4Instruction Book IB182023EN March 2016 www.eaton.com

AMH-4.76-VR

Replacement Circuit Breaker

SECTION 1: INTRODUCTION

The purpose of this book is to provide instructions for receiving

and handling, storage, installation, operation and maintenance of

the General Electric type AMH-4.76 VR-Series circuit breaker. The

Vacuum Replacement Circuit Breakers (also referred to as VR-Series)

are designed to be used in existing AMH-4.76 metal-clad switchgear

and provide equal or superior electrical and mechanical performance

as compared to the design ratings of the original circuit breaker.

VR-Series Circuit Breakers provide reliable control, protection and

performance, with ease of handling and maintenance. Like ratings

are interchangeable with each other.

This book is intended to be used in conjunction with the technical

information provided with the original equipment order which

includes, but is not limited to electrical control schematics and wiring

diagrams, outline diagrams, installation plans, and procedures for

installation and maintenance of accessory items.

Satisfactory performance is dependant upon proper application,

correct installation, and adequate maintenance. It is strongly

recommended that this instruction book be carefully read and

followed in order to realize optimum performance and long useful life

of the circuit breaker.

1.1 VISUAL INSTRUCTION BOOKLET ESSENTIALS

Eaton provides additional documentation designed to enhance the

technical information provided in this instruction booklet for the

VR-Series circuit breakers. The Visual Instruction Booklet Essentials

(VIBE) is a digital supplemental booklet featuring user interactive

content and informative videos intended to assist with the

maintenance of the VR-Series circuit breaker. The VIBE document is

available for immediate download at www.eaton.com/VR-Series.

1.2 QUICK RESPONSE CODE

VR-Series circuit breakers have a quick response code (QR Code) on

the escutcheon of the circuit breaker cover. This QR Code is a matrix

barcode that provides direct access to download VR-Series specific

documentation, such as product instruction booklets and the VIBE

documentation. See Figure 1.1 for the featured VR-Series QR Code.

ote:N A smart phone with an adequate QR Code Scanner application must be

used. Downloading content may incur data charges from the mobile service

provider.

WARNING

SATISFACTORY PERFORMANCE OF THESE BREAKERS IS CONTINGENT

UPON PROPER APPLICATION, CORRECT INSTALLATION AND ADEQUATE

MAINTENANCE. THIS INSTRUCTION BOOK MUST BE CAREFULLY READ

AND FOLLOWED IN ORDER TO OBTAIN OPTIMUM PERFORMANCE

FOR LONG USEFUL LIFE OF THE CIRCUIT BREAKERS. IT IS FURTHER

RECOMMENDED THAT THE INSTALLATION BE PERFORMED BY A EATON

CORPORATION TRAINED ENGINEER OR TECHNICIAN.

VR-SERIES BREAKERS ARE PROTECTIVE DEVICES, AS SUCH, THEY ARE

MAXIMUM RATED DEVICES. THEREFORE, THEY SHOULD NOT UNDER ANY

CIRCUMSTANCE BE APPLIED OUTSIDE THEIR NAMEPLATE RATINGS.

ALL POSSIBLE CONTINGENCIES WHICH MIGHT ARISE DURING

INSTALLATION, OPERATION, OR MAINTENANCE, AND ALL DETAILS

AND VARIATIONS OF THIS EQUIPMENT ARE NOT COVERED BY THESE

INSTRUCTIONS. IF FURTHER INFORMATION IS DESIRED BY THE

PURCHASER REGARDING A PARTICULAR INSTALLATION, OPERATION, OR

MAINTENANCE OF THIS EQUIPMENT, THE LOCAL EATON REPRESENTATIVE

SHOULD BE CONTACTED.

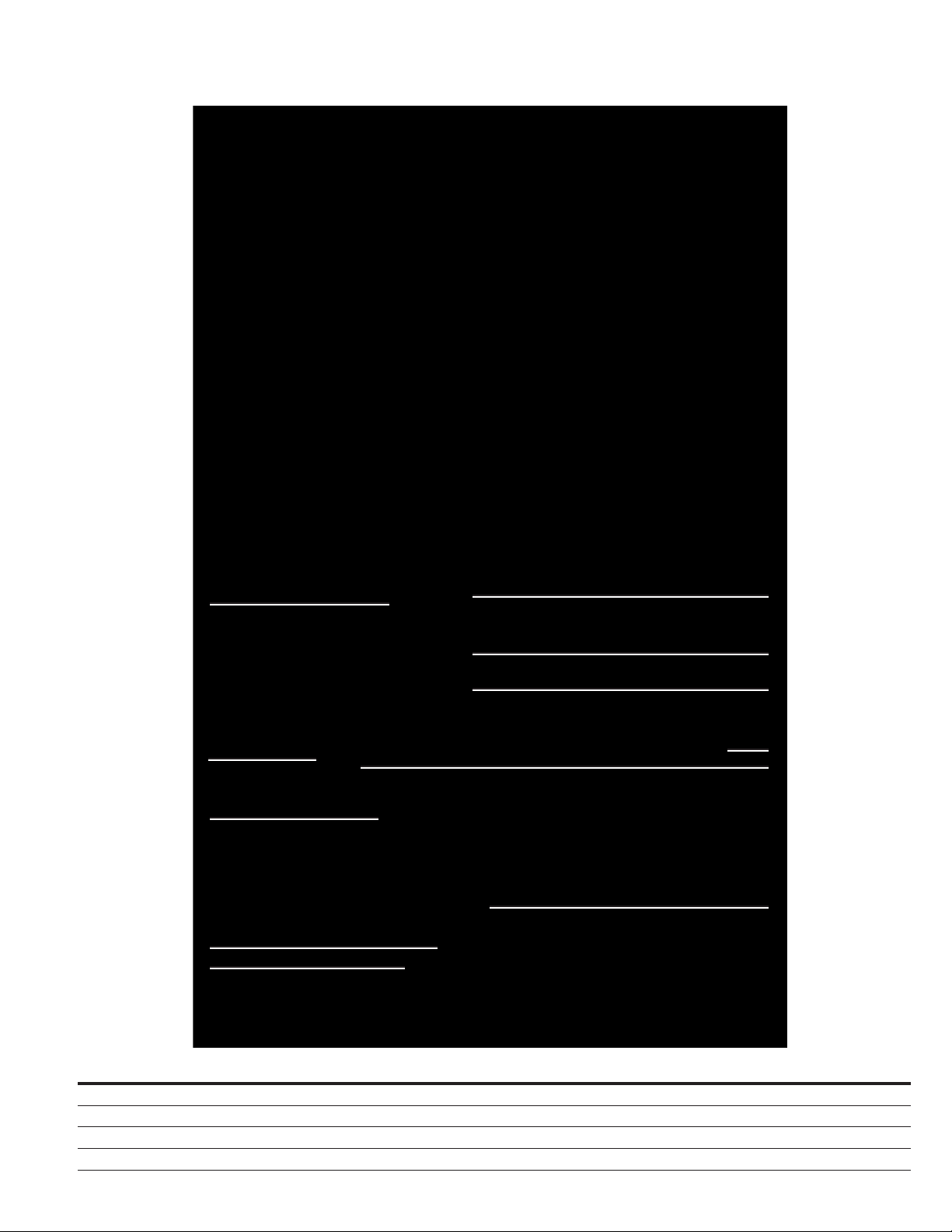

1.3 AVAILABLE AMH-4.76-VR CIRCUIT BREAKERS

Refer to Table 1.

Table 1. AMH-4.76-VR Availability and Interchangeability

Breaker

Type

Nominal

Voltage

Class

(kV)

Existing

Breaker

MVA

Rating

Existing Breaker

Rated Continuous

Current at 60 Hz

(Amps)

MVA

Designation

of VR-Series

Breaker

Rated

Voltage

Factor

K

Rated Withstand ANSI Test Voltage Rated Short-Circuit

kA RMS at Rated

Max kV

Closing and Latching /

Momentary Capabilities

kA RMS/Peak

Low Freq.

kV RMS

Impulse

kV Crest

AMH-4.76-VR 4.16 250 1200 / 2000 250 1.24 19 60 29 58 / 97

4.16 250 1200 / 2000 250U 1.19 19 60 41 78 / 132

Figure 1.1. Quick Response Code

VR-Series QR Code