WARNING

READ INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO

INSTALL, OPERATE OR SER ICE THIS WINCH. FAILURE TO COMPLY WITH

INSTRUCTIONS COULD RESULT IN SERIOUS OR FATAL INJURY. RETAIN THESE

INSTRUCTIONS FOR FUTURE REFERENCE.

• This brake winch is built for multi-purpose hauling and lifting operations. It is not to be used as a

hoist for lifting, supporting or transporting people, or for loads over areas where people could be

present.

• Respect this winch. High forces are created when using a winch, creating potential safety hazards.

It should be operated and maintained in accordance with instructions. Never allow children or any-

one who is not familiar with the operation of the winch to use it. A winch accident could result in

personal injury.

• Check winch for proper operation on each use. Do not use if damaged. Seek immediate repairs.

• Never exceed rated capacity. Excess load may cause premature failure and could result in serious

personal injury. This winch is rated on first layer of cable on the hub. Using more layers of cable

increases the load on the winch.

• Never apply load on winch with cable fully extended. eep at least three full turns of cable on the

reel. Check cable on every use. Replace at the first sign of kinks, broken wires, deformation or any

other damage.

• Secure load properly. When winching operation is complete, do not depend on winch to support

load.

• Operate with hand power only. This winch should not be operated with a motor of any kind. If the

winch cannot be cranked easily with one hand, it is probably over-loaded.

• If winch will be used in freezing, icy conditions, apply silicone spray to ratchet pawl and spacer

items, V, W, X, or Y. Do not spray other brake mechanism parts.

WINCH MAINTENANCE – In order to insure

maximum performance, a periodic inspection for

any necessary preventive maintenance should be

made. Check at least once annually and more fre-

quently when the winch is exposed to an environ-

ment which is particularly dirty or wet. For continued

smooth performance and increased life, occasional-

ly grease gears, reel shaft and handle threads. An

PERATING INSTRUCTI NS – Wind cable on

winch reel by turning winch handle in clockwise direc-

tion. This should produce a loud, sharp, clicking

noise. The load will remain in position when the han-

dle is released. Wind cable off the winch reel by turn-

ing winch handle counterclockwise (no noise will be

produced). The load will remain in position when the

handle is released, but for extra security it is recom-

mended that the handle be turned clockwise until at

least two clicks are heard. This will add extra tightness

to the brake mechanism. Always satisfy yourself that

the winch is holding the load before releasing the

winch handle.

IMP RTANT: Sufficient load must be applied to

the cable to overcome internal resistance and oper-

ate the brake properly, otherwise turning the crank

handle counterclockwise will only remove the han-

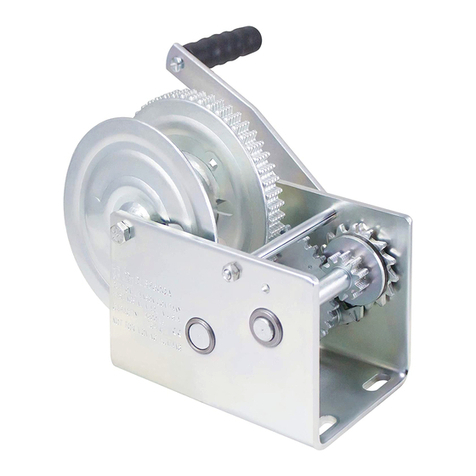

ASSEMBLY – Thread the handle onto the winch

drive shaft and be certain that a clicking noise is pro-

duced when the handle is turned clockwise. Install

the spring and locknut (Items E and G) on the end of

the drive shaft as shown on parts drawing. These

parts may appear to serve no function, but they pro-

vide several important fail-safe features, and should

not be altered or removed.

WINCH M UNTING AND CABLE

ATTACHMENT – For maximum strength and safe-

ty, this winch should be mounted with three 3/8"

bolts (M10), washers and lock washers. Use Grade

8 for 1500 lb/680 kg or greater capacity. (See parts

drawing). Using fewer bolts or alternate locations

will result in damage to the winch base and the

winch may malfunction.

Attach cable or rope by method shown in

sketch.

NOT FOR THE MO EMENT OF HUMAN BEINGS

ENGLISH

IMPORTANT SAFETY INFORMATION

occasional drop of oil on the drive shaft bearings is

also recommended. If winch will be used in freezing,

icy conditions, apply silicone spray to ratchet pawl

and spacer items V, W, X or Y. Note: Do not oil or

grease brake mechanism items H and J.

eep winch in good working order. Damaged or

severely-worn parts create unnecessary dangers and

could result in personal injury or property damage.

dle from the shaft – the reel will not turn. The mini-

mum operating load requirement is 50 lb (23 kg) for

Models DLB350A, DLB350AG, DLB800A,

DLB800AG, DLB1200A and DLB1200AG, 75 lb (34

kg) for DLB1500A and DLB1500AG, 175 lb (80 kg)

for DLB2000AG and DLB2500A.

Models DLB805A, DLB1205A, DLB1505A &

DLB2505A are equipped with a lockout lever for the

purpose of ‘freewheeling’ cable out when there is no

load on the winch. To ‘freewheel’ cable out, simply

turn the handle counterclockwise until lockout lever

can be engaged behind handle hub. In this condition

cable can be easily pulled from the winch drum.

WARNING: Never put winch in freewheel mode if

any potential for a load on the cable exists. Engaging

the lockout lever keeps the winch from stopping in the

event that a load is accidentally applied.

Original Instructions