6 OF 7 IG050619-3.0

HYDROLUME

®

SLIM RGB LED STRIP LIGHT

INSTALLATION GUIDE

HYDROLUME® SLIM RGB LED Strip Light

INSTALLATION GUIDE

Wire

Gauge

10 W

.42 A

20 W

.83 A

30 W

1.3 A

40 W

1.7 A

50 W

2.1 A

60 W

2.5 A

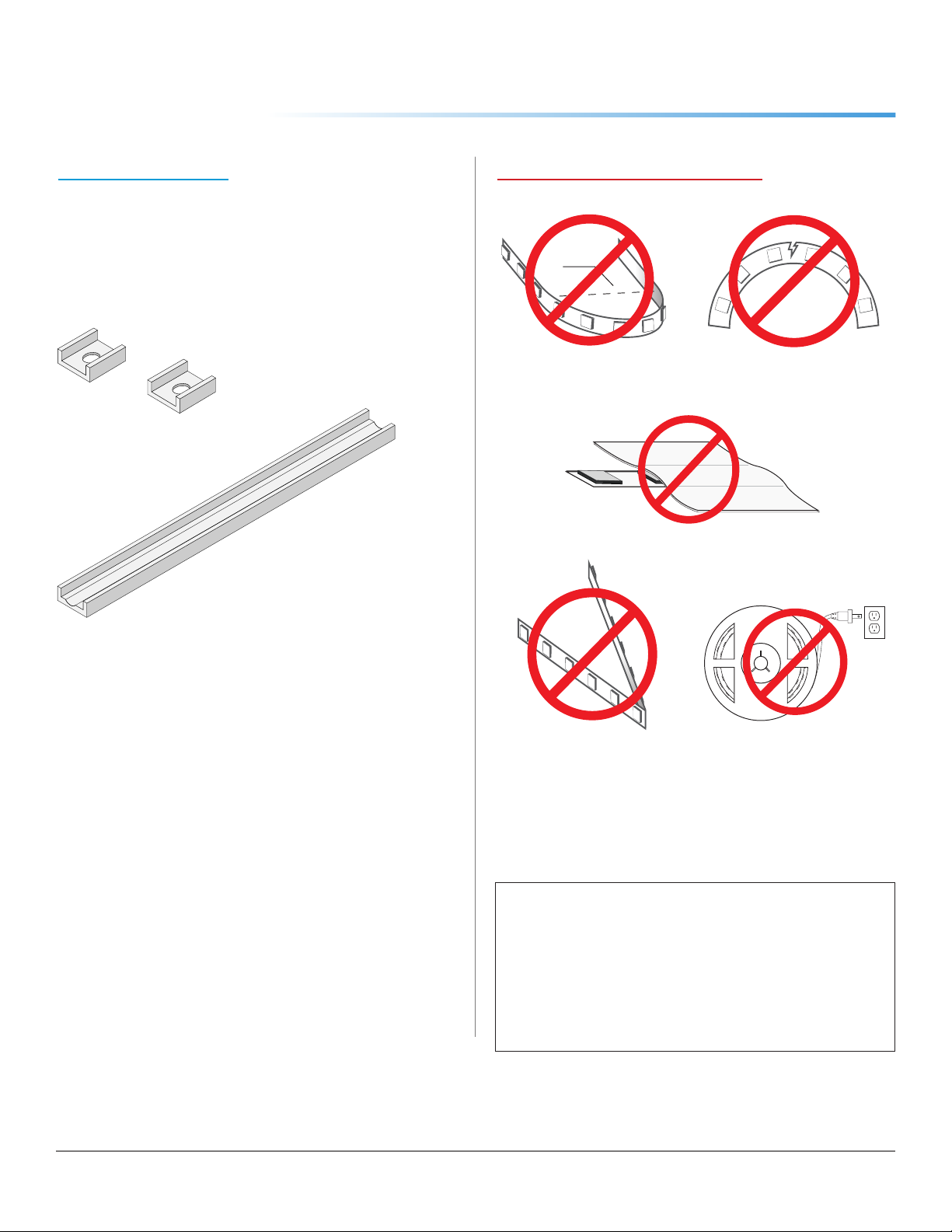

18 AWG 134 . 68 . 45 . 33 . 27 . 22 .

16 AWG 215 . 109 . 72 . 54 . 43 . 36 .

14 AWG 345 . 174 . 115 . 86 . 69 . 57 .

12 AWG 539 . 272 . 181 . 135 . 108 . 90 .

10 AWG 784 . 397 . 263 . 197 . 158 . 131 .

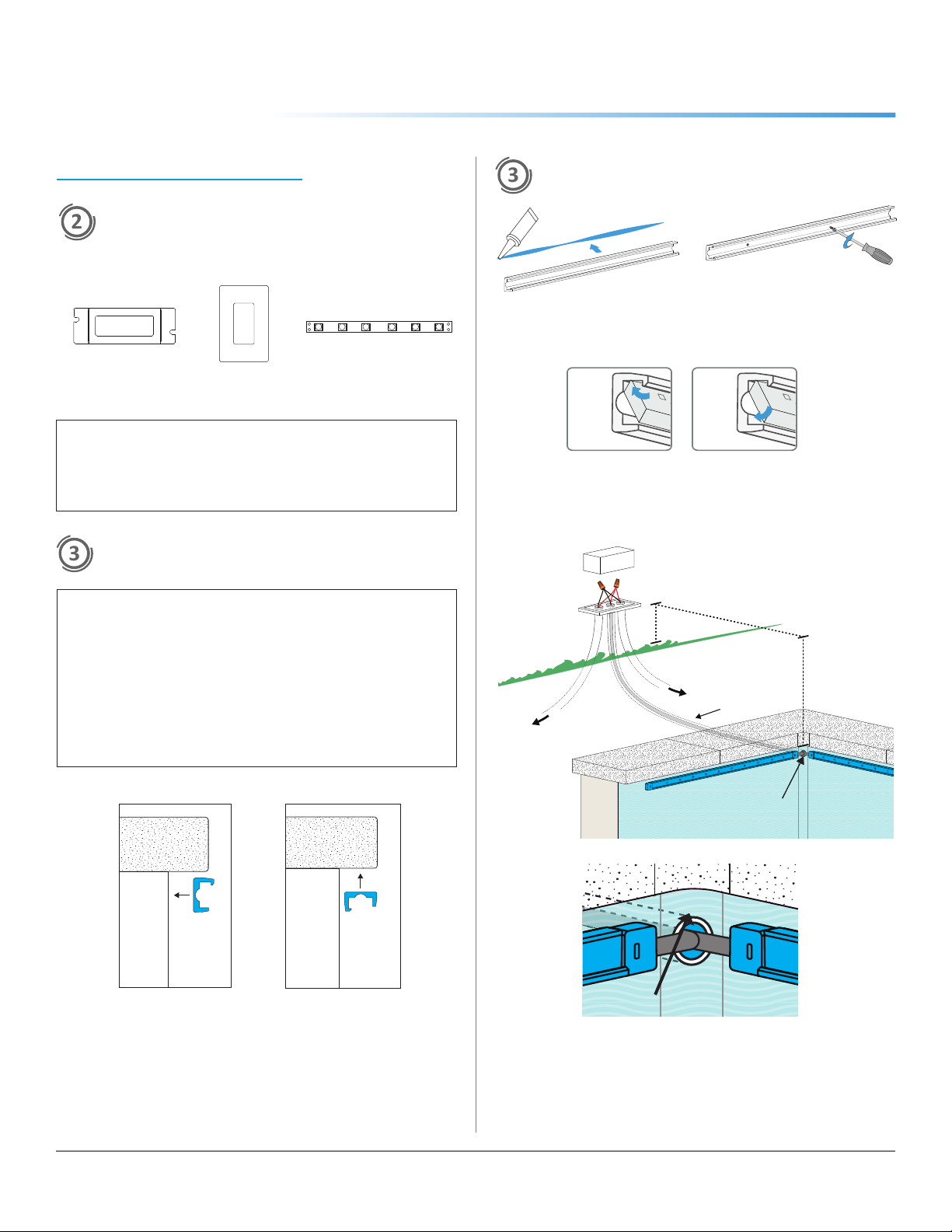

INSTALLATION (676) (CONT.)

Wire

Gauge

10 W

.42 A

20 W

.83 A

30 W

1.3 A

40 W

1.7 A

50 W

2.1 A

60 W

2.5 A

70 W

2.9 A

80 W

3.3 A

100 W

4. 2 A

18 AWG 134 . 68 . 45 . 33 . 27 . 22 . 19 . 17 . 14 .

16 AWG 215 . 109 . 72 . 54 . 43 . 36 . 31 . 27 . 22 .

14 AWG 345 . 174 . 115 . 86 . 69 . 57 . 49 . 43 . 36 .

12 AWG 539 . 272 . 181 . 135 . 108 . 90 . 77 . 68 . 56 .

10 AWG 784 . 397 . 263 . 197 . 158 . 131 . 112 . 98 . 82 .

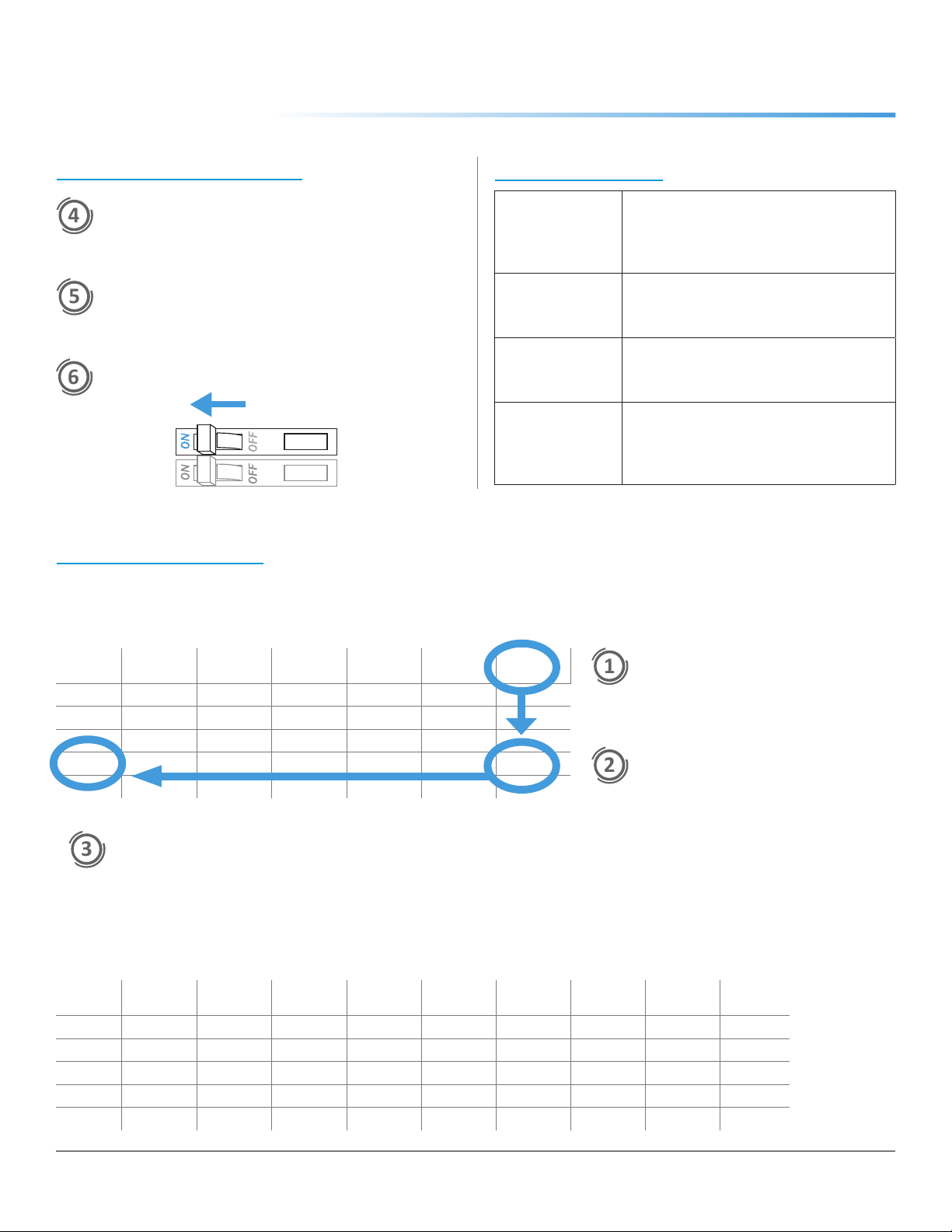

24V Voltage Drop & Wire Length Distance Chart

Example: 24V Voltage Drop & Wire Length Distance Chart

Determine load size. Let’s assume

load is 55 W. Round up to nearest

load.

Determine distance from driver

to load. Let’s assume the

distance is 90 ft.

It is recommended to install 12 AWG to

eliminate excess voltage drop.

VOLTAGE DROP CHARTS

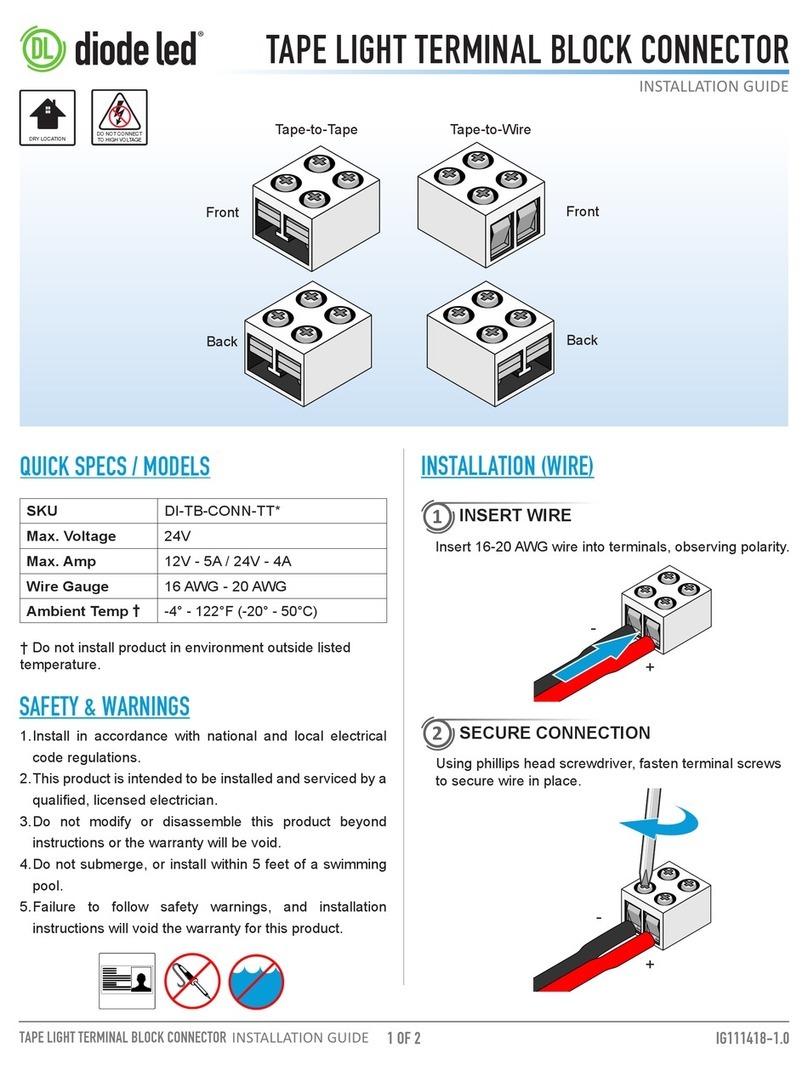

For best performance and lumen output, ensure proper wire gauge is installed to compensate for voltage drop of low voltage circuits.

ATTACH CONTROL AND DRIVER

Verify a compable constant voltage driver is installed. Ulize

applicable wiring when installing outdoors.

REVIEW SYSTEM

Ensure all polaries are correct and connecons are secured.

TURN POWER ON AT CIRCUIT BREAKER

Shift in

brightness

and/or kelvin

• Ensure an appropriate gauge of

wire is installed between strip light

and LED driver. See VOLTAGE

DROP CHARTS.

Some LEDs

are not

functional

• Ensure strip light has not been bent

excessively, which could damage

circuitry.

Lights are

ickering

• Ensure a compatible driver and/or

dimming control is installed. Check

for loose connections.

Lights are

turning on/off

repeatedly

• Ensure driver is not overloaded. An

overloaded driver will trip the internal

auto-reset (of driver) repeatedly,

turning the system on/off.

TROUBLESHOOTING