E2S Warning Signals Impress House, Mansell Road, Acton, London W3 7QH www.e2s.com

Tel: +44 (0)208 743 8880

Document No. D199-00-201-IS

Issue 5

28-11-22 Sheet 5 of 8

7) Installation Requirements

7.1. Installation Standards Compliance

Warning – High voltage may be

present, risk of electric shock.

DO NOT open when energised,

disconnect power before opening.

The beacon must only be installed by suitably qualified

personnel in accordance with the latest issues of the relevant

standards.

ATEX / IECEx & UKEx installation standards

EN60079-14 / IEC60079-14: Explosive atmospheres -

Electrical installations design, selection and erection.

EN60079-10-1 / IEC60079-10-1: Explosive atmospheres

- Classification of areas. Explosive gas atmospheres.

EN60079-10-2 / IEC60079-10-2: Explosive atmospheres

- Classification of areas. Explosive dust atmospheres.

The installation of the units must also be in accordance

with any local codes that may apply and should only be

carried out by a competent electrical engineer who has

the necessary training.

NEC / CEC Installation Standards

Cautions

Attention: Installation must be carried out by an

electrician in compliance with the National Electrical

Code, NFPA 70 or CSA 22.1 Canadian Electrical Code,

Part I, Safety Standard for Electrical Installations,

Section 32. / L'installation doit exclusivement être

réalisée par du personnel qualifié, conformément au

code national d'électricité américain, NFPA 70 ou CSA

22.1 Code canadien de l'électricité, première partie,

norme de sécurité relative aux installations électriques,

Section 32.

Attention: Disconnect from power source before

installation or service to prevent electric shock /

Débranchez-le de la source d'alimentation avant

l'installation ou l'entretien pour éviter tout choc

électrique.

The installation of the units must also be in accordance

with any local codes that may apply and should only be

carried out by a competent electrical engineer who has

the necessary training.

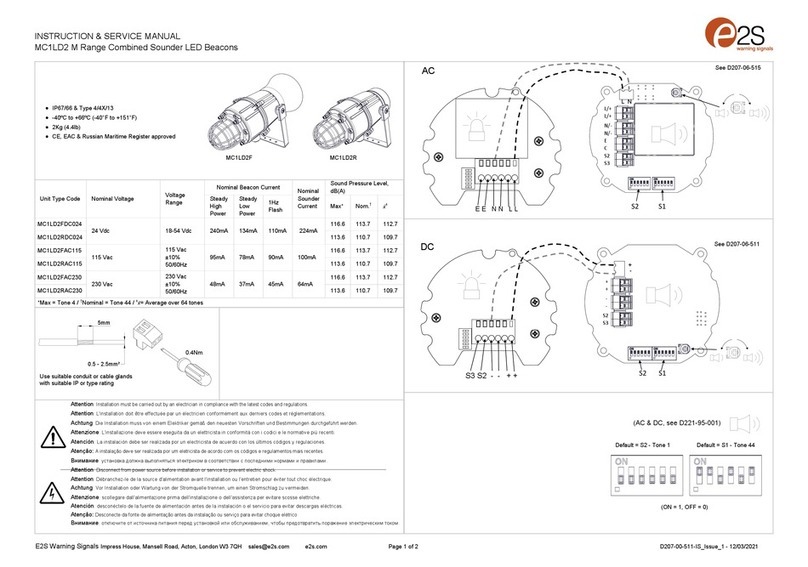

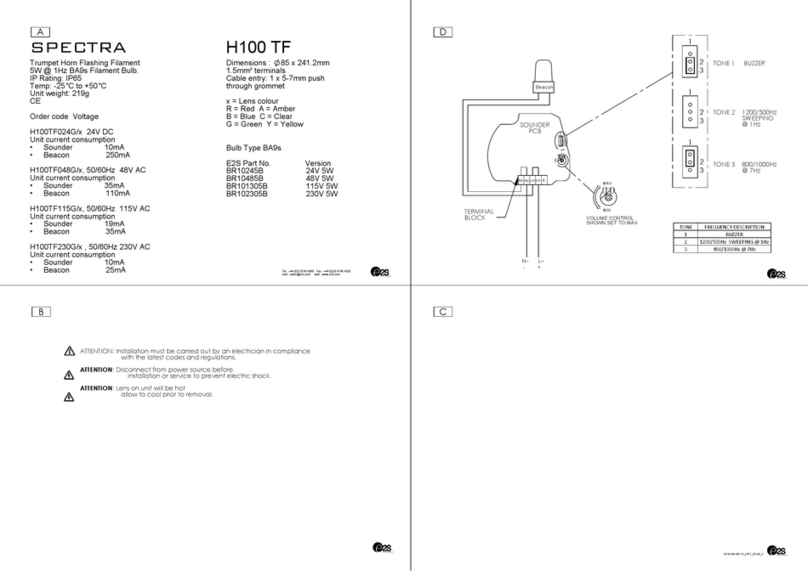

7.2. Cable Selection and Connections

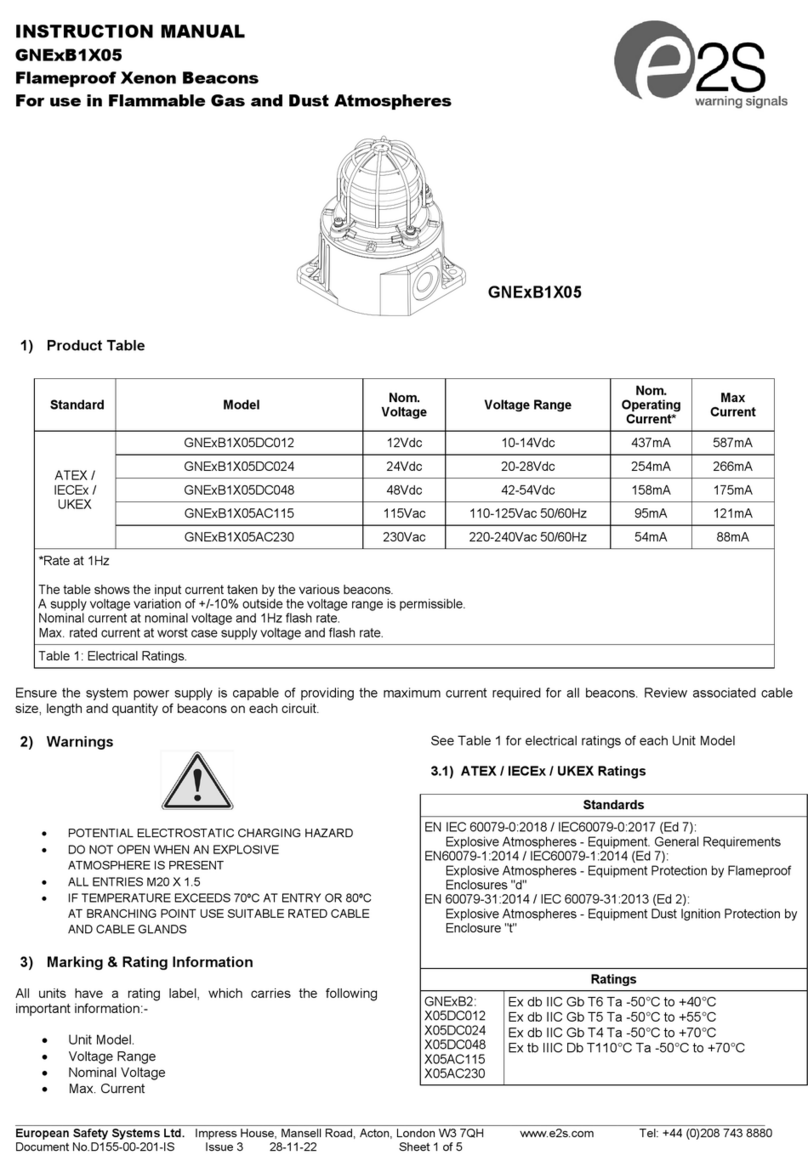

When selecting the cable size, consideration must be given to

the input current that each unit draws (see table 1), the number

of beacons on the line and the length of the cable runs. The

cable size selected must have the necessary capacity to

provide the input current to all of the beacons connected to the

line.

Electrical connections are to be made into the terminal blocks

on the PCBA, using solid wire 0.5-4mm2 / AWG 20-12 or

stranded wire, sizes 0.5-2.5mm2 / AWG 24-14. Wire insulation

needs to be stripped 8mm. Wires may be fitted securely with

crimped ferrules.

Figure 4: Wire Preparation.

Terminal screws need to be tightened down with a tightening

torque of 0.45 Nm / 5 Lb-in. A 5-way terminal block is provided

on the AC Beacon: 2-off Live, 2-off Neutral and 1-off Earth

terminals in total. A 4-way terminal block is provided on the DC

Beacon: 2-off +ve and 2-off -ve terminals.

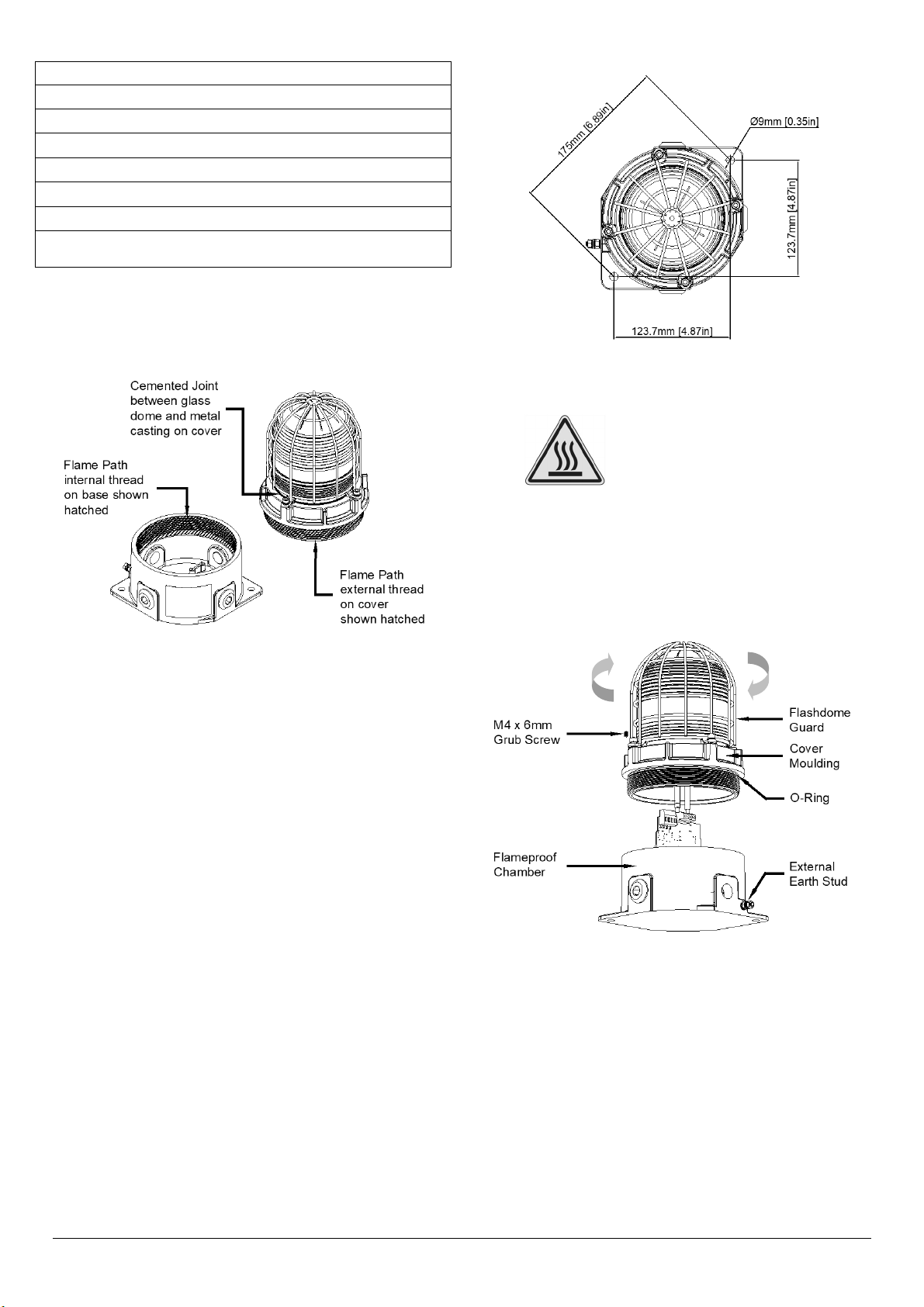

Figure 5: STExB2 Entries and Terminal Block Location.

When connecting wires to the terminals great care should be

taken to dress the wires so that when the cover is inserted into

the chamber the wires do not exert excess pressure on the

terminal blocks. This is particularly important when using

cables with large cross-sectional areas such as 2.5mm².

Earthing

Please note that for AC supply voltage product versions the

Earth terminal on the PCBA does not provide an earth

connection to the product enclosure. The enclosure must be

independently earthed using either the external or internal

earth fixing point, (see fig 9 and notes below).

Internal earthing connections should be made to the Internal

Earth terminal in the base of the housing using a ring crimp

terminal to secure the earth conductor under the earth clamp.

The earth conductor should be at least equal in size and rating

to the incoming power conductors.

External earthing connections should be made to the M5 earth

stud, using a ring crimp terminal to secure the earth conductor

to the earth stud. The external earth conductor should be at

least 4mm2 in size.