220V Ultimate Access by Draper Page 2 of 4

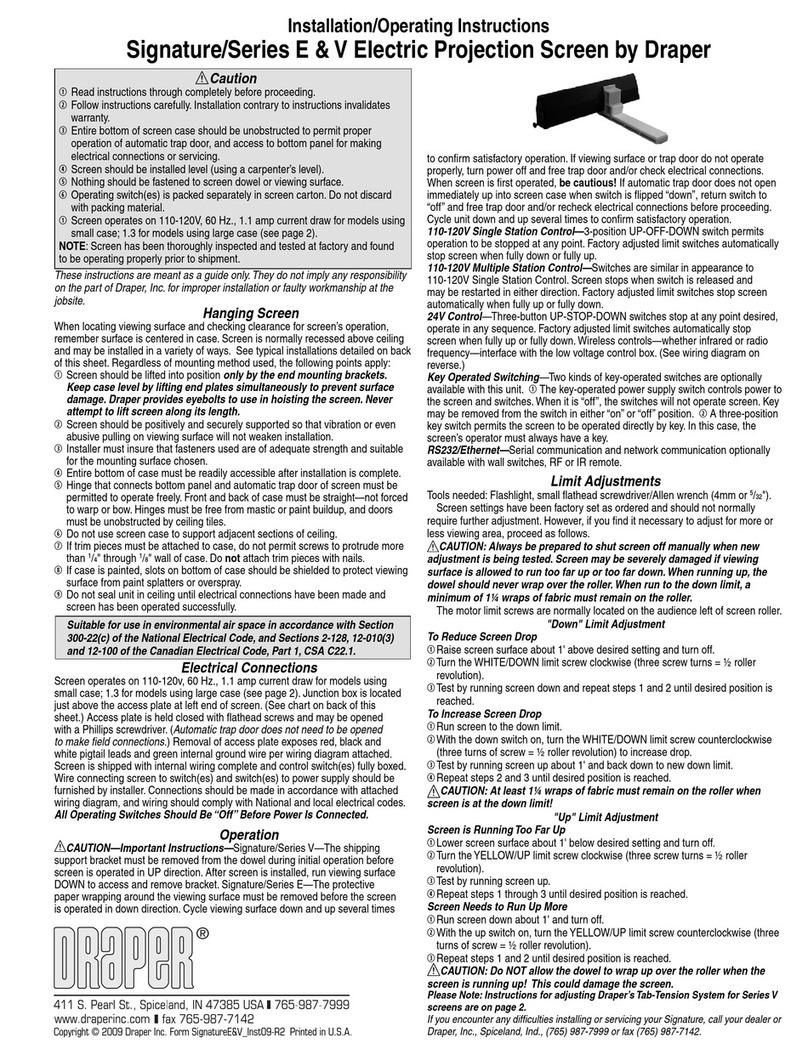

Motor roller

assembly

Retaining

clip

Washer

Idler end roller

mounting bracket

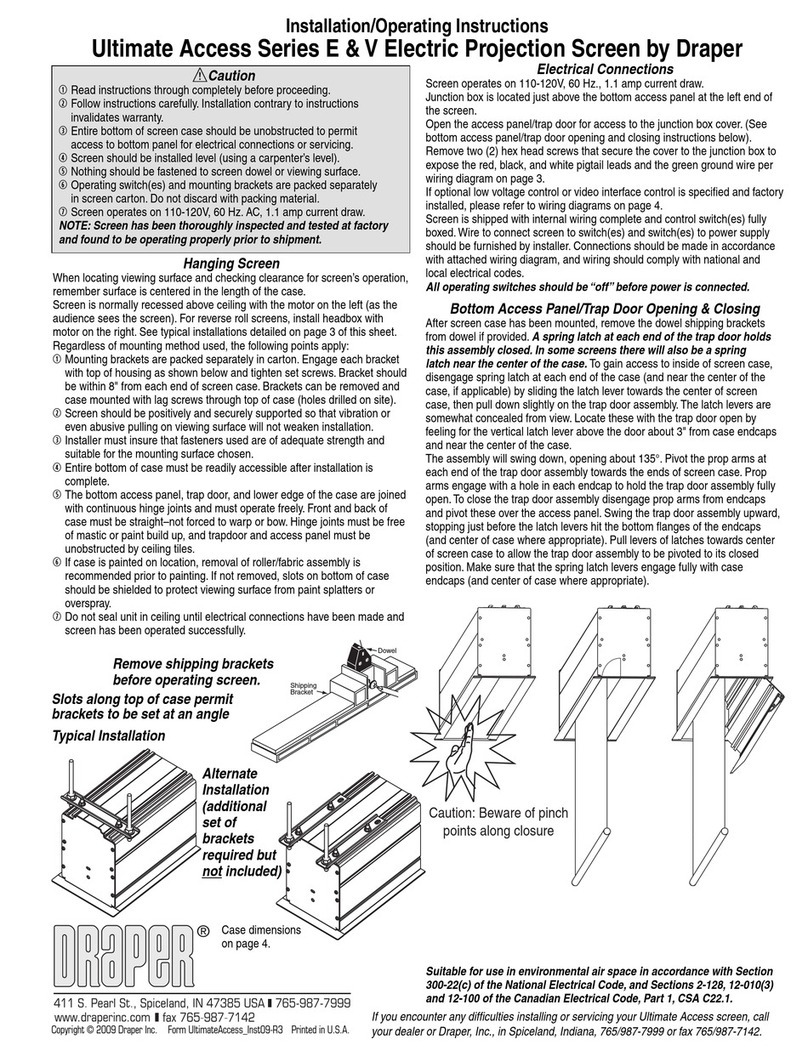

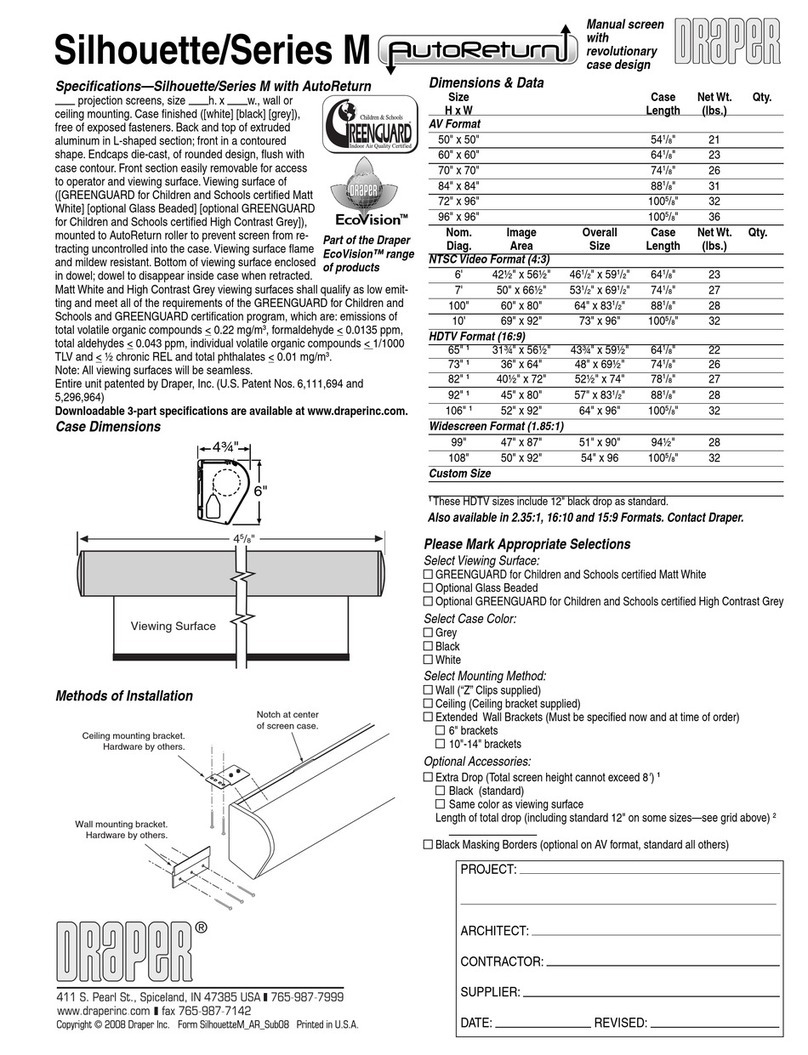

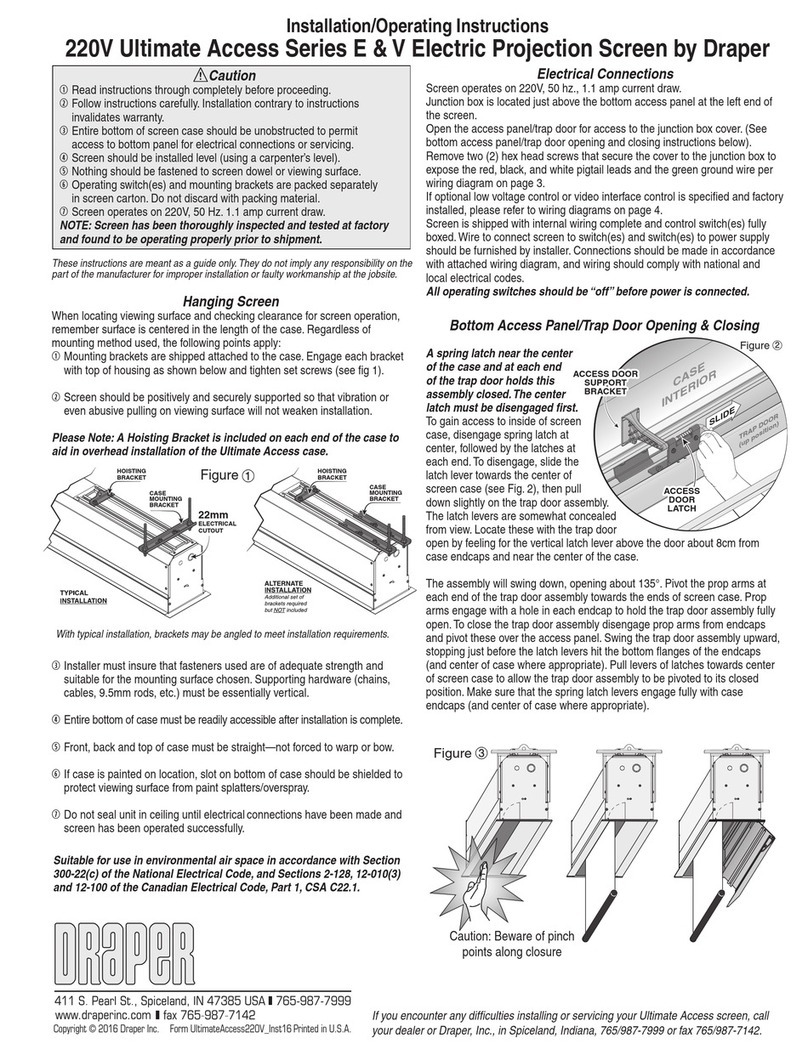

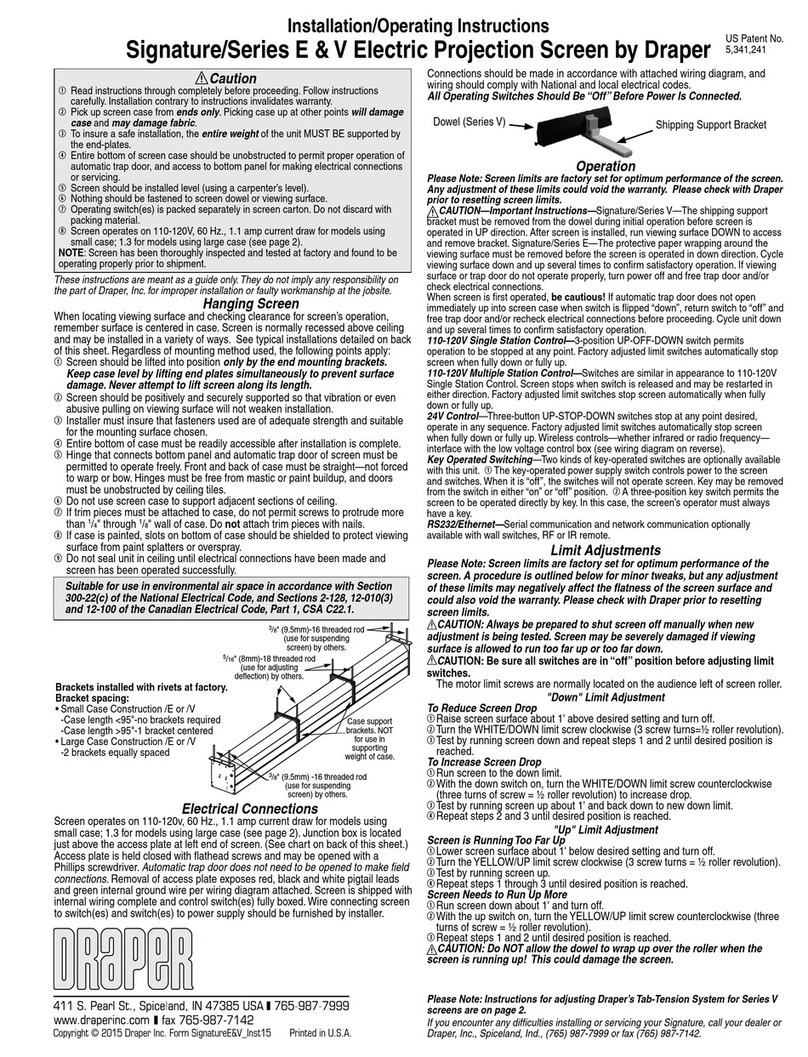

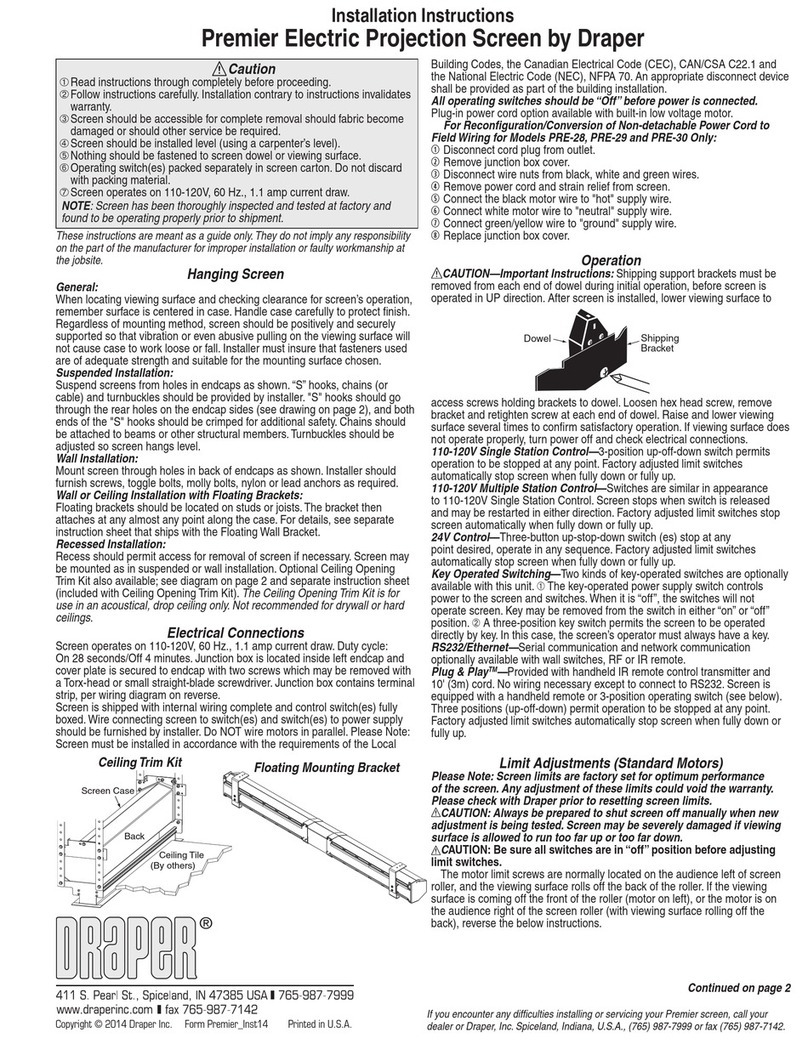

Motorized Roller/Fabric Installation

The bottom access panel/trap door assembly must be opened and placed in fully

opened position first.

The motor end mounting bracket has a metal bracket with snap ring for ac-

cepting motor head. Back out the four set screws in bracket until they are flush

with top side of bracket.

To engage the motor end bracket flange above the two channels in the top of the

screen housing, rotate the bracket approximately 45° counterclockwise to allow

the top surface of the motor bracket to rest flat against the top inside of the hous-

ing. Rotating the bracket clockwise until it is engaged with the channels, slide it

along the length of the housing against the electrical junction box.

Engage the idler end bracket (rectangular mounting pad) in the same manner as

the motor end bracket and slide it toward the opposite end of the screen housing.

Do not tighten the set screws on the brackets until the roller/fabric assembly is

installed, and centered in the case.

Locate the black washer and retaining clip.

Note: This will require two people to

perform safely. Raise the roller/fabric

assembly up into the screen housing and

engage the head of the motor completely

into the motor mounting bracket, making

sure the snap ring engages with the motor

and that the limit switch adjusting knobs

are visible from the bottom of the screen

housing.

While supporting the idler end of the roller,

slide the idler end mounting bracket toward

the roller. Insert the roller pin into the nylon

bushing on the idler end mounting bracket.

The roller idler pin needs to go through

the idler bracket far enough to allow the

washer and retaining clip to be reinstalled

on the pin.

Failure to replace the washer and retaining

clip as shown could result in the sepa-

ration of the roller from the brackets.

The roller/fabric assembly and roller

brackets may need to be slid left or right in

mounting channel of case to center fabric

within screen case.

Securely tighten the set screws on the

roller mounting brackets.

Connect the electrical plug from the motor

to the mating socket on the junction box.

Close the bottom access panel/trap door

as previously described.

Motorized Roller/Fabric Removal

Reverse the instructions above, under

“Motorized Roller/Fabric Installation,” for removal of the unit.

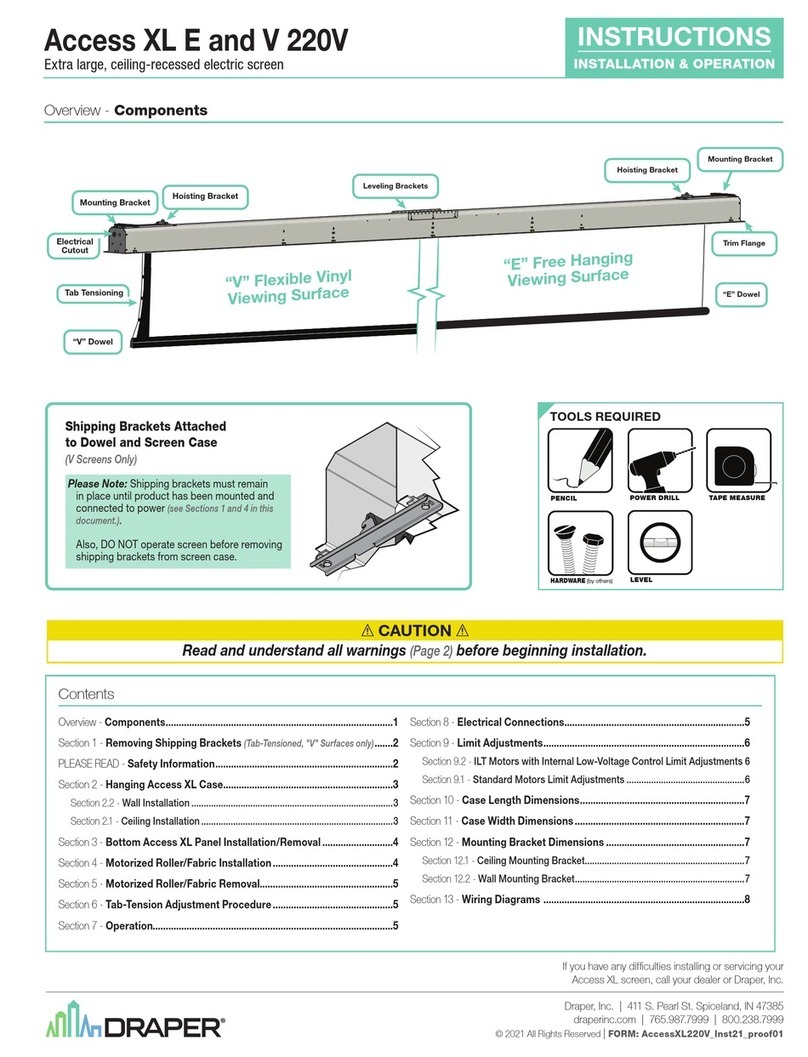

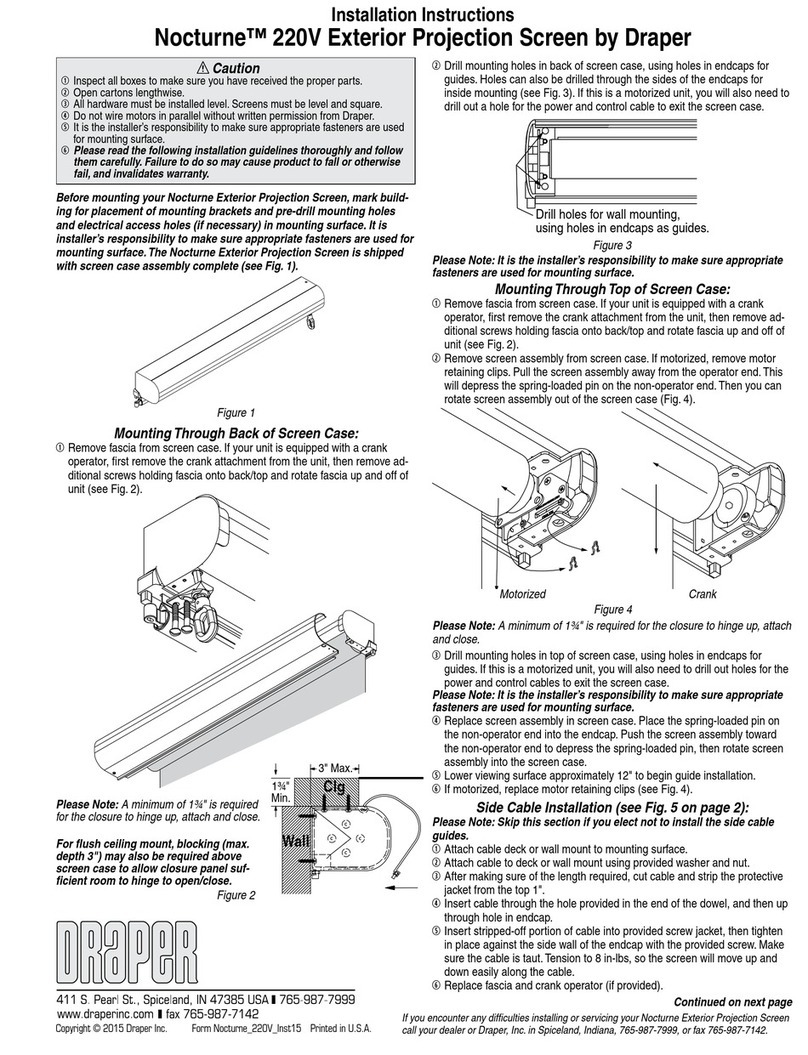

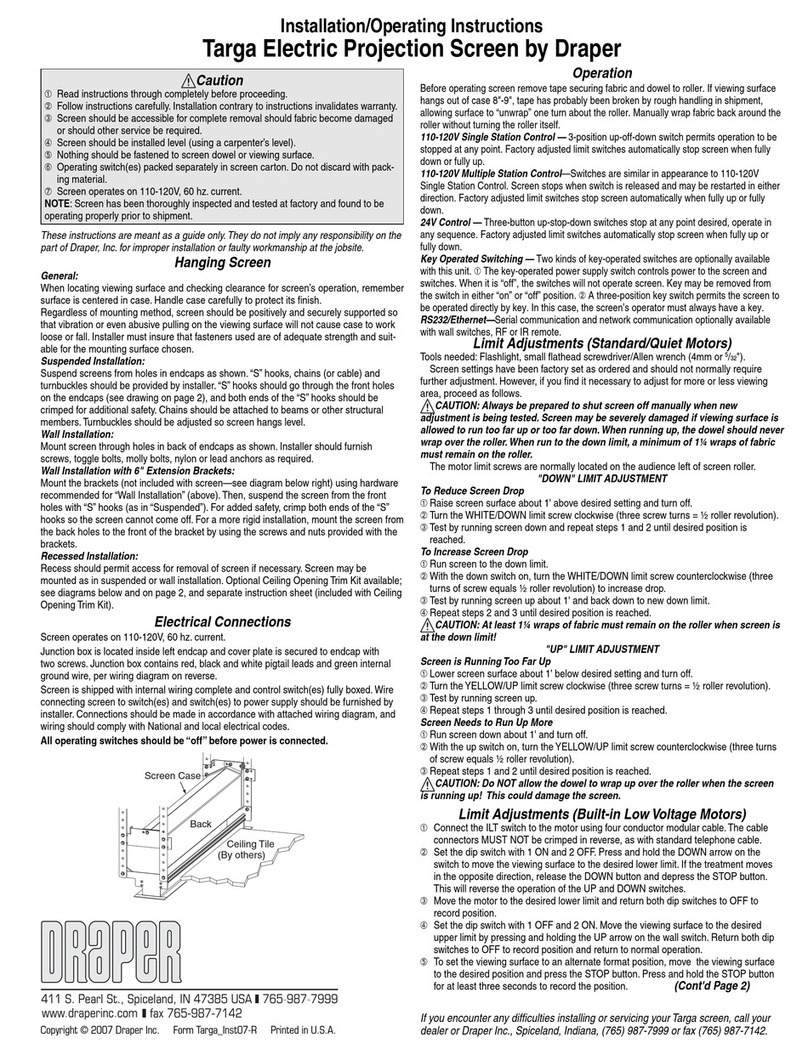

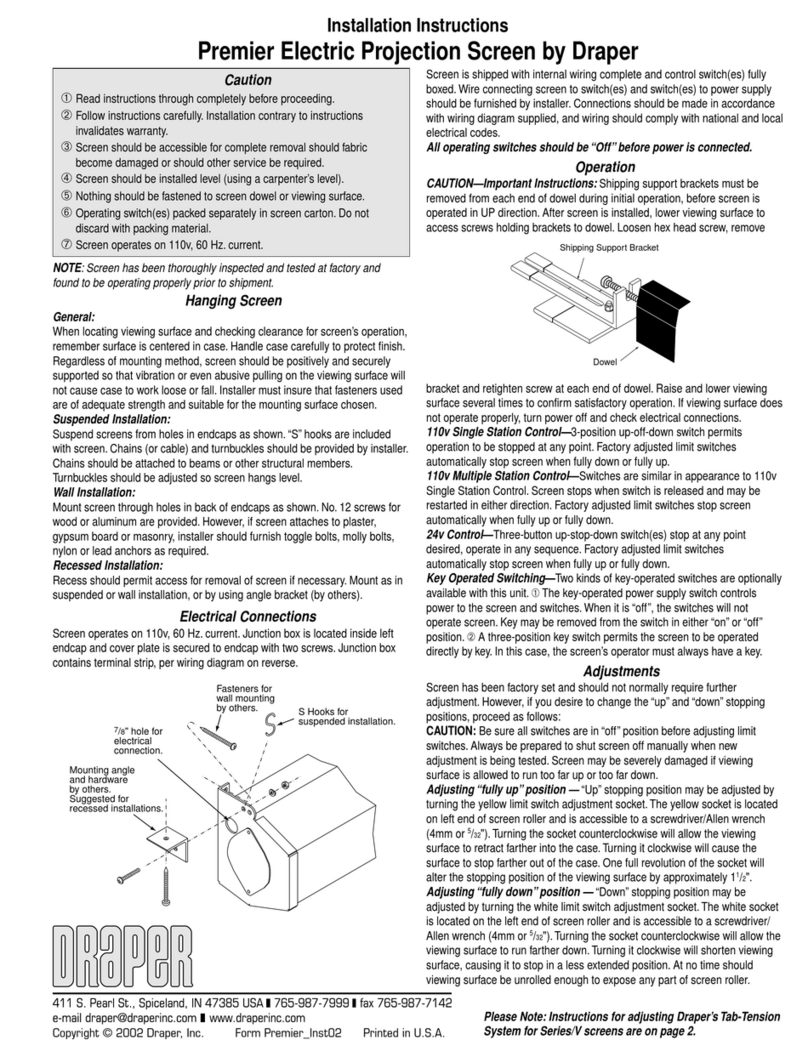

Adjustments

Screen has been factory set and should not normally require further

adjustment. However, if you desire to change the “up” and “down” stopping

positions, refer to drawing below, determine whether you need to adjust

the white or yellow socket, and proceed as follows:

CAUTION: Be sure all switches are in “off” position before adjusting limit

switches. Always be prepared to shut screen off manually when new

adjustment is being tested. Screen may be severely damaged if viewing

surface is allowed to run too far up or too far down.

ADJUSTING WHITE SOCKET—White socket is located on motor end of

screen roller and is accessible to a small flat screwdriver or a 4 mm (

5

/

32

")

hex key. Turning socket counterclockwise will allow the roller to run farther

up or down (as appropriate). Turning it clockwise will shorten operation,

causing screen to stop sooner. One full revolution of the socket will alter

the stopping position of the viewing surface by approximately 32 mm.

ADJUSTING YELLOW SOCKET—Yellow socket is located on the motor

end of screen roller and is accessible to a small flat screwdriver or a 4 mm

(

5

/

32

") hex key. Turning the socket counterclockwise will allow the roller to

run farther up or down (as appropriate). Turning it clockwise will cause the

roller to stop sooner. One full revolution of the socket will alter the stopping

position of the viewing surface by approximately 32 mm.

AT NO TIME SHOULD VIEWING SURFACE BE UNROLLED ENOUGH

TO EXPOSE ANY PART OF SCREEN ROLLER.

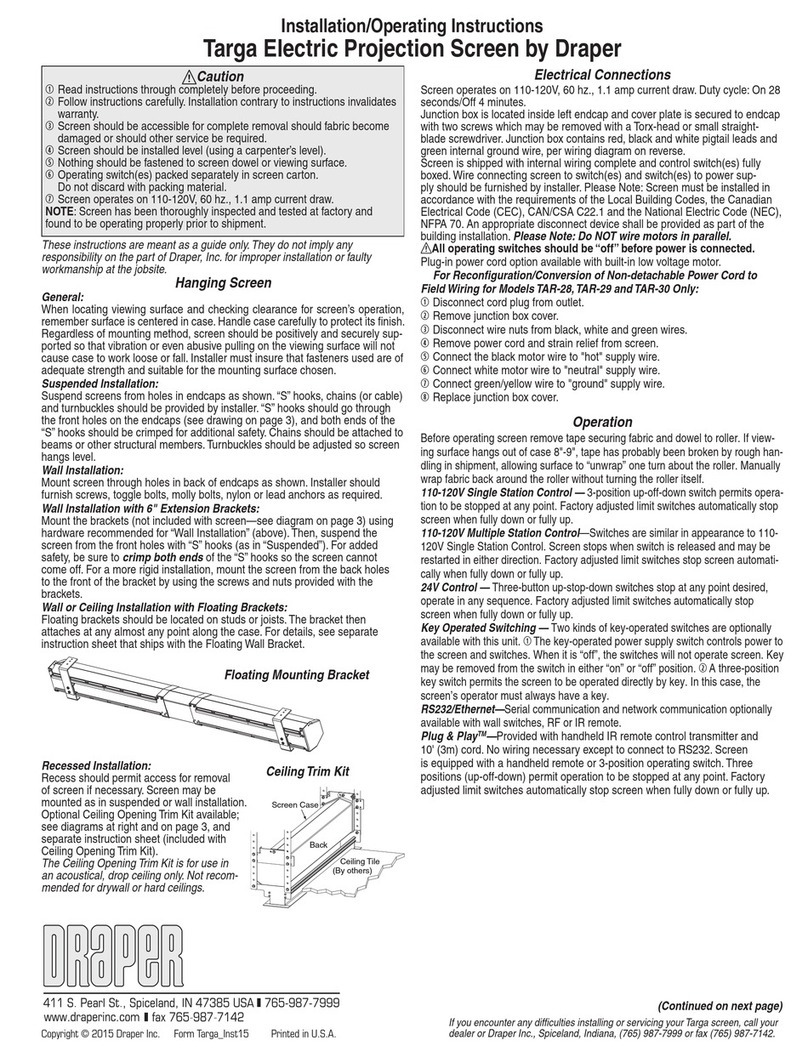

Operation

When screen is first operated, be cautious! Cycle unit down and up

several times to confirm satisfactory operation.

220V SINGLE STATION CONTROL—3-position UP-OFF-DOWN switch

permits operation to be stopped at any point. Factory adjusted limit switch-

es automatically stop screen when fully down or fully up.

220V MULTIPLE STATION CONTROL—(Not CE approved) Switches are

similar in appearance to 220V Single Station Control. Screen stops when

switch is released and may be restarted in either direction. Factory adjust-

ed limit switches stop screen automatically when fully up or fully down.

24V MULTIPLE STATION CONTROL—Three-button UP-STOP-DOWN

switches stop at any point desired, operate in any sequence. Factory

adjusted limit switches automatically stop screen when fully up or down.

220V & 12V VIDEO INTERFACE CONTROL—(Not CE Approved). Allows

screen to be controlled by a trigger signal—when signal comes on, screen

descends automatically. Two versions: Model VIC220 integrates screen op-

eration with a DRAPER video projector lift or a video projector or tuner with

a 220V switched outlet. Model VIC12 interfaces with 12V switched outlet.

Both available with override switch (VIC–OS), permitting independent

operation. VIC–OS not available with factory installed VIC220 & VIC12.

KEY OPERATED SWITCHING—Two kinds of key-operated switches are

optionally available with this unit.

➀The key-operated power supply switch controls power to screen and

switches. When it is “off”, the switches will not operate screen. Key

may be removed from the switch in either “on” or “off” position.

➁A three-position key switch permits screen to be operated directly by

key. In this case, the screen’s operator must always have a key.

RS232/Ethernet—Serial communication and network communication

optionally available with wall switches, RF or IR remote.

Fabric unrolling from back

of roller

Fabric unrolling from front

of roller

Audience

side

Audience

side

Left hand motor

White Socket—Down

Yellow Socket—Up

Left hand motor

White Socket—Up

Yellow Socket—Down

www.draperinc.com (765) 987-799