Edwards AIM-P-NW25 User manual

D14643880

Issue L

Original Instructions

Instruction Manual

Active Inverted Magnetron Gauge

Description Item Number

AIM-P-NW25 D14643000

AIM-PL-NW25 D14646000

Declaration of Conformity

This product has been manufactured under a quality management system certified to ISO 9001:2015.

This declaration is based on the requirements of EN ISO 17050-1 and the relevant directives.

P20003260G

Edwards Ltd,

Innovation Drive,

Burgess Hill,

West Sussex,

RH15 9TW, UK

The following product

Active Inverted Magnetron Gauges

AIM-P-NW25 D14643000

AIM-PL-NW25 D14646000

Is in conformity with the relevant requirements of European CE legislation:

2014/30/EU

Electromagnetic compatibility (EMC) directive

2012/19/EU

Waste from electrical and electronic equipment (WEEE) directive

2011/65/EU

Restriction of certain hazardous substances (RoHS) directive

Based on the relevant requirements of harmonised standards:

EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control and laboratory use.

General requirements

EN 61326-2-3:2013

(Class B Emissions,

Industrial Immunity)

Electrical equipment for measurement, control and laboratory use. EMC requirements.

Particular requirements. Test configuration, operational conditions and performance

criteria for transducers with integrated or remote signal conditioning

The product also complies with the following:

CSA-C22.2

No.61010-1-12

Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

UL61010-1

3

rd

Edition

Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

This covers all product serial numbers from the date of this declaration onwards.

17.01.2019, Eastbourne

Larry Marini, Senior Technical Manager

Date and Place

P200-10-052

Issue A

Material Declaration

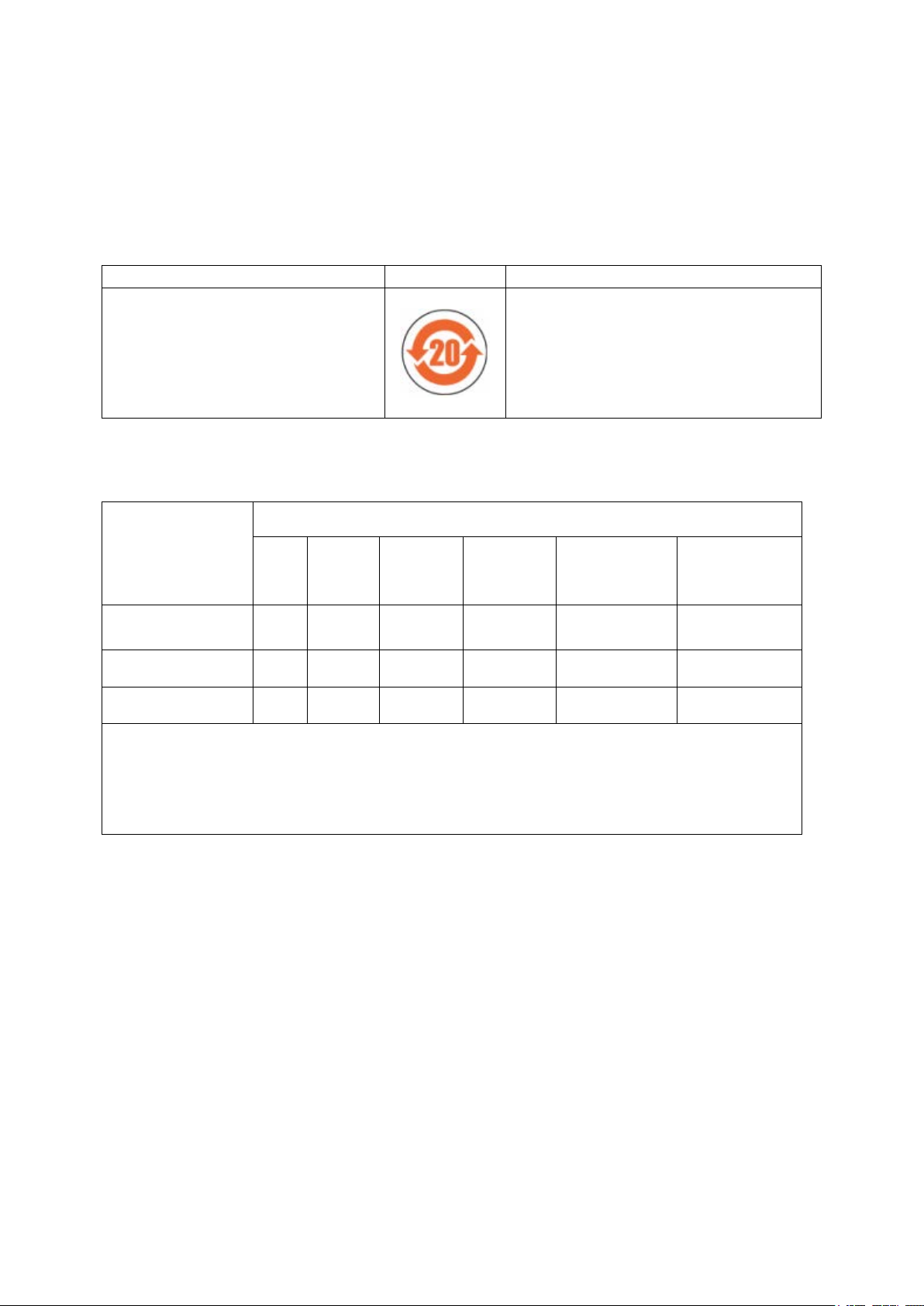

In accordance with the requirements of the Chinese regulatory requirement on the Management Methods for the

Restriction of the Use of Hazardous Substances in Electrical and Electronic Products Order No. 32 (also known as

‘China RoHS2’) and SJ/T 11364 Marking for the Restricted Use of Hazardous Substances in Electronic and Electrical

Products:

Product Product Label Meaning

D14643000 AIM-P-NW25

D14646000 AIM-PL-NW25

This product contains hazardous substances in

at least one of the homogeneous materials

used which are above the limit requirement in

GB/T 26572 as detailed in the declaration

table below.

These parts can safely be used for the

environmental protection use period as

indicated.

材料成分声明

Materials Content Declaration

部件名称

Part name

有害物质

Hazardous Substances

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr VI)

多溴联苯

Polybrominated

biphenyls (PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

印刷电路组件

(PCA)

Printed Circuit

Assembly (PCA)

X O X O O O

电缆/电线/连接器

Cable/wire/connector

X O O O O O

机械部件

Mechanical Components

X O O O O O

O: 表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

O: Indicates that the hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement in GB/T 26572.

X: 表示该有害物质在该部件的至少一种均质材料中的含量超出 GB/T26572 标准规定的限量要求。

X: Indicates that the hazardous substance contained in at least one of the homogeneous materials used for

this part is above the limit requirement of GB/T26572.

NOTE: These products are EU RoHS compliant, the following Exemptions apply:

6(b)

Lead

as an alloying element in aluminium containing up to 0.4% by weight

6(c) Copper alloy containing up to 4%

lead

by weight

7(a)

Lead

in in high melting temperature type solder (i.e. lead based alloys containing 85% by or more)

7(b)

Lead

in solders for servers, storage and storage array systems, network infrastructure equipment for switching, signalling,

transmission, and network management for telecommunications

7(c) I Electrical and electronic components containing

lead

in a glass or ceramic other than dielectric ceramic in capacitors, e.g.

piezoelectronic devices, or in a glass or ceramic matrix compound

7(c) II

Lead

in dielectric ceramic in capacitors for a rated voltage of 125 V AC or 250 V DC or higher

8(b)

Cadmium

and its compounds in electrical contacts

15

Lead

in solders to complete a viable electrical connection between semiconductor die and carrier within integrated circuit flip

chip packages

34

Lead

in cermet-based trimmer potentiometer elements

This page has been intentionally left blank.

Page left blank for D of C to be inserted

© Edwards Limited 2020. All rights reserved. Page i

Contents

D14643880 Issue L

Contents

Section Page

1 Introduction ....................................................................................... 1

1.1 Scope of this manual .................................................................................................... 1

1.2 General .................................................................................................................... 1

2 Technical data .................................................................................... 3

2.1 Pressure range ........................................................................................................... 3

2.2 Mechanical data .......................................................................................................... 3

2.3 Materials exposed to vacuum system ................................................................................. 3

2.4 Operating conditions .................................................................................................... 3

2.5 Electronic interface ..................................................................................................... 3

2.6 Electrical supply ......................................................................................................... 4

2.7 Output signal ............................................................................................................. 4

2.8 Gauge enable ............................................................................................................. 4

2.9 Set point .................................................................................................................. 4

2.10 Read set-point ............................................................................................................ 4

2.11 Error monitoring ......................................................................................................... 5

3 Installation ......................................................................................... 7

3.1 Unpacking and inspection .............................................................................................. 7

3.2 Connection to the vacuum system .................................................................................... 7

3.3 Positioning the gauges .................................................................................................. 7

3.4 Electrical connection .................................................................................................... 7

3.5 Gauge set-point .......................................................................................................... 8

3.5.1 Potentiometer adjustment ............................................................................................. 8

3.5.2 Set-point output ......................................................................................................... 9

3.5.3 Disable set-point ........................................................................................................10

4 Operation ........................................................................................ 11

4.1 Reading the pressure ...................................................................................................12

4.2 Error monitoring ........................................................................................................12

5 Maintenance ..................................................................................... 15

5.1 Dismantling the body tube ............................................................................................15

5.2 Bayonet fitting of body tube ..........................................................................................15

5.3 Cleaning ..................................................................................................................15

5.4 Fault finding .............................................................................................................16

6 Storage and disposal ........................................................................... 19

6.1 Storage ...................................................................................................................19

6.2 Disposal ...................................................................................................................19

6.3 Return the equipment or components for service..................................................................19

7 Spares and accessories ......................................................................... 21

7.1 Introduction .............................................................................................................21

7.2 Accessories and spares .................................................................................................21

7.2.1 Active gauge cables ....................................................................................................21

7.2.2 Gauge spares ............................................................................................................22

Appendix A1 ............................................................................................. 23

GEC/ 2020-AVI-GCN-0011

D14643880 Issue L

Page ii © Edwards Limited 2020. All rights reserved.

Contents

Illustrations

Figure Page

1 General view of AIM gauge showing NW25 flange .................................................................. 2

2 Connection to power supply and voltmeter ......................................................................... 8

3 Measuring gauge set-point trip voltage ............................................................................... 9

4 Connection of relay to set-point output ............................................................................. 9

5 Assembly of AIM gauge .................................................................................................17

Tables

Table Page

1 Calibration table for dry air and nitrogen ..........................................................................12

Trademark credits

Edwards and the Edwards logo are trademarks of Edwards Limited, Innovation Drive, Burgess Hill,

West Sussex, RH15 9TW, UK.

© Edwards Limited 2020. All rights reserved. Page 1

Introduction

D14643880 Issue L

1 Introduction

1.1 Scope of this manual

This manual provides installation, operation and maintenance instructions for the Edwards Active Inverted Magnetron

Gauge. Read this manual before attempting to install and operate the gauge.

This manual contains essential safety information which supplements the safety features of the gauge. Safety

procedures are highlighted as WARNING and CAUTION instructions. You must obey these instructions. The use of

WARNINGS and CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The units used throughout this manual conform to the SI international system of units of measurement.

The following symbol is on the AIM gauge:

1.2 General

The family of active vacuum instruments is a new generation of stand alone units which combine gauge head and

controller in one active unit.

The Active Inverted Magnetron (AIM) gauge is a cold cathode ionisation gauge. The pressure is measured indirectly

as a function of the current flowing in a Townsend discharge maintained within the body tube.

There are two gauge variants, AIM-P-NW25 and AIM-PL-NW25. The body tube of the gauges terminate in an NW25

flange.

The AIM-PL-NW25 has a very low external magnetic field applicable for use with sensitive analytical instrumentation.

Each gauge requires a 13.5 - 36 V power supply, the pressure reading can be monitored with a simple voltmeter or

the analogue to digital converter of a data acquisition system.

The design of the gauge incorporates features to improve both start up and operation in humid atmospheres, as well

as self monitoring fault detection circuitry.

A set-point output is also provided. The user adjusts the operating pressure of the set-point output using a

potentiometer accessed through the end cap.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

persons.

Edwards offer European customers a recycling service.

D14643880 Issue L

Page 2 © Edwards Limited 2020. All rights reserved.

Introduction

Figure 1 - General view of AIM gauge showing NW25 flange

© Edwards Limited 2020. All rights reserved. Page 3

Technical data

D14643880 Issue L

2 Technical data

2.1 Pressure range

2.2 Mechanical data

2.3 Materials exposed to vacuum system

Stainless steel (AISI 304), Fluoro-elastomer, Nickel (99% pure) Soda lime glass.

2.4 Operating conditions

2.5 Electronic interface

10-8 to 10-2 mbar (7.5 x 10-9 to 7.5 x 10-3 torr)

Gauge case dimensions 95 x 79 mm dia.

Overall length including flange 116 mm

Gauge tube volume 26 cm3

Weight AIM-P 810 g

Weight AIM-PL 860 g

Maximum internal pressure 10 bar absolute (9 bar gauge)

Temperature range +5 °C to +60 °C

Relative humidity (non condensing) 10 -90%

Maximum operating altitude 2000 m (indoor use only)

Pollution degree 2

Enclosure rating *

*Complete gauge attached to vacuum system.

IP40 and IP403

Socket connection (See Appendix A1) FCC68/RJ45 Type, 8 way

D14643880 Issue L

Page 4 © Edwards Limited 2020. All rights reserved.

Technical data

2.6 Electrical supply

Note: The gauge external power supply should have a source impedance less than 50

.

2.7 Output signal

2.8 Gauge enable

2.9 Set point

The set-point consists of an open drain transistor (FET) output which operates when the gauge pressure is below a

preset value. The set-point has a fixed hysteresis of 500 mV. That is, if the trip level is set to 4 V, then the trip is set

(ON) when the gauge output is below 4 V and reset (OFF) above 4.50 V. When the trip is ‘ON’ pin 6 is internally

connected to pin 2 (power supply common).

Note: The external relay must not exceed these ratings.

2.10 Read set-point

Specified at gauge socket

Type NEC Class 2 or Limited Power or Limited Energy

Input voltage range +13.5 V to +36 V d.c.

Voltage ripple 1 V peak to peak maximum

Maximum power consumption 2 Watts

Voltage range 2 V to 10 V d.c.

Minimum load impedance 10 k

Current source 1 mA maximum

Control sense Active low

Active level <1.3 V

Control impedance 12 k pull up to positive supply

Fixed hysteresis 500 mV

Set-point output transistor ratings:

Voltage rating 40 V

Current rating 100 mA

Output voltage:

Settable range < 1.8 to 10.0 V

Accuracy 10 mV

Minimum load 200 k

Maximum current source 50 A

© Edwards Limited 2020. All rights reserved. Page 5

Technical data

D14643880 Issue L

2.11 Error monitoring

When a gauge error is detected the set-point is turned off.

Error conditions

During gauge power up 0.5 s

Signal voltage low < 1.8 V

D14643880 Issue L

Page 6 © Edwards Limited 2020. All rights reserved.

This page has been intentionally left blank.

© Edwards Limited 2020. All rights reserved. Page 7

Installation

D14643880 Issue L

3 Installation

3.1 Unpacking and inspection

Remove all packing materials and protective covers and check the Active Inverted Magnetron Gauge for damage. If

the gauge is damaged, notify your supplier and the carrier in writing within three days; state the Item Number of the

unit together with your order number and your supplier’s invoice number. Retain all packing materials for inspection.

Do not use the gauge.

Note: Please consult your supplier in case of any difficulty.

3.2 Connection to the vacuum system

The gauge body tube terminates in a NW25 flange. To connect to a tube terminating in a NW25 flange, an O-ring, a

centring ring (or Coseal) and clamp will be required.

The gauge can be mounted in any orientation, however in order to avoid the build up of condensable material /

liquids in the body tube (causing probable reading errors) a vertical attitude is preferred; the face of the flange

should be horizontal and the body tube vertical so that the flat end of the case is facing upwards.

3.3 Positioning the gauges

The gauges should be mounted as close as possible to the point at which the pressure is to be measured. Use a short

connecting tube with an internal diameter not less than that of the gauge tube. Long, narrow and angled connections

can cause a significant reading error.

3.4 Electrical connection

Figure 2 shows how the gauge should be connected to an external power supply and voltmeter. Refer to Section 2.6

for full specification of the power supply. A voltage between 13.5 - 36 V should be applied between pins 1 and 2 of

the connector. Connect the gauge before switching ON. Pin 7 must be connected to 0 V to enable the high voltage

supply as shown in Figure 2. (The Edwards Active Pirani Gauge can be used to enable the gauge at the correct pressure

by suitable connection of its set-point output).

WARNING

The AIM gauge incorporates magnets. Keep away from heart pacemakers, computers, credit cards

and any other magnetically sensitive devices.

WARNING

Magnetic Field may interfere with pacemakers. Maintain a distance of minimum 10 cm between

the magnet and the heart pacemaker. You can also use anti-magnetic shield to prevent the

influence of strong magnetic field.

WARNING

If the electronics are disconnected from the body tube and the body tube is left connected to a

vacuum system, then if a plasma discharge is maintained in the system in the vicinity of the body

tube, the anode and guard ring of the body tube assembly may become charged up.

D14643880 Issue L

Page 8 © Edwards Limited 2020. All rights reserved.

Installation

Note: It is advisable to ‘enable’ the gauge below a pressure of 1 x 10-2 mbar since above this pressure erroneous

readings may occur. Continuous operation above 1 x 10-2 mbar can lead to contamination of the gauge.

The signal output can be measured between pins 3 and 5. It is important to keep the signal common (5) separate from

the power supply common (2) for accurate readings.

The total source resistance of the power supply, including cabling, should be less than 50 .

CAUTION

For correct operation the Active Inverted Magnetron gauge should be connected to an earthed vacuum system.

When using a cable longer than 30 m, full compliance with European Standards requires an in-line surge suppressor

(please refer to Section 7.2.1).

3.5 Gauge set-point

3.5.1 Potentiometer adjustment

The set-point trip is adjusted by a multi-turn potentiometer accessed through a labelled hole in the end of the gauge

case. The voltage at which the trip operates can be measured with a voltmeter between pins 4 and 5 (See Figure 3).

The voltage to pressure conversion for the trip level is identical to that of the gauge signal output and is shown in

Table 1.

Figure 2 - Connection to power supply and voltmeter

A. Active inverted magnetron gauge

B. Power supply

C. Voltmeter or chart recorder

D. Grounding switch

E. External DC relay

F. Back EMF suppression diode

1. Positive supply

2. Supply common

3. Signal output

4. Set-point trip level

5. Signal common

6. Set-point output

7. Gauge enable

© Edwards Limited 2020. All rights reserved. Page 9

Installation

D14643880 Issue L

Figure 3 - Measuring gauge set-point trip voltage

Figure 4 - Connection of relay to set-point output

3.5.2 Set-point output

Figure 4 illustrates how the open drain transistor output of the set-point should be connected to operate an external

relay (E) (refer to Key).

Note: The external relay must not exceed the ratings specified in Section 2.10.

Due to the inductive nature of a relay, a transient voltage can be generated when the relay is switched OFF. The

surge rating of the back emf clamping diode must be at least ten times the rated operating current of the relay, that

is, a minimum of 1 amp surge rating and have a minimum reverse voltage rating of 100 volts (e.g. 1N4002 diode).

D14643880 Issue L

Page 10 © Edwards Limited 2020. All rights reserved.

Installation

3.5.3 Disable set-point

The set-point can be permanently turned off by adjusting the potentiometer so that the level is < 1.8 V. This is

achieved by turning the potentiometer fully anticlockwise.

The set-point can also be used to indicate that the gauge is operating correctly by adjusting the potentiometer so

that the level is 10 V, (potentiometer fully clockwise) - in normal operation, the set-point is switched on when the

output of the gauge is below the user adjustable trip level but above 1.8 V.

Note: If the set-point trip level is set to > 9.5 V then the set-point may not switch off when the pressure rises

since the hysteresis point will be > 10.0 V. It would then only switch off when the gauge is disabled.

© Edwards Limited 2020. All rights reserved. Page 11

Operation

D14643880 Issue L

4 Operation

CAUTION

Do not operate Active Inverted Magnetron gauges at high pressures above 10-2 mbar for long periods as the high

voltage discharge inside the gauge at these pressures can damage the anode pin and cause severe contamination

of the gauge.

CAUTION

Do not operate Active Inverted Magnetron gauges above an ambient temperature of +60 °C.

WARNING

Do not exceed an internal pressure of 5 bar gauge (6 bar absolute).

WARNING

Do not use the Active Inverted Magnetron gauge to measure the pressure of explosive or flammable

gas mixtures.

WARNING

Do not operate the Active Inverted Magnetron Gauge in external explosive atmospheres. (No

special precautions are made to limit the energy in the gauge electronics to the low levels

necessary to make an explosion possible).

WARNING

Do not operate an Active Inverted magnetron gauge when it is disconnected from the vacuum

system as high voltages (3kV) are present inside the gauge tube.

WARNING

An Instrument failure could cause a malfunction of signal outputs. If malfunction of a gauge could

cause danger to life or limb, additional safeguards MUST be taken.

WARNING

Fluoro-elastomer can decompose to hydrofluoric acid when heated above 315°C.

WARNING

The AIM gauge incorporates magnets. Keep away from heart pacemakers, computers, credit cards

and any other magnetically sensitive devices.

D14643880 Issue L

Page 12 © Edwards Limited 2020. All rights reserved.

Operation

4.1 Reading the pressure

The Active Inverted Magnetron gauge has a 2 to 10 V d.c. analogue output signal which is a function of pressure. To

find the pressure, the output voltage is measured (between pins 3 and 5 on the connector) using a standard voltmeter

and compared to the calibration table shown in Table 1.

4.2 Error monitoring

The Active Inverted Magnetron gauge has an error monitoring feature which checks the gauge output signal such that

the set-point is turned off when any of the following conditions are true:

a. A short delay (0.5 seconds) during gauge power up.

b. When the gauge signal is out of range, that is, <1.8 V, possibly because the gauge has failed to strike.

Table 1 - Calibration table for dry air and nitrogen

Pressure mbar Output voltage Pressure torr

1.0 x 10-8 2.00 7.5 x 10-9

2.4 x 10-8 2.50 1.8 x 10-8

5.8 x 10-8 3.00 4.4 x 10-8

8.1 x 10-8 3.20 6.1 x 10-8

1.1 x 10-7 3.40 8.3 x 10-8

1.5 x 10-7 3.60 1.1 x 10-7

2.1 x 10-7 3.80 1.6 x 10-7

2.9 x 10-7 4.00 2.2 x 10-7

4.0 x 10-7 4.20 3.0 x 10-7

5.4 x 10-7 4.40 4.1 x 10-7

7.3 x 10-7 4.60 5.5 x 10-7

9.8 x 10-7 4.80 7.4 x 10-7

1.3 x 10-6 5.00 9.8 x 10-7

1.7 x 10-6 5.20 1.3 x 10-6

2.2 x 10-6 5.40 1.7 x 10-6

2.8 x 10-6 5.60 2.1 x 10-6

3.6 x 10-6 5.80 2.7 x 10-6

4.5 x 10-6 6.00 3.4 x 10-6

5.6 x 10-6 6.20 4.2 x 10-6

6.9 x 10-6 6.40 5.2 x 10-6

8.4 x 10-6 6.60 6.3 x 10-6

1.0 x 10-5 6.80 7.5 x 10-6

1.2 x 10-5 7.00 9.0 x 10-6

1.4 x 10-5 7.20 1.1 x 10-5

1.7 x 10-5 7.40 1.3 x 10-5

2.0 x 10-5 7.60 1.5 x 10-5

2.4 x 10-5 7.80 1.8 x 10-5

2.9 x 10-5 8.00 2.2 x 10-5

3.5 x 10-5 8.20 2.6 x 10-5

© Edwards Limited 2020. All rights reserved. Page 13

Operation

D14643880 Issue L

4.3 x10-5 8.40 3.2 x 10-5

5.7 x 10-5 8.60 4.3 x 10-5

7.9 x 10-5 8.80 5.9 x 10-5

1.2 x 10-4 9.00 9.0 x 10-5

1.9 x 10-4 9.20 1.4 x 10-4

3.3 x 10-4 9.40 2.5 x 10-4

6.7 x 10-4 9.60 5.0 x 10-4

1.7 x 10-3 9.80 1.3 x 10-3

3.6 x 10-3 9.90 2.7 x 10-3

1.0 x 10-2 10.00 7.5 x 10-3

Table 1 - Calibration table for dry air and nitrogen (continued)

Pressure mbar Output voltage Pressure torr

D14643880 Issue L

Page 14 © Edwards Limited 2020. All rights reserved.

This page has been intentionally left blank.

This manual suits for next models

3

Table of contents

Other Edwards Industrial Equipment manuals

Edwards

Edwards WRH gauge User manual

Edwards

Edwards E1M40/80 Installation instructions

Edwards

Edwards Iron Worker User manual

Edwards

Edwards FL20K User manual

Edwards

Edwards Drystar GV80-EH250 User manual

Edwards

Edwards AdaptaBeacon 96DV2-N5 Series User manual

Edwards

Edwards AIM-YSL-NW25 User manual

Edwards

Edwards GV250 User manual

Edwards

Edwards HV8000 aftercooler Mk4 User manual

Edwards

Edwards ELD500 Series User manual