DSF-A.DOC 11/02 1

DOYON SEMI-AUTOMATIC DIVIDER ROUNDER

DSF015 / DSF022 / DSF030

TABLE OF CONTENTS

TO GET THE BEST PERFORMANCE OF YOUR MACHINE, PLEASE READ THIS

MANUAL CAREFULLY.

CHAPTER 1 - RECEPTION OF THE MERCHANDISE . . . . . . . . . . . . . . . . . . . 2

- NAMEPLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHAPTER 2 - GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 3 - THE USE OF THE DIVIDER ROUNDER

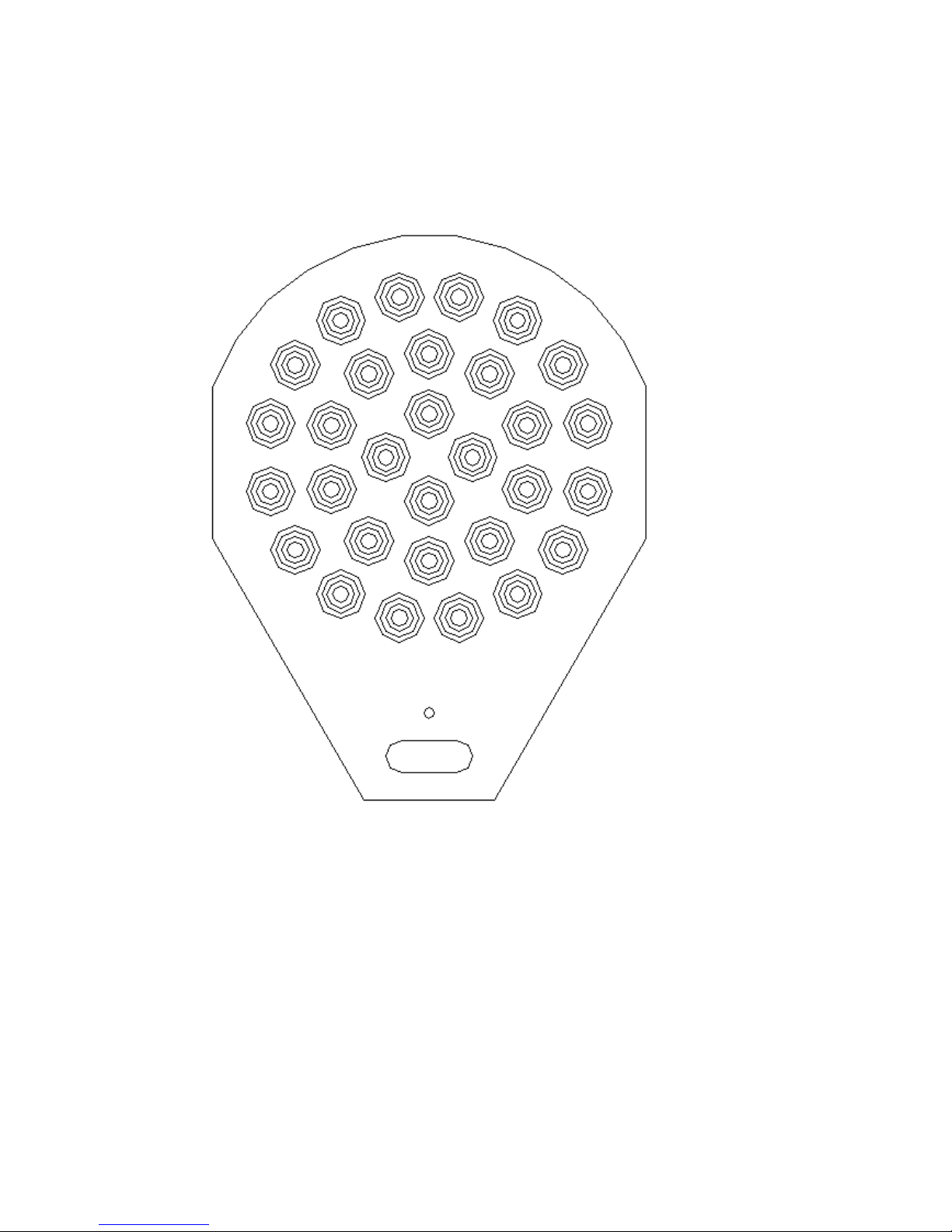

3.1 - General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 - Machine’s characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 - Improper use of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 4 - TECHNICAL DATA

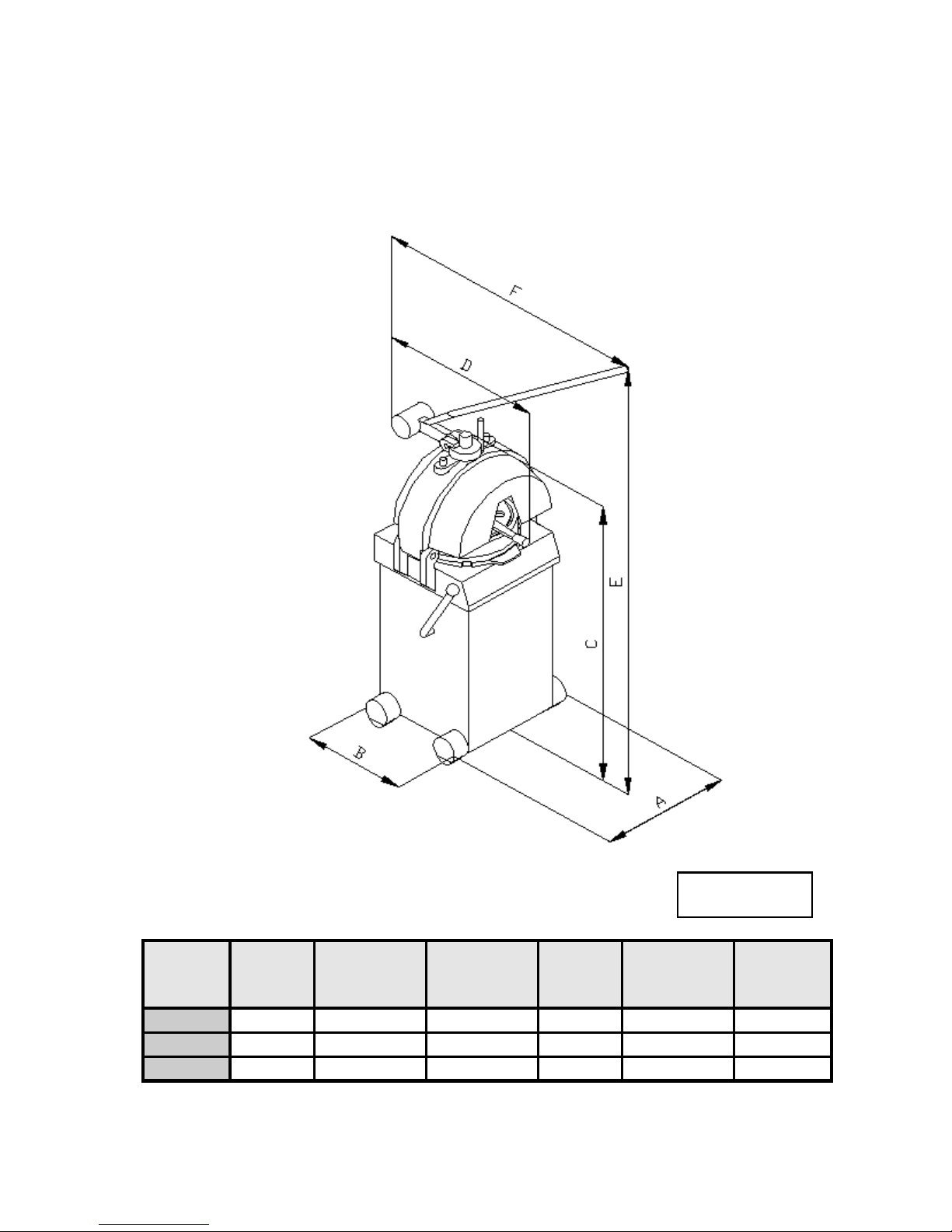

4.1 - General dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 - Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 - Electric specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 - Electric installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.5 - Security system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CHAPTER 5 - ELECTRIC CONNECTION AND INSTALLATION

5.1 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 - Electric installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CHAPTER 6 - THE WORKING PROCESS

6.1 - Description of the working cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CHAPTER 7 - MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ELECTRIC SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18