2 3 4

+

-

2 3 4

+

-

DEVICE POLARITY

ZENER

DIODE

DIODE

M/S 1

EOL

-

+

M/S 1

-

+

87654321

R Y B

M/S 1

SERIES

-

+

M/S 1

-

+

87654321

R Y B

M/S 1

SERIES

EOL

-

+

M/S 1

-

+

87654321

R Y B

SERIES

M/S 1

EOL

-

+

M/S 1

-

+

87654321

R Y B

3 4

+

-

3 4

+

-

DIODE

ZENER

DIODE

DEVICE POLARITY

+

21

+

21

DEVICE POLARITY

ZENER

DIODEDIODE

2

+

3

+

4

-

5

-

EOL

SERIES

5

-

4

-

3

+

2

+

2

+

3

+

4

-

5

-

EOL

SERIES

SERIES

EOL

5

-

4

-

2

+

1

+

Series Device

EOL Device

Voltage

Product Version

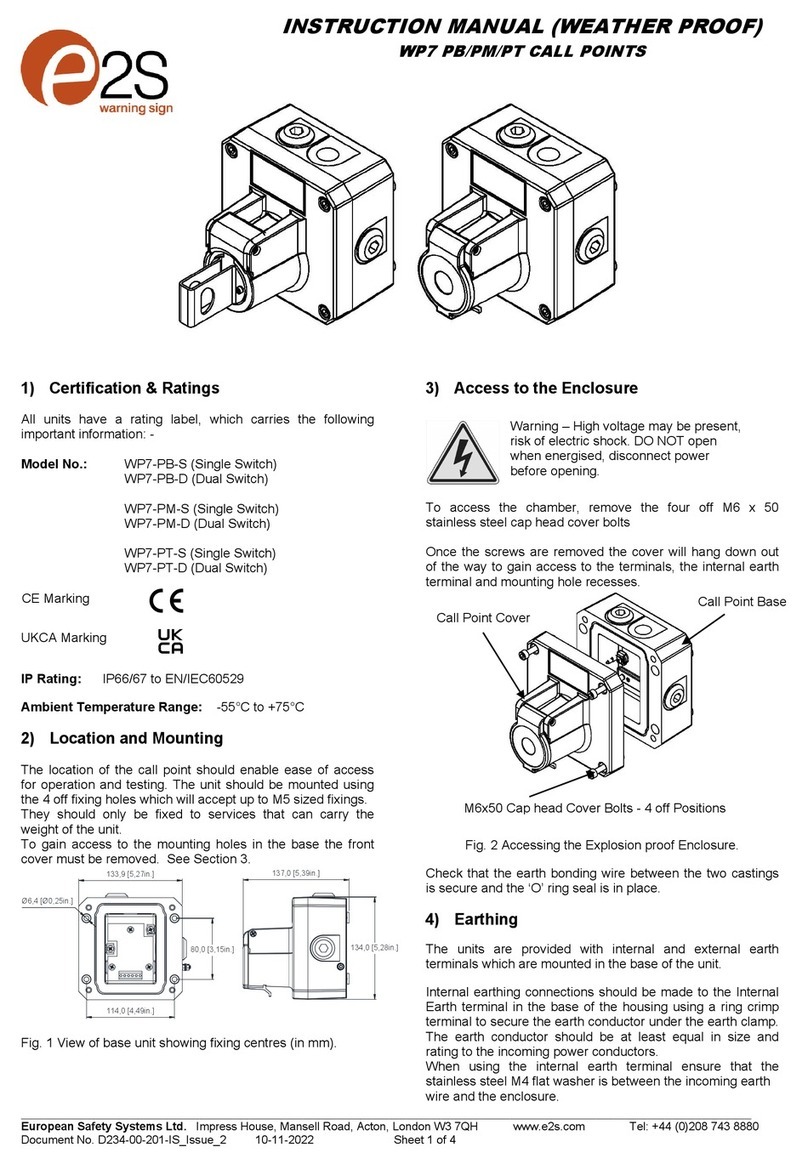

BEXCP3B-BG[s][t][l][e][m][d][v][x][n]-[v][e][s]

--

2 3 4

+

-

+

DIODE

ZENER

DIODE

DEVICE POLARITY

2 3 4

+

-

+

D.HOWGILL

warning signals

2S

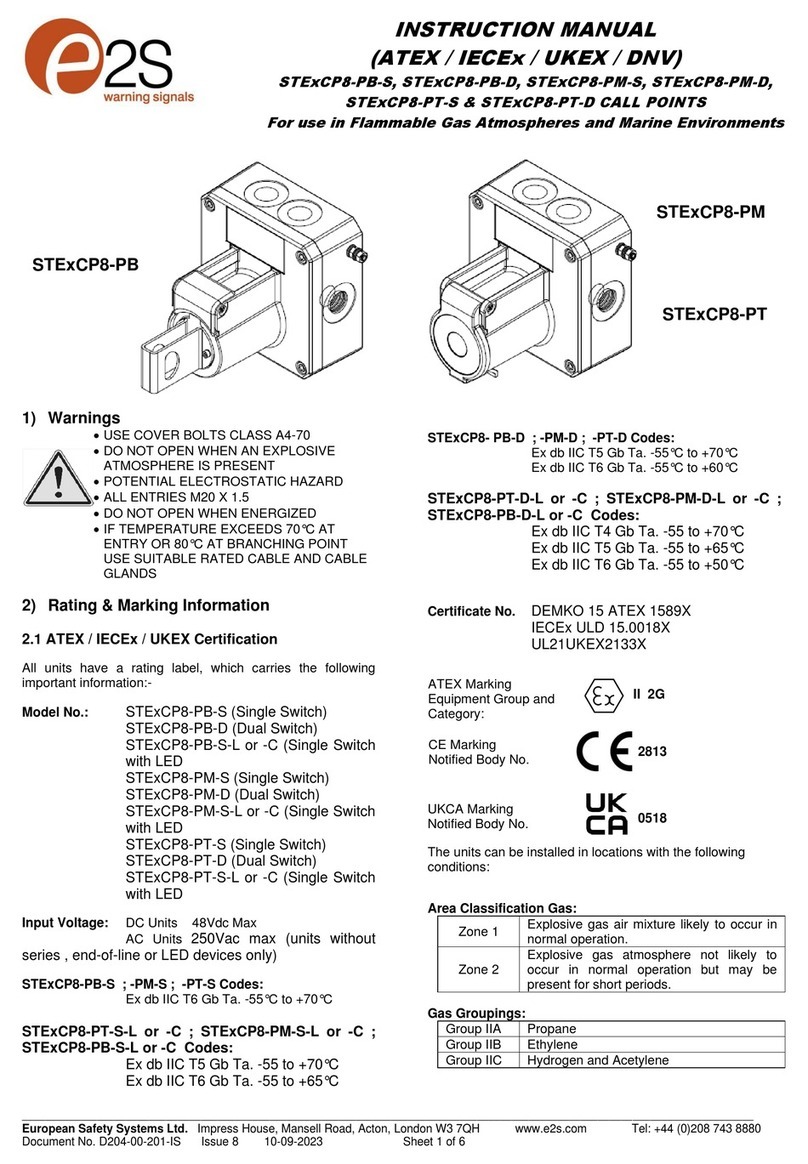

BExCP3B/C/D/E CALL POINTS

3

ACN0077

2ADDED. D.A.H - 26-08-2020

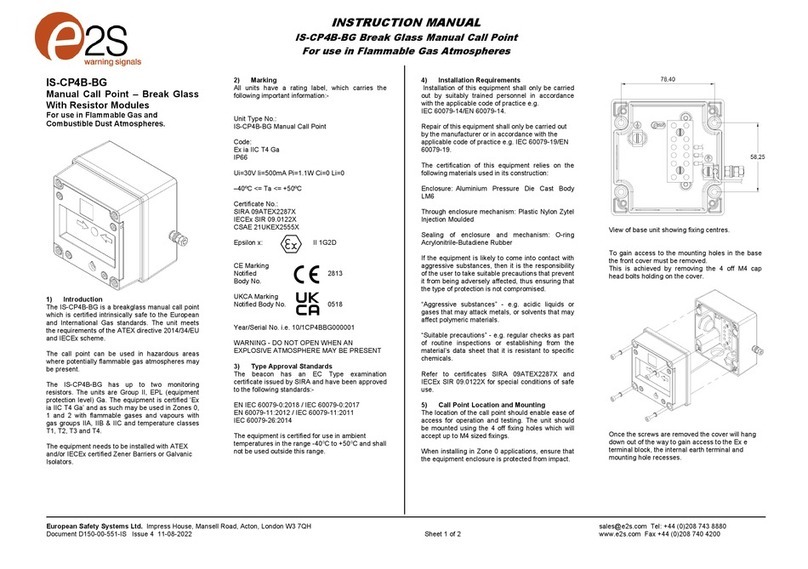

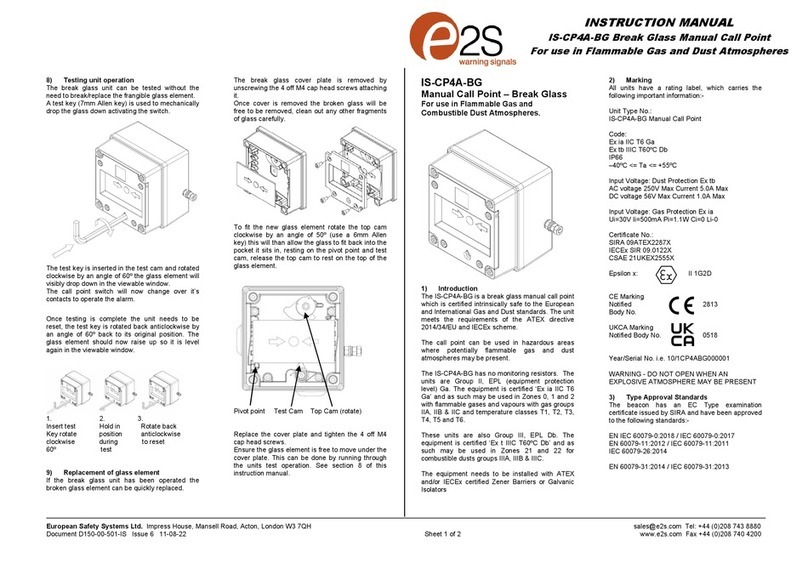

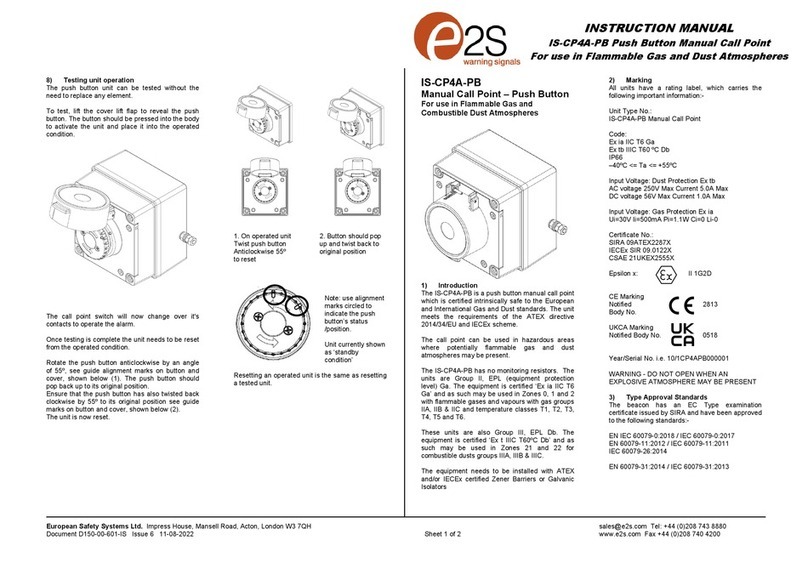

INTRODUCTION

WWW.E2S.COM

C

LONDON W3 7QH

ACTON

MANSELL ROAD

IMPRESS HOUSE

EUROPEAN SAFETY SYSTEMS LTD

1

07-02-20

07-02-20

AS PER LATEST DATE OF ISSUE SHOWN ABOVE

EUROPEAN SAFETY SYSTEMS LTD.

WRITTEN CONSENT.

MANUFACTURING OR TENDERING PURPOSES WITHOUT THEIR

ANGULAR DIMENSIONAL TOLS

STANDARDS

MOD No. REASON - INITIAL - DATEISSUE

DATE

APPROVED

CHECKED DATE

DATE

DRAWN WEIGHT (Kg)

SURFACE FINISH

MATERIAL

ALTERNATIVE MATERIAL SHEETSCALE

TITLE

A3

LINEAR DIMENSIONAL TOLS

DO NOT SCALE

ALL DIMENSIONS IN MM

DRAWING NUMBER

A

B

C

D

E

F

G

109

G

F

E

78

6

5

D

C

134

2

A

B

D150-06-051

R.N.POTTS

TYPE E ADDED ; SIMPLIFIED DIAGRAMS

R.N.POTTS

07-02-20

OF

IF IN DOUBT, ASK -

CALL POINT WIRING SCHEMATIC

BExCP3B/C/D/E-BG/PB/PT MANUAL

D.A.H - 07-02-2020

NTS 1 1

THIS DRAWING AND ANY INFORMATION OR DESCRIPTIVE

MATTER THEREIN IS COMMUNICATED IN CONFIDENCE AND

IS THE COPYRIGHT PROPERTY OF EUROPEAN SAFETY

SYSTEMS LTD. NEITHER THE WHOLE OR ANY EXTRACT MAY

BE DISCLOSED, LOANED, COPIED OR USED FOR

DRAWING TO BS8888:2000

GEOMETRIC TOLERANCES TO ISO1101:1983

DEVICE POLARITY DETAIL ADDED ;

CODING UPDATED D.A.H - 21-12-2021

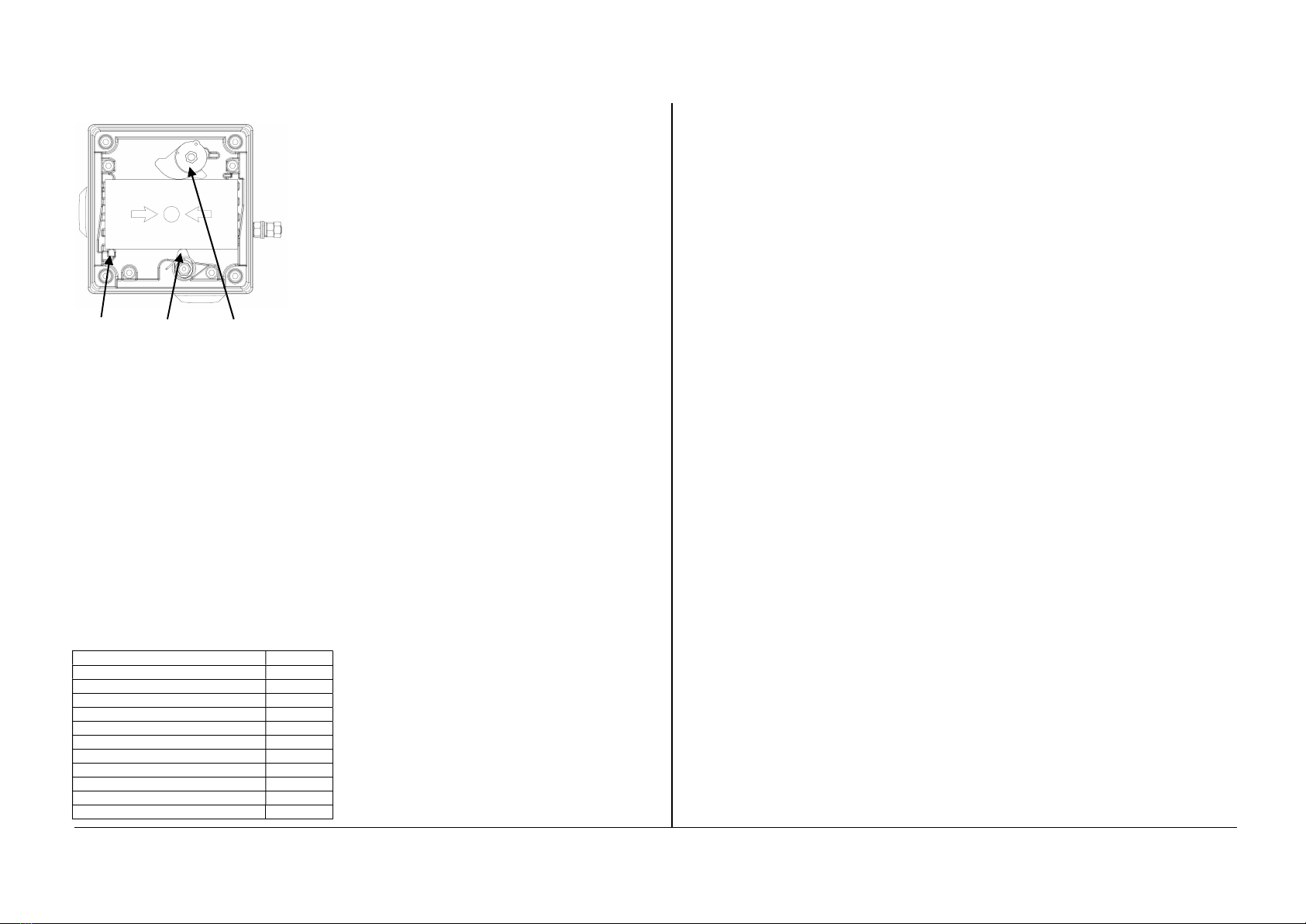

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(1,2) & -(4,5) M/S 1 open

Terminals +(1,2) & (6) M/S 1 closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(1,2) & -(4,5) M/S 1 closed

Terminals +(1,2) & (6) M/S 1 open

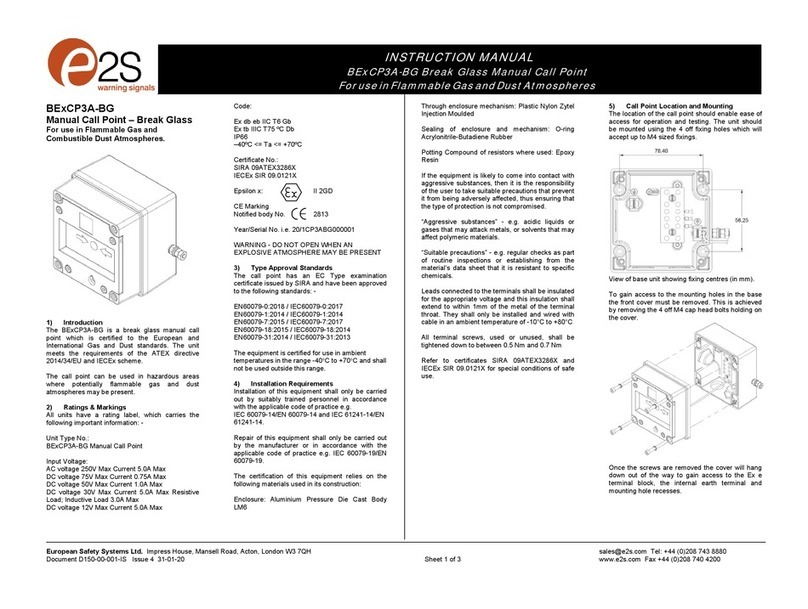

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

Single

Alternative Wiring

EOL + Series

[S]

[W]

[Exxxx][Sxxxx]

Single

Standard

EOL + Series

[S]

[1]

[Exxxx][Sxxxx]

Single

Standard

Series Device

[S]

[1]

[Sxxxx]

Single

Standard

EOL Device

SWITCH TYPE [s]

PRODUCT OPTION [o]

SERIES MODULE [s]

[S]

[1]

[Exxxx]

CONFIG. 4CONFIG. 3

SWITCH TYPE [s]

PRODUCT OPTION [o]

MODULE [e][s]

SINGLE SWITCH WITH EOL & SERIES DEVICE

SWITCH TYPE [s]

PRODUCT OPTION [o]

MODULES [e][s]

SINGLE SWITCH WITH EOL & SERIES DEVICECONFIG. 2CONFIG. 1SINGLE SWITCH WITH EOL DEVICE

SWITCH TYPE [s]

PRODUCT OPTION [o]

EOL MODULE [e]

SINGLE SWITCH WITH SERIES DEVICESINGLE SWITCH WITH EOL DEVICE

SINGLE MICROSWITCH WITH DEVICES

Module Device Codes

EOL Series

Resistor ExxxR SxxxR

Diode ED1 SD1

Zener Diode ExxxZ SxxxZ

LED N/A L or C

Notes:

1. Other configurations of dual switch units are possible.

Contact E2S sales to discuss options.

PRODUCTS:

BExCP3B/C/D/E - BG

BExCP3B/C/D/E - PB

BExCP3B/C/D/E - PT

SINGLE SWITCH WITH EOL & SERIES DEVICE SINGLE SWITCH WITH EOL & SERIES DEVICE

Single

Standard

EOL + Series

Single

Alternative Wiring

EOL + Series

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(2,3) & -(4,5) open

Terminals +(2,3) & (6) closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(2,3) & -(4,5) closed

Terminals +(2,3) & (6) open

Circuit shown in Unoperated condition

Unoperated condition

(Glass Intact / Standby Condition)

Terminals +(1,2) & -(4,5) M/S 1 open

Terminals +(1,2) & (6) M/S 1 closed

Operated condition

(Glass Broken / Button pushed in)

Terminals +(1,2) & -(4,5) M/S 1 closed

Terminals +(1,2) & (6) M/S 1 open