CC Series Wiring

A CC series lightbar has a 2-wire power cable and a 16-wire control cable. The entire power load of the bar goes through the power cable.

The black ground wire should be connected directly to the battery. The 10 AWG red power wire requires a constant 10 to 16V power source

with a customer supplied in line fuse. To select an appropriately rated ATO (regular) or Maxi Fuse, add the amp ratings, found in the speci-

cations section, of the modules in your conguration specic lightbar and based on that sum, insert a fuse of the next larger size (to be no

larger than a 30 A fuse). The 16 control cable wires carry only low power (30 mA average) input signals to control the lightbar functions and

must be routed to the output of a control switch (or directly to multiple switches).

Before attempting to connect the lightbar wiring harness, refer to the conguration specic wiring key included with the lightbar for the con-

guration specic functions of each wire. Use an appropriate high-temperature wiring if it passes through the engine compartment. Use cable

ties and grommets to secure and protect all cables and wires.

Note:

-When the Arrowstik Left and Arrowstik Right wires are both connected to +power, the Center-Out Arrowstik function is activated.

-The Front Cut and Rear Cut functions must be used with the greatest care to ensure that the use of these functions do not diminish

the effectiveness of the Emergency Warning signal.

-When the Pattern Select wire is connected to +power alone, test mode is enabled to exercise all outputs in sequence.

-The Dim Function lowers the brightness of the LEDs in both the ArrowStik mode and Emergency Warning Flash modes.

-The WHT Drivers Side Cut wire may be changed to Arrowstik Flash. Please see the Arrowstik ash pattern selection section below

for details.

-Lightbars equipped with a DOT strip assembly are wired in conjunction with the STT tail light function. All STT functions are

powered independent of the central driver PCA.

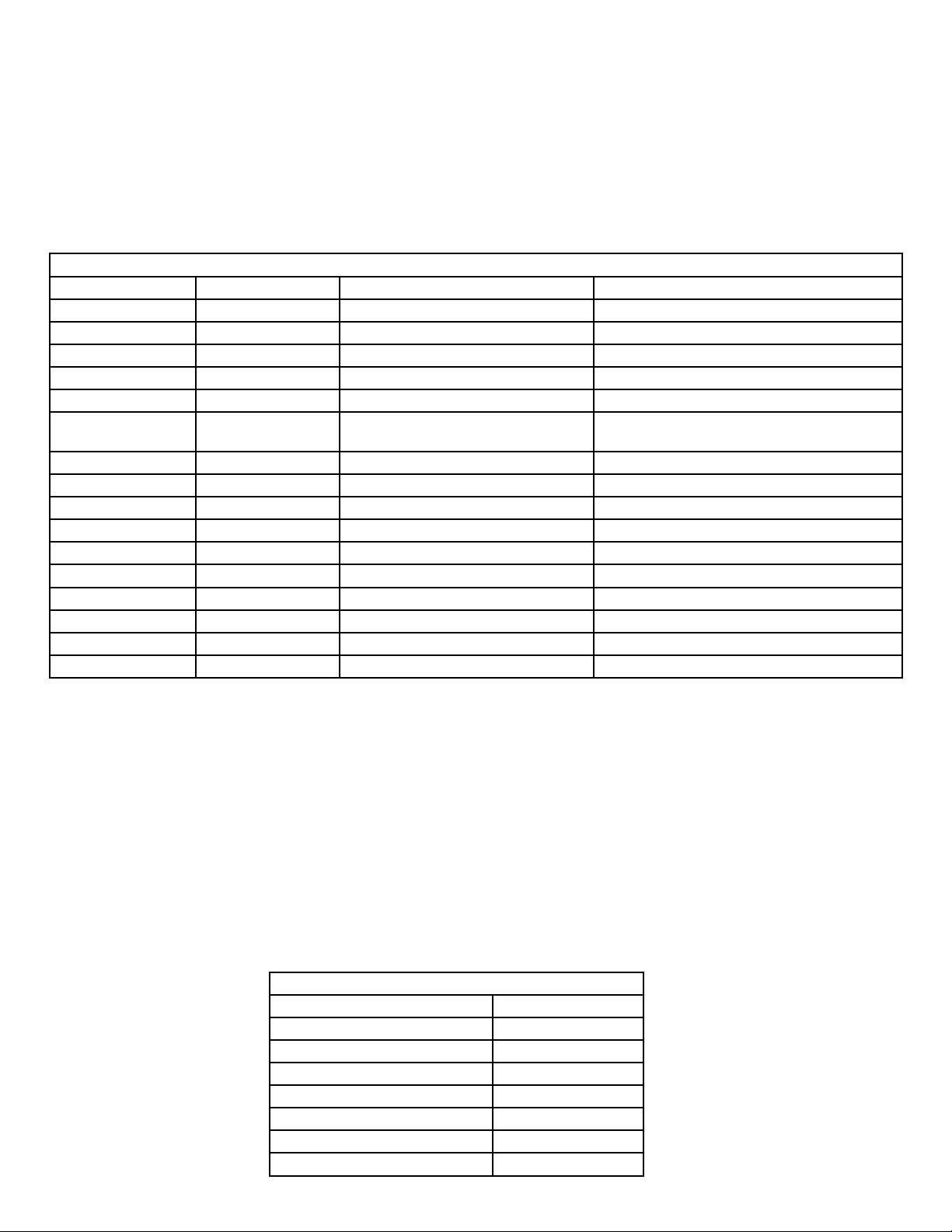

TABLE 2

Standard CC Function Wire Denitions

Function Wire Color Function Description Notes

GRN/BLK L1 Level 1 Emergency Mode

WHT/BLK L2 Level 2 Emergency Mode

RED/BLK L3 Level 3 Emergency Mode

RED Arrowstik Left Left Arrowstick Overrides L1, L2, & L3 for rear of lightbar

ORG Arrowstick Right Right Arrowstick Overrides L1, L2, & L3 for rear of lightbar

WHT Drivers Side Cut Cut Driver Side Directional and Alley

Lights

Designed to interface with the driver’s door

switch

BLK/RED Pattern Select Pattern Select

BLK Take Down Flash Take Down/Work Light Wig/Wag Flash

ORG/BLK Take Down Lights Take Down/Work Light Steady Burn Overrides Take Down Flash

BLU/WHT Alley Light Flash Enables Alley Light Wig/Wag Flash

BLK/WHT Left Alley Light Left Alley Steady Burn Overrides Alley Light Flash

RED/WHT Right Alley Light Right Alley Steady Burn Overrides Alley Light Flash

GRN/WHT Front Cut-Off Blacks-Out Front Facing LEDs

BLU/BLK Rear Cut-Off Blacks-Out Rear Facing LEDs

GRN Cruise Lights End LEDs only Overridden by all other functions except for Dim

BLU Lightbar DIM Sets LEDs to DIM mode

Emergency Mode Flash Pattern Selection

There are seven customizable emergency ash pattern modes available based on the wire combinations shown in TABLE 3. When using

individual switches, make sure to congure all possible switch combinations. The default setting is unsynchronized which allows each light

head module group to be congured separately and the lightbar to ash in an unsynchronized pattern. Steps to synchronize the light head

module groups together are detailed in later sections.

Level Mode Combinations

Function Wire Color Flash Pattern Modes

GRN/BLK L1

WHT/BLK L2

GRN/BLK & WHT/BLK L1 + L2

RED/BLK L3

GRN/BLK & RED/BLK L1 + L3

WHT/BLK & RED/BLK L2 + L3

GRN/BLK, WHT/BLK & RED/BLK L1 + L2 + L3

TABLE 3