Edwards WRH gauge User manual

D14750880_A Original Instructions

WRH Gauge

INSTRUCTION MANUAL

edwardsvacuum.com

D14750880_A - Copyright notice

Page 2

Copyright notice

©Edwards Limited 2019. All rights reserved.

Trademark credits

Edwards and the Edwards logo are trademarks of Edwards Limited, Innovation Drive,

Burgess Hill, West Sussex RH15 9TW.

Associated publications

D02691880 Digital Gauge Range Serial Communication

Disclaimer

The content of this manual may change from time to time without notice. Edwards accepts no

liability for any errors that may appear in this manual nor does it make any expressed or

implied warranties regarding the content. So far as is reasonably practicable Edwards has

ensured that its products have been designed and constructed so as to be safe and without

risks when correctly installed and used in accordance with Edwards operating instructions.

Edwards accepts no liability for loss of profit, loss of market or any other indirect or

consequential loss whatsoever.

Product warranty and limit of liability are dealt with in Edwards standard terms and conditions

of sale or negotiated contract under which this document is supplied.

To use the WRH gauge, refer to the information provided in this manual. Read this manual

before you install, operate and maintain the WRH gauge.

P20010249A

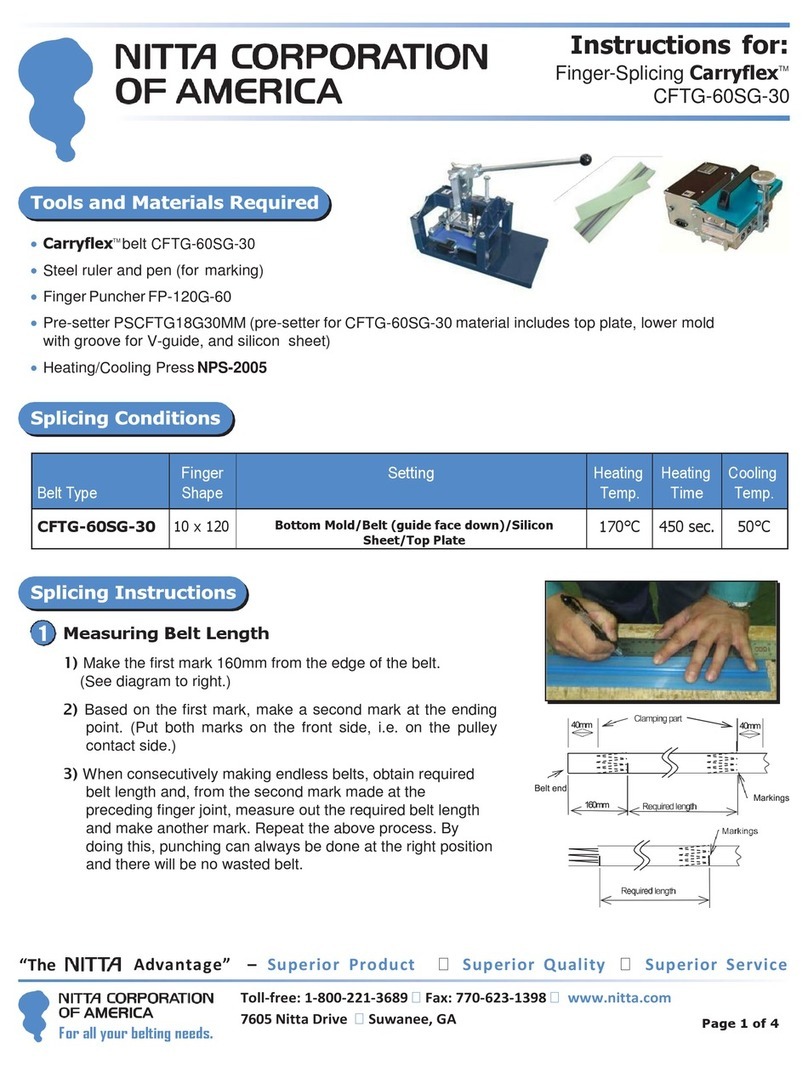

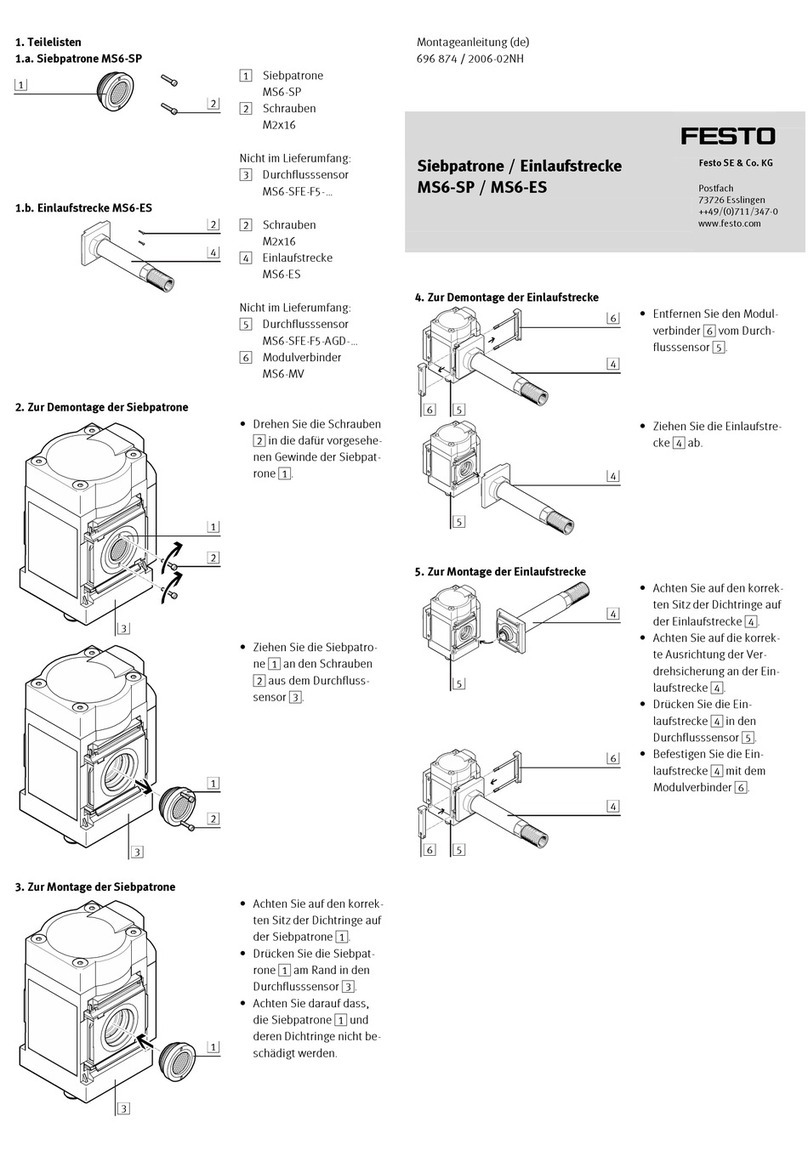

CE Declaration of Conformity

The following product

WRH gauges:

D14750100

WRH – NW25

D14750110

WRH – NW40

D14750120

WRH – DN40CF

D14750101

WRH – NW25 Spare sensor

D14750111

WRH – NW40

D14750121

WRH – DN40CF

Is in conformity with the relevant requirements of European CE legislation:

2014/30/EU

Electromagnetic compatibility (EMC) directive

2011/65/EU

Restriction of certain hazardous substances (RoHS) directive

as amended by Delegated Directive (EU) 2015/863

Based on the relevant requirements of harmonised standards:

EN 61326-1:2013

Electrical equipment for measurement, control and laboratory use. EMC requirements.

General requirements

Class B Emissions, Industrial Immunity

Documentation Officer:

Jelena Havelkova, Spielberk Office Centre, Holandska 10, Brno, 63900 Czech Republic,

: +42(0) 734 418 896,

This declaration, based on the requirements of the listed Directives and EN ISO/IEC 17050-1, covers all product

serial numbers from this date on: 15th November 2019.

Nick Barratt – Engineering Manager

Research and Development

Eastbourne, UK

Andy Marsh – General Manager

Eastbourne, UK

Edwards Ltd

Innovation Drive

Burgess Hill

West Sussex

RH15 9TW

UK

This product has been manufactured under a quality management system certified to ISO 9001:2015

Additional Legislation and Compliance Information

EU EMC Directive: Class A/B Industrial equipment

Caution: This equipment is not intended for use in residential environments and may not provide adequate protection to

radio reception in such environments.

EU RoHS Directive: Material Exemption Information

This product is compliant with no Annex III or IV Exemptions.

EU REACH Regulation Compliance

This product is a complex article which is not designed for intentional substance release. To the best of our knowledge

the materials used comply with the requirements of REACH. The product manual provides information and instruction to

ensure the safe storage, use, maintenance and disposal of the product including any substance based requirements.

Article 33.1 Declaration

This product does not knowingly or intentionally contain Candidate List Substances of Very High Concern above 0.1%ww

by article as clarified under the 2015 European Court of Justice ruling in case C-106/14.

材料成分声明

China Material Content Declaration

表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

Indicates that the hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement in GB/T 26572.

Page 3

D14750880_A - Contents

Introduction 7

Safety symbols ............................................................................................................... 7

Safety precautions ......................................................................................................... 7

Description 8

Correct use ..................................................................................................................... 8

Incorrect use .................................................................................................................. 8

Orientation ..................................................................................................................... 8

Delivery content ............................................................................................................. 9

Technical data 10

Installation 12

Installation notes .........................................................................................................12

Vacuum connection ..................................................................................................... 12

Electrical connection .................................................................................................... 13

Operation with other supply and evaluation units ............................................ 13

Operation 15

General ......................................................................................................................... 15

Measurement principle ..................................................................................... 15

Output signal ..................................................................................................... 15

Serial interface RS485 ........................................................................................ 15

Warm-up time ................................................................................................... 15

Accuracy ............................................................................................................. 15

Dependence on gas type ................................................................................... 15

Operate the transducer ............................................................................................... 16

Degas ............................................................................................................................ 17

Degas control by pushbutton ............................................................................ 17

Degas control by external voltage signal ........................................................... 18

Degas control with a software command .......................................................... 18

Bake-out ....................................................................................................................... 18

Readjustment ............................................................................................................... 19

Readjustment by pushbutton ............................................................................ 19

Readjustment with a software command ......................................................... 19

Communication 20

Serial interface ............................................................................................................. 20

Interface parameter ........................................................................................... 20

Survey of commands .................................................................................................... 21

Device parameters and information ............................................................................ 22

Measurement query .................................................................................................... 22

Switch-points (754/764) .............................................................................................. 22

Readjustment (761) .....................................................................................................23

Sensor parameters ....................................................................................................... 23

Degas (762) ........................................................................................................ 23

Sensor Transition (763) ...................................................................................... 24

Contents

Page 4

D14750880_A - Contents

Cathode Control (752) ....................................................................................... 24

Filament Control (765) ....................................................................................... 24

Gas correction factor (756) ................................................................................ 24

VacuGraphTM Software ............................................................................................... 25

Maintenance and service 26

Error messages and fault finding ................................................................................. 26

Page 5

D14750880_A - List of Figures

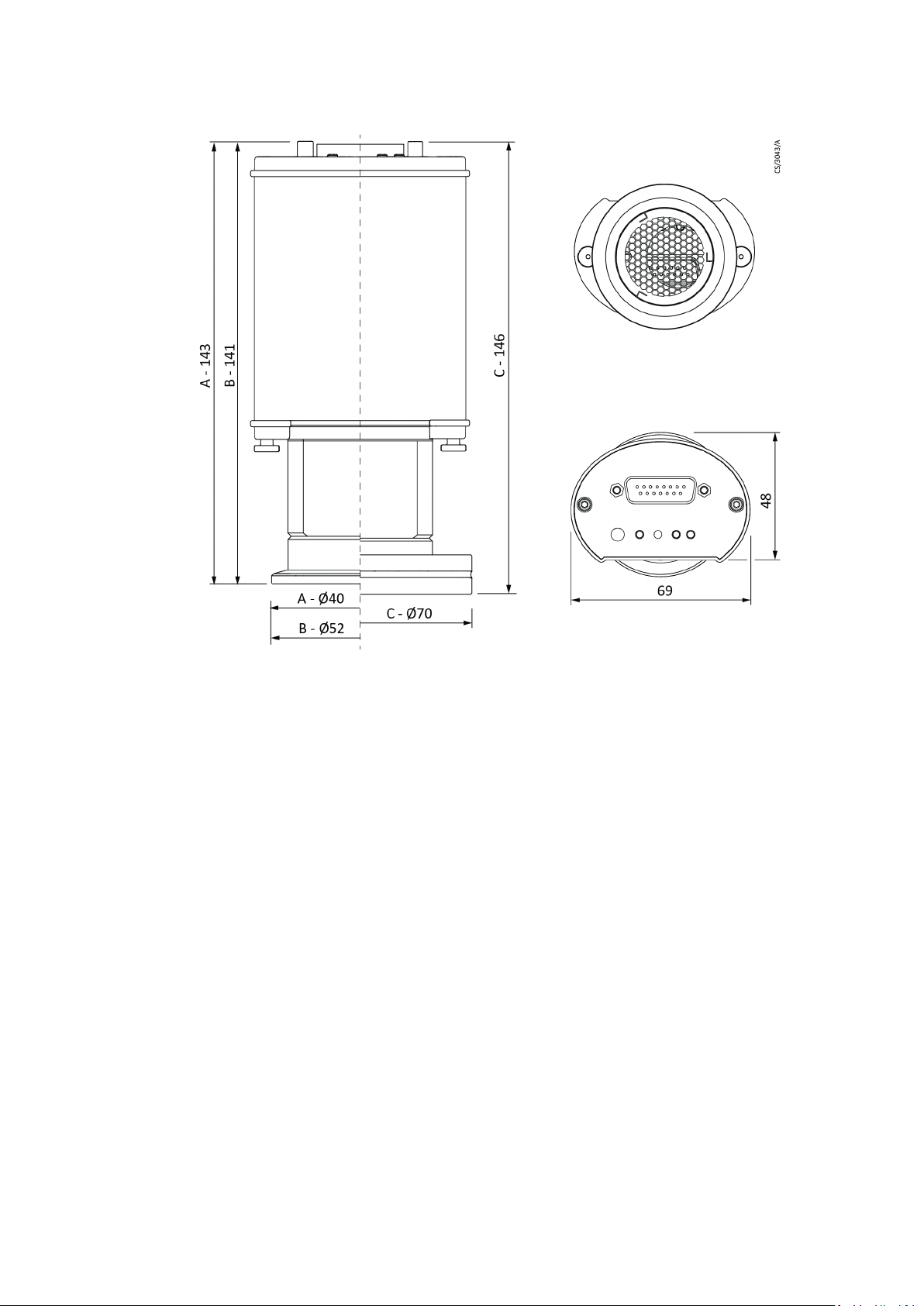

Figure 1: Dimensions .............................................................................................................. 11

Figure 2: Pin description .........................................................................................................14

Figure 3: General arangement ............................................................................................... 16

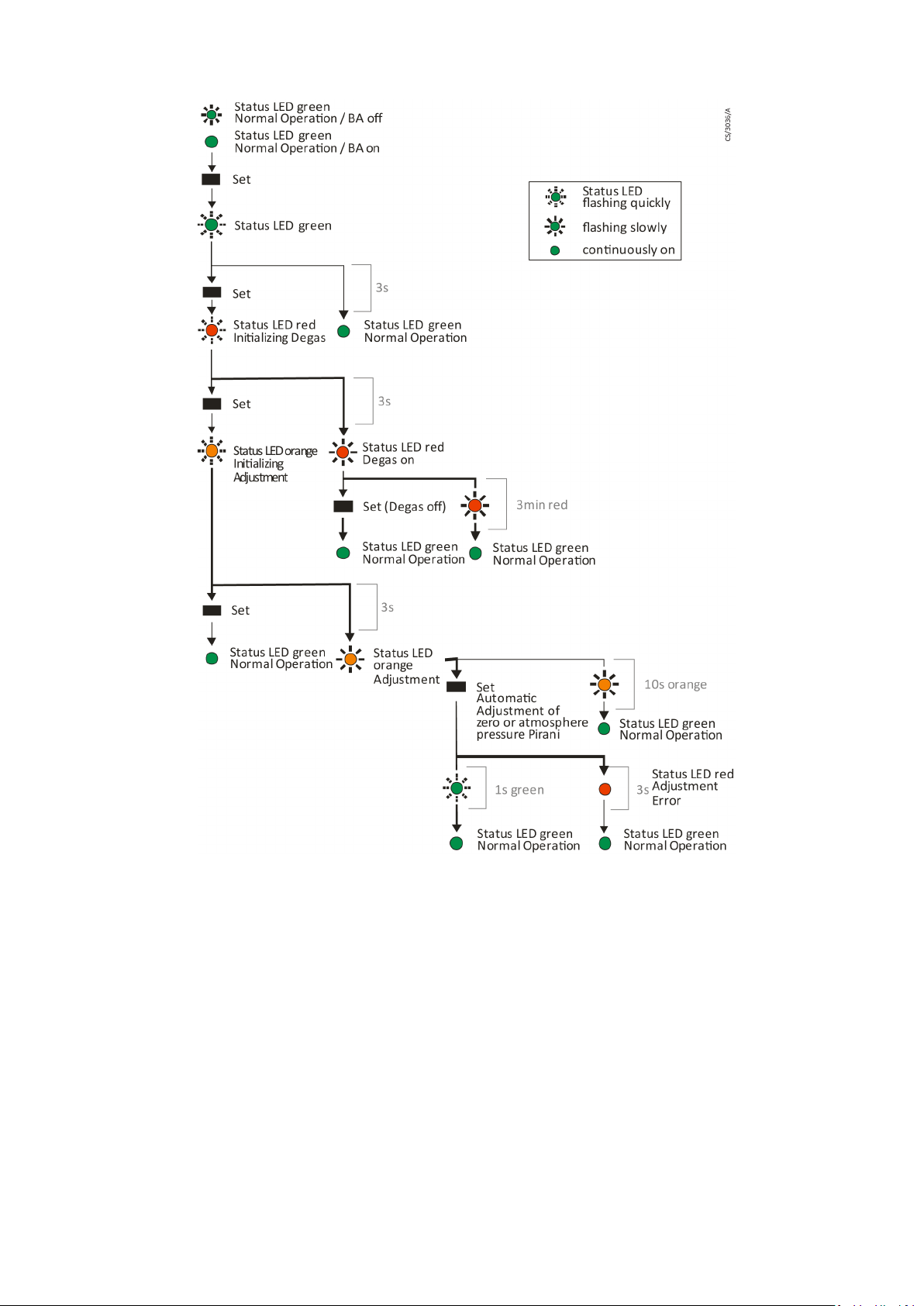

Figure 4: Manual degas .......................................................................................................... 18

Figure 5: Manual readjustment .............................................................................................. 19

Figure 6: Set the address ........................................................................................................ 20

Figure 7: VacuGraph™ software ............................................................................................. 25

List of Figures

Page 6

D14750880_A - List of Tables

Table 1: General ..................................................................................................................... 10

Table 2: Survey of commands ................................................................................................ 21

List of Tables

Page 7

D14750880_A - Introduction

Introduction

Safety symbols

Safety procedures are highlighted as WARNING and CAUTION instructions. These instructions

must be obeyed. The use of WARNINGS and CAUTIONS is defined as follows:

Safety precautions

Read and obey the instructions in this manual.

You must know the hazards that can be caused by the product.

Obey all safety instructions and regulations.

The ambient conditions must be considered before you install the transducer. The

protection class is IP 40 (the unit has protection against penetration of foreign

bodies) or IP54 when applicable electrical connectors are used.

Obey the applicable regulations and take the necessary precautions for the process

media used.

Think of possible reactions between the materials and the process media.

Think of possible reactions of the process media as a result of heat generated by the

product.

Do not do any unauthorized conversions or modifications to the unit.

Before you start work, make sure that the vacuum components are not

contaminated.

Obey the applicable regulations and the necessary precautions when you handle

contaminated parts.

A Return of Edwards Equipment Declaration form must be completed and sent with

the unit before you return it to Edwards.

Give information to others about the applicable safety instructions.

WARNING:

Warnings are given where failure to obey the instruction could result in injury or death to

people. The actual symbol shown will change and refer to the applicable hazard.

CAUTION:

Cautions are given where failure to obey the instruction could result in damage to the

equipment, associated equipment or process.

Page 8

D14750880_A - Description

Description

The transducer measures absolute pressure in gaseous media in the range of 1000 to

5.0 x 10-10 mbar. The transducer can be connected to a customer related power supply and

evaluation units in compliance with the pin assignment. The analogue output signal of 1.219 V

to 8.6 V has a logarithmic dependence on pressure over the whole range. The device has a

serial RS485 interface for digital data transfer (see Serial interface on page 20).

The transducer has a metal-sealed combination sensor type Pirani/Hot Cathode (Bayard

Alpert) and temperature compensated. It can be mounted to a flange connector.

Correct use

The transducer gives total pressure measurements in gaseous media in the range 1000 to

5.0 x 10-10 mbar only. It can only be connected to components specified for this function.

Incorrect use

All functions not given in Correct use on page 8 are regarded as incorrect, in particular:

The connection to components not permitted in the operation instructions.

The connection to components containing touchable, voltage carrying parts.

No liability or warranty will be accepted for claims caused by incorrect use. The user is

responsible for the used process media.

The device must not be used in a corrosive gas atmosphere. Aggressive media such as

halogenides, carbon or oxygen plasma can decrease the sensor life.

Orientation

These instructions give information about the installation and operation of transducers with

part numbers:

D14750100, D14750110, D1470120, D14750101, D14750111 and D14750121.

The part number can be found on the product identification label. Technical modifications are

reserved without prior notification.

CAUTION: INCORRECT OPERATION

Risk of incorrect operation. Dust, oil or condensed vapours will have an unwanted effect

on the sensor’s performance and can cause a malfunction.

CAUTION: DAMAGE TO EQUIPMENT

Risk of damage to equipment. Oil sealed vacuum pumps can cause hydrocarbons to form

in the process gas which will increase the wear and tear of the hot cathode filaments.

Page 9

D14750880_A - Description

Delivery content

The package includes:

The transducer

The protective flange cover

The instruction manual

The software package

Page 10

D14750880_A - Technical data

Technical data

Table 1 General

Measurement principle Heat conduction Pirani/hot cathode Bayard Alpert

depending on gas type

Measurement range 1000 to 5.0 x 10-10 mbar

(750 to 5.0 x 10-10 Torr)

Maximum overload 4 bar absolute

Accuracy 1000 to 10 mbar: approximately 30% of full reading

10 to 1.0 x 10-8 mbar: 10 % of full reading

Repeatability 10 to 1.0 x 10-2 mbar: 2 % of full reading

1.0 x 10-2 to 1.0 x 10-8 mbar: 5% of full reading

Materials with vacuum contact Stainless steel 1.4307, tungsten, nickel, glass, platinum,

iridium, yttria oxide

Filaments Bayard Alpert yttria coated iridium

Emission current 9 µA, 100 µA, 1.0 mA, and 2.0 mA

Degas method Ohmic heating of the anode

Reaction time 50 ms (switching of emission current < 2.0 seconds)

Operating temperature 5 to 60 °C

Storage temperature -40 to +65 °C

Bake-out temperature Maximum 180 °C at the flange (voltage supply

switched-off)

Voltage supply 20 to 30 V d.c.

Power consumption Maximum 8 W, additionally 1 W for degas, 0.8 W for

relays

Output signal 0 to 10 V d.c., minimum 10 kΩ

measuring range 1.219 to 8.6 V d.c., logarithmic

Serial interface RS485: 9.6 to 115 kBd, 8 data-bit, 1 stop-bit, no parity

Switch-points 2x relay, potential free

50 V a.c./2 A or 30 V d.c./2 A, maximum 60 VA

Electrical connection Sub-D, 15-pole, male, lockable

Vacuum connection D14750100: DN25 ISO KF

D14750110: DN40 ISO KF

D14750120: DN40 CF

Dimensions 141 x 69 x 48 mm (D14750110)

Protection class IP 40 (IP54)

Weight 475 g (D14750110)

Page 11

D14750880_A - Technical data

Figure 1 Dimensions

A. D14750100

B. D14750110

C. D14750120

Page 12

D14750880_A - Installation

Installation

Installation notes

For open buildings and operation rooms without air conditioning:

Vacuum connection

Remove the protective cover. Store the cover for future maintenance.

Make the vacuum connection with a small flange DN25 ISO KF, DN40 ISO KF or

conflat flange DN40CF.

Use clamps which can open and close with applicable tools only (for example, a strap

retainer tension ring), use sealing rings with a centring ring.

Make sure that the sensor flange is connected to ground, for example, by having

electrical contact to the grounded vacuum chamber (use metallic clamps).

The transducer can be installed in any orientation. If installed with the flange at the top, it can

lead to early contamination and malfunction.

An upright orientation with the flange to the bottom is recommended to keep particles and

condensates out of the sensor cell. The transducer is adjusted in the upright position.

Reorientation without a readjustment will decrease accuracy at pressures above 20 mbar.

Installation location: Indoor

Temperature: +5 °C to +60 °C

Relative humidity: Maximum 80% up to 30 °C, maximum 50% at 40 °C,

non-condensing

Air pressure: 860 to 1060 mbar

CAUTION: DAMAGE TO EQUIPMENT

Risk of damage to equipment. Dirt and damage can have a bad effect on the function of

the transducer.

WARNING: PRESSURIZED CONTAINER

Risk of injury or death. A release of parts and process gases because of system

overpressure more than 1 bar causes a hazard. Do not open any clamps while the vacuum

system is pressurized. Use clamps designed for overpressure conditions.

WARNING: PRESSURIZED CONTAINER

Risk of injury or death. A release of process gases because of system overpressure more

than 1.5 bar causes a hazard. KF flange connections with elastomer seals cannot resist

such pressures. Use O-rings with an outer centring ring.

Page 13

D14750880_A - Installation

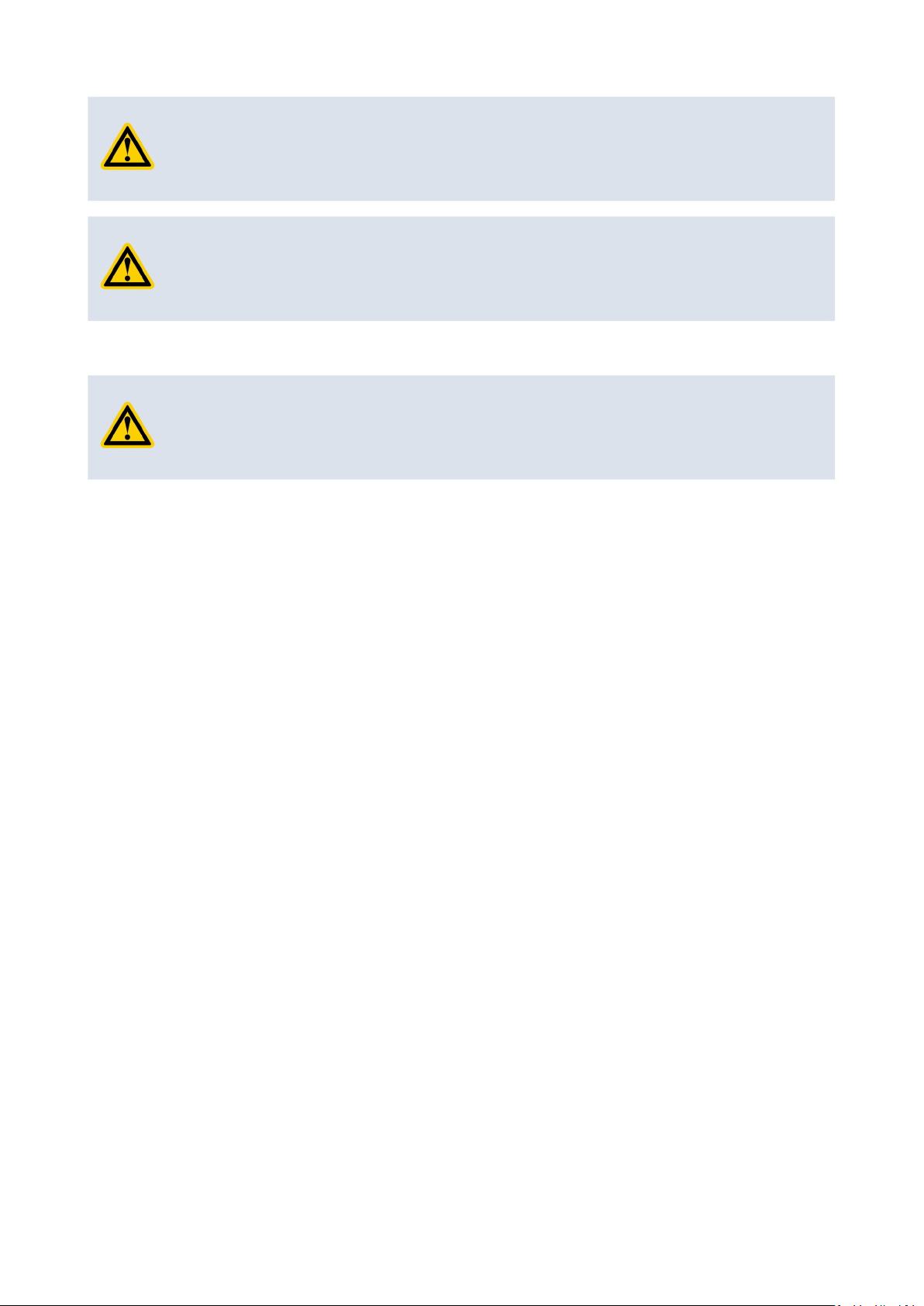

Electrical connection

Operation with other supply and evaluation units

The transducer can operate with customer related display units or voltage supplies.

Use an applicable cable for the electrical connection and consider the EMI demands while you

refer to the pin description shown in Figure 2 on page 14.

WARNING: NOT FAIL-SAFE DESIGNED

Risk of death. Do not use the gauge for safety critical applications. The gauge is not

intended to be fail-safe.

CAUTION: DAMAGE TO EQUIPMENT

Risk of damage to equipment. Prevent forced twisting or violent opening when you install

the transducer. This can damage the transducer.

CAUTION: DAMAGE TO EQUIPMENT

Risk of damage to equipment. Do not connect or disconnect the transducer when the

cable is on circuit.

Page 14

D14750880_A - Installation

Figure 2 Pin description

Note:

We recommend to have a shield (Pin 12) and a supply common (Pin 5) grounded in the supply

unit.

CAUTION: DAMAGE TO EQUIPMENT

Risk of damage to equipment. An incorrect connection or supply voltage can damage the

transducer. Make sure the supply is connected and is of the correct voltage.

Socket Type Sub-D, 15-pole, male

Pin 1: Identification: 160 kΩ

Pin 2: Signal output 0-10 V d.c.

Pin 3: AGND

Pin 4: Voltage supply 24V d.c.

Pin 5: Supply common

Pin 6: Relay 1, N.O.

Pin 7: Relay 1, common

Pin 8: Relay 1, N.C.

Pin 9: Degas, external

Pin 10: RS485 +

Pin 11: RS485 -

Pin 12: Shield

Pin 13: Relay 2, N.O.

Pin 14: Relay 2, common

Pin 15: Relay 2, N.C.

Page 15

D14750880_A - Operation

Operation

General

Measurement principle

The transducer has a Pirani/hot cathode internal combination sensor.

The Pirani principle uses the heat conduction of gases to measure vacuum. A sensor filament

in a Wheatstone bridge circuit is heated to a constant temperature, so the bridge voltage is a

measure for total gas pressure.

The hot cathode sensor of Bayard Alpert type ionizes gas molecules by electron

bombardment. The ion current that results is a measure for the number of gas molecules in

the sensor and proportional to the absolute pressure.

Output signal

The output signal 1.219 to 8.6 V of your transducer has a logarithmic dependence on pressure

over the whole measurement range of 5.0 x 10-10 to 1000 mbar.

Conversion of the voltage signal and pressure is done according to the following formula:

Vout/V = 0.6 log (p/mbar) + 6.8

p/mbar = 10((Vout/V - 6.8)/0.6)

Serial interface RS485

The absolute pressure measured can be read out digitally by the transducers serial RS485

interface. Additionally you can set various parameters like gas correction factors or setpoints.

For further information see Communication on page 20.

Warm-up time

The signal output of the transducer is available for approximately 2 seconds after the unit is

switched on. To get the maximum accuracy of the unit, you should allow 5 minutes for

stabilization, especially when extreme pressure changes have occurred.

Accuracy

The unit is adjusted ex works in the upright position and a 24 V d.c. voltage supply. Through

contamination, ageing, extreme climatic conditions or alternate mounting orientation,

readjustment can become necessary. Accuracy is decreased in the range above

20 mbar.

Dependence on gas type

The composition and the type of the gas being measured controls the output signal. The unit

is adjusted for nitrogen and dry air. For other gases correction factors for both sensor types

can be set by the RS485 (see Sensor parameters on page 23). This results in a correct pressure

display below 0.1 mbar.

Page 16

D14750880_A - Operation

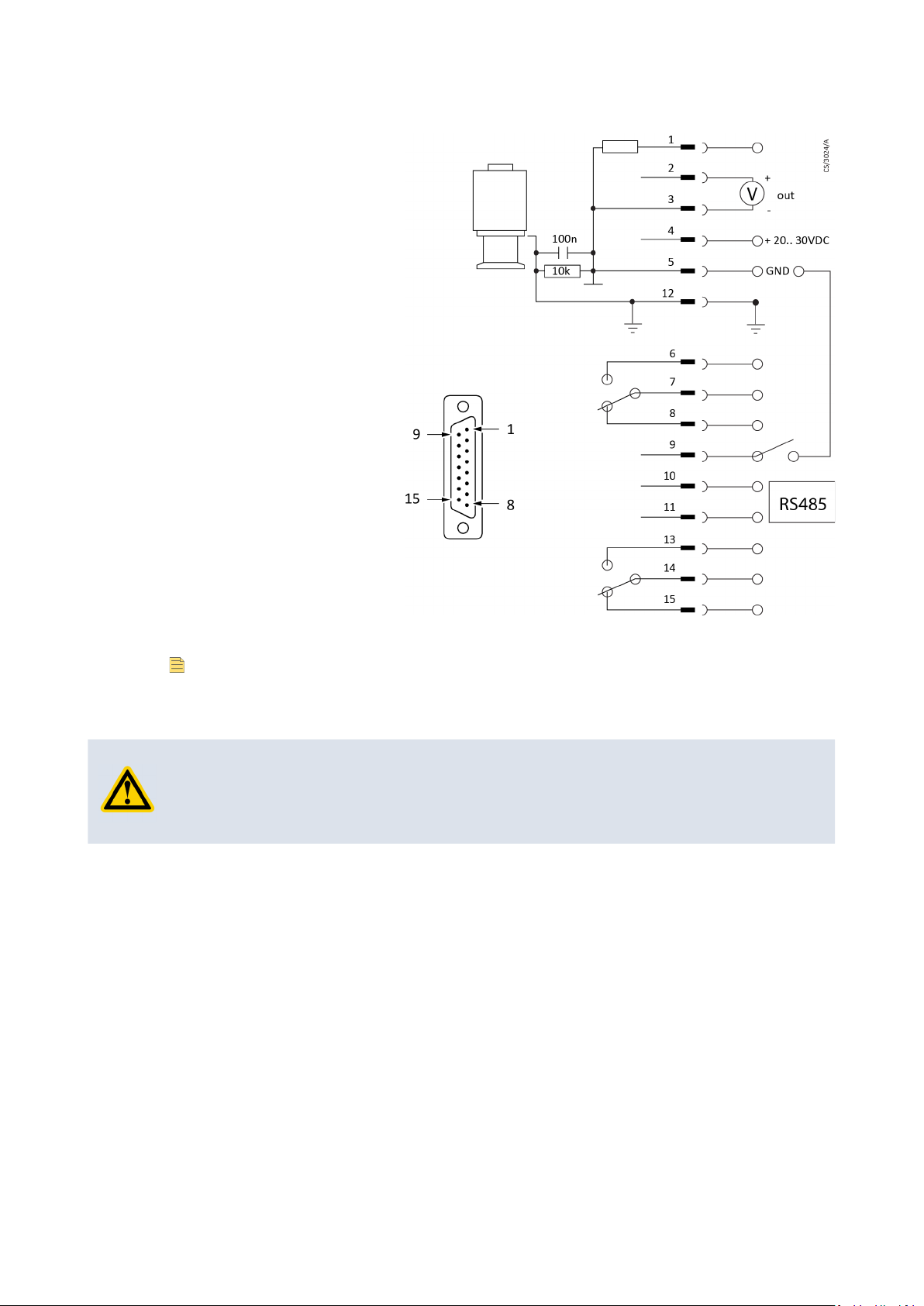

Operate the transducer

Figure 3 General arangement

The transducer has a status LED which indicates the following operational states:

The switch-point LEDs are illuminated when the related relay is activated.

The transducer ADJ pushbutton can start the "degas" and "adjustment" functions.

Normal operation/hot cathode on (green LED continuously on)

Normal operation/hot cathode off (green LED flashes slowly)

Initialize input (green LED flashes quickly)

Error (red LED continuously on)

Degas on (red LED flashes slowly)

Initialize degas (red LED flashes quickly)

Warning: Hot cathode filament 1 defective (orange LED continuously on)

Ready for adjustment (orange LED flashes slowly)

Initialize adjustment (orange LED flashes quickly)

1. Address switch

2. Status LED

3. Pushbutton

4. Switch-point LEDs

Page 17

D14750880_A - Operation

Degas

Deposition or adsorbed gas molecules on the electrodes of the hot cathode sensor may lead

to increased degassing in ultra-high vacuum or even cause instabilities of the measurement

signal.

If this occurs, clean the sensor anode from the deposited material and adsorbed gas molecules

by degassing. This is done at pressure below 2.0 x 10-6 mbar by ohmic heating of the anode to

temperatures approximately 800 °C.

Degas control by pushbutton

The degas function can be activated by the pushbutton on the transducer (see Operate the

transducer on page 16).

Page 18

D14750880_A - Operation

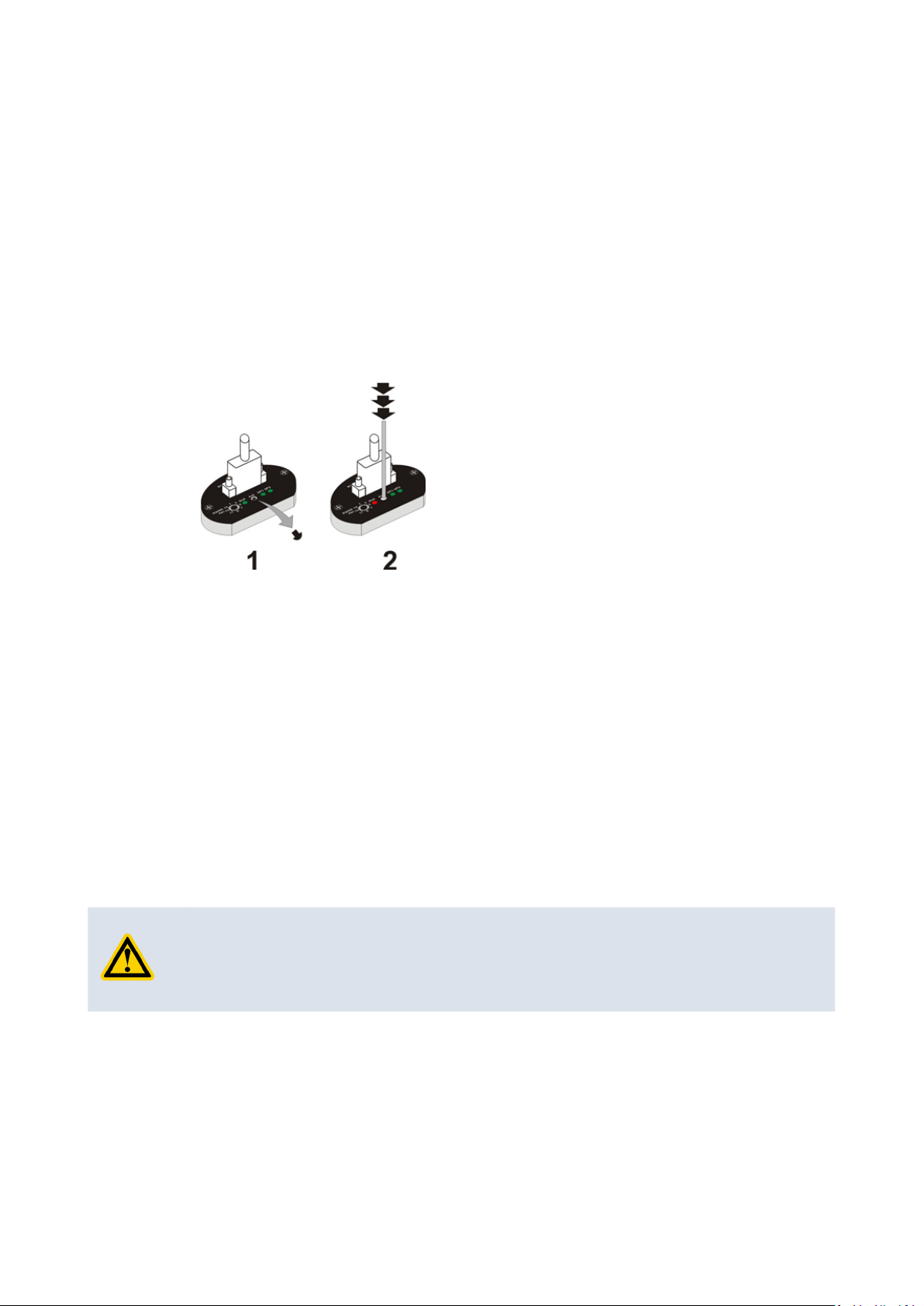

To do this:

1. Remove the rubber cap above the ADJ pushbutton (1).

2. Press the button several times with a small screwdriver or similar tool (2) until the

red status LED starts flashing quickly.

3. After 3 seconds, the degas process starts, red status LED flashes slowly.

4. The degas procedure will end automatically after approximately 3 minutes. To stop

the degas procedure anytime before the process ends automatically, press any key.

5. Insert the rubber cap again.

Figure 4 Manual degas

Degas control by external voltage signal

Degas is started when you connect Pin 9 (see Operation with other supply and evaluation units

on page 13) to GND for a minimum of 20 milliseconds.

The degas procedure will stop automatically after approximately 3 minutes, but can be

stopped any time by reconnecting Pin 9 to its previous state.

The red status LED flashes when the sensor degasses.

Degas control with a software command

See Sensor parameters on page 23.

Bake-out

When a bake-out operation of the vacuum chamber is done with the transducer being

installed to the chamber, the temperature at the sensor flange must be less than 180 °C.

CAUTION: DAMAGE TO EQUIPMENT

Risk of damage to equipment. The voltage supply to the transducer must be stopped

while the chamber is heated. If not, damage to the electronic components can result.

Table of contents

Other Edwards Industrial Equipment manuals

Edwards

Edwards GV250 User manual

Edwards

Edwards E1M40/80 Installation instructions

Edwards

Edwards HV8000 aftercooler Mk4 User manual

Edwards

Edwards Iron Worker User manual

Edwards

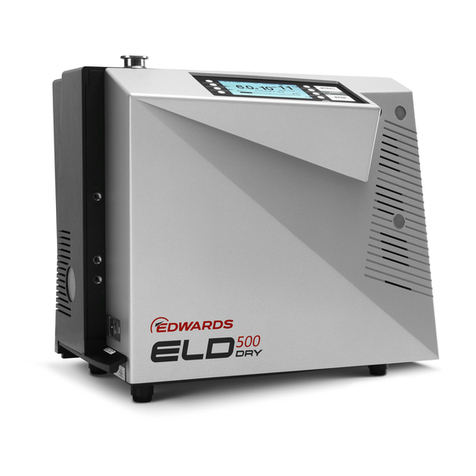

Edwards ELD500 Series User manual

Edwards

Edwards CDP User manual

Edwards

Edwards AIM-P-NW25 User manual

Edwards

Edwards FL20K User manual

Edwards

Edwards APG-M-NW16 AL User manual

Edwards

Edwards AdaptaBeacon 96DV2-N5 Series User manual