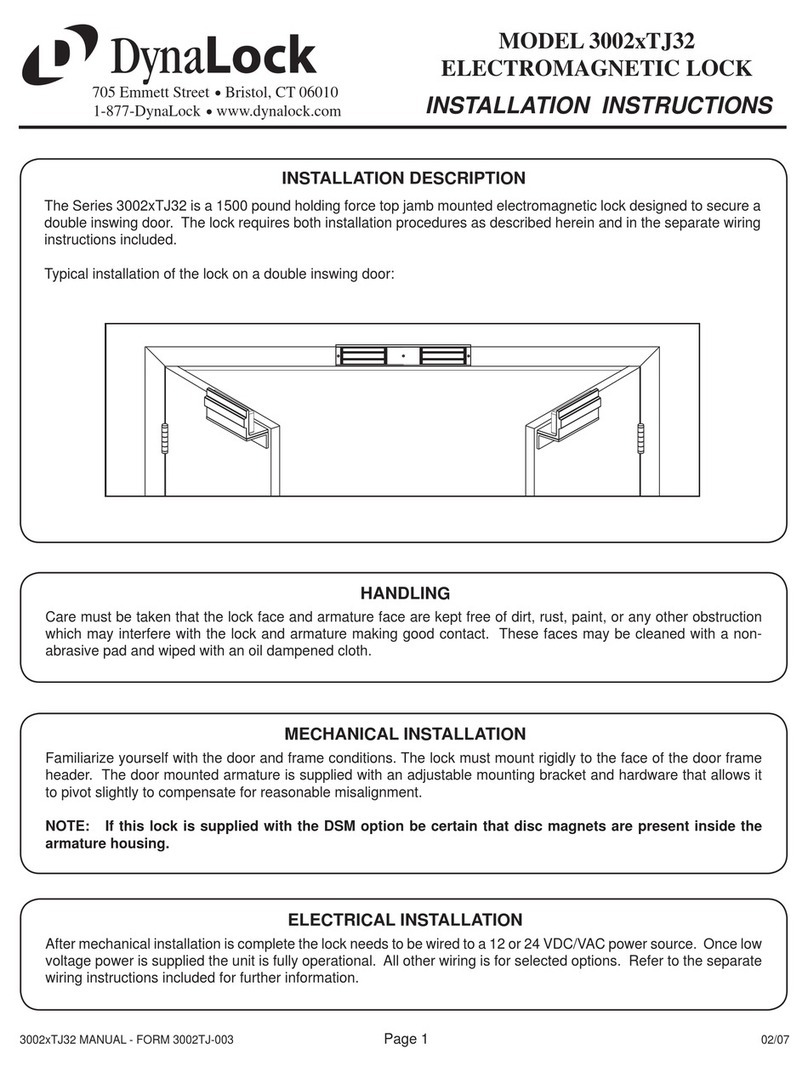

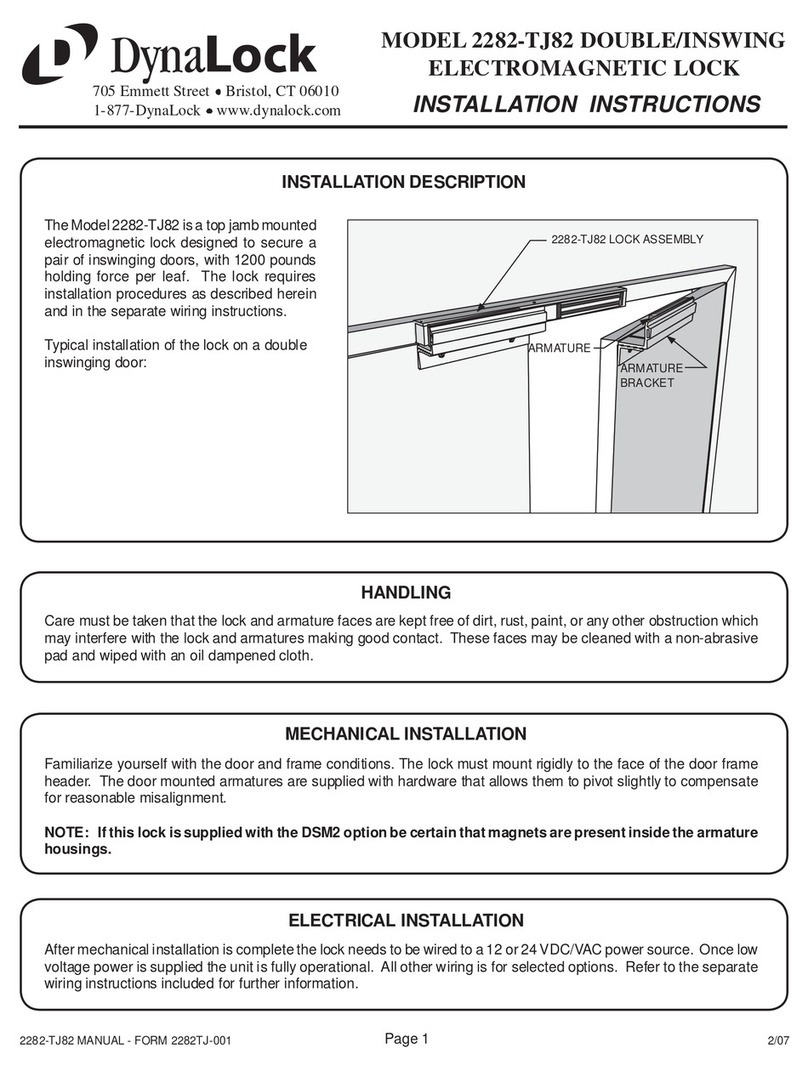

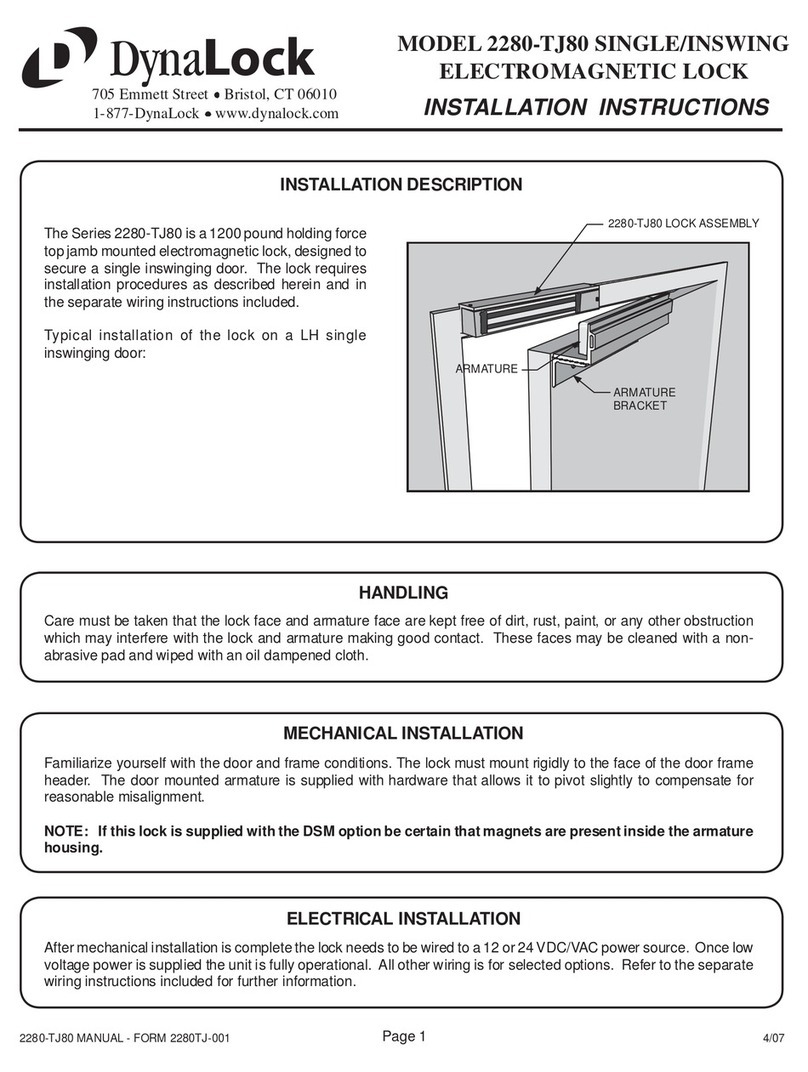

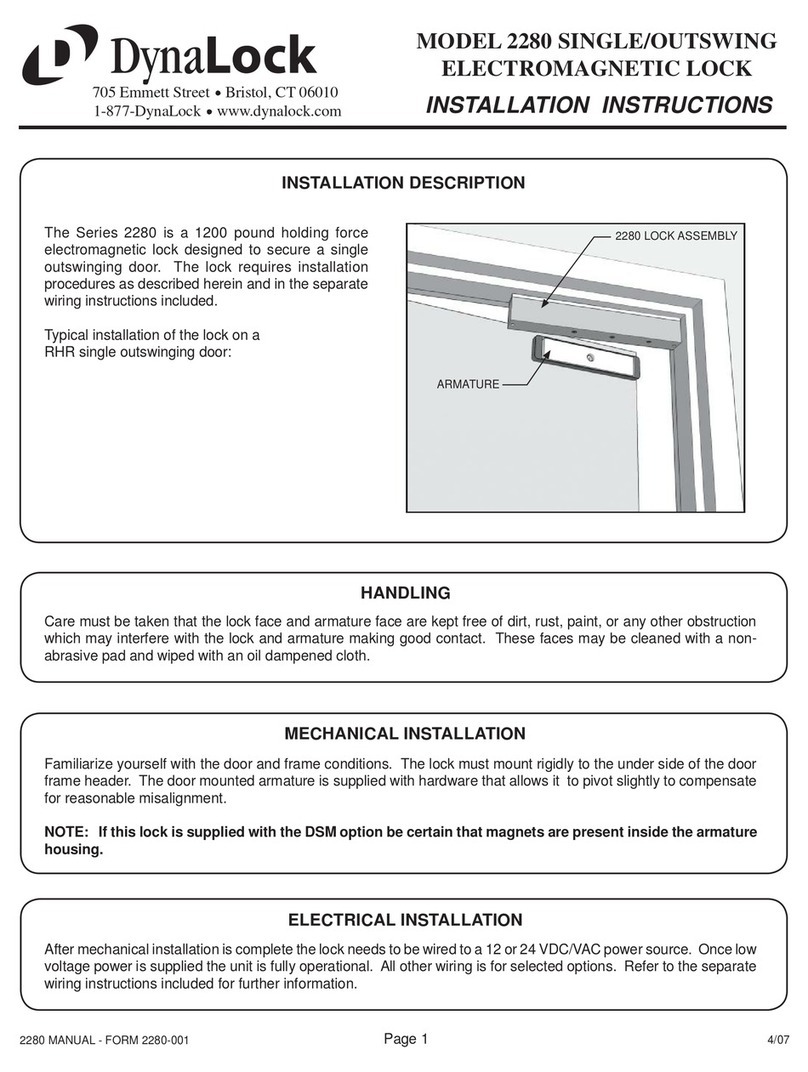

The illustrations below depict typical installations of the Model #2511 Lock on single-outswing doors. The lock

assembly must be surface mounted to the underside of the frame header with the armature affixed to the inside

faceofthedoorasshown.

Electric Security Hardware

705 Emmett Street P.O. Box 9470 Forestville, CT 06011-9470 Phone (860)582-4761 Fax (860)585-0338

SERIES 2511 ELECTROMAGNETIC LOCK

FOR A SINGLE OUTSWING DOOR

PLEASE READ BEFORE INSTALLATION

Familiarize yourself with the door and frame conditions prior to installation. The lock must rigidly mount to the

underside of the frame header. The armature is designed to pivot slightly to compensate for reasonable

misalignment.

Armature mounting hardware is supplied for a standard 1-3/4" thick door. For thicker doors order the following

specialarmaturehardwarekits:

Part#300687for2"thickdoors.

Part#300688for2-1/4"thickdoors.

HANDLING MAINTENANCE

The Electromagnetic lock and armature are

ruggedly constructed and designed to provide

years of trouble-free service. Care must be taken

during installation and use to keep the lock face

and armature face free from dirt, rust, burrs, paint,

or any other obstruction which may interfere with

thelockandarmaturemakinggoodcontact.

The lock assembly and door armature have been

plated for maximum corrosion resistance. To

ensure peak performance clean the lock and

armature faces with a mild detergent and a clean,

softcloth,thenapplyalightcoatofWD40toprotect

these surfaces. This need only be done when dirt

build-upisnoticed.

GENERAL MOUNTING INFORMATION

LHRB DOOR RHRB DOOR

LOCK

ASSEMBLY

ARMATURE