EATON HP-30 MOTOR SERVICE MANUAL E-MOGG-RR001-E June 20154EATON HP-30 MOTOR SERVICE MANUAL E-MOGG-RR001-E June 2015 5

Part List

(Single Speed - Bearingless Motor)

Item Description

Ref No. Part No. Description Quantity

1 5998727-001 Housing, Valve 1.0625-12 UN-2B SAE O-Ring Ports (2) 1

5998727-007 Housing, Valve G 1 BSP Straight Thread Ports 1

2 201494-002 Piston, Shuttle 1

3 8567-000 Poppet 2

4 230079-000 Spring 2

5 112126-001 Sleeve, Dash Pot 2

6 9266-006 Plug Sub-Assembly 2

X 250003-904 O-ring 2

7 9266-006 Plug Sub-Assembly 1

X 250003-904 O-ring 1

8 18026-000 Ball, Steel 1

9 5992342-001 Seat, Ball Sub-Assy 1

X 250003-902 O-ring 1

10 9266-006 Plug Sub-Assembly 1

X 250003-904 O-ring 1

11 6203-000 Spring, Compression 10

X 12 14502-032 O-ring 1

X 13 5989483-001 Ring, Backup 1

14 5991782-001 Inner Balance Ring Sub-Assy 1

268009-005 Pin, Roll 2

X 15 14502-040 O-ring 1

X 16 5989483-002 Ring, Backup 2

17 5991783-001 Outer Balance Ring Sub-Assy 1

268009-005 Pin, Roll 2

18 5987800-001 Pin, Dowel 1

19 5987445-001 Valve 1

20 5987844-001 Drive, Valve 1

X 21 250002-161 O-ring (Section Seal) 3

22 5989335-001 Plate,Valve 1

32 * Geroler Sub-Assy 1

33 * Drive, Main 1

34 * Cap Screw, 12 PT 9

35 5987755-007 Flange, Mounting Shuttle Valve With .5625-18 UNF-2B 1

SAE O-Ring Case Drain Port In Mounting Flange .

5987755-009 Flange, Mounting Check Valve With Orice Plug, 1

5625-18 UNF-2B SAE O-Ring Case

Drain Port In Valve Housing

36 113538-001 Poppet (for relief valve unit only) 1

38 113186-001 Spring (for relief valve unit only) 1

39 9072-006 Plug Sub-Assembly 1

X 250003-905 O-ring

X 40 9080-001 Seal, Shaft Face 1

47 285020-140 Ball (for open loop design only) 2

48 9289-001 Plug, Orice (for open loop design only) 1

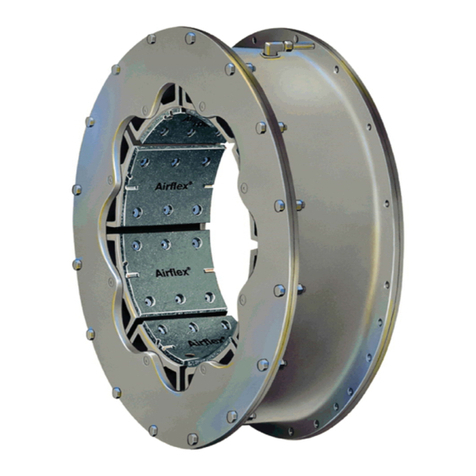

49 31500-452 Strainer (for open loop design only)

9900847-000 Seal Kit - Contains Parts Indicated by X 1

* = See Chart