_______________________________________________________________________________________________________________________________

European Safety Systems Ltd. Impress House, Mansell Road, Acton, London W3 7QH www.e2s.com Tel: +44 (0)208 743 8880

Document No. D226-00-125-IS_Issue_4 20/04/2023 Sheet 4 of 5

To move the duty labels, use a spanner or equivalent tool to

carefully remove the hex nuts and spring washers from the

positions shown on the rear of the plate. Care should be

taken not to drop them, especially if working from height.

Fig. 7: Plate underside

duty label fixings

For horizontal mounting, the hex spacers are optional.

If using the hex spacers:

Position the duty label assembly in the desire position (fig. 6).

Place spring washers over the spacer threads on the

underside of the plate and tighten M4 hex nuts fully.

If not using hex spacers:

Carefully remove the duty labels from spacers using a posi-

drive screwdriver to loosen the M4 screws. Place duty label

flush to plate with screws inserted into holes (fig. 6). Place

spring washers over the spacer threads on the underside of

the plate and tighten M4 hex nuts fully.

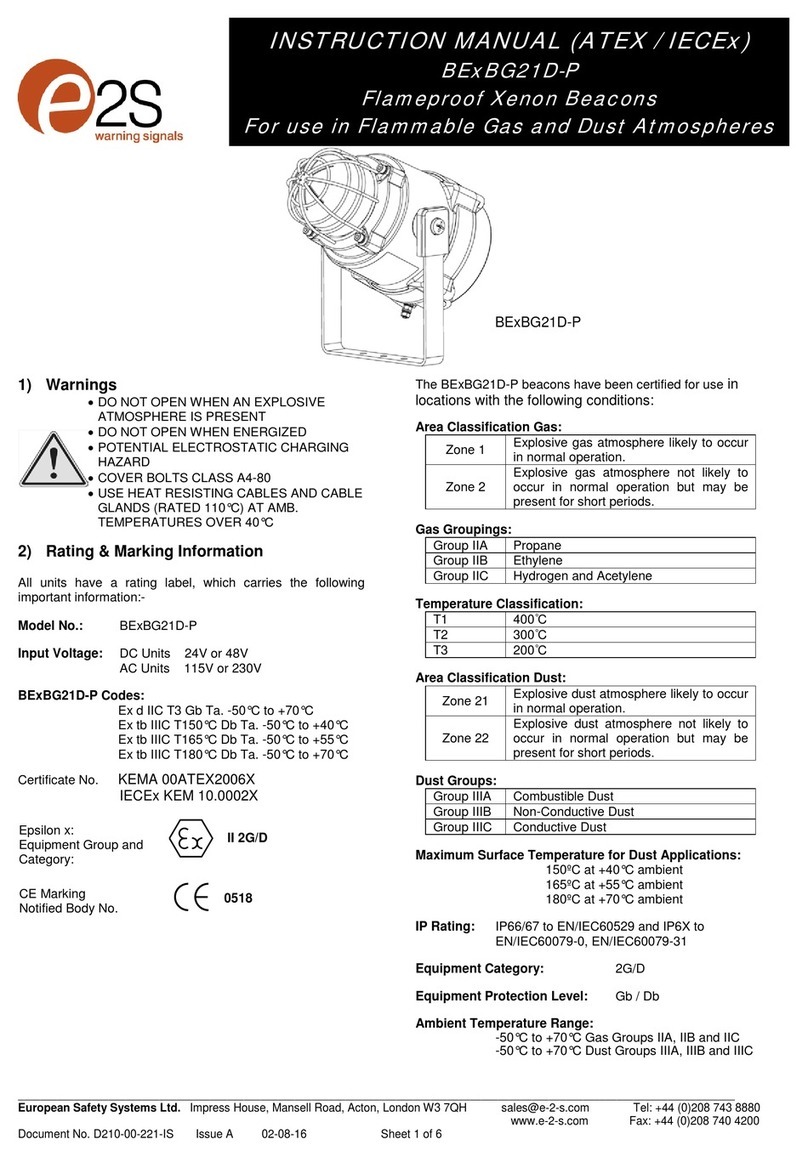

Beacons can be configured with a traffic light cowl to

enhance visibility. Figure 8 shows the optional Traffic Light

Cowl pre-assembled to the Beacon by E2S.

Fig. 8: Traffic Light Cowl

To disassemble the cowl, loosen the M6 Nut using a spanner

or wrench and carefully remove from the beacon lid casting.

To re-assemble, manoeuvre the cowl back into position and

tighten the M6 Screw and Nut until the cowl is fixed securely.

15) Maintenance, Overhaul and Repair

Please see individual product instruction manual. See Table

1 for Instruction Manual Document Number.

16) SIL Approvals

16.1 Standard Configurations

Beacons and Sounders have been assessed for Reliability

and Functional safety under IEC/EN61508 and are

considered suitable for use in low demand safety functions:

1. Random Hardware Failures and Architectural constraints

(route 2H).

2. As an unvoted item (i.e. hardware fault tolerance of 0) at

SIL 2.

Please see individual product instruction manual in Table 1

for information on reliability data.

16.2 SIL Module Configuration

For plated stacks with Product Version S, the units are

configured with SIL 2 relay modules and have been assessed

under route 1H. For further information on reliability data and

operation, please see the individual SIL documents

referenced in table 2.

Table 2: SIL Product Instruction Manual Reference

17) Telephone/ Relay Module Configuration

For plated stacks with Product Version T, the beacon and

sounder can be powered simultaneously using the relay

board. This can be configured to be either relay operated

(DC) or initiated by a telephone signal.

See Document D226-00-725-IS for full details.

Component

Part Code

Component Description SIL Document

Number

D191-00-621-IS