_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH www.e2s.com Tel: +44 (0)208 743 8880

Document No. D234-00-201-IS_Issue_1 10-11-2022 Sheet 2 of 4

M/S 1 M/S 2

+ - + -

1 3 4 6

SERIES 1 SERIES 2

EOL 1 EOL 2

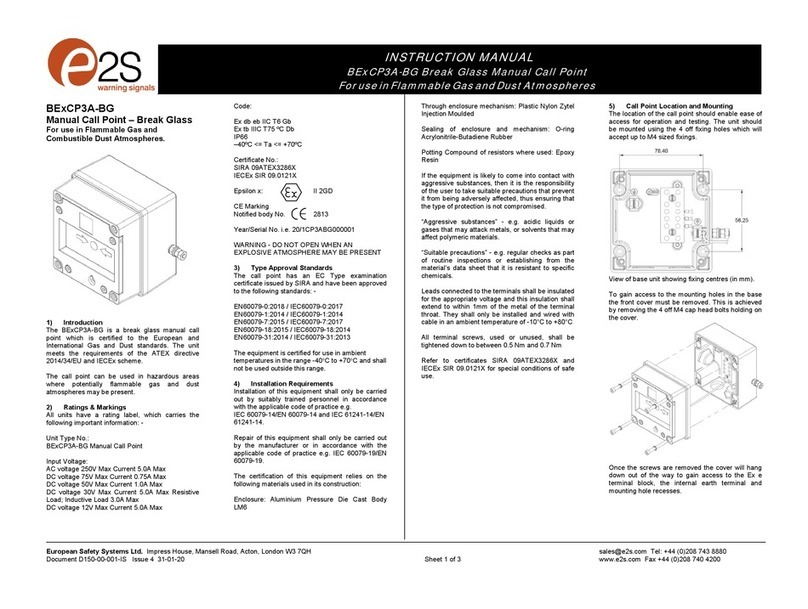

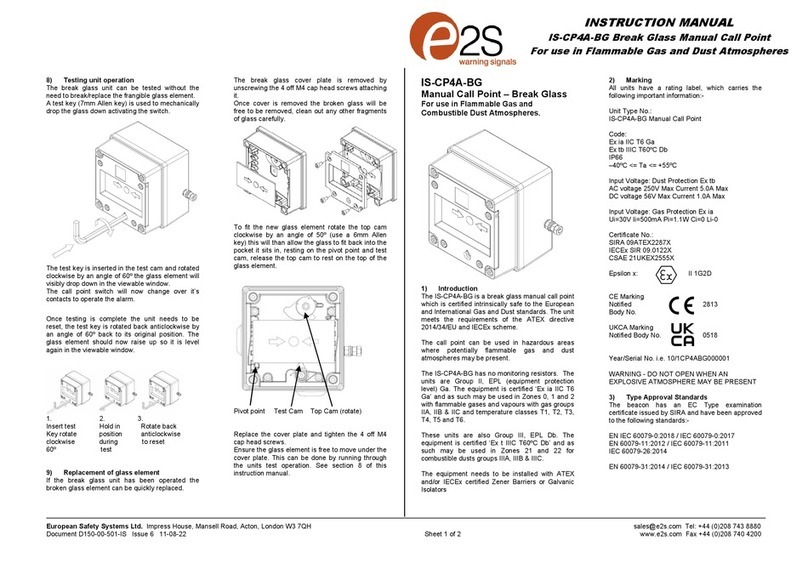

Fig 3 Earth terminals

5) Power Supply Selection

Electrical Ratings

Input Voltage:

AC voltage 250V Max Current 5.0A Max

DC voltage 75V Max Current 0.75A Max

DC voltage 50V Max Current 1.0A Max

DC voltage 30V Max Current 5.0A Max Resistive Load;

Inductive Load 3.0A Max

DC voltage 12V Max Current 5.0A Max

Electrical connections are to be made into the terminal blocks

/ DIN rail provided. See Section 8 for wiring options.

6) Selection of Cable. Cable Glands, Blanking

Elements & Adapters

The cable gland entries have an M20 x 1.5 entry thread.

The WP7 Call Point range can be supplied with the following

types of adapters:

M20 to ½” NPT

M20 to ¾” NPT

M20 to M25

7) Cable Connections

Electrical Connections are to be made into the terminal

blocks using solid or stranded wire. See section 3 of this

manual for access to the enclosure.

Wires having a cross sectional area between 0.5 mm² to

2.5mm² (AWG 20 – 14) can be connected to each terminal

way.

If an input and output wire is required the 2-off Live/Neutral or

+/- terminals can be used. If fitting 2-off wires to one terminal

way the sum of the 2-off wires must be a maximum cross

sectional area of 2.5mm².

Strip wires to 8mm. Wires may also be fitted using ferrules.

Terminal screws need to be tightened down with a tightening

torque of 0.45 Nm / 5 Lb-in.

When connecting wires to the terminals great care should be

taken to dress the wires so that when the cover is inserted

into the chamber the wires do not exert excess pressure on

the terminal blocks. This is particularly important when using

cables with large cross sectional areas such as 2.5mm².

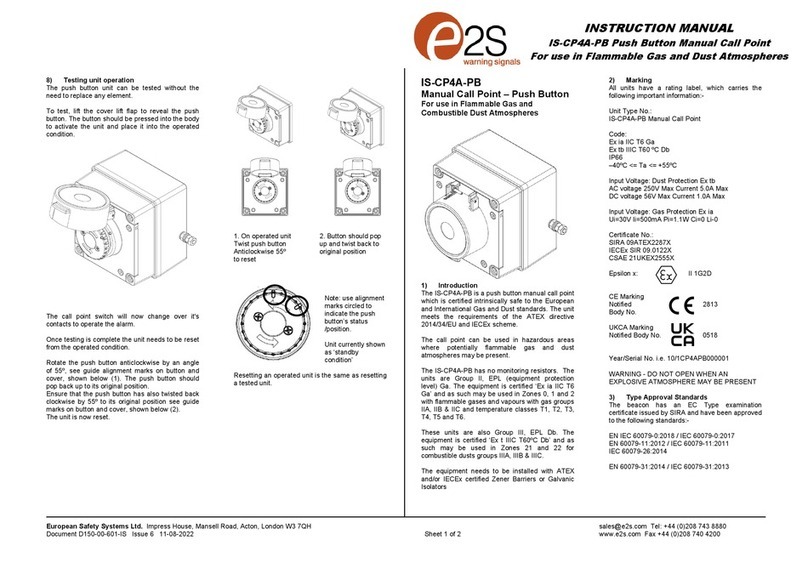

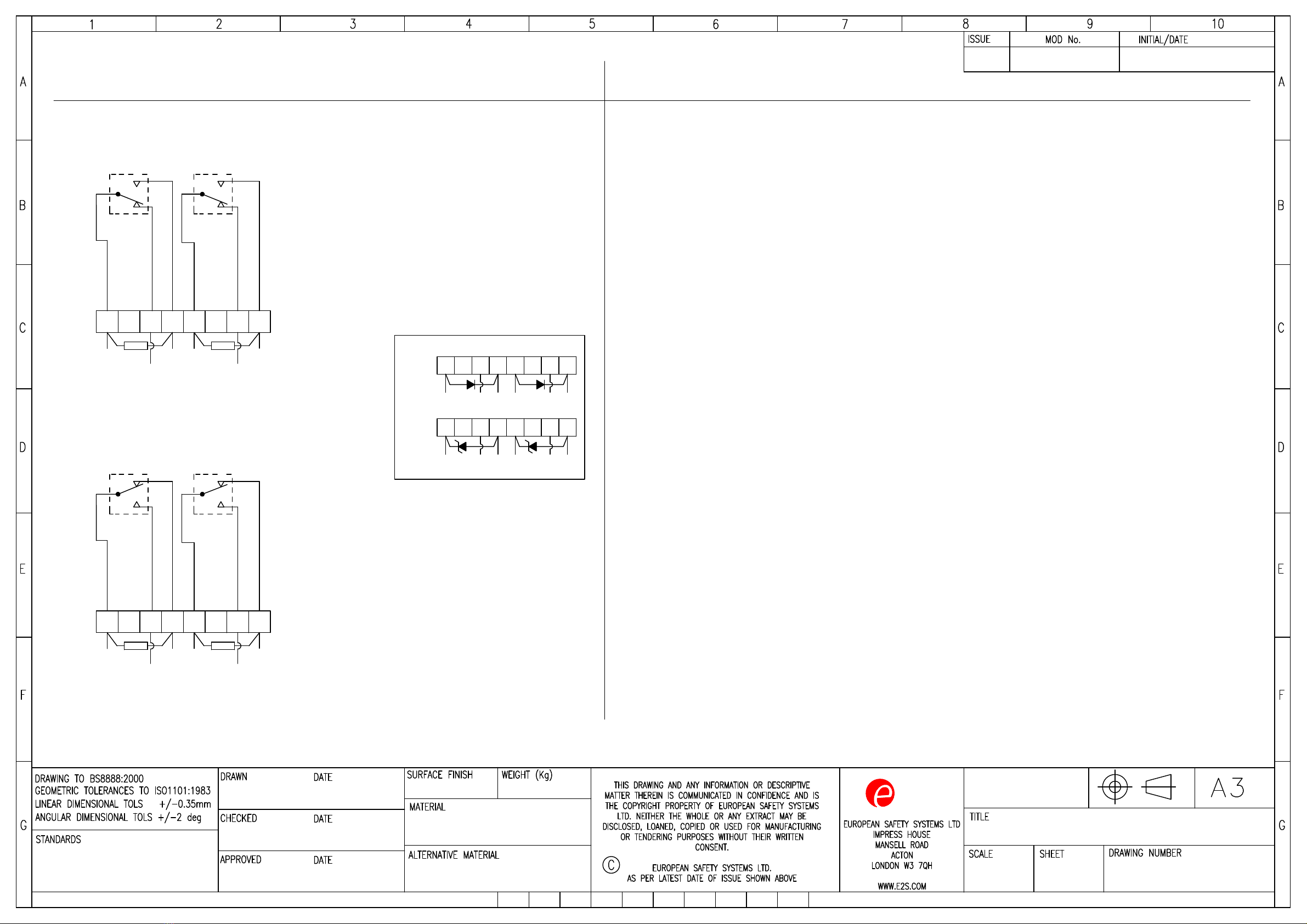

8) Wiring Unit

The units come with two options for the terminal block.

A DIN rail version which has 8-way connection and allows for

full configuration at factory or limited wiring of EOL devices by

customer.

The PCB Terminal Version has a 6-way connector but is

designed to allow for full configuration with Series and EOL

devices in a number of wiring configurations.

For EOL and Series device limitations and configurations see

Section 9.

For full wiring details see wiring schematic D234-06-001.

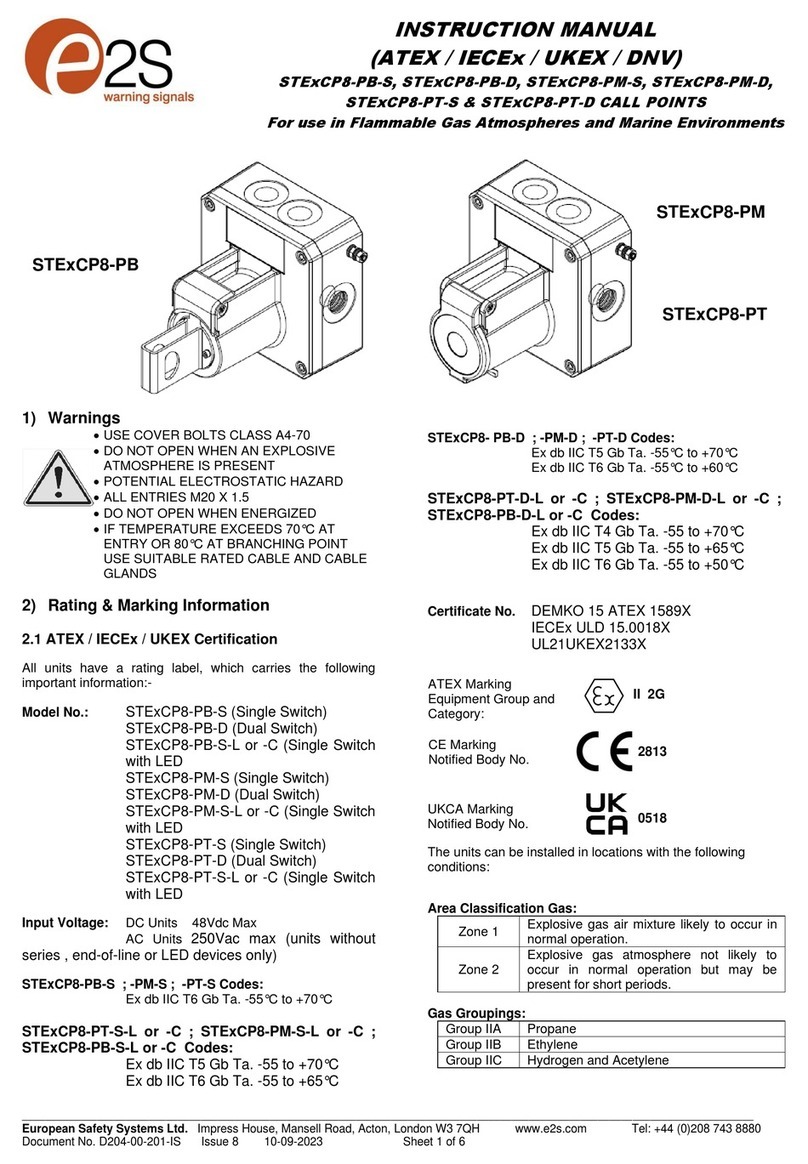

Wiring Connections for 8-Way DIN Rail

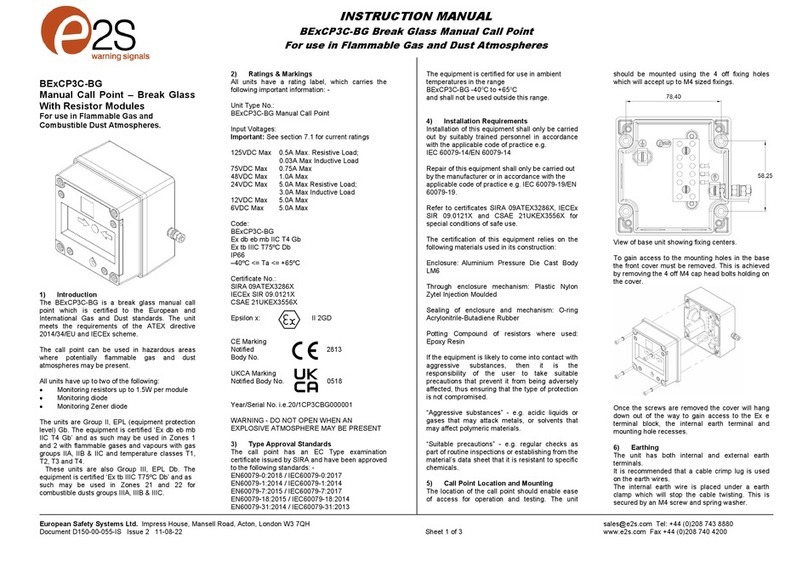

Fig. 4 DIN Rail in Base

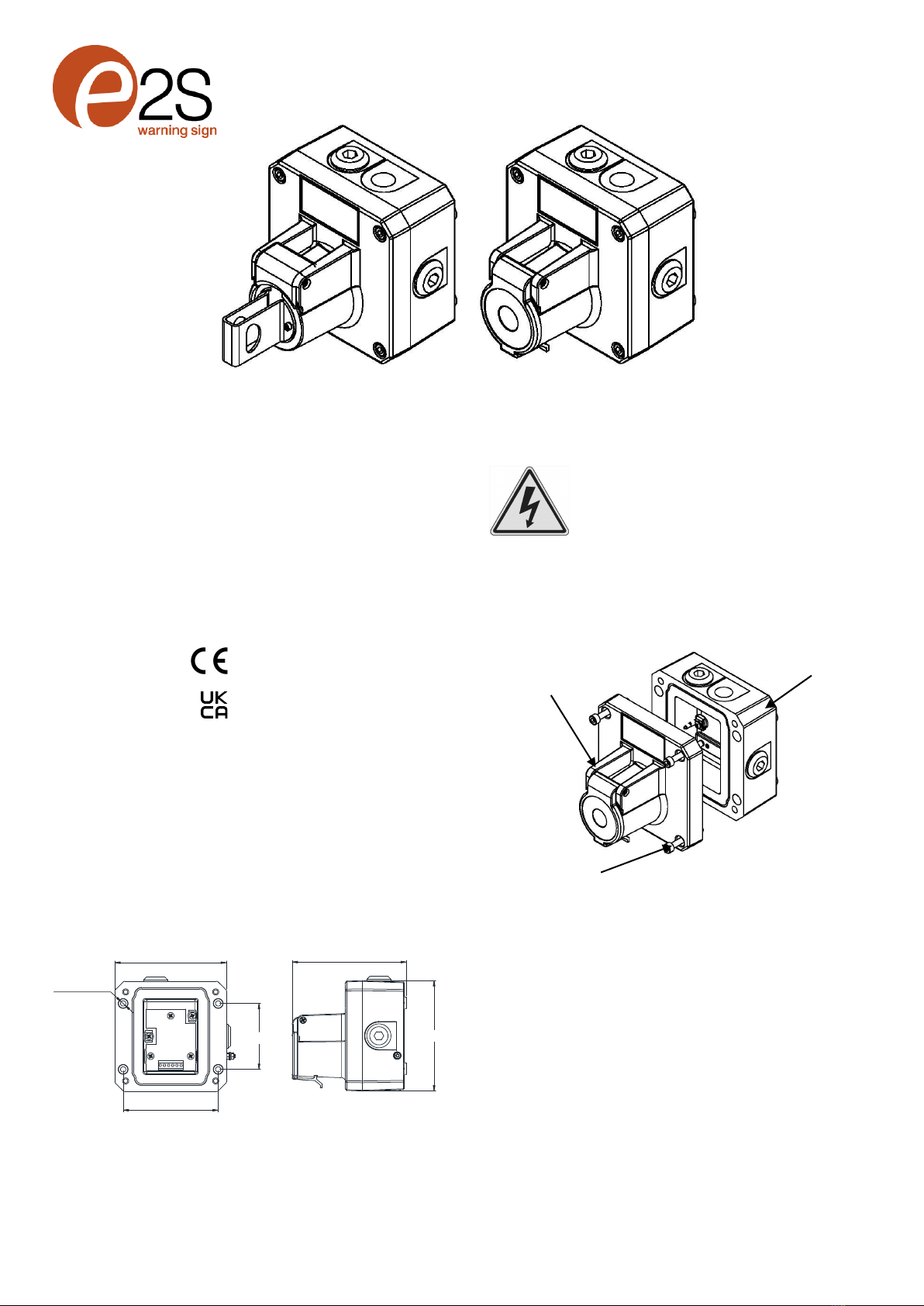

Wiring Connections For 6-Way PCB Terminal Board

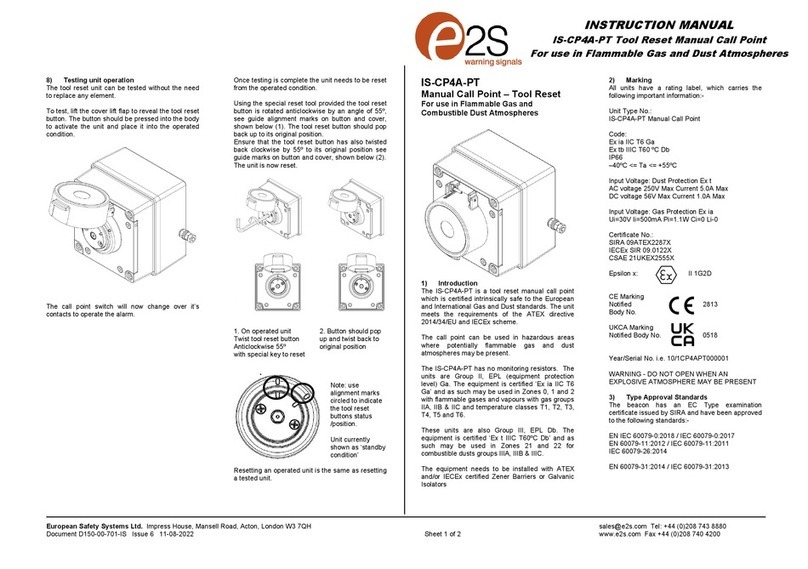

Fig. 5 PCB Terminal Block in Base

See section 9 and pages 5, 6 & 7 for details of adding Series

and EOL devices on the PCB. This can either be done at the

order stage or added to the correct terminal blocks afterward.

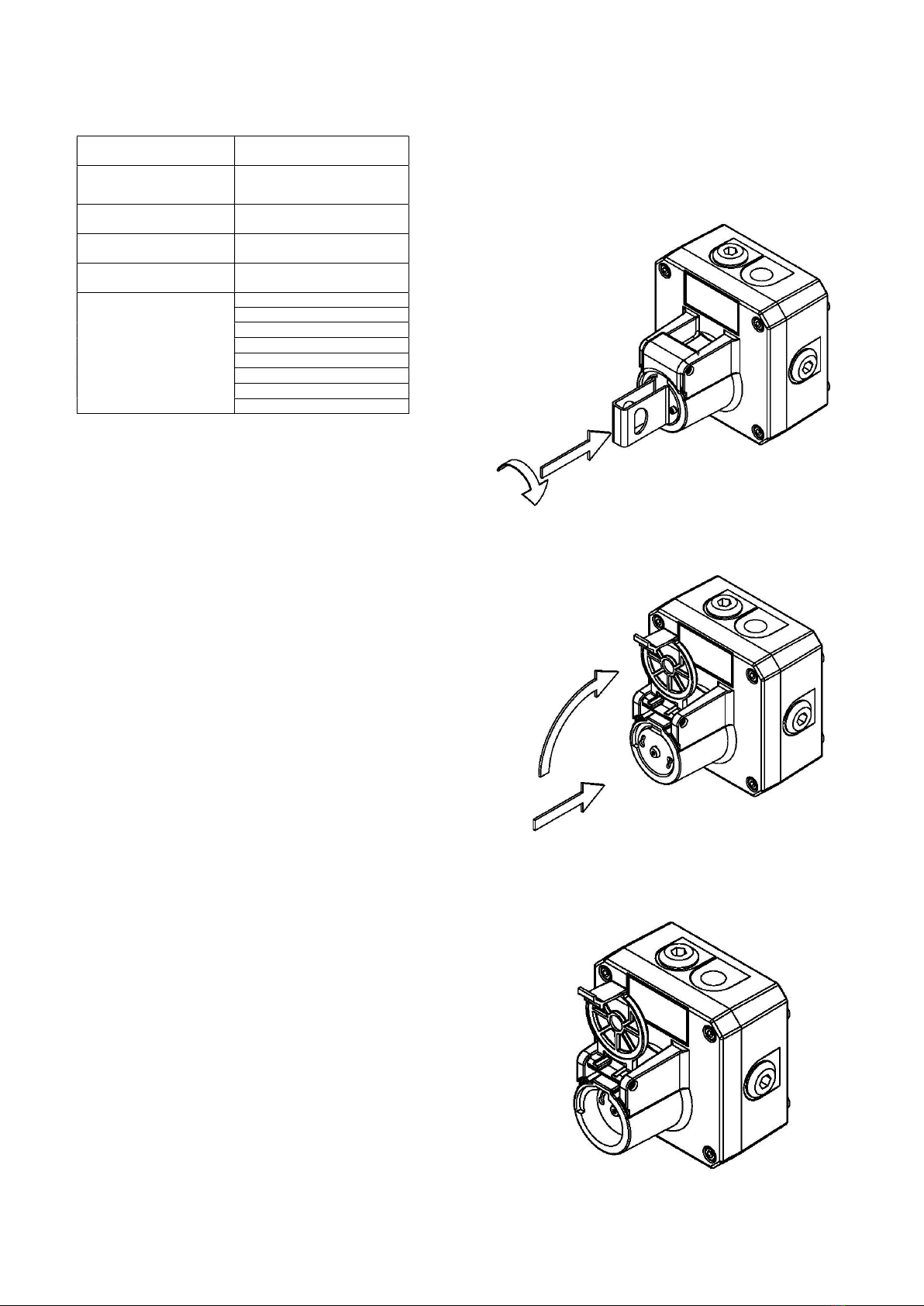

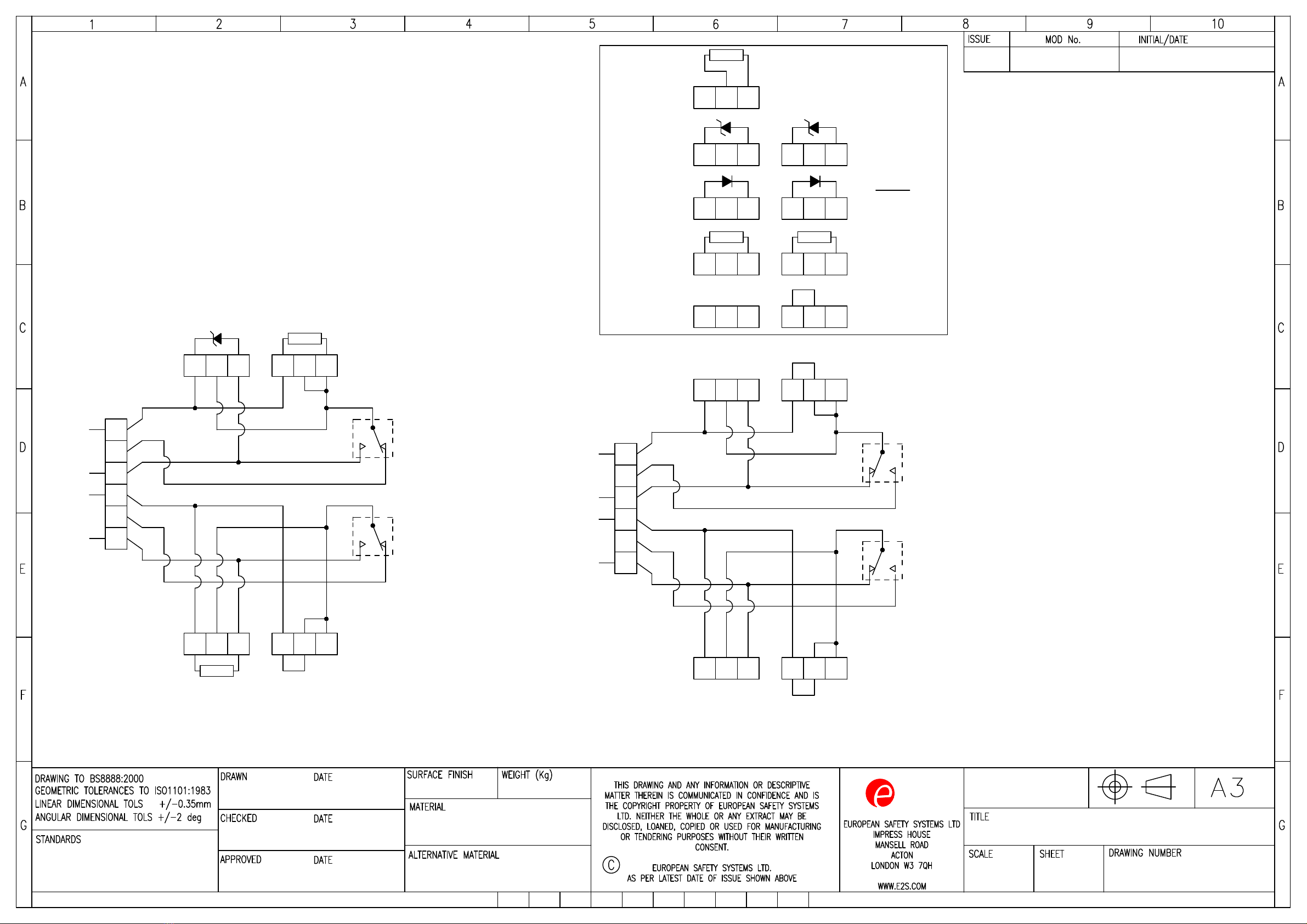

9) End-of-Line and Series Devices

All models can be fitted with series resistors, end-of-line

monitoring resistors, monitoring diodes, zener diodes and

also specific customer modules if supplied with direct current

up to 50Vdc.

Wiring terminal

Internal Earthing

External Earthing