1592007261 XR70C-D XR72C GB r1.0 18.11.2015 XR70C –XR70D - XR72C 2/4

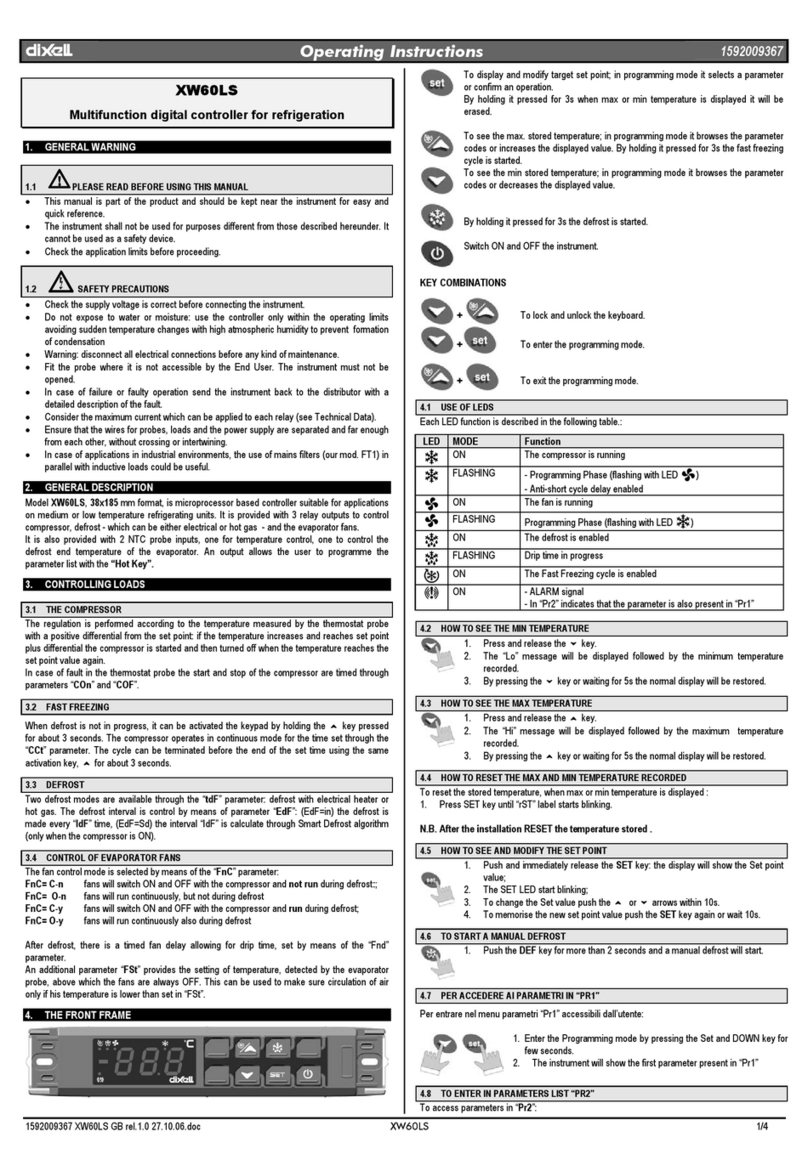

6. MAIN FUNCTIONS

6.1 HOW TO SEE THE SETPOINT

1. Push and immediately release the SET key: the display will show

the Set point value;

2. Push and immediately release the SET key or wait for 5 seconds to display the probe

value again.

6.2 HOW TO CHANGE THE SETPOINT

1. Push the SET key for more than 2 seconds to change the Set point value;

2. The value of the set point will be displayed and the LED starts blinking;

3. To change the Set value push the o or narrows within 10s.

4. To memorise the new set point value push the SET key again or wait 10s.

6.3 HOW TO START A MANUAL DEFROST

Push the DEF key for more than 2 seconds and a manual defrost will

start.

6.4 HOW TO CHANGE A PARAMETER VALUE

To change the parameter’s value operate as follows:

1. Enter the Programming mode by pressing the Set and DOWN key for

3s ( and start blinking).

2. Select the required parameter.

3. Press the “SET” key to display its value (now only the LED is

blinking).

4. Use “UP” or “DOWN” to change its value.

5. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + UP or wait 15s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to

expire.

6.5 THE HIDDEN MENU

The hidden menu Includes all the parameters of the instrument.

6.5.1 HOW TO ENTER THE HIDDEN MENU

1. Enter the Programming mode by pressing the Set + nkey for 3s

(LED 1 and start blinking).

2. When a parameter is displayed keep pressed the Set+nfor more

than 7s.

The Pr2 label will be displayed immediately followed from the HY

parameter. NOW YOU ARE IN THE HIDDEN MENU.

3. Select the required parameter.

4. Press the “SET” key to display its value (Now only the LED is blinking).

5. Use o or nto change its value.

6. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + o or wait 15s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to

expire.

6.5.2 HOW TO MOVE A PARAMETER FROM THE HIDDEN MENU TO

THE FIRST LEVEL AND VICEVERSA.

Each parameter present in the HIDDEN MENU can be removed or put into “THE FIRST

LEVEL” (user level) by pressing “SET + n”.

In HIDDEN MENU when a parameter is present in First Level the decimal point is on.

6.6 HOW TO LOCK THE KEYBOARD

1. Keep pressed for more than 3 s the UP and DOWN keys.

2. The “POF” message will be displayed and the keyboard will be locked. At this point it will

be possible only to see the set point or the MAX o Min temperature stored

3. If a key is pressed more than 3s the “POF” message will be displayed.

6.7 TO UNLOCK THE KEYBOARD

Keep pressed together for more than 3s the o and nkeys, till the “Pon” message will be

displayed.

6.8 THE CONTINUOUS CYCLE

When defrost is not in progress, it can be activated by holding the “o”

key pressed for about 3 seconds.

The compressor operates in continuous mode for the time set through the “CCt” parameter.

The cycle can be terminated before the end of the set time using the same activation key “o”

for 3 seconds.

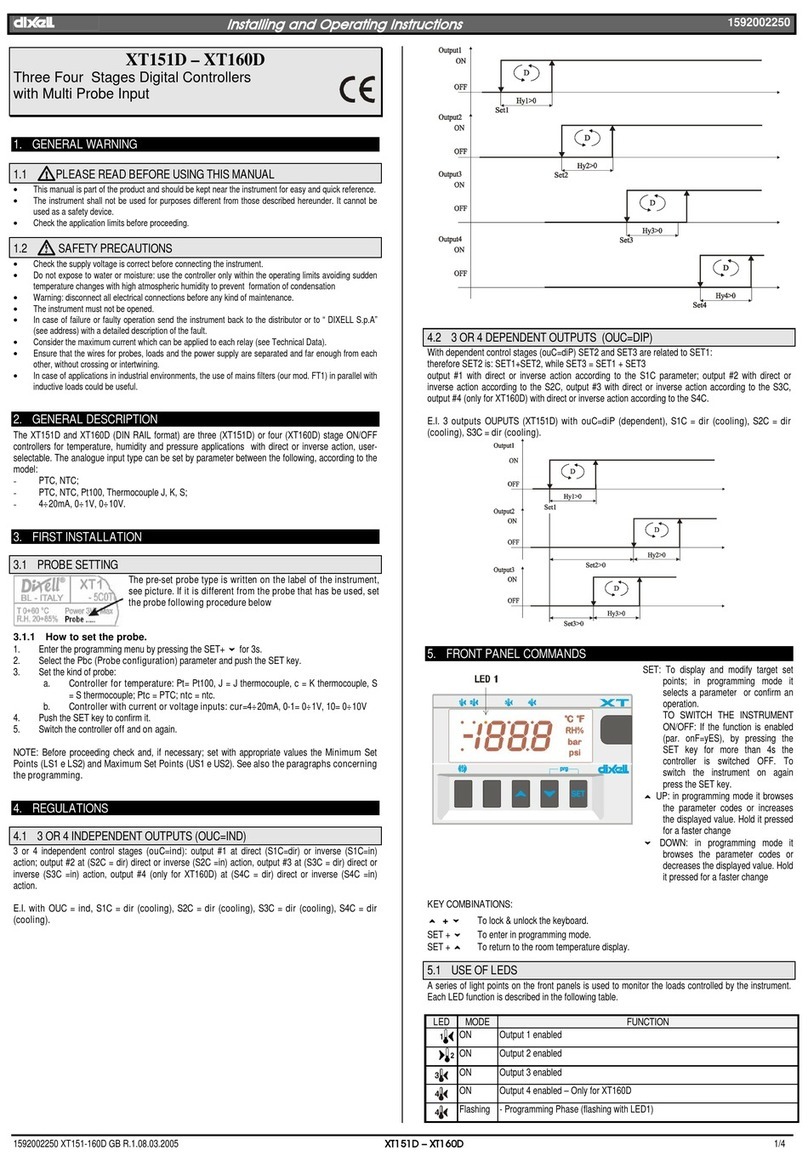

7. PARAMETERS

NOTE: the parameters preceded by dots are in the Hidden Menu.

REGULATION

Hy Differential: (0,1 ÷ 25,5°C / 1÷255 °F) Intervention differential for set point. Compressor

Cut IN is Set Point Plus Differential (Hy). Compressor Cut OUT is when the temperature

reaches the set point.

LS Minimum set point: (- 50°C÷SET/-58°F÷SET): Sets the minimum acceptable value

for the set point.

US Maximum set point: (SET÷110°C/ SET÷230°F). Set the maximum acceptable

value for set point.

Ot Thermostat probe calibration: (-12.0÷12.0°C; -120÷120°F) allows to adjust possible

offset of the thermostat probe.

P2P Evaporator probe presence: n= not present: the defrost stops by time; y= present: the

defrost stops by temperature.

OE Evaporator probe calibration: (-12.0÷12.0°C; -120÷120°F). allows to adjust

possible offset of the evaporator probe.

OdS Outputs activation delay at start up: (0÷255min) This function is enabled at

the initial start up of the instrument and inhibits any output activation for the period of

time set in the parameter.

AC Anti-short cycle delay: (0÷50 min) minimum interval between the compressor stop and

the following restart.

AC1 2nd compressor delay at start up (only for XR72C). (0÷255s) Time interval between

the switching on of the first compressor and the second one.

CCt Compressor ON time during continuous cycle: (0.0÷24.0h; res. 10min) Allows to

set the length of the continuous cycle: compressor stays on without interruption for the

CCt time. Can be used, for instance, when the room is filled with new products.

COn Compressor ON time with faulty probe: (0÷255 min) time during which the

compressor is active in case of faulty thermostat probe. With COn=0 compressor is

always OFF.

COF Compressor OFF time with faulty probe: (0÷255 min) time during which the

compressor is OFF in case of faulty thermostat probe. With COF=0 compressor is

always active.

DISPLAY

CF Temperature measurement unit:

°C=Celsius; °F=Fahrenheit. WARNING: When the measurement unit is changed the

SET point and the values of the parameters Hy, LS, US, ot, oE, dtE, FCt, FSt, ALU and

ALL have to be checked and modified if necessary).

rES Resolution (for °C): (in = 1°C; dE = 0.1 °C) allows decimal point display.

Lod Display : select which probe is displayed by the instrument: P1 = Thermostat

probe; P2 = Evaporator probe

DEFROST

tdF Defrost type: EL = electrical heater; in = hot gas

dtE Defrost termination temperature: (-50÷50 °C/ -58÷122°F) (Enabled only when

EdF=Pb) sets the temperature measured by the evaporator probe, which causes the end

of defrost.

IdF Interval between defrost cycles: (0÷120h) Determines the time interval between the

beginning of two defrost cycles.

MdF (Maximum) length for defrost: (0÷255min) When P2P = n, (not evaporator probe:

timed defrost) it sets the defrost duration, when P2P = y (defrost end based on

temperature) it sets the maximum length for defrost. With MdF=0 the defrost is disabled.

dSd Start defrost delay: ( 0÷99min) This is useful when different defrost start times are

necessary to avoid overloading the plant.

dFd Temperature displayed during defrost: (rt = real temperature; it = temperature at

defrost start; SEt = set point; dEF = “dEF” label)

dAd MAX display delay after defrost: (0÷255min). Sets the maximum time between

the end of defrost and the restarting of the real room temperature display.

Fdt Drip time: (0

120 min) time interval between reaching defrost termination

temperature and the restoring of the control’s normal operation. This time allows the

evaporator to eliminate water drops that might have formed due to defrost.

dPo First defrost after start-up: (y = immediately; n = after the IdF time)

dAF Defrost delay after continuous cycle: (0

23.5h) time interval between the end

of the fast freezing cycle and the following defrost related to it.

FANS

FnC Fans operating mode: C-n= runs with the compressor, OFF during defrost;

o-n = continuous mode, OFF during defrost;

C-Y = runs with the compressor, ON during defrost;

o-Y = continuous mode, ON during defrost;

Fnd Fans delay after defrost: (0÷255min) Time interval between end of defrost and

evaporator fans start.

Fct Temperature differential avoiding short cycles of fans (0÷59°C; Fct=0 function

disabled). If the difference of temperature between the evaporator and the room probes

is more than the value of the Fct parameter, the fans are switched on.

FSt Fans stop temperature: (-50÷50°C/122°F) setting of temperature, detected by

evaporator probe, above which fans are always OFF.

ALARMS

ALC Temperature alarms configuration: (Ab; rE)

Ab= absolute temperature: alarm temperature is given by the ALL or ALU values. rE =

temperature alarms are referred to the set point. Temperature alarm is enabled when the

temperature exceeds the “SET+ALU” or “SET-ALL” values.

ALU MAXIMUM temperature alarm: (SET÷110°C; SET÷230°F) when this temperature is

reached the alarm is enabled, after the “ALd” delay time.

ALL Minimum temperature alarm: (-50.0 ÷ SET°C; -58÷230°F when this temperature is

reached the alarm is enabled, after the “ALd” delay time.

ALd Temperature alarm delay: (0÷255 min) time interval between the detection of an

alarm condition and alarm signalling.

dAO Exclusion of temperature alarm at startup: (from 0.0 min to 23.5h) time interval

between the detection of the temperature alarm condition after instrument power on and

alarm signalling.

tbA Alarm relay manual silencing(only for XR70C): (y= when an alarm is

occurring the alarm relay is disabled by pushing a key; n=the alarm relay is activated for

the duration of the alarm).