European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH www.e2s.com Tel: +44 (0)208 743 8880

Document D154-00-001-IS Issue 6 12-09-2022 Sheet 1 of 2

INSTRUCTION MANUAL

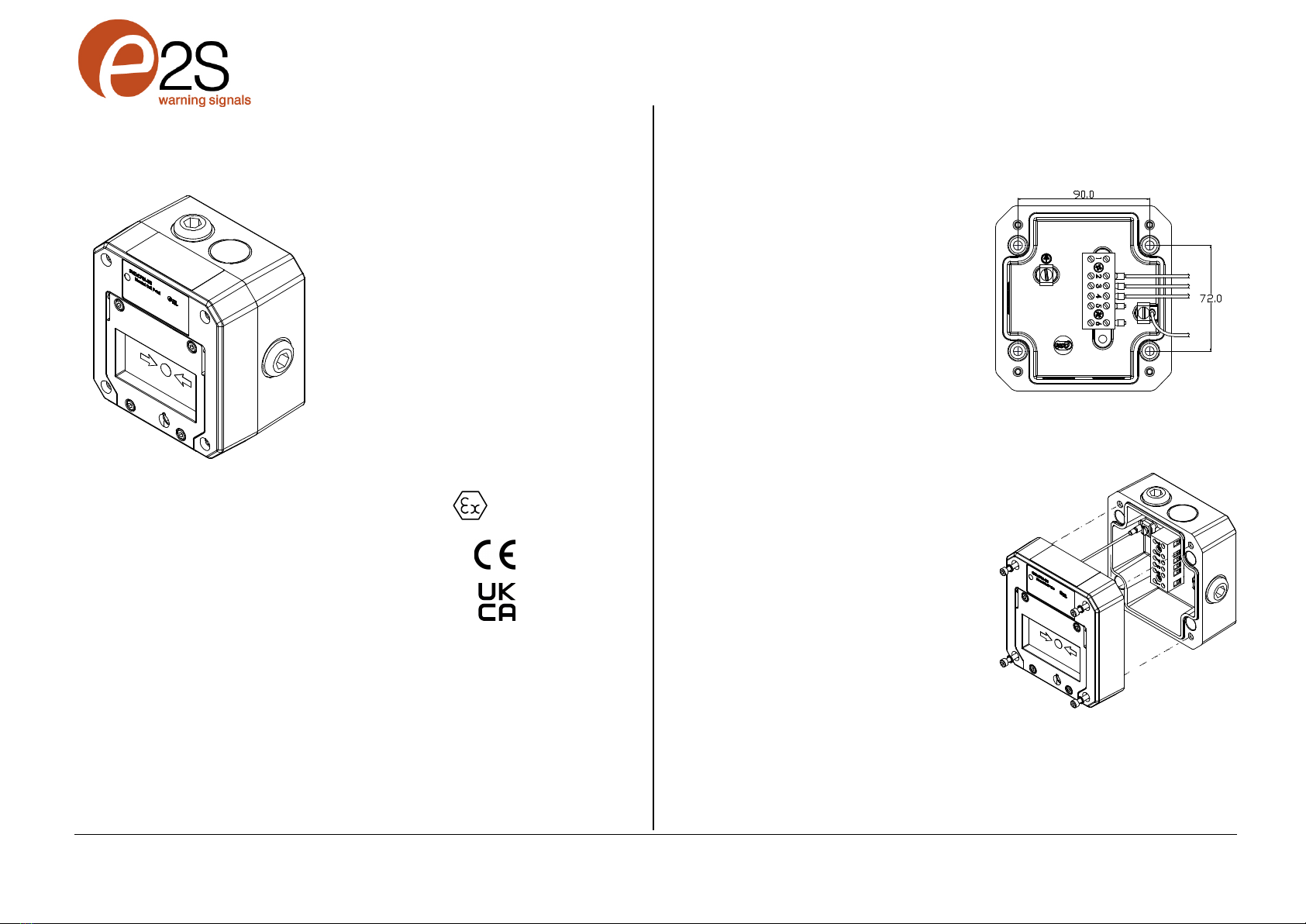

GNExCP6A-BG Break glass Manual Call Point

n Flammable Gas and Dust Atmospheres

GNExCP6A-BG

Manual Call Point – Break Glass

For use in Flammable Gas and

Combustible Dust Atmospheres.

1) Introduction

The GNExCP6A-BG is a break glass manual call

point which is certified to the European and

International Gas and Dust standards. The unit

meets the requirements of the ATEX directive

2014/34/EU, IECEx and UKEX schemes.

The call point can be used in hazardous areas

where potentially flammable gas and dust

atmospheres may be present.

All units have no monitoring resistors, diodes or

zener diodes and are not fitted with an LED

indicator.

The units are Group II, EPL (equipment protection

level) Gb. The equipment is certified ‘Ex db eb IIC

T6 Gb’ and as such may be used in Zones 1 and 2

with flammable gases and vapours with apparatus

groups IIA, IIB & IIC and temperature classes T1,

T2, T3, T4, T5 and T6.

These units are also Group III, EPL Db. The

equipment is certified ‘Ex tb IIIC T75ºC Db’ and as

such may be used in Zones 21 and 22 for

combustible dusts groups IIIA, IIIB & IIIC.

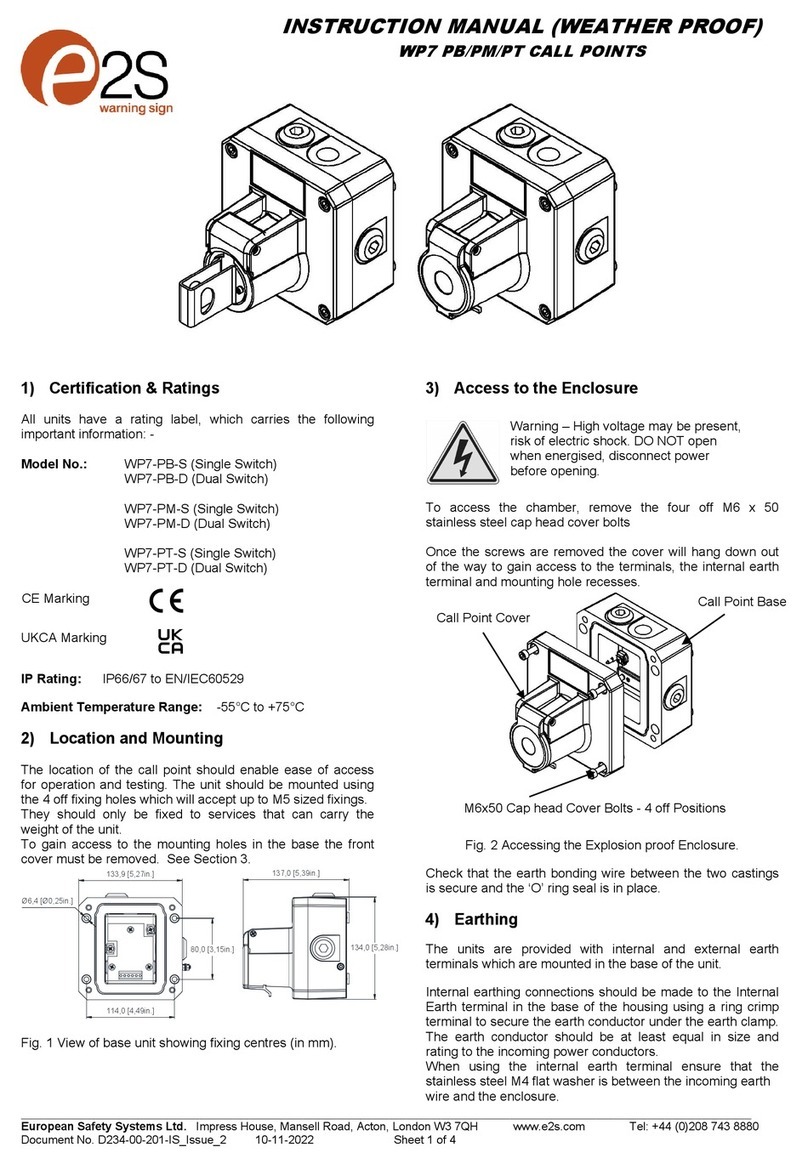

2) Ratings & Markings

All units have a rating label, which carries the

following important information:-

Unit Type No.:

GNExCP6A-BG Manual Call Point

Input Voltage:

AC voltage 250V Max Current 5.0A Max

DC voltage 250V Max Current 0.25A Max Resistive

load : 0.03A Max Inductive load

DC voltage 125V Max Current 0.5A Max Resistive

load : 0.03A Max Inductive load

DC voltage 75V Max Current 0.75A Max

DC voltage 50V Max Current 1.0A Max

DC voltage 30V Max Current 5.0A Max Resistive

Load; Inductive Load 3.0A Max

DC voltage 12V Max Current 5.0A Max

Code:

Ex db eb IIC T6 Gb

Ex tb IIIC T75 ºC Db

IP66

–40ºC <= Ta <= +70ºC

Certificate No.:

SIRA 09ATEX3286X

IECEx SIR 09.0121X

CSAE 21UKEX3556X

Epsilon x: II 2GD

CE Marking

Notified 2813

Body No.

UKCA Marking

Notified Body No. 0518

Year/Serial No. i.e. 20/1CP6ABG000001

WARNING - DO NOT OPEN WHEN AN

EXPLOSIVE ATMOSPHERE MAY BE PRESENT

ELECTROSTATIC HAZARD – CLEAN ONLY

WITH A DAMP CLOTH

3) Type Approval Standards

The call point has an EC Type examination

certificate issued by SIRA and have been approved

to the following standards:-

EN60079-0:2018 / IEC60079-0:2017

EN60079-1:2014 / IEC60079-1:2014

EN60079-7:2015 / IEC60079-7:2017

EN60079-18:2015 / IEC60079-18:2014

EN60079-31:2014 / IEC60079-31:2013

The equipment is certified for use in ambient

temperatures in the range -40oC to +70oC and shall

not be used outside this range.

4) Installation Requirements

Installation of this equipment shall only be carried

out by suitably trained personnel in accordance

with the applicable code of practice e.g.

IEC 60079-14/EN 60079-14

Repair of this equipment shall only be carried out

by the manufacturer or in accordance with the

applicable code of practice e.g. IEC 60079-19/EN

60079-19.

Refer to certificates SIRA 09ATEX3286X, IECEx

SIR 09.0121X and CSAE 21UKEX3556X for

special conditions of safe use.

The certification of this equipment relies on the

following materials used in its construction:

Enclosure: GRP - Glass Reinforced Polyester

Through enclosure mechanism: Plastic Nylon Zytel

Injection Moulded

Sealing of enclosure and mechanism: O-ring

Acrylonitrile-Butadiene Rubber

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility

of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that

the type of protection is not compromised.

“Aggressive substances” - e.g. acidic liquids, gases

or solvents that may affect polymeric materials.

“Suitable precautions” - e.g. regular checks as part

of routine inspections or establishing from the

material’s data sheet that it is resistant to specific

chemicals.

Under extreme conditions the unit may generate an

ignition-capable level of electrostatic charges. The

unit must not be installed in a location where it may

be subjected to external conditions (such as high

pressure steam) which may cause a build-up of

electrostatic charges on non-conducting surfaces.

Cleaning of the unit must only be carried out with a

damp cloth.

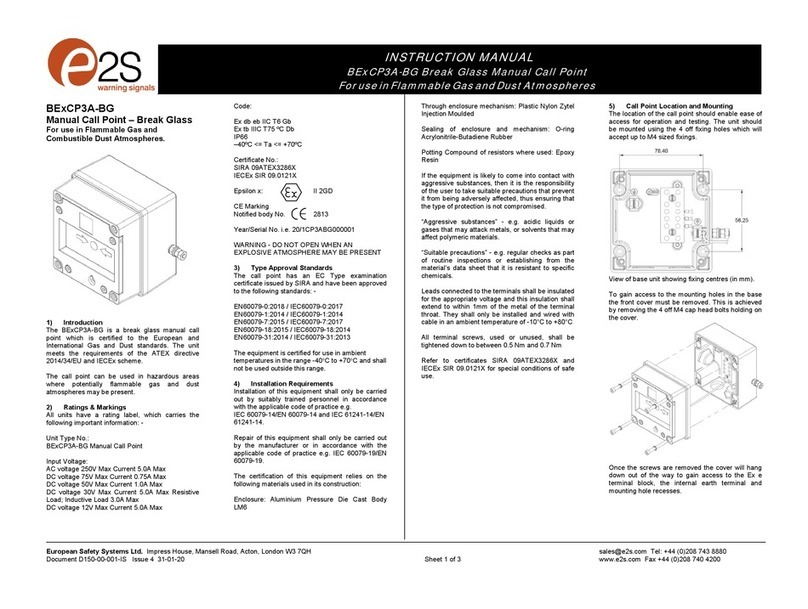

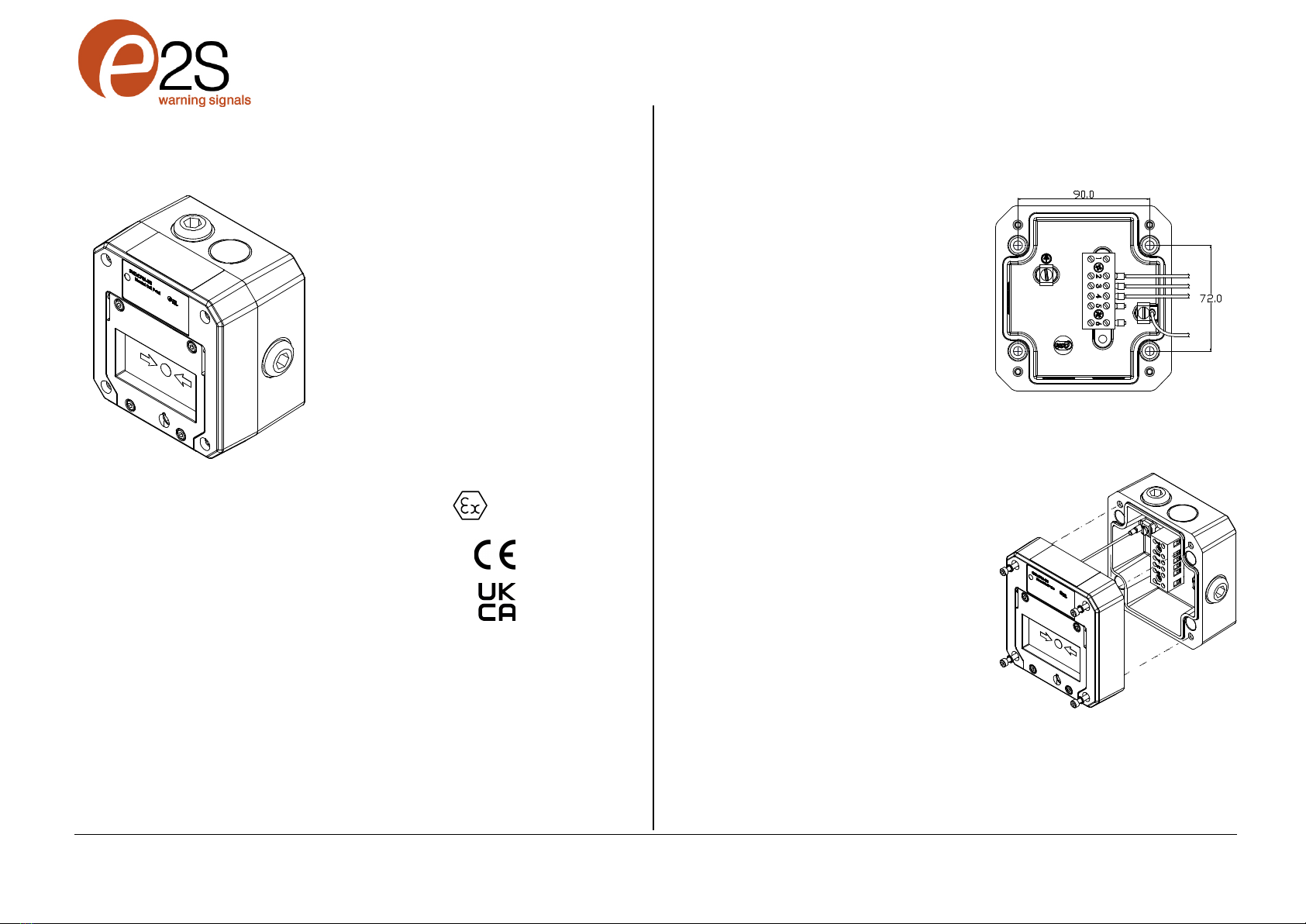

5) Call Point Location and Mounting

The location of the call point should enable ease of

access for operation and testing. The unit should

be mounted using the 4 off fixing holes which will

accept up to M4 sized fixings.

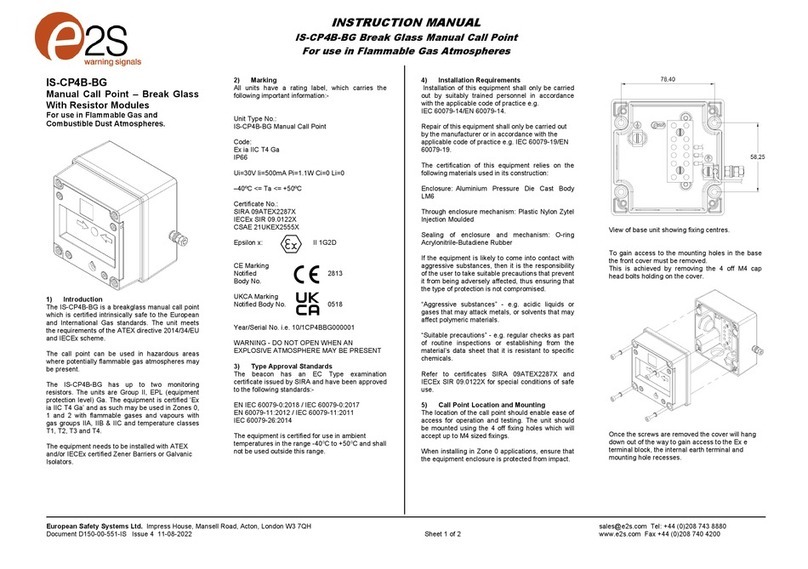

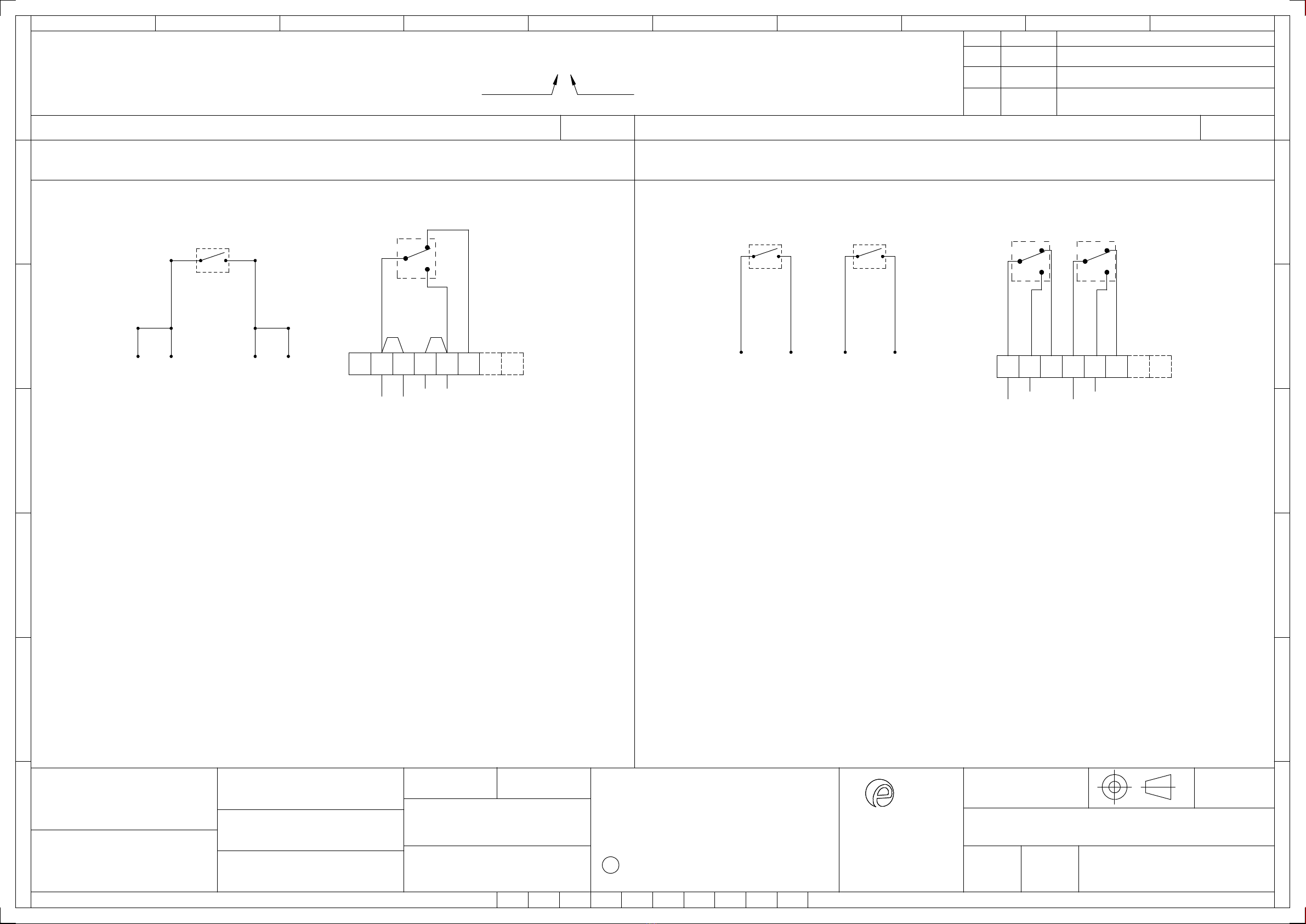

View of base unit showing fixing centres (in mm).

To gain access to the mounting holes in the base

the front cover must be removed.

This is achieved by removing the 4 off M4 cap

head bolts holding on the cover.

Once the screws are removed the cover will hang

down out of the way to gain access to the Ex e

terminal block, the internal earth terminal and

mounting hole recesses.