Figure

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

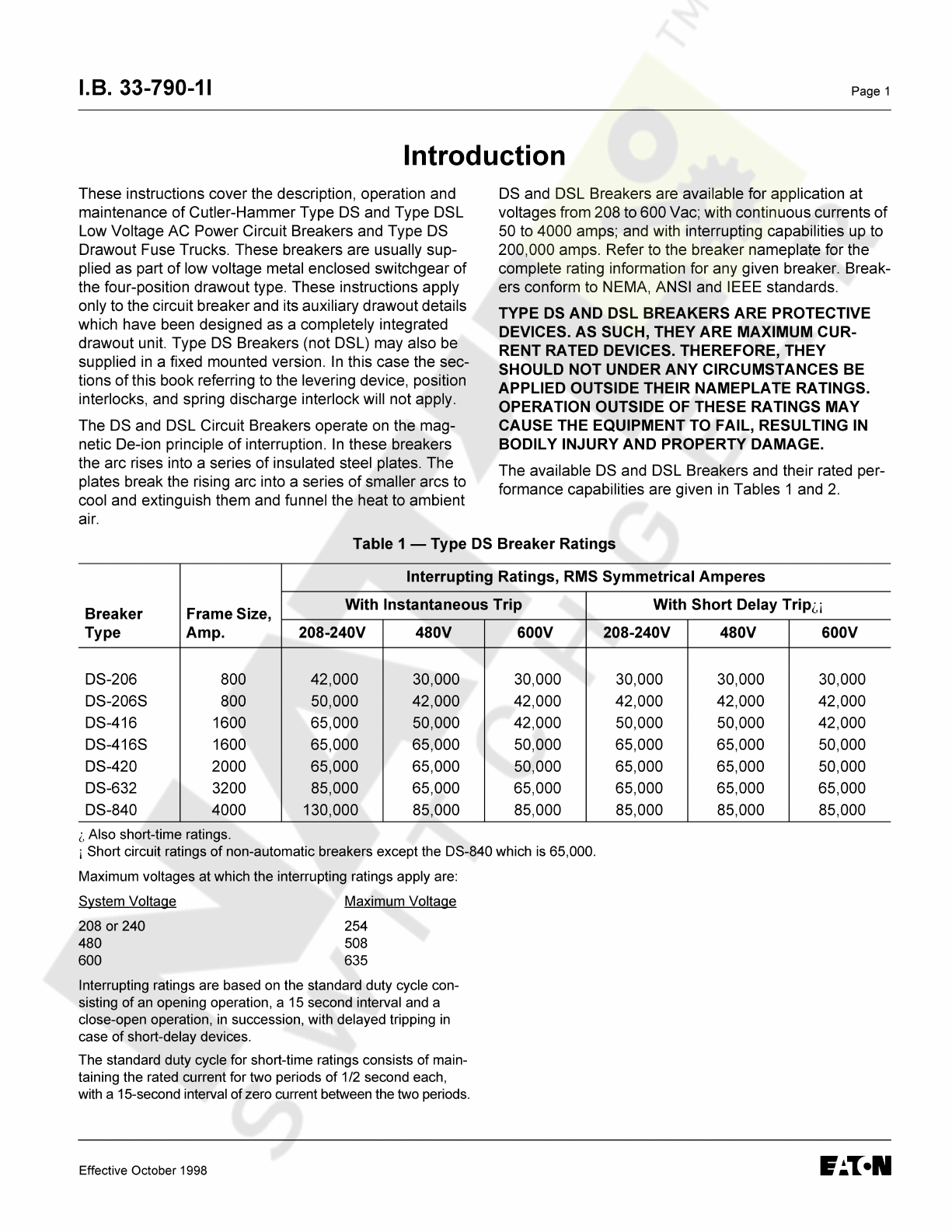

Title

Type DS-416 Pole Unit

Assembly-

Front View

..................................

.

Type DS-416 Pole Unit

Assembly-

RearView

..................................

.

Type DS-420 Pole Unit Assembly -Front

View

..................................

.

Type DS-420 Pole Unit Assembly -Rear

View

..................................

.

Type DS-632 Pole Unit Assembly -Front

View

..................................

.

Type DS-632 Pole Unit Assembly -Rear

View

..................................

.

Type DS-840 Pole Unit Assembly -Front

View

..................................

.

Type DS-840 Pole Unit Assembly -Rear

View

..................................

.

Moving and Stationary Contact Details DS-206

.................................

.

Moving and Stationary Contact Details DS-416

.................................

.

Moving and Stationary Contact Details DS-420

.................................

.

Moving Contact Details DS-632

.............................................

.

Stationary Contact Details DS-632

...........................................

.

Moving Contact Details DS-840

.............................................

.

Stationary Contact Details DS-840

...........................................

.

Breakerwith Barrier Removed to Show Mounting

of

Arc Chutes

....................

.

DS-206

Arc

Chute with Details

..............................................

.

DS-416/420 Arc Chute with Details

...........................................

.

DS-632

Arc

Chute with Details

..............................................

.

DS-840

Arc

Chute with Details

..............................................

.

Schematic Illustration

of

Tripping System

......................................

.

Standard Amptector II-A Solid-State Trip Unit

...................................

.

Amptector II-A Trip Unitwith Front Cover Removed

..............................

.

Optional Amptector I-A Solid-State Trip Unit

....................................

.

Amptector I-A Trip Unit with Front Cover Removed

..............................

.

Trip Actuator

............................................................

.

DS-840 Breakerwith Front Panel Removed

....................................

.

DS-840 Breaker Rear View Showing Sensors

..................................

.

Undervoltage Trip Device

..................................................

.

Undervoltage Trip Device Operation

..........................................

.

Overcurrent Trip Switch

....................................................

.

Overcurrent Trip Switch Operation

............................................

.

High Load Switch

........................................................

.

Latch Check Switch

.......................................................

.

Latch Check Switch Operation

...............................................

.

Auxiliary Switch Construction Details

..........................................

.

Amptector Trip Unit Test Kit (ForAmptector

1-A

and

11-A)

..........................

.

Test Kit in Operation

......................................................

.

DSL-206 Breaker Side View

................................................

.

DSL-206 Breaker Front View (DSL-416 Similar)

.................................

.

DSL-416 Breaker Side View

................................................

.

Blown Limiter Indicator

.....................................................

.

DS-3200 Fuse Truck FrontView

.............................................

.

DS-3200 Fuse Truckwith Front Cover Removed

................................

.

DS-4000 Fuse Truck Side View

.............................................

.

Contacts and their Adjustment, DS-206 Breaker

.................................

.

Contacts and their Adjustment, DS-416/420 Breaker

.............................

.

Effective October 1998

Page v

Page

43

43

43

43

44

44

44

44

45

46

47

48

49

50

51

52

52

52

52

53

54

55

55

56

57

61

62

62

63

63

64

64

64

65

65

65

66

67

68

69

69

70

70

71

71

73

74

Courtesy of NationalSwitchgear.com