55

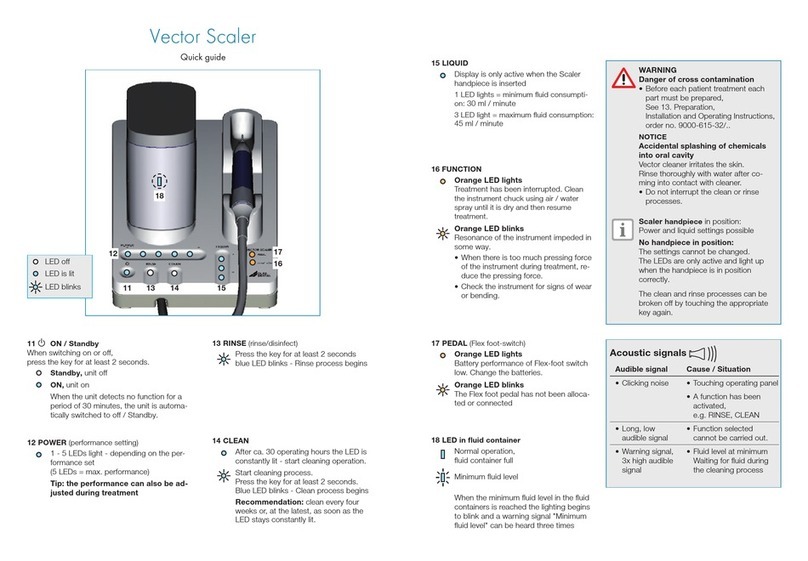

6.3 Electronic Adjustments

117 LED-dimming plug: plugging the bridge

in allows LEDs B, C, D, which show the

operation status on the cover, to be

switched to LIGHT

or DARK in order to

suit the surrounding conditions or the film

sensitivity.

Example: Machine is set up in the dark-

room, where orthochromatic films are used

(e.g. T-Mat G) = LED dimming set at DARK

118 LED lights up when the Service function

is activated.

119,125B Service button

120 Bath temperature potentiometer: for

adjusting the bath temperature

Range of adjustment 20 - 40°C

Works setting = 28°C

121 Process time potentiometer: for setting a

second through-put time

Range of adjustment 3 - 20 minutes

Works setting = 3 minutes

122 Drier 6 minutes potentiometer: drier

output can be adjusted in conjunction

with the 6-minute through-put time.

Range of adjustment 0 - 100%

123 Drier variable potentiometer: drier output

can be adjusted in conjunction with the

variable through-put time.

Range of adjustment 0 - 100%

124 Light beam, flap

125A Button for second through-put time

125B, 119 Service button

Pressing the service button allows the

developer to be turned on for test

purposes. The service button remains

activated for about 20 minutes, during

which time the orange indicator light

flashes.

Pressing the service button again

reverses the command. The orange

(”busy”) LED continues to flash until the

lifting bath has returned to the upper

position.

If a film is inserted into the film intake

while the service button is activated, the

film intake flap is pressed and the normal

film through-put process starts. This takes

precedence over the service button

function.

126 Service plug: a display module can be

connected here to show the pre-set and

actual bath temperature, percentage drier

output, through-put time, etc.

127 6 minute through-put time plug

Plugging the bridge to OFF enables the

6-minute through-put time to be switched

off.

There is then one other through-put time

which can be adjusted at the process

time potentiometer (121).

128 LED top: lifting bath is in the upper

position.

129 LED bottom:

lifting bath is in the lower

position.

If neither of the two LEDs is on, the lifting

bath is travelling either upwards or

downwards.

130 LED film: Film intake flap has been

actuated.

131 LED synchronisation motor: the lift

motor for the lifting bath is switched on,

and the lifting bath is travelling either

upwards or downwards.

132 LED drier: the heater for drying the film is

on.

133 LED water valve, fan: the water valve is

open and the fan is on.

134 LED bath pump: the rotary pump is on.

135 LED bath heating:

the continuous-flow

heater is on.

136 LED roller driver: the driver motor is

activated. The LED flashes at a rate that

corresponds to the speed of the motor.

Electronic regenerator (141)

The electronic regenerator (141) is fitted to the

electronic circuit board at slot (137). The

regeneration time is set at 30 seconds (=

approx. 190 ml developer and fixative) on the

machine as delivered.

137 Slot for electronic regenerator

138 Development time

potentiometer: the

regeneration time can be set between >0

and 60 seconds.

139 Power Regenerator plug:

Bridge at OFF: in this position the

regenerator pump switches on after 1.3

metres of film have been developed.

Bridge at ON: in this position the

regeneration is switched on not only at

the normal regeneration phase but also

every time the mains switch is switched on

140 50%/100% plug: if the bridge is plugged

at the ”50%” position, the pump running

time set at the potentiometer (138) is halved

141 Electronic regenerator