Dialight VIGILANT Series User manual

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 1of 21

VIGILANT®SERIES

Dual Red/White (L-864/865)

White Lighting System (L-865)

D1xWPS94x9 - Power Supply

with

D1xWFH408 or D1xWFH409 –Flashhead

FAA Type D1+1 or E1+1 Systems

FAA Type D2(+1) or E2(+1) Systems

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 2of 21

DO NOT let any supply cords touch

hot surfaces higher than cord ratings.

DO NOT mount near gas or electric

heaters

Equipment should be mounted in

locations and at heights where it will

not be subjected to tampering by

unauthorized personnel.

The use of accessory equipment not

recommended by the manufacturer

may cause unsafe conditions.

DO NOT use this equipment for other

than intended use.

DO take pictures: Installation Photos

Required for Warranty Coverage. (All

electrical connections, bonding,

system support and grounding)

Refer to Quick Manual for list of

required pictures and commissioning

checklist

The cable information provided are for

cable lengths less than 680 feet.

SAVE THESE INSTRUCTIONS!!

The operation and maintenance must be

carried out by authorized personnel.

Repairs and Installation must only be

carried out by a qualified electrician.

Only genuine Dialight replacement parts

must be used when unforeseen repairs

are required.

Observe the national safety rules and

regulations during installation!

Earth Grounding is required throughout

the install process. Failure to do so could

void all warranties!

No alterations should be done without

agreement from Dialight Corp.

Alterations other than written in this

manual will void all warranties.

The light source contained in this

luminaire shall only be replaced by the

manufacturer or his service agent or a

similar qualified person.

SAVE THESE INSTRUCTIONS!!

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 3of 21

Table of Contents:

WARRANTY: ......................................................................................................................................................................4

SYSTEM DESCRIPTIONS:........................................................................................................................................................4

INTRODUCTION:..................................................................................................................................................................5

NOTICE AND WARNINGS:.....................................................................................................................................................6

DIMENSIONS FOR MOUNTING THE ENCLOSURE:........................................................................................................................7

DIMENSIONS FOR MOUNTING THE D1XWL864/865 FLASHHEADS:............................................................................................8

ELECTRICAL SPECIFICATIONS:...............................................................................................................................................10

ENVIRONMENTAL SPECIFICATIONS:.......................................................................................................................................10

INSTALLATION TIPS AND REQUIREMENTS:..............................................................................................................................10

SYSTEM CABLE SPECIFICATIONS: ..........................................................................................................................................11

POWER SUPPLY COMPONENT LAYOUT:.................................................................................................................................12

CONNECTION OF INPUT POWER:..........................................................................................................................................13

CONNECTION OF THE RS485 CABLE:....................................................................................................................................14

TRANSLATOR BOARD SETTINGS:...........................................................................................................................................15

FLASHHEAD CABLE PREPARATION:........................................................................................................................................16

FLASHHEAD/POWER SUPPLY CABLE CONNECTIONS: ................................................................................................................17

SPARE PARTS -POWER SUPPLY:...........................................................................................................................................19

SYSTEM CONFIGURATION SCREENS:......................................................................................................................................20

COMMISSIONING PHOTOGRAPHS:........................................................................................................................................21

TECHNICAL SUPPORT:........................................................................................................................................................21

SERIAL NUMBER CODING: ..................................................................................................................................................21

REVISION HISTORY:...........................................................................................................................................................21

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 4of 21

Warranty:

Please visit www.dialight.com/resources/warranties for the latest warranty policy.

System Descriptions:

The below devices are covered in this manual. The listed power supplies will require a

controller (D1xWCTR4x9) with photocell (D2566000PEC) for proper operation.

D1RWPS9409

Gen5 Dual Red/White Power Supply

120/277AC 50/60Hz Input Voltage

L-864/865 or L-865 flash head, 4 conductor cable required

D1RWPS9449

Gen5 Dual Red/White Power Supply

±48VDC Input Voltage

L-864/865 or L-865 flash head, 4 conductor cable required

D1CWPS9409

Gen5 Dual Red/White w/Infrared (IR) Power Supply

120/277VAC Input Voltage

L-864/865 or L-865 flash head w/IR, 4 conductor cable required

D1CWPS9449

Gen5 Dual Red/White w/Infrared (IR) Power Supply

±48VDC Input Voltage

L-864/865 or L-865 flash head w/IR, 4 conductor cable required

D1RWFH409

Gen5 Dual Red/White w/4 conductor Flash Head

- Configured in controller as Dual Red/White or White Only

D1CWFH409

Gen5 Dual Red/White w/Infrared (IR) & 4 conductor Flash Head

- Configured in controller as Dual Red/White or White Only

System not listed, please contact Dialight technical support at 844-436-5422.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 5of 21

Introduction:

This manual is for installing the FAA Type E (L-864/865, Dual Red/White) or FAA Type D

(L-865, White only) lighting systems that have multiple flashheads. Please see the

separate user manual for FAA Type A (L-864, Red Only) systems.

Covered in this manual is the following information.

Warranty Policy

System Descriptions

Notice and Warnings

Dimensions of Power Supply Enclosure

Dimensions of D1xW Flashhead

Electrical & Environmental Specifications

Installation Tips and Requirements

System Cable Specifications

RS485 Communication Connections for multiple systems

Power Supply Component Layout

AC Power, RS485 & Flashhead Connections

Spare Parts for Power Supply

Commissioning Photographs

Technical Support

Serial Number Coding

Not included in this manual:

Refer to the quick start manual for the below information

Controller Status LED’s

Dry contact connections

Navigating the LCD Display in Main Controller

Resetting system & external GPS option

Display Events and Alarm Descriptions

Alarm list and possible causes

INEM installation and setup

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 6of 21

Notice and Warnings:

This manual contains important information regarding the proper installation, operation,

and maintenance of this product. Before using the product, read and understand all

instructions, cautions, notes and warnings, as well as all of the labels affixed to the

product. Failure to do so could result in personal injury or damage to equipment and/or

void the product warranty.

FAILURE TO LEAVE THE ENCLOSURES FREE FROM DEBRIS UPON COMPLETION OF INSTALLATION MAY

CAUSE SHORT CIRCUITS

FAILURE TO TIGHTEN DOWN CLAMP WASHERS WILL MAKE INTERNAL COMPONENTS VULNERABLE TO

SURGE OR LIGHTNING DAMAGE

FAILURE TO PROPERLY BOND THE EARTH GROUND WIRE TO THE JUNCTION BOX WILL RESULT IN

EVENTUAL LIGHTNING DAMAGE OF THIS SYSTEM.TO AVOID WARRANTY NULLIFICATION,FOLLOW

THE DIRECTIONS IN THEIR ENTIRETY.

CAUTION:ONLY APPROVED DIALIGHT PHOTOCELLS CAN BE USED WITH THIS SYSTEM

FAILURE TO PROPERLY BOND THE FLASHHEADS AND CONTROLLER ENCLOSURE TO THE TOWER

STRUCTURE WILL RESULT IN EVENTUAL LIGHTNING DAMAGE OF THIS SYSTEM.THE SYSTEM’S

WARRANTY SHALL BE VOID IF ALL FLASHHEADS AND CONTROLLER ENCLOSURE ARE NOT

PROPERLY BONDED TO THE TOWER STRUCTURE.TO AVOID WARRANTY NULLIFICATION,FOLLOW

THE DIRECTIONS IN THEIR ENTIRETY.

CAUTION:NEVER LOOK AT THE FLASH HEAD WHILE THE SYSTEM IS ENERGIZED.THE FLASH HEAD

COULD START FLASHING CAUSING TEMPORARY BLINDNESS WHICH WOULD BE DANGEROUS AT HIGH

ELEVATIONS.

FAILURE TO SET UP THE SYSTEM CORRECTLY DURING STARTUP MAY RESULT IN THE TOWER HAVING

TO BE CLIMBED AGAIN TO PERFORM TROUBLESHOOTING.

USE PROPER METHODS OF LIFTING AND CARRYING TO PROTECT AGAINST

INJURY. FOLLOW THE RECOMMENDATIONS BELOW TO ENSURE ENCLOSURES

ARE HANDLED IN A SAFE MANNER:

BASED ON FACILITY SAFETY REQUIREMENTS DETERMINE IF THE

ENCLOSURE REQUIRES TEAM LIFTING

BEND AT THE KNEES AND MAKE SURE YOUR BACK IS STRAIGHT BEFORE

LIFTING

LIFT WITH YOUR LEGS AND NOT YOUR BACK

KEEP THE ENCLOSURE CLOSE TO YOUR BODY WHILE CARRYING

KEEP YOUR BACK STRAIGHT WHEN LOWERING

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 7of 21

Dimensions for Mounting the Enclosure:

NOTE: Both the Controller and Power Supply use the same enclosure.

Recommended mounting hardware diameter is 3/8” (10.3mm)

Weight of the complete enclosure is 49.5 lb (22.45kg).

Six (6) ¾-inch NPT entrance holes provided on bottom side of enclosure

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 8of 21

Dimensions for Mounting the D1xW L864/865 Flashheads:

D1xWFH409 Flashhead

Weight 21 lbs.(9.5kg)

D1RWFH408 Flashhead

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 9of 21

Recommended Locations for Cable Entry:

The enclosures are supplied with six factory-drilled holes. Remove any red dust caps and

all entrance holes must be properly sealed with watertight connectors or plugs to ensure

proper moisture protection. Typical port entrances for cables/seal-tight are shown below.

Input voltage location has red dust cap from factory, this must be removed and replaced

with watertight connector or plug.

To maintain water ingress protection all additional holes should located at the bottom side

of the enclosure.

NOTE: Dimensions are suited for ¾-inch NPT cord grips or seal tight.

NOTE: Additional Grounding can be added at either the mounting feet or inserted to the

ground terminal block (GL) located in the enclosure. Grounding cables not supplied.

Multiple grounding points provided in the enclosure for protective and functional

Earth/Ground connections.

RS485

Interconnection

Flash Head

Earth Ground

Input Voltage

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 10 of 21

Electrical Specifications:

D1xWPS9409 Power Supply –90 Watts, 120/277 VAC 50/60Hz

D1xWPS9449 Power Supply –75 Watts, ±48VDC

D1xWFH4xx Flashhead –36 Watts

Environmental Specifications:

Operating Temperature Range: -40°F to +130°F (-40°C to +55°C)

Humidity: 95% relative humidity

Wind: up to 150 mph (240kmph)

Protection: IP66, Suitable for outdoor use

Pollution degree: P1

Equipment intended to be installed at an altitude of 2000m or less

Installation Tips and Requirements:

The D1xWPS4x9 Power Supply is housed in a NEMA4X rated outdoor enclosure and can

be installed either outside or in a shelter. If installed outside, the installer must consider

water ingress and proper earth grounding to reduce the risk of premature failures.

For AC or DC Input, it is recommended that the electrician or installer calculate the wire

requirements based on the system being installed. It is recommended that installation

does not utilize less than 14AWG 600V cable with at least a 90ºC temperature rating. See

electrical parameters for further information.

It is recommended that the lighting system be on its own breaker adequately rated for the

system’s power consumption. The breaker MUST be rated for at least 20% higher than the

systems total current draw.

Proper grounding techniques must be utilized based on local, state and federal

guidelines and customer specifications. The system has built in Lightning and RF

immunity at each section, but for it to be effective proper ground connection

techniques must be used.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 11 of 21

System Cable Specifications:

NOTE: Cables for AC/DC Input and remote monitoring are not supplied.

Specification for Input cable:

Requires three conductors for AC or DC Input.

Typical AC color code is Black, White and Green.

Typical DC color code is Red, Black and Green.

Earth Ground is required in the controllers.

A minimum of 14AWG is to be used.

Bonding ground wire when required is to be 6AWG.

Individual wires can be used in lieu of a cable but must be routed through conduit or

seal tight.

Specification for RS485 Cable:

Requires three conductors of 18AWG, drain wire plus a braid for grounding.

Typical color code is Grey, Yellow, and Blue.

Specification for the Flashhead cable

The Vigilant® flashhead requires a 4-conductor cable with a minimum of 14 AWG

with foil and braid shielding.

Typical colors are Red, Red with black stripe, White and White with black stripe.

Cable needs to be an un-cut (no splices) run from flashhead to controller/power

supply surge protection devices.

NOTE: Stripes are always for the negative connection on DC systems.

All cables that extend up the structure must be

adequately secured to the structure with the

use of ¾” filament tape and 2” black all

weather tape at a maximum of 5 foot

intervals. Route cables inside the structure

leg when possible. Maximum #14-AWG

cable length is 680 feet (207 meters).

#12-4C should be used on taller structures.

Failure to meet any of the above cable requirements

could void all factory warranties. If in doubt please

contact your sales representative or Dialight.com.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 12 of 21

Power Supply Component Layout:

I D

Description

I D

Description

W1

WHITE LED DRIVER #1

I/L

INTERLOCK SWITCH

W2

WHITE LED DRIVER # 2

AC/DC

POWER SUPPLY CONVERTER

TB2

RS485 TERMINAL

M/F

MICRO/FILTER ASSY

GL

EARTH GROUND LUG

CAP

CAPACITOR BOARD

TB1

INPUT VOLTAGE (AC or DC)

LPB

LIGHTNING PROTECTION BOARD

F/S

FILTER/SURGE BOARD

R

RED LED DRIVER

(W1)

(W2)

(CAP)

(LPB)

(M/F)

(R)

(TB2)

(TB1)

(F/S)

(I/L)

(GL)

(AC/DC)

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 13 of 21

Connection of Input Power:

Input cable or wire NOT supplied with the system. Input power connected at terminals

labeled TB1 (see below).

The AC connection requires three conductors. Live, Neutral and Earth Ground.

Input Voltage is 120/277 VAC 50/60Hz (100-305 VAC range).

The DC connection requires three conductors. Positive, Negative and Ground.

Input Voltage is ±48VDC (40-60 VDC range).

Individual wires can be used but must be fed through seal tight or conduit.

Earth ground connection is required to provide safety and proper operation of the

system.

WARNING: Floating Neutrals are not permissible within the wiring of the system and

the installer must verify the connections. This will “Void” all warranties and cause

system failure during turn on.

WARNING: No more than 305VAC measured from Live to Earth Ground or Live to

Neutral on TB1, or 60VDC from Positive to Negative or Positive to Ground. This must

be measured before powering up the system.

NOTE: The load and voltage loss of the cable must be quantified before selecting the

cable size requirements. See electrical specifications for details.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 14 of 21

Connection of the RS485 Cable:

A 3-conductor cable with braid and foil is required for the interconnection of the RS485

between the main controller at TB2 and subsequent power supplies at TB2. The

minimum size will be 18AWG.

The connection between the units is vitally important to the operation of the system. All

communication of mode, sync, alarms, and events are transmitted on this connection

between units back to the main controller.

The factory color code will be as follows on top of RS485 terminal block:

Terminal

Description

Color Code

Label “A”

Communications “A”

Gray

Common

Common for RS485

Yellow

Label “B”

Communications “B”

Blue

The interconnection between main controller-power supply or power

supply-power supply will follow same color code on bottom of terminal

block. Systems can be daisy chained to other power supplies at this

terminal by using the second set of connections.

Braid/Foil should be properly stripped back away from the terminal block.

The bare drain wire should be connected to the internal ground lug within

the power supply.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 15 of 21

Translator Board Settings:

The translator boards (located in upper right corner of the power supply) needs to be

individually assigned a number in order to communicate with the main controller and the

rest of the system.

Factory setting is “0” zero.

Translator Board Rotary knob “SW1” settings, the use of a small flathead screwdriver is

required. Failure to set the addresses will cause “config alarms” and “communications

alarms”.

NOTE: If the setting is changed when power is on, the system will need to be reset for

the change to be recognized by the main controller.

Verification of operation can be confirmed by the illumination of the multiple LEDs

located on the translator board.

5V

12V

ISO 5V

TX_EN

TX1

RX1

WDOG

STAT1

Green

Solid

Green

Solid

Green

Solid

Amber

x2 Flash

Amber

x2 Flash

Amber

x2 Flash

Green

Fast Flashing

Green

Slow Flash

Setting

Description

0

Reserved for Main Controller

1

Power Supply #1

2

Power Supply #2

3

Power Supply #3

4

Power Supply #4

5

Power Supply #5

6

Power Supply #6

7

Power Supply #7

8

Power Supply #8

9

Power Supply #9

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 16 of 21

Flashhead Cable Preparation:

1. Run the cable through the provided strain relief before stripping the outer jacket

in order not to fray the braiding.

2. Remove 10” of the outer jacket. Careful not to damage internal braid. If cut, cable

should be re-stripped to ensure proper bonding.

3. Wrap electrical tape 3-4” from end of outer jacket to prevent fraying.

4. Remove remaining braiding for the wires to be connected at flashhead terminal

block (Red/Black, Red, White/Black, and White) back to electrical tape.

5. Strip conductors back 3/8” for termination into terminal block.

6. Connect the four conductors to terminal block and ground connection as detailed

the next section.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 17 of 21

Flashhead/Power Supply Cable Connections:

Flashheads and Power Supply have the same surge/terminal connections so the

information below will be used for connecting inside the Flashhead. Use same

installation method for the controller.

The flashhead cable must be an uncut run from the flashhead to the controller.

Mixing wires will result in severe damage to the controller and/or flashhead. This will

VOID all warranties.

NOTE: This is the only connection in the flashhead pedestal that is required.

NOTE: If color code is different than shown, the installer must provide this information to the site manager

upon completion for future reference when required.

J2 pin designators Description

RED Connections (RED)

- Pin 1 (Red/Black wire)

RED LED’s negative (Cathode connection)

+ Pin 2 (Red wire)

RED LED’s positive (Anode connection)

White Connections (WHT)

- Pin 3 (White/Black wire)

WHITE LED’s negative (Cathode connection)

+ Pin 4 (White wire)

WHITE LED’s positive (Anode connection)

Terminal block in Flashhead shown

Using a small tipped Flat head screwdriver, insert and lift handle

upwards to push the internal latch down to insert the wire.

Do a pull test to ensure conductor is properly seated.

Insert braiding in to the clip and use zip tie to secure to clip.

See NOTICE on inside lid of flashhead for more details.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 18 of 21

WARNING: It is vitally important that the braid and foil be properly connected under the clamping

washers for lightning protection. Failure to do will result in premature failures during lightning strikes.

NOTE: For commissioning the system, pictures must be taken of all the clamping washers and the cables

secured under them.

Terminal block in Controller shown

Using a small tipped Flat head screwdriver, insert and lift handle

upwards to push the internal latch down to insert the wire.

Do a pull test to ensure conductor is properly seated.

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 19 of 21

Spare Parts - Power Supply:

I D

Description

Part Number

W1 / W2

WHITE LED DRIVER BOARD

D1W0084WA

CAP

CAPACITOR BOARD

D1RW0084CP

LPB

LIGHTNING PROTECTION BOARD

D7208SUR

M/F

MICRO/FILTER ASSY

D7300ASY

R

RED LED DRIVER

D1CW0084RA

AC/DC

POWER SUPPLY CONVERTER (AC Units Only)

D1RW9005RA

I/L

INTERLOCK SWITCH

7700865000100

F/S

FILTER/SURGE BOARD (AC Units)

D7202SUR

F/S

FILTER/SURGE BOARD (DC Units)

D7204SUR

(W1)

(W2)

(CAP)

(LPB)

(M/F)

(R)

(F/S)

(I/L)

(AC/DC)

Document: 9100-127-2966-99

Revision B

Release Date: 12/12/2022

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 20 of 21

System Configuration Screens:

After all wiring connections are completed checked for accuracy. Provide Input Voltage

to the Controller and Power Supply(ies). Ensure the front panel is closed and locked so

the interlock switch is fully engaged on all units. The Main Controller front panel LCD

screen will turned on and display the Startup and Initializing screens automatically.

In the user manual 9100-127-3481-99, follow the steps outlined in “System

Configuration Screens” to properly configure the system.

LCD Display inside Main Controller

Other manuals for VIGILANT Series

1

This manual suits for next models

5

Table of contents

Other Dialight Lighting Equipment manuals

Dialight

Dialight HBXW3SSL304FT User manual

Dialight

Dialight SAFESITE LSD3C4M2P Manual

Dialight

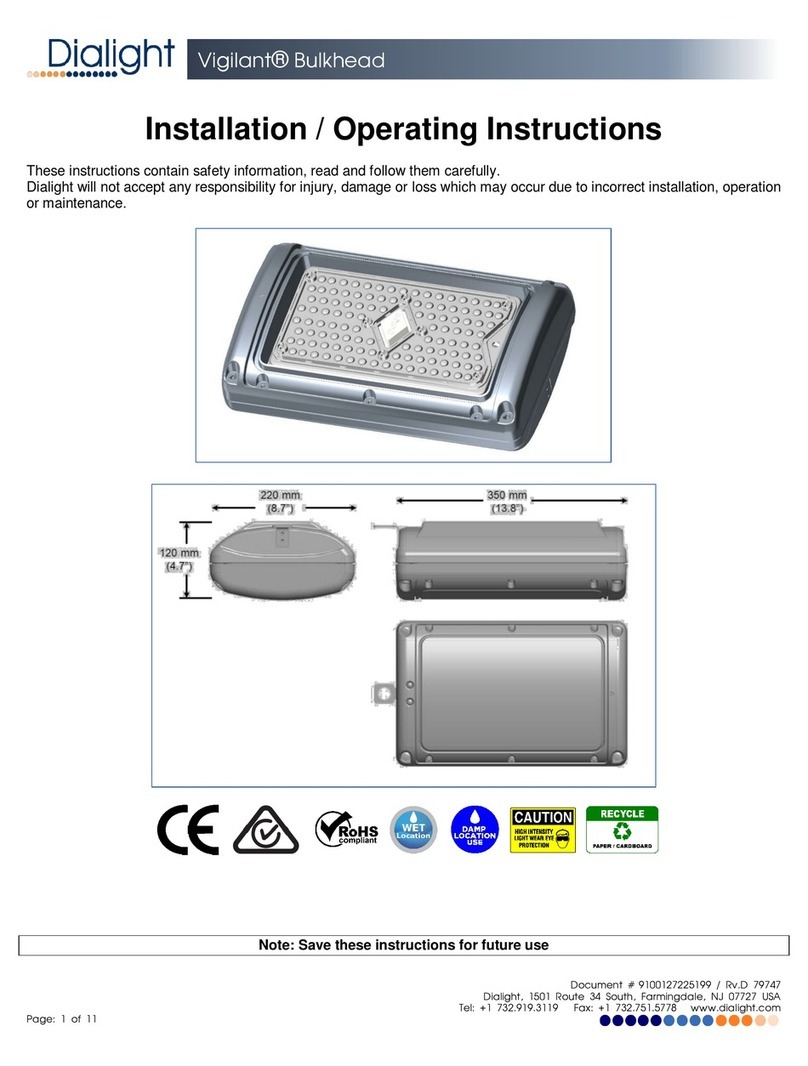

Dialight Vigilant Bulkhead Guide

Dialight

Dialight Reliant User manual

Dialight

Dialight VIGILANT Series User manual

Dialight

Dialight DuroSite User manual

Dialight

Dialight L-856 Troubleshooting guide

Dialight

Dialight L-856 Manual

Dialight

Dialight Vigilant Manual

Dialight

Dialight HBXREF22 User manual