P/N 920-0558-00 (Rev A) 2016-12-21

© 2016 at ECCO

Page 2 of 4

ECCO Safety Group Europe

Victoria Industrial Park, Victoria Road

Seacroft, Leeds, England

LS14 2LA

+44 (0)113 2375340

www.eccosafetygroup.com

Caution: When drilling into any vehicle surface, make sure the area

is free from any electrical wires, fuel lines, vehicle upholstery, etc.

that could be damaged

WARNING!

Maximum recommended vehicle speed for safe operation using

the Mount model is 65 mph (104 km/h), when tted to the center

of a vehicle roof of steel construction. Higher speeds could

cause the mount to fail, resulting in the minibar ying off of

the vehicle, which could cause damage to other vehicles, and

injury or death to the passengers. The magnet mount is not

intended as a permanent mounting for the minibar. The magnet

mount unit must be mounted on a at smooth magnetic surface

(i.e. no berglass, ribbed style roofs, etc.). Ensure that the

magnet is kept clean.

Important! Disable power before wiring up the Microbar.

Note: Operating the Microbar without the lens installed on this

product will result in damage that will not be covered under warranty.

WARNING!

Failure to follow these instructions can result in re or injury from excessive heat build up.

Operator is responsible for ensuring auxiliary plug ts correctly into auxiliary power plug outlet used.

For proper operation, verify auxiliary power outlet circuit is rated to supply a minimum of 10 amps. (See specications section for rated current in amperes).

Do not exceed the current rating for the auxiliary power outlet recommended by vehicle manufacturer.

Keep auxiliary plug and outlet clean and free of debris.

Do not use the auxiliary plug when wet.

Insert auxiliary plug fully into the outlet for proper connection.

Grasp auxiliary plug, NOT cord, to remove from outlet.

Remove auxiliary plug completely from outlet when light is not in use.

NOTE: Operating the vehicle without the outer lens installed on the

product may result in damage that will NOT be covered under

warranty.

PULL/ROLL TAB

UPWARD TO

RELEASE VACUUM

PULL/ROLL TAB UPWARD TO RELEASE VACUUM

FIGURE 1

FIGURE 2

Permanent Mounting:

1. Select the desired location on a at surface for the

Microbar to be mounted. The visibility of the ash and

ease of wiring access should be taken into

consideration in the selection of the mounting location.

2. Drill Ø13mm hole for bolt in central location.

3. Remove nut/ shakeproof washer/ washer from bolt. (rubber

spacer to stay on bolt above mounting surface)

4. Place sponge gasket in position on vehicle roof.

5. Place lightbar on roof with wires and bolt through the hole.

6. Ensure bolt head is located correctly in base moulding.

7. Re-apply washer/ shakeproof washer/ nut on underside of

mounting surface and tighten nut to 5Nm.

8. Connect the wires as shown in the wiring section (see Figure 2).

Magnetic Mount Installation for 5500 Series:

1. Remove round black stickers for Magnetic placement

2. Remove lens screws, then remove lens.

3. Unclip and remove wire harness

4. Position vacuum magnets, place, and tighten screws.

5. Insert pinned end of cable through the wire harness hole from the

bottom of the base. Pull at least 6 inches of slack.

6. Turn pins crimp side up, and insert pins into connector as shown in

Figure 3.

7. Place zip-tie 1.0” from base of the connectors shown in Figure 4. Zip-tie

must not slide on cord.

8. Trim excess zip-tie.

9. Clip connector to the PCA board and pull slack until zip-tie touches base.

10.Install lens, reverse of removal.

11.Slide o-ring onto screw until it reaches head, before placing into lens.

If o-rings are damaged, replace with new ones.

Wiring:

The wiring for the permanent mount Microbar is as shown in Figure 5. All

wiring should be a minimum of 18AWG. The positive line must have a 5 amp

fuse, as shown. A switch may be used to control the on/off function.

Flash patterns can be selected on permanent mount Microbar by

touching the yellow wire to the red power wire for less than a second.

Contacting the yellow and red wires for longer than a second toggles to

the preceding ash pattern. The VM models have ash pattern select

via a momentary switch on the cigarette plug.

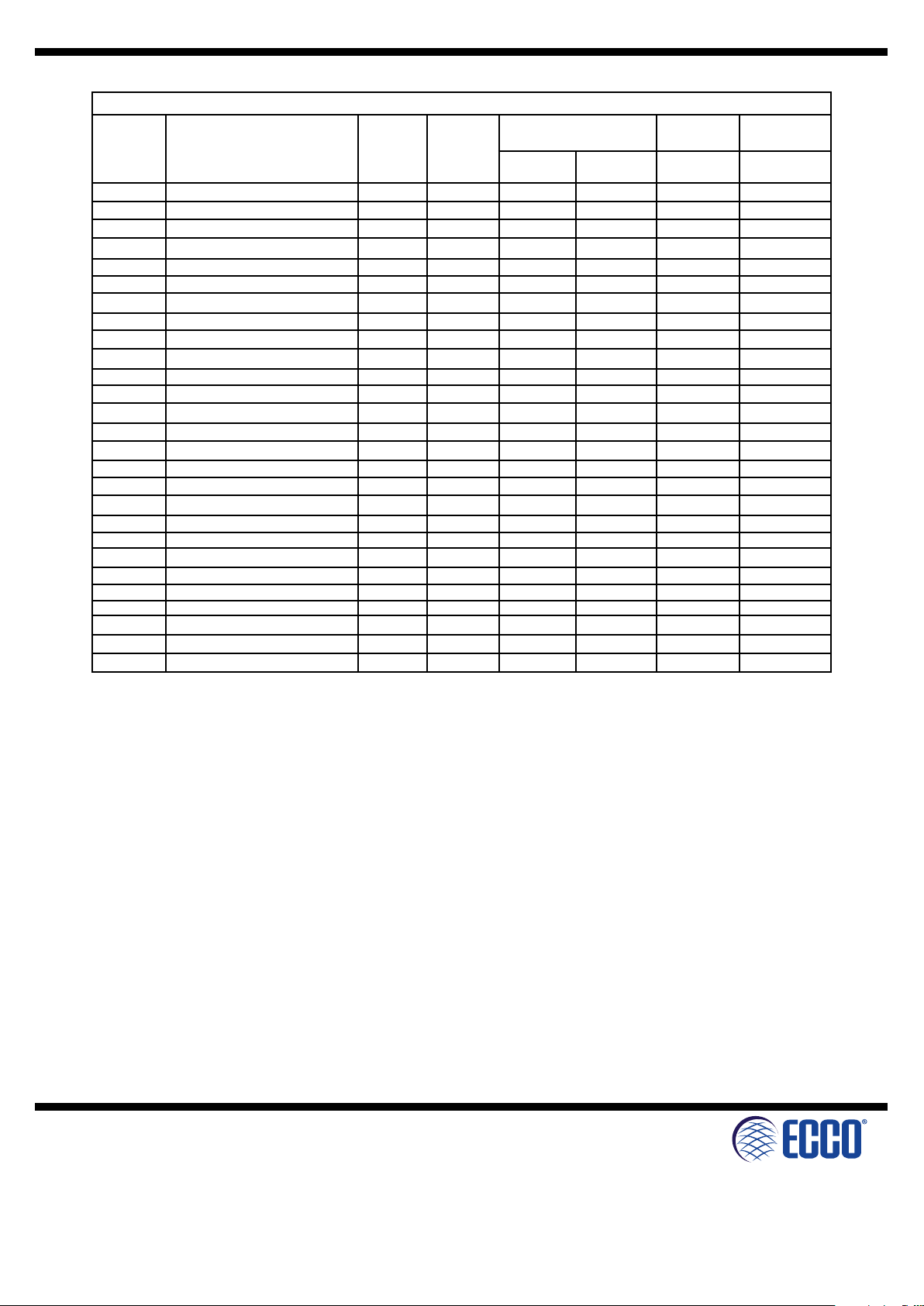

Flash Mode Selection:

The 5550 permanent mount models sync with other compatible ECCO

products via the blue wire:

1. Determine the desired style of ash pattern for each unit and seteach

unit individually (without the BLUE wires connected together) to avoid

confusion. It is also strongly recommended that the same style of

ash pattern be used on all units to produce the most effective

warning pattern. (NOTE: Phases A and B for each style of ash

pattern in the table denote the relative timing between units

connected in synchro-nizing installation. To operate simultaneously,

each unit must be set to the same phase (A + A or B + B); to operate

alternately, units must be set to have the opposite phase

(A + B or B + A)).

2. Connect the BLUE (SYNC) wires together and check that the units

are ashing in a synchronized manner as expected. If a pattern on

one module appears to be wrong, the YELLOW (PATTERN SET)

wire can be used to cycle forward or backward on that individual

unit until the correct pattern is selected. Note: This will only change

the pattern in the one unit and will not affect the other units

connected to the BLUE (SYNC) wire.

3. If the blue wire is unused, leave unconnected and insulated.