DIG LEIT-2 User manual

1

English

2-Way Radio Controller

Operating Instructions

Table of Contents

A. Introduction ………………………………………………………………… 3

B. About the LEIT-2 system ……………………………………………………… 3

C. Technical assistance ………………………………………………………… 4

D. Copyright and compliance …………………………………………………… 5

E. Features …………………………………………………………………… 6

1. System ………………………………………………………………7-10

1.1 Parts identification …………………………………………………… 7

1.2 System components ……………………………………………… 7-8

1.3 Tools and supply requirements ………………………………………… 9

1.4 Quick installation setup and operation review ………………………9-10

2. Installation ………………………………………………………… 10-17

2.1 Solenoid and valve installation …………………………………… 10-11

2.2 Controller installation ……………………………………………… 12

A. Valve box mounting dome …………………………………… 12-13

B. Mounting column …………………………………………… 14-16

C. Valve mounting ………………………………………………… 16

2.3 Maximum wire run ………………………………………………… 17

3. Initial communication between handset and controller …………………… 17

3.1 Initiating communication for the first time …………………………… 17

3.2 Initial connection to the LEIT-2 using the LEIT RC2 handset ………… 17-19

4. Using a sensor ………………………………………………………… 19

4.1 Sensor installation ………………………………………………… 19

4.2 Compatible sensors ………………………………………………… 19

5. Troubleshooting ……………………………………………………… 19

5.1 Troubleshooting controller ………………………………………… 19

5.2 Troubleshooting solenoids ………………………………………… 20

5.3 Troubleshooting hydraulic valves …………………………………… 21

5.4 Troubleshooting control valves ……………………………………… 21

5.5 Troubleshooting LEIT-2, LEIT-2ET ………………………………… 22-25

6. Record chart …………………………………………………………… 26

7. Programming Quick Reference Chart …………………………………… 27

7. Warranty ……………………………………………………………… 28

2

A. Introduction

Thank you for purchasing DIG’s LEIT-2 controller, which operates as part of the

LEIT-2 system. This manual describes how to get the LEIT-2 controller up and

running quickly. After reading this manual and having been familiarized with

the basic functionality of the controller, the manual can be used as a reference

for less common tasks in the future.

B. About the LEIT-2 System

The LEIT-2 ambient light (solar) powered irrigation controller is an advanced

wireless device that is programmed using the LEIT RC2 remote handset. The

LEIT-2 controller is comprised of a photovoltaic module (PVM panel), 2 pairs

of 18” (45 cm) station wires used to connect the controller with up to two

S-305DC solenoids, plus a pair of yellow wires for a sensor connection. The

LEIT-2 has an ultra-compact photovoltaic module that harnesses light energy

to generate electricity that is stored and used to power the controller day and

night in any kind of weather. The LEIT-2 controller is operated using the LEIT

RC2 remote control handset, which has an operating range via a 2-way radio

of up to 350 ft (100 m) line of sight.

The LEIT-2 controller requires daily exposure to light levels at a minimum of

3000 lux, which is equivalent to daylight around 7-8 AM on a cloudy day. On

very cloudy days the controller requires more time to charge up and to operate

with the radio.

IMPORTANT: Communication between the LEIT RC2 handset and the

LEIT-2 controllers are automatically limited to daylight hours when there is

sufficient light energy. Longer bright light days will enable the radio to operate

automatically over longer parts of the day, including through the night.

3

C. Technical Assistance

Should you encounter any problem(s) with this product or if you do not

understand its many features, please refer to this operating manual first. If

further assistance is required DIG offers the following customer support:

Technical Assistance USA

DIG’s Technical Service Team is available to answer questions from

8:00 AM to 5:00 PM (PST), Monday-Friday (except holidays) at 1-800-322-9146.

Questions in can be emailed to questions@digcorp.com or faxed to

760-727-0282.

Specification documents and manuals are available for download at

www.digcorp.com.

Customer Assistance Outside the USA

Contact your local distributor.

4

D. Copyright and Compliance

Copyright 2010 DIG Corporation. All rights reserved. LEIT-2 and LEIT RC2 are

each trademarks of DIG Corporation. Patent pending.

FCC, CE, IC, Canada and Australia compliance.

To comply with FCC RF exposure compliance requirements, the antenna used for this

transmitter is installed to provide a separation distance of at least 8 inches (20 cm) from all

persons (not including hands, wrist, feet and ankles) and must not be co-located or operating

in conjunction with any other antenna or transmitter.

This device is required to comply with FCC RF exposure requirements for mobile and fixed

transmitting devices. This model transceiver generates and uses radio frequency energy.

If not installed and used in accordance with the manufacturer’s instructions, it may cause

interference to radio and television reception.

CONTROLLER FCC ID: UJV-LEIT01 IC: 6694A-LEIT01

HANDSET FCC ID: UJV-LEIT02 IC: 6694A-LEIT02

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy. If not installed and used in accordance with the

instructions, the remote may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult DIG technician for help.

WARNING: the user should make no field changes or modifications to the LEIT-2 controller or

the LEIT RC2 handset. All adjustments and changes must be made at DIG’s facility under the

specific guidelines suggested in our instruction manual. Any tampering or modification to the

equipment will void the users authority to operate the unit, render the equipment in violation

of FCC part 15 and will void the warranty.

5

E. Features

• All power is provided by an internal photovoltaic module and

microelectronic energy management system fueled by ambient light

• Multilingual software in English, Spanish, Italian, French, German and

Portuguese

• Controller has a 2-way radio with operating range of up to 350 ft (100

meters) line of sight

• Radio frequency is in the ISM band 902-928 MHz (868 MHz international

& 868 MHz Hong Kong) CE and FCC certified

• Default program; if not programmed the controller defaults to 5 minutes per

day (if ID has been entered)

• Manual run via the RC2 handset

• Client ID enables the user to have a unique identity code for the controllers

and handset; this is a security feature, which locks out unauthorized users

• The LEIT-2 operates up to 2 Unimax S-305DC solenoids installed on most

valves using one of DIG’s solenoid valve adapters

• Dedicated Rain Sensor input allows for a sensor connection promoting

better water efficiency

• Electrical protection for up to 50 volts; resistant to damage from lightning

and currents from power lines

• Non-volatile memory retains program integrity indefinitely (excludes time)

• Built from tough, rugged material - resistant to harsh environmental

conditions

• Environmentally friendly: Certified lead free, uses light as a source of

energy

• Waterproof, complies with IP68 requirements

• Mounting configurations include valve mounting, valve box mounting and

column mounting

6

1. System

1.1 Parts Identification

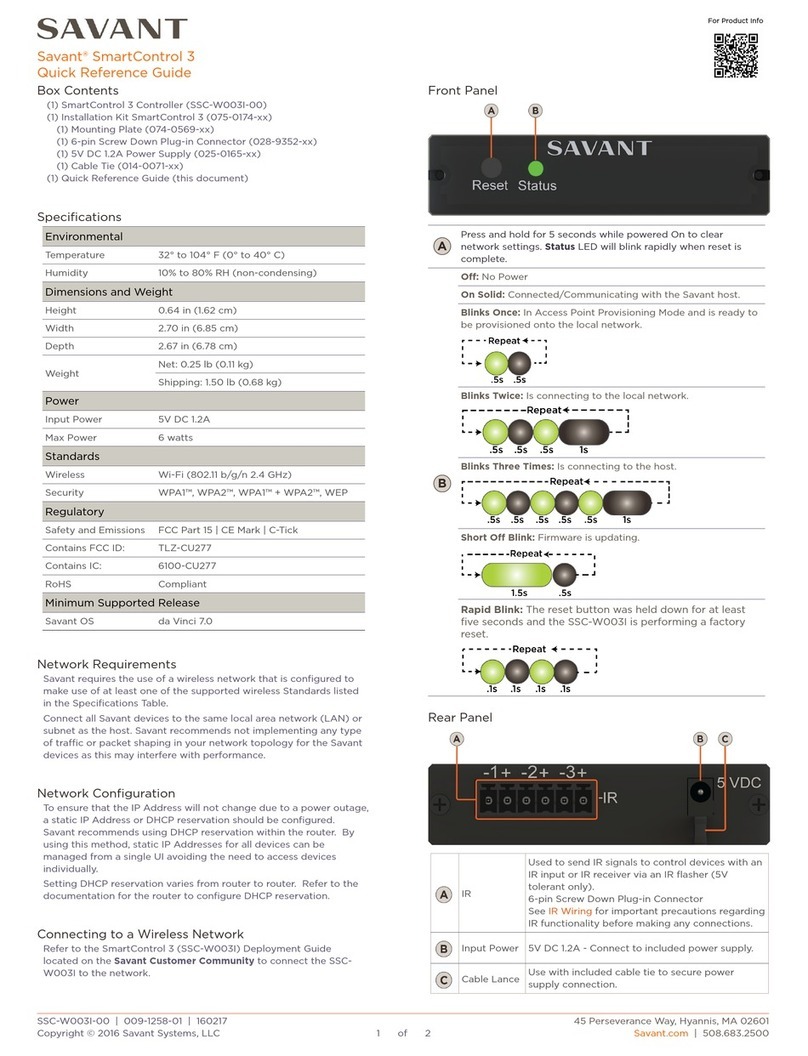

1. PVM Photovoltaic module harnesses the

energy of light and generates the electricity

to power the unit day and night in any of

weather condition

2. Antenna

3. Stations and sensor wires

1.2 System Components

To properly install the LEIT-2 controller, the following components are needed:

1. Control unit: LEIT-2 two station ambient light (solar) powered wireless

controller.

2. The controller is installed using one (1) of the mounting

configurations available:

a. Model 30-830: Valve box mounting dome, color green

b. Model 30-835: Valve box mounting dome, color tan

c. Model 30-836: Valve box mounting dome, color purple

d. Model 30-831*: Mounting column plastic

attachment used with galvanized mounting column;

i. MCOL2S: 25” (63 cm)

galvanized mounting column

ii. MCOL2L: 50” (123 cm)

galvanized mounting column

e. Model 30-832: Valve clip attachment with four (4) screws

b

d

7

c

e

a, b, c

d

i, ii

*The mounting column includes a mounting tool kit with cement

glue to firmly attach the mounting bracket to the column.

3. 305DC-XXX complete in-line valve with solenoid or

S-305DC solenoid (one for each valve used).

4. Seven (7) solenoid adapters are available to fit most valves:

a. Model 30-920 use with BERMAD series 200, HIT series 500, DOROT series 80,

GRISWOLD series 2000, DW and BUCKNER series VB valves

b. Model 30-921 use with RAIN BIRD DV, DVF, PGA, PEB (1” only), GB, EFB-CP, BPE,

PESB (1” only) and ASVF valves

c.

Model 30-922 use with

HUNTER series ASV, HPV, ICV, PGV, SRV, IBV and ASVF valves

d. Model 30-923 use with WEATHERMATIC series 12000, 21000, 8200CR valves

e. Model 30-924 use with IRRITROL series 100, 200B, 205, 217B, 700, 2400, 2500,

2600 and TORO series 220, P220 valves

f. Model 30-925 use with SUPERIOR series 950, HUNTER HBV and TORO series 252

valves (1.5” and larger)

g. Model 30-926 use with RAIN BIRD series PEB and PESB (1 1/2” and 2”only) valves

8

5. LEIT RC2 remote handset (version SW U:1.XX.XX EE 1.XX.XX)

to communicate with up to 99 LEIT-2 controllers.

E1 O-ring

200-014

model #30-494

E2 Short sleeve

model #30-422

E

F1 O-ring

200-014

model #30-494

F

D

D1 O-ring

200-015

model #30-494

D2 Sleeve

model #30-424

C

C1 O-ring

200-012

model #30-495

C2 Long sleeve

model #30-423

B

B1 O-ring

200-021

model #03-077

A

A1 O-ring

200-014

model #30-494

A2 Sleeve

model #30-424

G1 O-ring

200-021

model #30-926

G

Additional system components

1.3 Tools and Supply Requirements

1. Standard wire stripper.

2. Philips screwdriver (#1) if using the valve clip attachment or the mounting

column plastic attachment or Philips screwdriver (#2) used with the valve

box mounting dome.

3. Concrete: approximately 1, 90 lb (40 kg) bag (if using mounting column).

NOTE: Only needed with the mounting column.

4. WATERPROOF WIRE CONNECTORS (not included).

1.4 Quick Installation Setup and Operation Review

In order to establish communication for the first time between a LEIT RC2

handset and LEIT-2 controller the following steps must be taken:

1. Charge the LEIT RC2 handset (see LEIT RC2 instruction).

2. Setup the LEIT RC2 handset (see LEIT RC2 instruction).

3. Install the LEIT-2 controller following the LEIT–2 installation instructions,

see Section 2, then set it out in the light for initial charge

a.

In bright light conditions (full sun) charging the controller will take under 30 min.

b. In shaded conditions charging the controller could take up to 2 hours.

c. Communication will only initiate when the controller is fully charged.

4. Follow the instructions steps of how to establish initial communication

between a LEIT-2 controller and LEIT RC2 handset.

STEP 1: Splice the two, yellow and yellow with black stripe sensor

wires together using waterproof connectors. This splice will distinguish

that the controller is ready to communicate with a LEIT RC2ET handset.

NOTE: Do not connect yellow wires together until after the

unit has charged and you are ready to assign the ID number.

STEP 2: Using the LEIT RC2 Handset, select Default Setup and

connect

to the LEIT-2 controller using Radio Uplink icon (see page 17).

STEP 3: After establishing communication between a LEIT RC2 handset

and a LEIT-2 controller, setup the controller selecting Setup icon found

in the Controller Menu. Then select Cont. Setup icon found in the Setup

Menu Screen (see RC2 handset operation instructions).

9

STEP 4: After setting up the controller, program the controller (See RC2

handset operating instruction).

The handset and controller should now be available for communication.

2. Installation

2.1 Solenoid and Valve Installation

NOTE: Maximum operating pressure is up to 150 PSI (10.5 BAR).

Use DIG’s 305DC-XXX 3/4” to 2” valves or Model S-305DC solenoid and select

the appropriate conversion adaptor for the valve(s) that will be used with the

S-305DC solenoid (see list 1.2, #4 on page 8).

1. Shut off the mainline to the valve.

2. Install the valve (model 305DC-XXX) or unscrew the conventional solenoid

from the valve installed and remove the solenoid housing, solenoid stem,

plunger, spring, and O-ring (if necessary).

3. Select the appropriate conversion adapters for the valve(s) (see list 1.2, #4

on page 8).

IMPORTANT:

Do not remove existing O-ring on BUCKNER and SUPERIOR

valves.

When installing adaptor on BUCKNER and SUPERIOR valves remove

the adapter sleeve (model 30-424) before installing.

4. Thread and tighten the conversion adapter clockwise to the compatible

valve port. Do not over tighten (see A).

5. Screw model S-305DC solenoid into the selected adapter. Tighten the

solenoid by hand, but do not over tighten (see B).

6. After installation is complete, turn the water supply on and pressurize the

main line. The valves will open momentarily and then shut off. Test each

valve in manual operation by turning the solenoid counter clockwise a half

turn or until the valve opens, and clockwise to close (see C).

10

7. Splice the solenoid hot wires (red) to the controller’s incoming red station

wire with stripe (V1). Splice the solenoid white wire to the single incoming

white wire with stripe (V1). If needed, repeat for the second valve. USE 2

CONVENTIONAL DRY-SPLICE WATERPROOF CONNECTORS WITH

CRIMP SLEEVE. Leave slack on each side of the wires so that repairs can

be carried out easily.

NOTE: The solenoid operates only

with 2-way normally closed valves.

NOTE: Station one red and white controller

wires are identified by the black stripes.

IMPORTANT: If a valve remains open in manual operation, you may need to

examine the solenoid and the solenoid adaptor to see that they are installed

correctly and the adaptor is firmly secured. Do not over tighten the solenoid

to the adapter and to the valve and do not cross thread the adaptor into the

solenoid cavity.

CAUTION: For all valves with built-in internal manual bleed lever, make

sure the lever is in closed position. Do not move the lever after installing the

solenoid with the valve adapter. If the manual lever on the valve is used, it can

damage the adapter or the sleeve causing the valve to stay open.

11

Additional system components

Additional system components

Additional system components

A B C

ONOFF

c

d

e

2.2 Controller Installation

Option A: Valve Box Mounting Dome, color: green (model 30-830), tan

(model 30-835) or purple (model 30-836)

1. Lay the template on top of the rectangular or round irrigation box cover

and drill 4-8 holes, make sure to review the template position on the valve

box before drilling (see drilling instruction on the template) using 1/4”

drill (.250”) (6 mm). The holes are used to hold the mounting dome to the

irrigation box cover. Using the same template, drill 1 hole using a 1/2”

(.500”) (12 mm) drill bit to allow the

wires from the controller into the valve

box cover (see - ).

2. Insert the controller into the mounting dome (see ).

3. Insert the controller wires into the valve box cover (see ).

4. Use #2 Philips screwdriver to attach the mounting dome to the valve box

cover with the #10 Philips head screws included with the mounting dome

(see ).

12

1

3

4

2

5

1

3

4

2

5

1

3

4

2

5

1

3

4

2

5

c

b

d

e

b

f

g

g

5. There are 6 wires or three sets of wires from the controller, one pair

for each valve and one pair for sensor connection (yellow). Connect the

controller’s station #1 output red wire #1 (striped red and white) to the red

wire on valve #1. Then connect the controller’s output station common wire

(V1 stripe) to the white wire on the solenoid

USING CONVENTIONAL DRY-

SPLICE WATERPROOF CONNECTORS WITH CRIMP SLEEVE.

Repeat the same

steps for station #2. Leave slack in the wires on each side so repairs can be

carried out easily (see ).

NOTE: Station #1 is identified with striped wires.

6. Reattach the valve box cover on top of the valve box and if available lock

the cover to the box (recommended) (see ).

13

1

3

4

2

5

f

g

Detailed Installation

S

Option B: Mounting Column (model 30-831)

1. Excavate a trench from the valve to the column location and then, pull a

set of colored wires from the valve area to the mounting column location

(one pair for each valve). Each pair should consist of one white wire, and

one red or colored wire, preferably of differing colors. Each pair should be

taped and marked separately at both ends, so that the wires do not get

cross-connected (see ).

2. Insert the pairs of wires through the bottom of the mounting column and

push the wires up through the column until at least 6”

(15 cm) of wire

extends from the top of the mounting column (see ).

3. Install the mounting column, setting the curved bottom of the mounting

column in an 8” x 8” x 6” (20 x 20 x 15 cm) frame and pour in the 90 lb

(40 kg) sack of cement (see detailed illustration). Make sure the column is

vertical and the opening in the curved bottom is accessible and unclogged

(see ).

IMPORTANT: Make sure the cement pad is dry before continuing

installation.

14

d

c

b

Column mounting (phase 1)

Column mounting (phase 2)

d

c

b

4. Pull the 2 pairs of field wires from the valves through

the center hole in the bottom of the mounting plastic

bracket (see ). There are three sets of wires from the

controller, 1 pair for each valve and 1 pair for sensor

connection (labeled V-1, V-2 and S on the housing where

the wires enter the controller). First, trim the controller

valve wires to about 3-4” (7-10 cm) from the controller

and then, connect the controller’s station #1 output

red wire #1 (striped red and white) to the red wire

on valve #1 using 2 small waterproof wire nuts. If

necessary, repeat the same procedure for valve #2

using the wires labeled V2 (see ). Next, bring the

two yellow sensor wires through the small hole on the

side of the mounting bracket (see ). Finally, place

wires with nut inside the bracket body and secure the

plastic bracket into the controller using the 4 small

Phillips screw provided (see - ).

5. Next, apply a thin layer of cement glue (included

with the column) to the top on the outside area of the

column and slide the controller-mounting bracket into

place on top of the column (see ).

6. At the valves, connect the incoming station #1 wire (striped

red) to the hot wires (red) on the solenoid USING CONVENTIONAL

DRY-SPLICE WATERPROOF CONNECTORS WITH CRIMP SLEEVE.

Connect the controller incoming station common wire (striped white) to

the white wire on the solenoid USING CONVENTIONAL DRY-SPLICE

WATERPROOF CONNECTORS WITH CRIMP SLEEVE and if needed

repeat for the second valve and sensor. Leave slack in the wires on each

side so that repairs can be carried out easily (see ).

15

Column mounting (phase 1)

e

f

g

Column mounting (phase 1)

h

e

f g

f

g

h

i

Option C: Valve Mounting (model 30-832)

1. Slide the wires from the controller into the valve-mounting bracket and

connect the valve-mounting bracket to the controller using the 4 screws

included (see ).

2. Connect the incoming station wire (V1 red) to the hot wires (red) on the

solenoid

USING CONVENTIONAL DRY-SPLICE WATERPROOF CONNECTORS

WITH CRIMP SLEEVE.

Connects the controller incoming station common

wire (V1 white) to the white wire on the solenoid

USING CONVENTIONAL

DRY-SPLICE WATERPROOF CONNECTORS WITH CRIMP SLEEVE

and if

needed repeat for the second valve and sensor. Leave slack on each side of

the wires so that repairs, if needed can be carried out easily (see ).

NOTE: Station #1 wires are identified with striped wires.

3. Attach the controller into place on the top of the solenoid (see ).

16

b

c

d

Column mounting (phase 2)

i

b

c

d

2.3. Maximum Wire Run

100’ (30 m) using 18 AWG (0.75 mm) solid core direct burial irrigation wire

200’ (60 m) using 14 AWG (2.5 mm) solid core direct burial irrigation wire

300’ (90 m) using 12 AWG (4 mm) solid core direct burial irrigation wire

3. Initial Communication

3.1 Initiating Communication for the First Time

NOTE: Prior to initial LEIT-2 connection, LEIT RC2 handset Client ID must be

set at AAA (factory default setting).

Use the 2 yellow-colored, sealed sensor wires on the controller to signal to

the LEIT-2 controller that it is about to be programmed. Splice the 2 yellow

sensor wires together USING WATERPROOF CONNECTORS. This splice

will distinguish that the controller is ready to communicate with a LEIT RC2

handset. Use the handset to connect to the controller via the Radio Uplink icon

using the default address.

NOTE: When more than one LEIT-2 controller is to be installed on site,

connect the yellow wires and ID each controller one at a time.

3.2 Connecting to the LEIT-2 Controller for the First Time Using the

LEIT RC2 Handset

In the LEIT RC2 handset’s main menu press and highlight the RADIO UPLINK

icon. Press and the RADIO UPLINK screen will appear. This is the default

address screen. The description in this screen is: CONTROL ID: 00, DEFAULT

SETUP.

Press to connect to the controller. The ARE YOU SURE? screen will appear

with the Radio Uplink icon selected. Press to connect to the controller

without an ID. After establishing communication, CONNECTED will appear

momentarily and then, CONNECTED TO: CONTROLLER ID: 00, DEFAULT SETUP.

Press again. The UPLOADING screen appears momentarily then, CONT.

SETUP with CONTROL ID: XX (digits flashing), which means the controller’s ID

is available for modification.

17

To assign a new controller ID number, press or and enter a number (2-9)

for the first digit. Press and repeat the steps with the second digit. Press

to continue to the next step, setting controller address (the default is

DESCRIPTION). Repeat the steps for selecting the controller address or name.

It is not recommended to change the controller client ID from AAA at this time.

If necessary, it can be changed at a later date. When finished, press to

connect and upload the new information. The ARE YOU SURE?

screen will appear. Press again to download the information. The UPDATE

SUCCESSFUL message will appear momentarily confirming that controller

setup is updated and complete and then, CONTROLLER MENU appears.

18

The controller is ready to program:

Repeat the steps for additional controllers.

NOTE: When connecting to a LEIT-2 controller, the controller and handset

CLIENT ID must be the same.

10:00 10:00 10:00 10:00 10:00

10:00 10:00 10:00 10:00 10:00

10:00 10:00 10:00

<

>

MAIN MENU RADIO UPLINK RADIO UPLINK YES / NO CONNECT

CONNECT CONNECTED TO: CONNECT CONT. SETUP YES / NO

CONNECT CONNECT CONTROLLER MENU

CONTROL ID: XX

NO DESCRIPTION

ARE YOU SURE? CONNECTING

CONNECTED

CONTROL ID: XX

NO DESCRIPTION

CONTROL ID: XX

NO DESCRIPTION

CLIENT ID: XXX

UPLOADING

CONNECTING UPDATE

SUCCESSFUL

ARE YOU SURE?

ATTENTION: The two yellow (or yellow and black) sensor wires are left connected

so the RAIN OFF alert will not appear. If a rain sensor needs to be added, see

Section 4 – Using a Sensor.

4. Using a Sensor

NOTE: Do not install sensor until after the controller has been given an ID #

by the RC-2 handset.

4.1 Sensor Installation

Remove the WATERPROOF CONNECTOR from the controller’s two yellow

wires and splice them to the sensor’s two normally closed (N/C) black wires.

Connect 1 of each yellow wire from the controller with 1 of each black

wire from the sensor USING WATERPROOF CONNECTORS (if sensor is

connected, the sensor will override the program when triggered).

4.2. Compatible Sensors

Sensors compatible with LEIT-2 controllers:

Rain sensors: ………………… HUNTER MINI-CLIK and the RAIN BIRD RSD

Moisture sensors: ………………………………… IRROMETER WEM-B

Freeze sensor: ………………………………… HUNTER FREEZE-CLICK

5. Troubleshooting

The LEIT-2 wireless irrigation control system is a series of components

consisting of LEIT-2 ambient light powered 2 station controller, the RC2

handset, S-305DC solenoids, solenoid adapters, hydraulic control valves, and

wires/splices. It is best to troubleshoot this DC system (like an AC system)

by a process of elimination; the goal being to determine which component(s)

has failed. The following facts and tips may be helpful to eliminate certain

components and facilitate faster troubleshooting. It is assumed that these

are installed controllers that are receiving the proper amount of light. Keep in

mind that the problem may be with more than one component.

5.1 Troubleshooting Controller

1. To test the controller’s output, connect a solenoid to one of the controller’s

19

red and white wire pairs. Institute a test run via the handset with 1 minute

on the station in question and zero minutes on the other station. If the

solenoid is not installed, verify that the plunger retracts and extends or

that you hear the sound of the plunger latching. If the solenoid is installed

onto a valve, see that the valve turns on and the sprinklers or drip system

is working. If it does not turn on, the plunger does not retract and extend

or no sound is heard of the plunger latching, repeat the process using a

second solenoid. If the problem continues you may have an issue with the

controller wires and the WATERPROOF CONNECTORS.

2.

The LEIT-2 controllers function only with S-305DC solenoids or 305DC-XXX

valves.

3. The LEIT-2 controllers function only with compatible normally closed

sensors (HUNTER MINI-CLICK or RAIN BIRD RSD).

5.2 Troubleshooting Solenoids

1. Verify that the correct solenoid and adapters are being used for the valve in

question.

2. Verify that the white and red wires from the solenoid are connected to the

white and red wire pair on the controller and that these splices are tight,

and corrosion free.

3. Verify that no water is leaking externally near the adapter, stem, or bonnet.

4. Verify that all O-rings and/or rubber hoses are in place, if in doubt, check

the adaptor and the solenoid.

a. To test S-305DC solenoid, remove the solenoid from the valve and

disconnect the hot and common wires. Verify the solenoid functions

properly using a 9-volt battery by briefly touching the wires to the

positive and negative contacts. Reverse polarity if nothing happens.

Plunger should retract. Reverse polarity to close, (plunger should extend

and a sound of the plunger latching should be heard).

b. If the solenoid does not function with a 9-volt battery, check the battery.

If the problem with the solenoid continues after using a second battery,

it should be replaced.

20

Other manuals for LEIT-2

1

Table of contents

Other DIG Controllers manuals