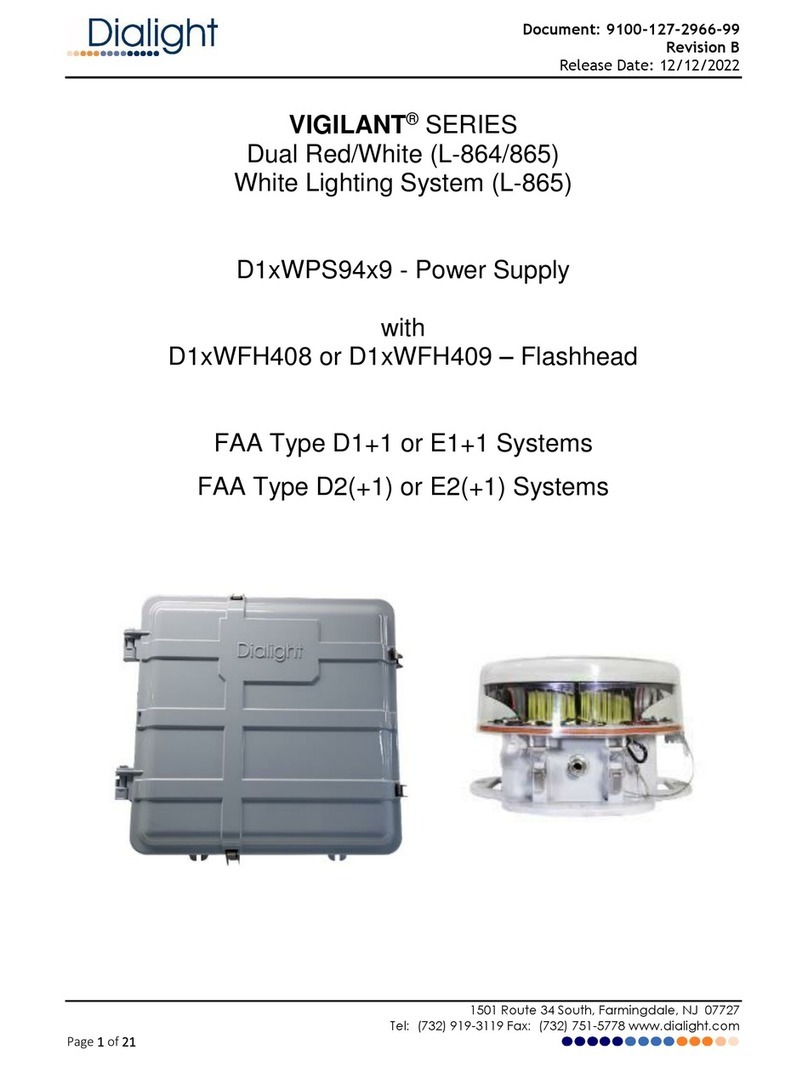

Dialight VIGILANT Series User manual

Dialight

Dialight SAFESITE LSD3C4M2P Manual

Dialight

Dialight HBXREF22 User manual

Dialight

Dialight SafeSite User manual

Dialight

Dialight Reliant User manual