920-5135-00 Rev. D Page 2 of 4

Permanent Mounting:

Select the mounting location for the minibar on a at, smooth

surface. If the minibar is to be mounted on a curved surface,

such as on the roof of the vehicle, choose a placement with

the least amount of curvature. The mounting location for the

minibar should be chosen such that there is maximum

visibility to the oncoming trafc.

CAUTION:

When drilling into any vehicle surface, make sure that the

area is free from any electrical wires, fuel lines, vehicle

upholstery,etc., that could be damaged.

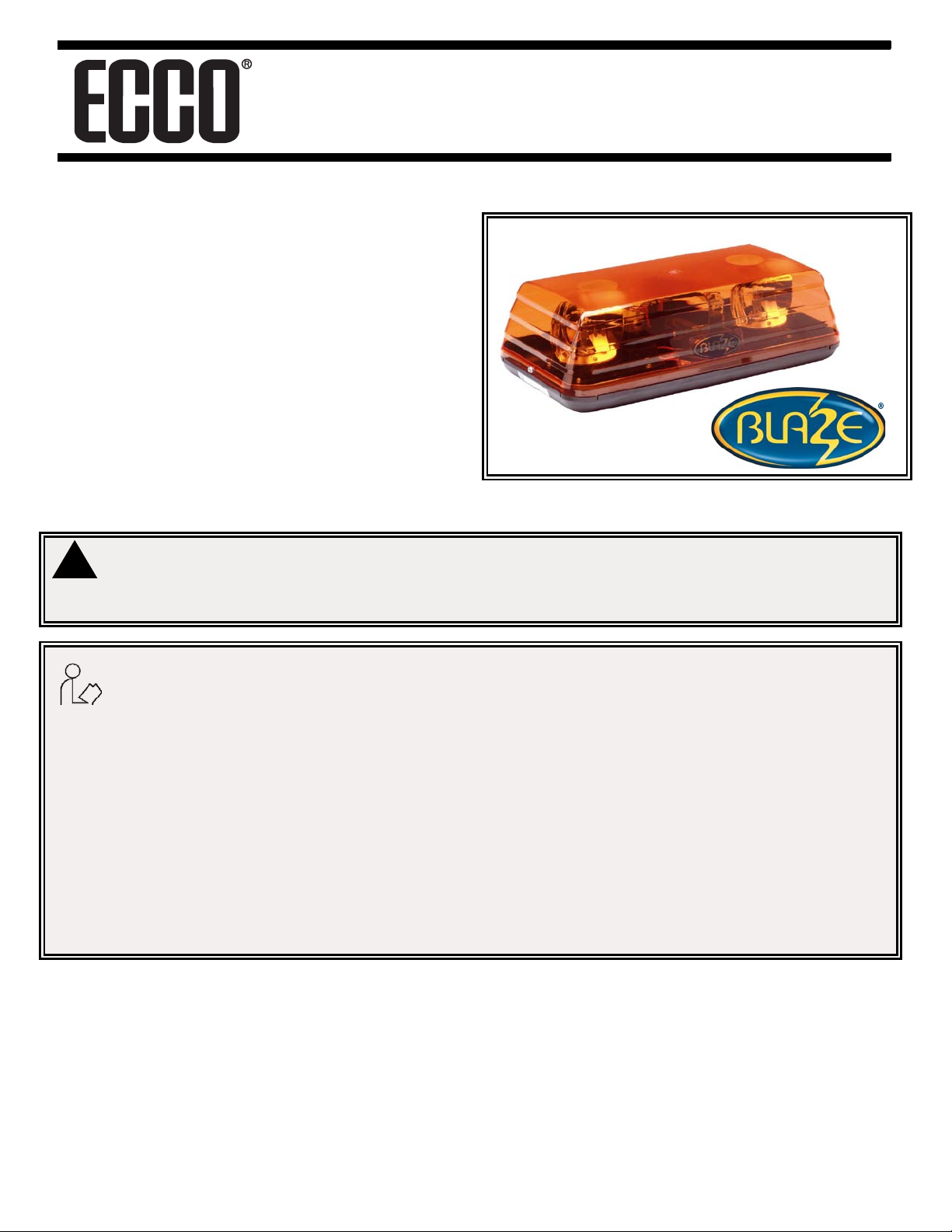

1. Using the mounting holes of the minibar, mark the loca-

tions for the mounting holes. Drill the mounting holes

using a 7/32” drill.

2. Drill a 3/8” hole for the minibar’s power supply wire.

The hole should be underneath where the minibar will

be mounted. Place the supplied grommet in the hole, to

protect the wires from the sharp edges of the hole.

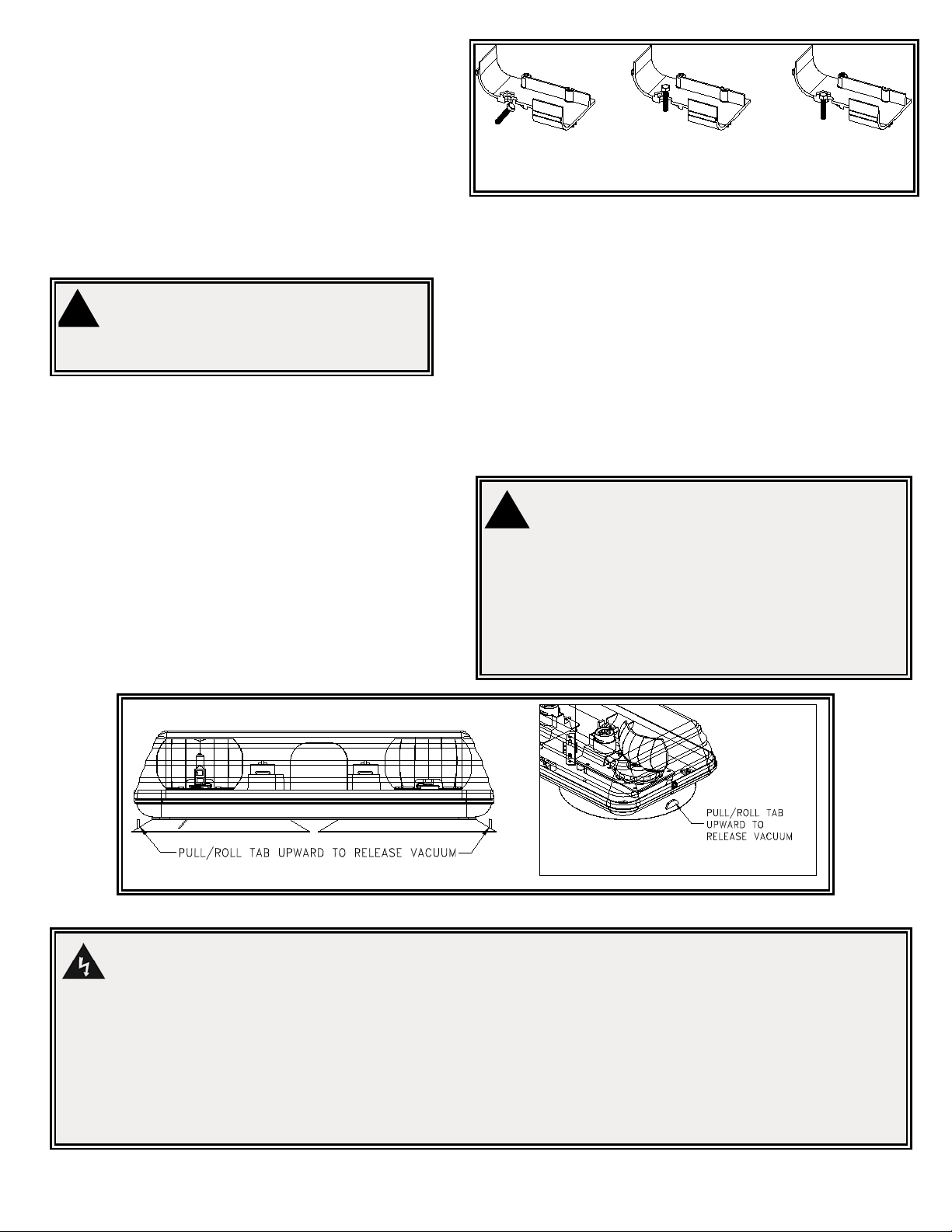

3. Place the four (4) mounting bolts in the bottom of the

base as shown in Figure 1. The base has a mechanism

to hold the bolts in place for installation.

4. Mount the minibar, with the bolts going through the holes

drilled in step 1, routing the wire through the grommet

installed in step 2. See the Wiring section of this manual

for further wiring instructions. Install washers and nuts,

and secure the unit.

INSERT BOLT

THROUGH LARGE

END OF SLOT

PUSH BOLT TO

SMALL END

OF SLOT

PULL BOLT

HEAD DOWN

INTO PLACE

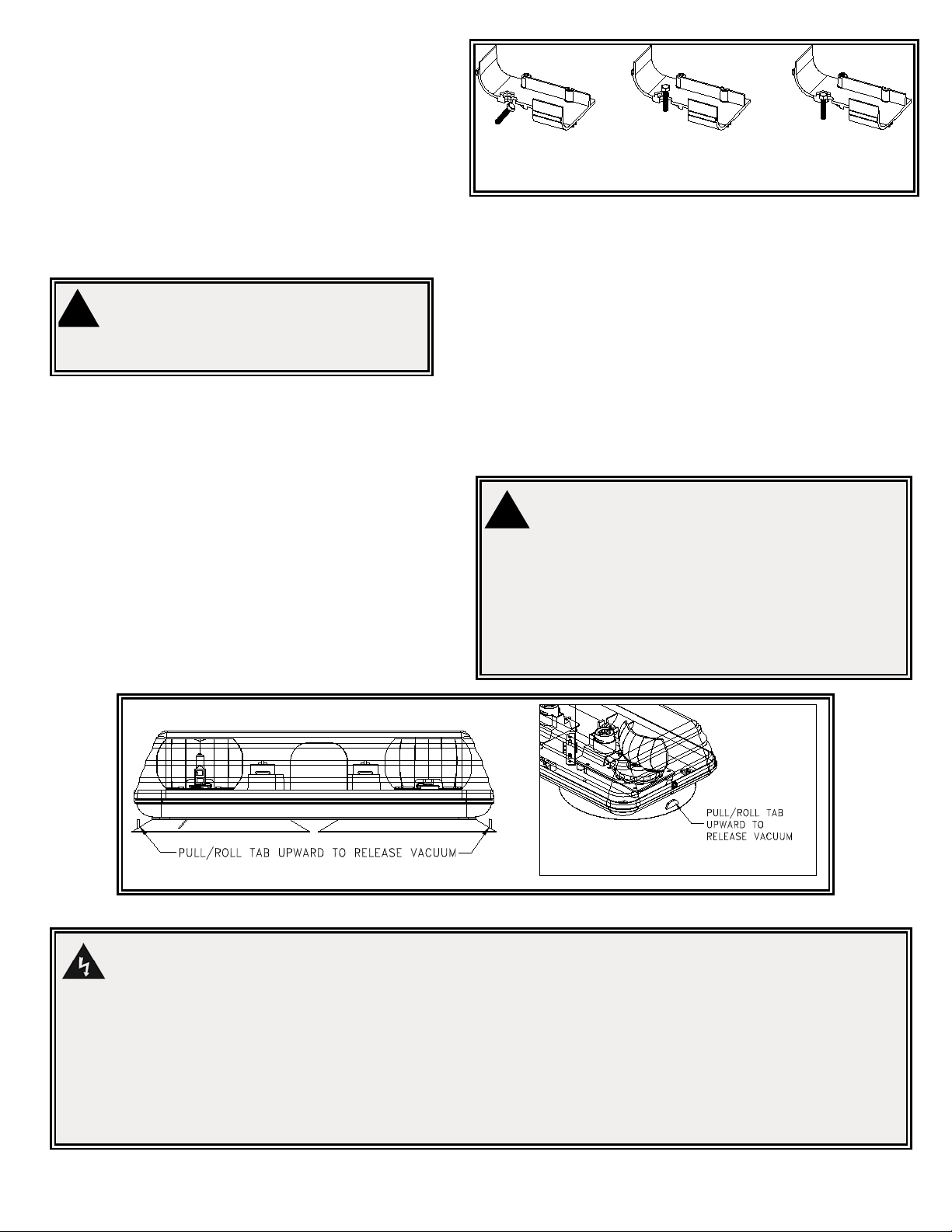

Vacuum-Magnet Mounting:

The vacuum-magnet mount feature includes two (2) suction cups on

the bottom of the minibar, with a magnet inside each of the suction

cups, for a secure, temporary mount. The minibar should be placed

in the center or the roof where the least amount of curvature occurs.

Before installing, make sure there is no debris on the bottom of the

minibar or on the roof of the vehicle, which could reduce the holding

power of the suction cups and magnets. Place and remove the mini-

bar without sliding to avoid scratching the paint on the vehicle. After

placement, the minibar should adhere rmly to the surface. If the unit

slides or moves easily, a proper installation has not been obtained.

To release the vacuum, lift each tab to release the airlock (see Figure

2). To protect the rubber cushion/magnet assembly, return minibar to

the box when not in use. Do not attempt to attach to ice-covered

surface.

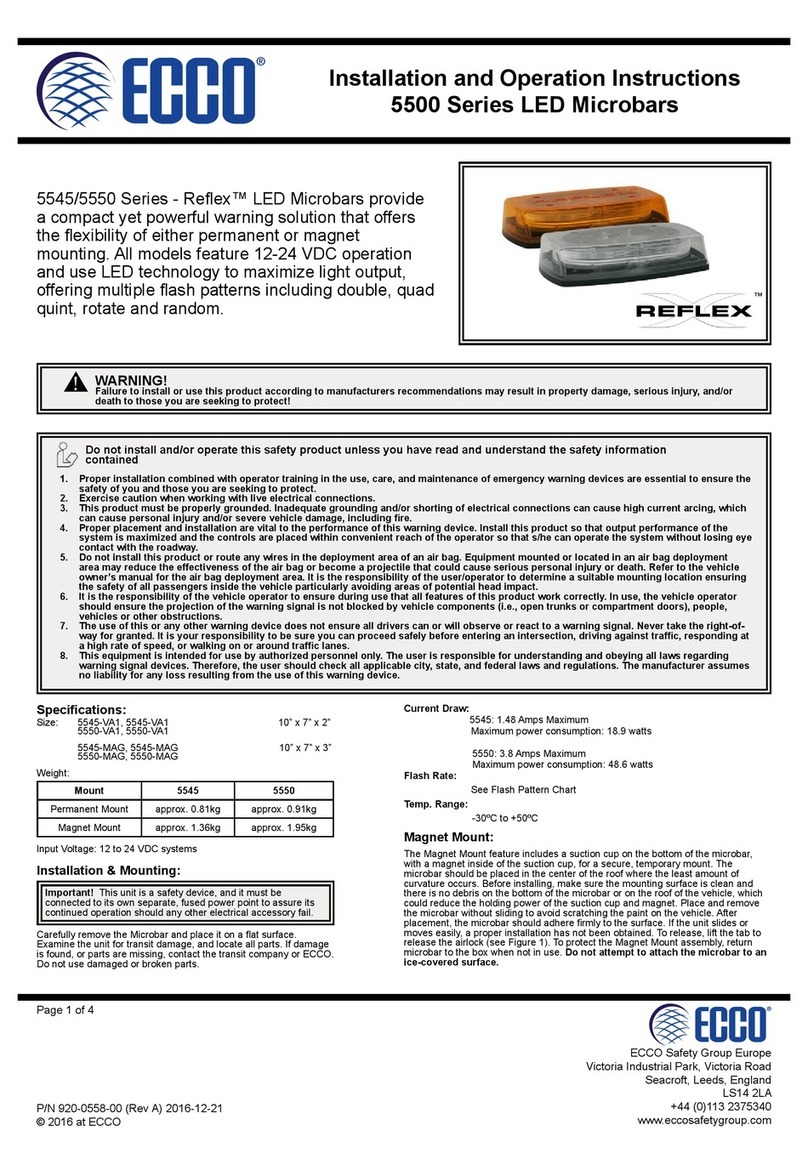

Installation & Mounting:

Carefully remove the minibar and place it on a at surface.

Examine the unit for transit damage, broken lamps, etc. If

damage is found, contact the transit company or ECCO. Do

not use damaged or broken parts.

WARNING!

Maximum recommended vehicle speed for safe operation using the

Vacuum Mount model is 65 mph (104 km/h), when tted to the center

of a vehicle roof of steel construction. Higher speeds could cause the

mount to fail, resulting in the minibar ying off of the vehicle, which

could cause damage to other vehicles, and injury or death to the pas-

sengers. The vacuum-magnet mount is not intended as a permanent

mounting for the minibar. The vacuum-magnet mount unit must be

mounted on a at smooth magnetic surface (i.e. no berglass, ribbed

style roofs, etc.). Ensure that the magnet is kept clean.

Figure 2

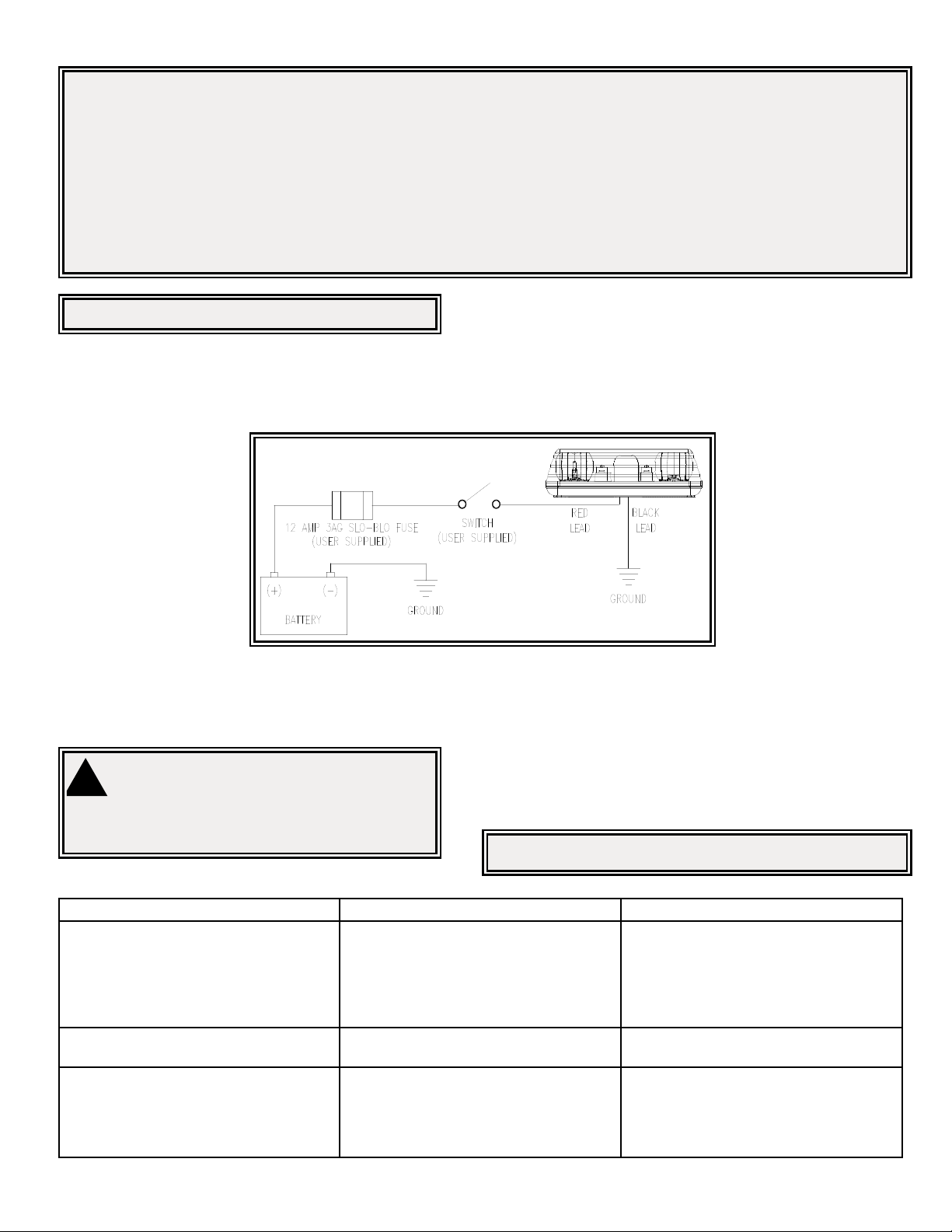

Failure to follow these instructions can result in re or injury from excessive heat build up.

Operator is responsible for ensuring cigarette adapter ts correctly into cigarette/auxiliary outlet used.

For proper operation, verify cigarette/auxiliary outlet circuit is rated to supply, a minimum of 12 amps. (See specications section for rated current in

amperes). Do not exceed the current rating for the cigarette lighter power outlet recommended by vehicle manufacturer.

Keep cigarette lighter adapter, and outlet, clean and free of debris.

Do not use the cigarette lighter adapter when wet.

Insert cigarette lighter adapter fully into the outlet for proper connection.

Grasp cigarette lighter adapter, NOT cord, to remove from outlet.

Remove cigarette lighter adapter completely from outlet when light is not in use.

WARNING!