4

1.OO overview

1.O4 Panel Dimensions

Panel Height: 4 & 6 & 8 product: 17.9 in (455 mm)

Panel Width: 4 & 6 product: 37.2 in (945 mm)

8 product: 45.1 in (1145 mm)

Panel Depth: 4 & 6 & 8 product: 8 in (203 mm)

1.O3 Package Contents

Multi-Washer 3000 with EvoClean

Metric Models

North America Models

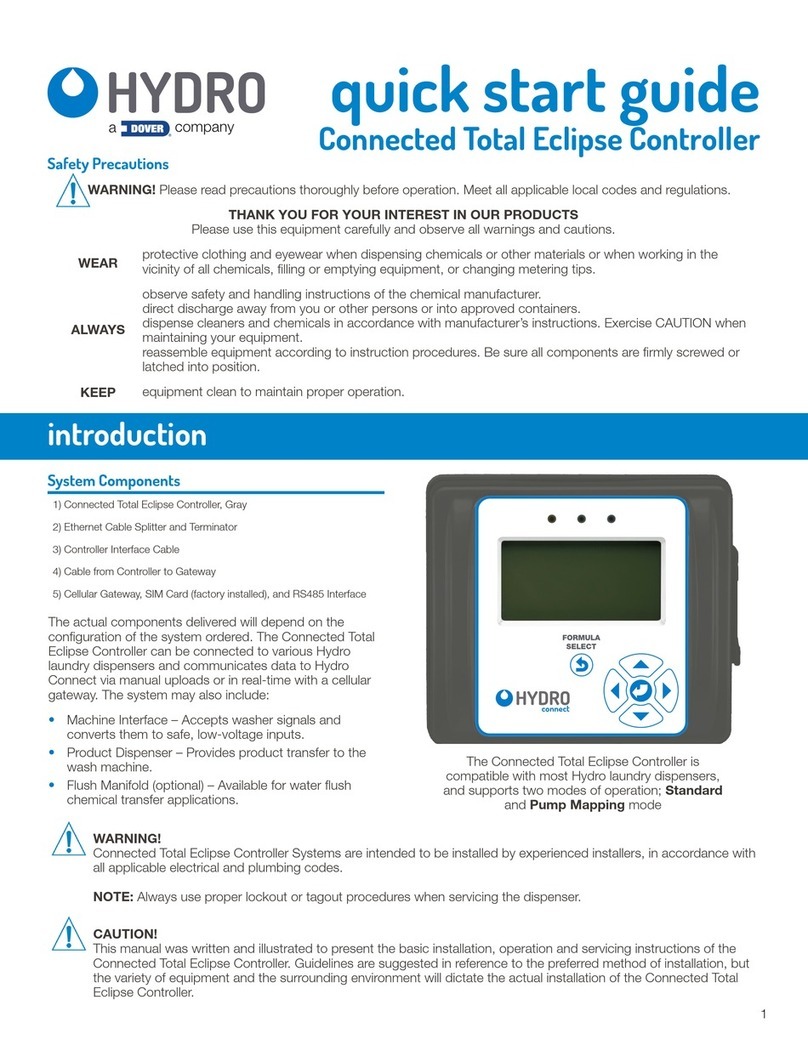

A key feature to these systems is delivering up to 8

chemicals to up to 3 washers using the low-maintenance,

highly accurate EvoClean dispenser.

Aiding in the reliability and longevity of the system is a water

flush that cleans the entire channel after every product

delivery. The eductors, manifold, and all the way through

the distribution manifold to the washer is flushed with

clean water, to prevent the effects of long-term chemical

exposure.

2.OO installation

2.O1 Preliminary Tasks

• Choose a clear and flat wall near to the laundries machines.

• It is highly recommended to use the specific kit of materials for installation which is available under request. In case the

elements for mounting are obtained from local providers, all items should be the same as the ones listed in the kit.

• In case a previous unit is already working in the site, all the existing elements must never interfere with the new installation.

2.O2 Panel Mounting

• In order to make the unit work correctly, it must be

placed on a clear and flat wall.

• The system must be placed at such a height that the

dispenser and control box can be easily accessed.

• The panels’ approximate mounting dimensions are

shown to the right but may vary slightly. Use the panel

being installed as a template.

• To use the supplied mounting hardware, drill four 5/16

in (8 mm) holes at the locations indicated, and insert the

included anchors.

• Place the unit on the wall and use the provided

fasteners to affix it securely.

HYDSPD0093M 4P, 3WE, 1CH, EVCL, V, MET

HYDSPD0091M 6P, 3WE, 1CH, EVCL, V, MET

HYDSPD0092M 8P, 3WE, 1CH, EVCL, V, MET

HYDSPD0093 4P, 3WE, 1CH, EVCL, V, USA

HYDSPD0091 6P, 3WE, 1CH, EVCL, V, USA

HYDSPD0092 8P, 3WE, 1CH, EVCL, V, USA

37.2 in (945 mm)

17.9 in (455 mm)

16.7 in

(425 mm)

45.1 in (1145 mm)

36 in (915 mm)

43.3 in (1115 mm)

8 in (203 mm)

4 Product

4+6 Product

6 Product

8 Product

8 Product

16.7 in

(425 mm)

Multi-Washer 3000 with 6-Product EvoClean