DIG Irrigation-Mart 710 Series User manual

This manual suits for next models

7

Table of contents

Other DIG Controllers manuals

DIG

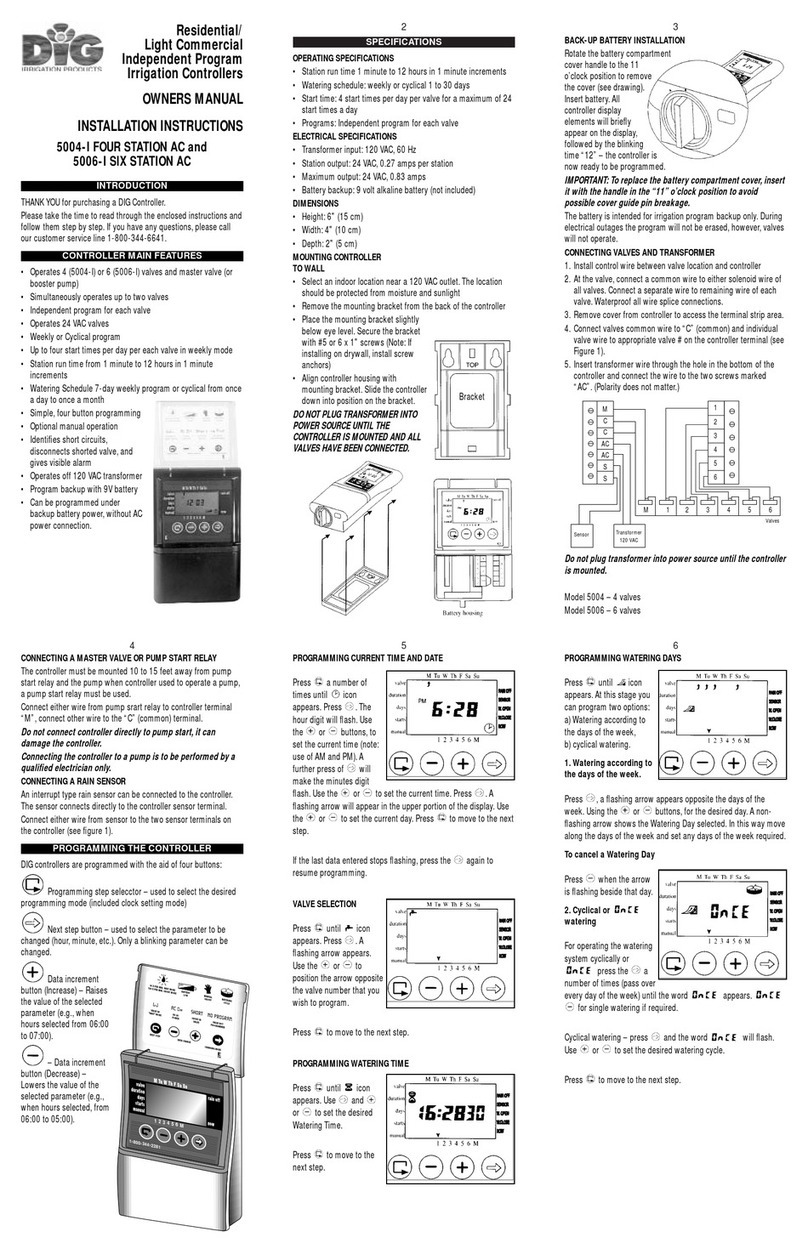

DIG 5004-I Four Station User manual

DIG

DIG 710 Series User manual

DIG

DIG ECO1 MVA User manual

DIG

DIG GQ-AC4 User manual

DIG

DIG 710AP Series User manual

DIG

DIG RBC MVA User manual

DIG

DIG LEIT 4000 Series User manual

DIG

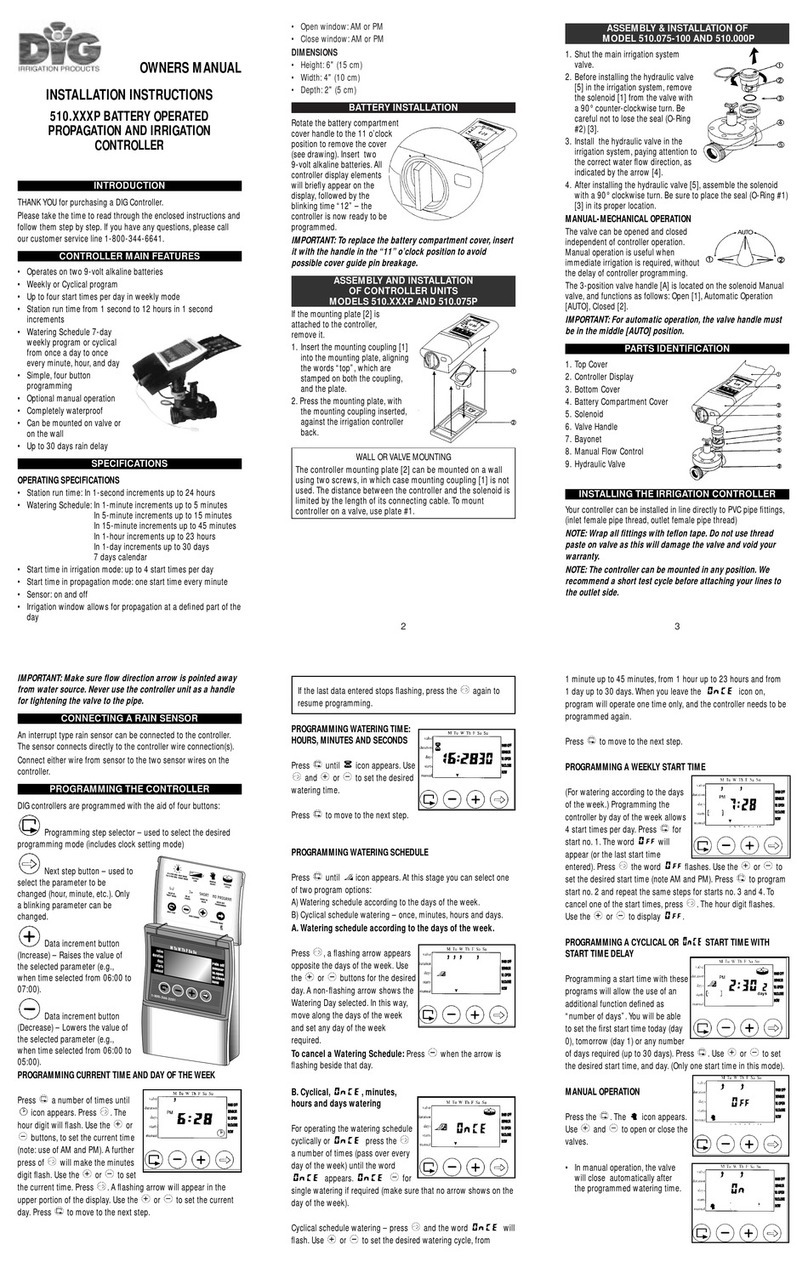

DIG 510.P Series User manual

DIG

DIG RBC 7000 User manual

DIG

DIG ECO1 ILV-075 User manual

Popular Controllers manuals by other brands

DekoLight

DekoLight 843024 manual

AL Tech

AL Tech ALTHC023 Installer Manual and Quick Guide

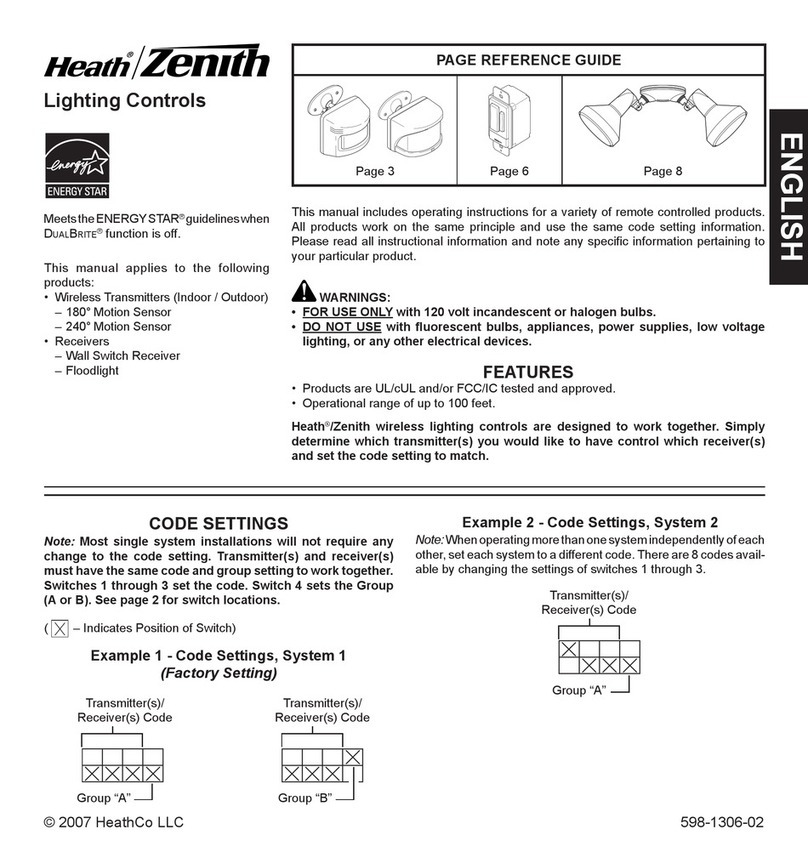

Heath Zenith

Heath Zenith Lighting Controls 598-1306-02 owner's manual

Welbilt

Welbilt Frymaster YUM K3000 Operation manual

Oriental motor

Oriental motor DG Series operating manual

Kromschroeder

Kromschroeder DG smart operating instructions

Astral Pool

Astral Pool DIGITAL CURTAIN Installation, operation and maintenance manual

alphainnoTec

alphainnoTec Luxtronik operating instructions

Power A

Power A Wireless Controller Gamecube Style user manual

AquaMetrix

AquaMetrix 2300 Installation and operation manual

Timeguard

Timeguard NSLDD1000 Installation & operating instructions

Clean Logix

Clean Logix ALX-PRO user manual