SAFETY PRECAUTIONS

TO PREVENT ANY RISK OF ELECTRIC

SHOCK OR FIRE, READ THIS MANUAL

CAREFULLY BEFORE INSTALLING THE

EQUIPMENT.

In the event of a problem or if you do not

understand, contact REYA.

This equipment is not designed for use

by people (including children) with

diminished physical, sensorial or mental

capacities or people without experience

or knowledge of such equipment, unless

they have received instructions in the

use of the equipment from a person

responsible for their safety or are under

the supervision of such a person. Ensure

that children are supervised to avoid

them playing with the device.

This equipment contains components

that may cause electric arcs or sparks,

when connecting cables for example. To

prevent any risk of re or explosion, do not

install this equipment close to inammable

materials, liquids or gases.

Installation precautions.

In order to prevent any risk of permanent

damage to the charger, the following

recommendations should be strictly

observed.

4The device must not be installed close

to a heat source.

4It must not be installed in an airtight or

badly-ventilated compartment.

4The cooling vents must not be

obstructed.

4Leave a free space of at least 10 cm

all around the case, to allow proper

convection.

4This device must not be exposed to

running water, water spray or dust of any

nature.

4It is recommended that the charger be

mounted vertically, with the cable exit

facing downwards.

4The case must not be mechanically

modied, for example by drilling additional

holes.

4In no sense is this device a toy. It should

therefore not be left in the hands of a

child.

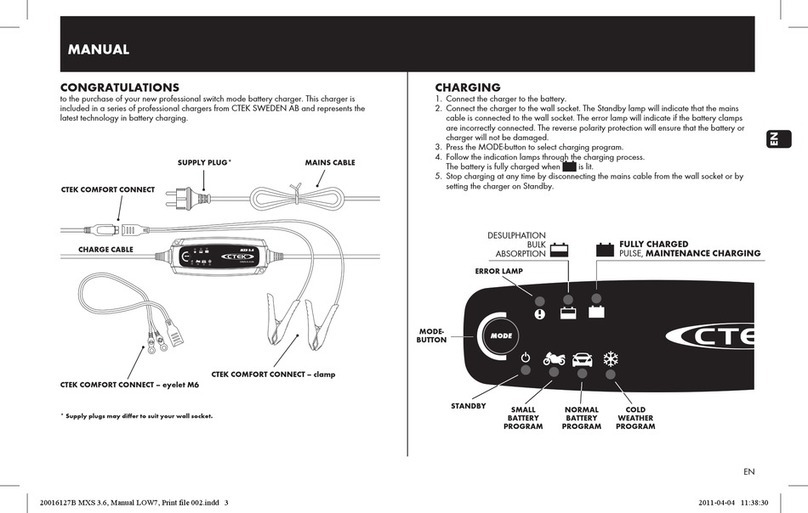

Connection precautions.

To prevent any risk of electric shock or

irreversible damage to the equipment,

ensure you scrupulously respect the

recommendations below.

4The installation to which the device

is connected must be compliant with

applicable standards.

4The charger is designed to operate on

single phase mains power supplies 230V

50Hz or 115V 60Hz. 115V / 230V selection

is automatic. (230V only for the 24V100A

model)

4The mains power supply must have

a main power on/off switch, with

differential protection, to protect persons,

notably in cases of electric shock. Refer

to the charger electrical consumption

characteristics for the rating and selection

of the protection circuit breaker.

4Before connecting the charger, the

mains power cable grommet supplied in

the package carton must be assembled

and properly mounted on the case (using

the mounting nut), in the specic hole

provided.

4For safety, the charger EARTH terminal

(marked PE “Protective Earth”) must be

connected to the main site earth circuit

EN

SAFETY PRECAUTIONS