Queries Procedure

Important Information

Please retain all documentation with regards to your purchase.

In the unlikely event that you need to contact us, please do so in writing to:

Email: cs@dunsterhouse.co.uk

Post: FAO Customer Services, Dunster House Ltd - Factory 1, Caxton Road, Bedford, MK41 0LF

Our Customer Services department is open 9:00 - 17:00, Monday to Friday. Please include your Sales Order number

starting with SO or your postcode so we can locate your order.

The nature of timber

The timber provided for this product is a soft wood which has been kiln dried and is pressure treated for protection

against rot and insect infestation.

Timber is a natural product and inherent properties can include knots, knot holes, imperfections, cracks and warping.

Due to the inherent properties of timber we make no guarantees that the timber you receive for your product will be

free from these natural properties. We will not replace any components for any of the following reasons:

•Timber that contains knots where they do not influence the structural stability of the product

•Cosmetics appearances - colour variations

•Timber that has shakes, cracks, gaps or sap which do not influence the structural strength of the product

•Timber that has been covered or buried underground

•Twisted timber that can be installed

•Queries arising from a neglectful manner during assembly or as a result of incorrect assembly

•Queries due to modifications by the owner causing the timber to deform

Any valid queries will be satisfied by the exchange or replacement of the defective parts only on a supply only basis.

Colour transfer

This product has been pressure treated with wood preservative and a brown colour additive. Consideration should be

given to the propensity of the material to stain light colour adjacent surfaces, such as paving flags, render or coated

timber surfaces. We recommend contact between the timber and these surfaces is limited, and careful consideration to

storing the product prior to assembly should be taken in order to prevent such discolouration.

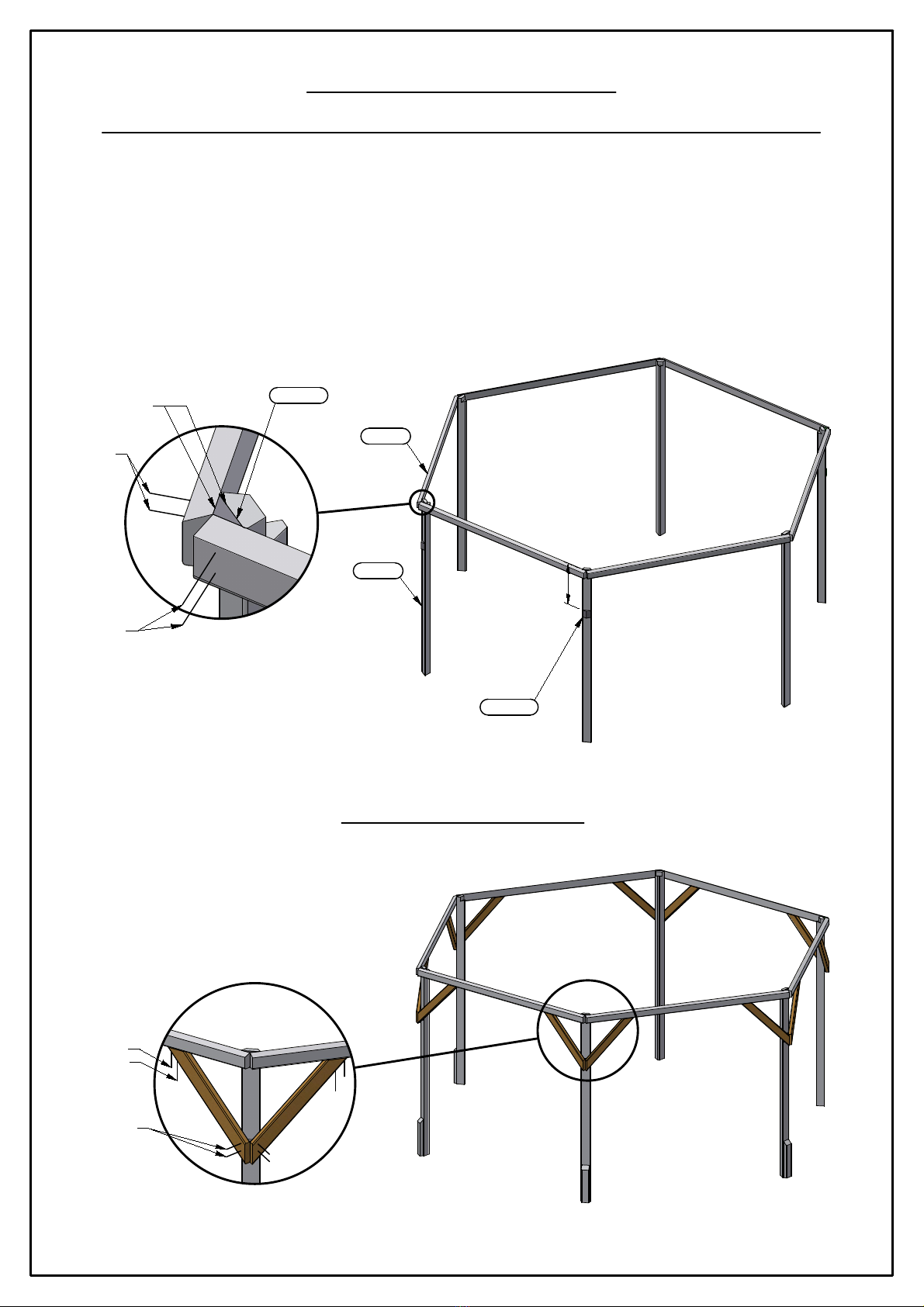

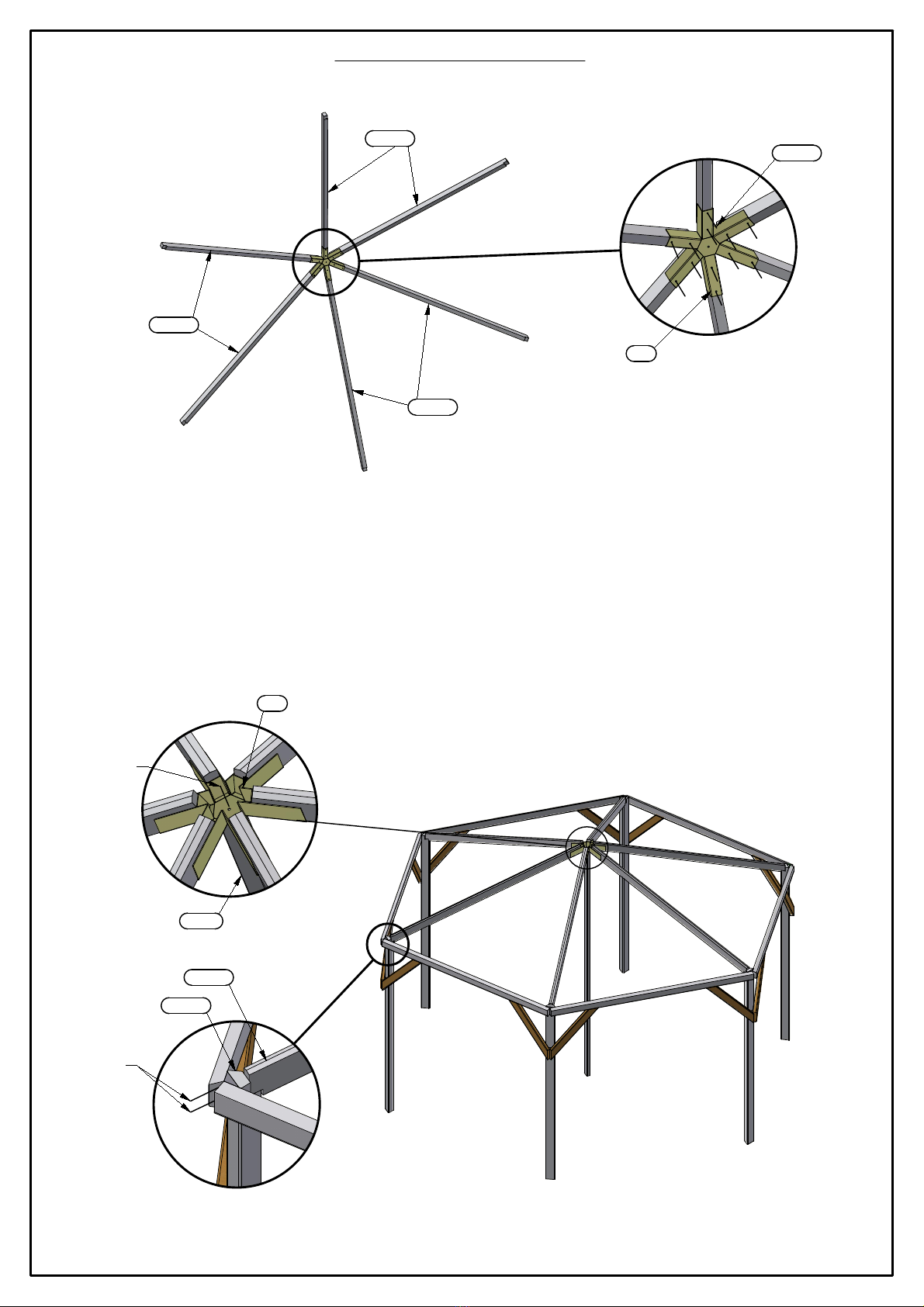

Assembly Preparation

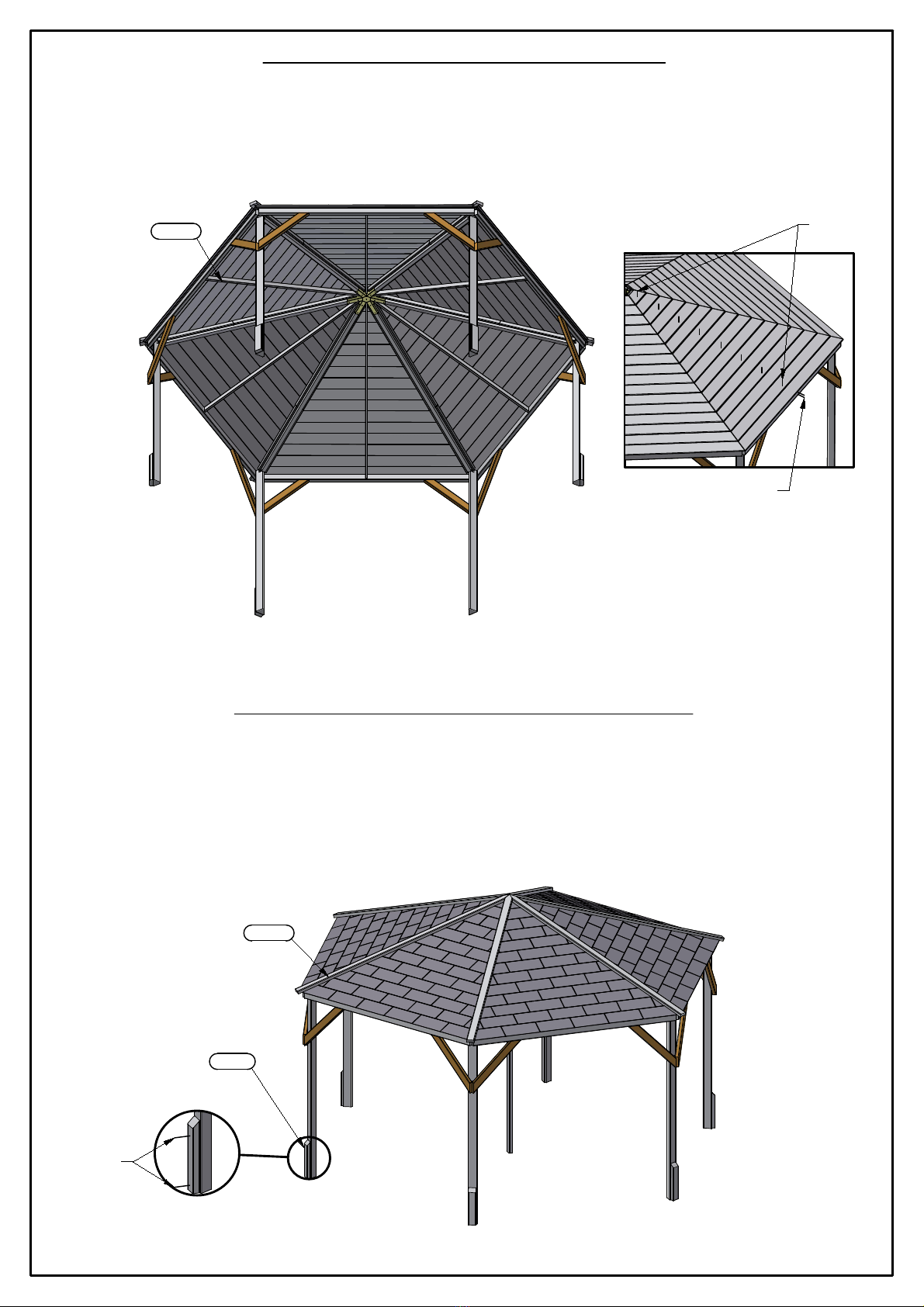

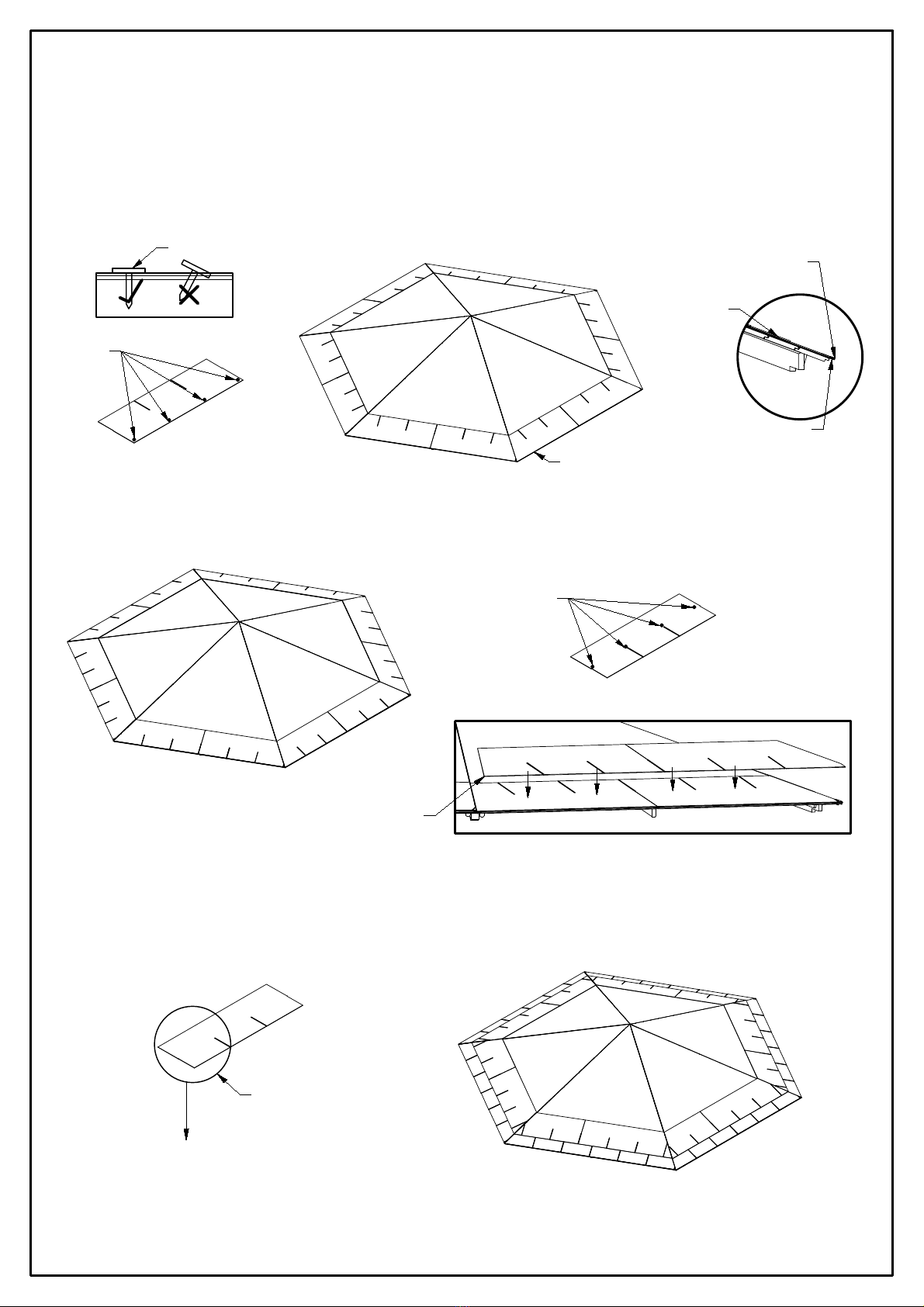

This product has been designed for self-assembly and recommend that assembly is carried out by two DIY competent

people. It is important that the assembly instructions are followed carefully and we recommend that the assembly

instructions are read through in their entirety prior to assembly to allow you to familiarise yourself first.

We recommend ensuring that the product is assembled in an appropriate location and on an appropriate base for

the product. It is imperative that the product is installed square, level and plumb.

To assemble your product we recommend that you have the following:

•Stepladder

•Drill and 3mm drill bit

•Spirit level

•Tape measure

•Screwdriver

•Rubber mallet

•Gloves - if you wish for extra protection when handling pressure treated timber

All screw holes need to be pre-drilled using a 3mm drill bit (not provided) to avoid timber splitting.

Pressure treated products do not need to be treated immediately or have a timber preservative applied.

Pressure treatment does not mean that the timbers are waterproof, so you may wish to apply a water repellent.

Page 1