11. Safety warning when lifting the product

If the product is lifted by holding only the handle, there is a possibility that

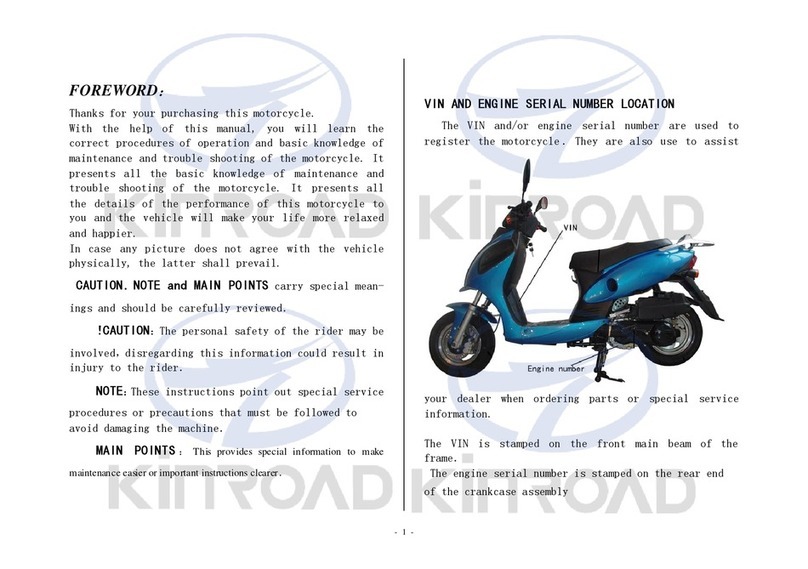

the product may be damaged due to deformation of the folding part due to

load or movement of the product. When lifting the product, be sure to hold

the product's body (footrest) with one hand and hold the handle with the

otherhand so that you do notget hurt in your back or knees.

2) Precaution before driving

1. Night driving should be avoided in any case, besure to wearhelmets andother guards (knees,

elbows,hands, upperbody, etc.) and drivesafely.

2. Select the mode that suits you and drive. In order to cope with the sudden situation, exercise

to slow down tohold the brakeat all times.

3. When turning left / right, slow down to avoid danger of overturning or slipping., And then

slowlyturn safely.

4.

To go to backward, it is safe if you getting off from the productafter stopping before moving.

5. It is prohibited to use in a slippery place, a crowded place, a steep slope, roads with a risk of

accident,uneven road.

6. When crossing a pedestrian crossing, get off from the product for pedestrian safety.

7. Do not drive in a threat any other means of transport, such as animals, pedestrians, bicycles,

motorcycles, cars, etc.

8. If you pass the speed bumps and obstacles, be

sure to slow down.

9. When decelerating or braking, do not stop with

using foot, but stop with using brake appropriately.

10. Be careful that there is a risk of burns due to heat

from motor and brake (especially disk rotor) after

driving.

11. It is prohibited to drive with all the way by holding

thehandlewith one hand.

12. Do not ride ordrive when the kick stand is down.

10. Do not drive onsteepslopes

Acceptable gradeabilityis different for each product. Excessive hill roads

exceeding the specification may cause damage to the product(parts) due

to temperature cut, overcurrent or low voltage cut, which may cause the

product to malfunction.

12. Be sure to wear safety equipment

For the safety of passengers, be sure to wear a full face helmet and the

other protective gear(knee, elbow, hand, upper body) and do not wear shoes

such as slippers, high heels interfere with driving.

9. Do not accelerate downhill

Slow down at downhill. When reducing the speed, to prevent brake

overheat, use the brakes properly to reduce the heat on the disk with

proper brakeuse.

05

Dualtron Storm User Manual