Edwards AIM-YSL-NW25 User manual

D14558880

Issue H

Original Instructions

Instruction Manual

YSL Active Inverted Magnetron Gauge

Description Item Number

AIM-YSL-NW25 D14558000

This product has been manufactured under a quality management system certified to ISO 9001:2008

Declaration of Conformity

We, Edwards Limited,

Crawley Business Quarter,

Manor Royal,

Crawley,

West Sussex, RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

Active Inverted Magnetron Gauge

AIM-YSL-NW25 D145-58-000

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN 61326-2-3: 2013 Electrical equipment for measurement, control and laboratory

(Class B Emissions, Use. EMC requirements. Particular requirements. Test

Basic Immunity) configuration, operational conditions and performance criteria

for transducers with integrated or remote signal conditioning

EN50581: 2012 Technical Documentation for the Assessment of Electrical and

Electronic Products with respect to the Restriction of Hazardous

Substances

and fulfils all the relevant provisions of

2014/35/EU Low Voltage Directive

2014/30/EU Electromagnetic Compatibility (EMC) Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

19.08.2015, Eastbourne

Mr L. Marini,

Senior

Technical Manage

r

Date and Place

P200-03-220 Issue

E

P200-10-059

Issue A

Material Declaration

In accordance with the requirements of the Chinese regulatory requirement on the Management Methods for the

Restriction of the Use of Hazardous Substances in Electrical and Electronic Products Order No. 32 (also known as

‘China RoHS2’) and SJ/T 11364 Marking for the Restricted Use of Hazardous Substances in Electronic and Electrical

Products:

Product Product Label Meaning

D14558000 AIM-YSL-NW25

This product contains hazardous substances in

at least one of the homogeneous materials

used which are above the limit requirement in

GB/T 26572 as detailed in the declaration

table below.

These parts can safely be used for the

environmental protection use period as

indicated.

材料成分声明

Materials Content Declaration

部件名称

Part name

有害物质

Hazardous Substances

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr VI)

多溴联苯

Polybrominated

biphenyls (PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

印刷电路组件

(PCA)

Printed Circuit

Assembly (PCA)

X O X O O O

电缆/电线/连接器

Cable/wire/connector

X O O O O O

机械部件

Mechanical Components

X O O O O O

O: 表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

O: Indicates that the hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement in GB/T 26572.

X: 表示该有害物质在该部件的至少一种均质材料中的含量超出 GB/T26572 标准规定的限量要求。

X: Indicates that the hazardous substance contained in at least one of the homogeneous materials used for

this part is above the limit requirement of GB/T26572.

NOTE: These products are EU RoHS compliant, the following Exemptions apply:

6(b)

Lead

as an alloying element in aluminium containing up to 0.4% by weight

6(c) Copper alloy containing up to 4%

lead

by weight

7(a)

Lead

in in high melting temperature type solder (i.e. lead based alloys containing 85% by or more)

7(b)

Lead

in solders for servers, storage and storage array systems, network infrastructure equipment for switching, signalling,

transmission, and network management for telecommunications

7(c) I Electrical and electronic components containing

lead

in a glass or ceramic other than dielectric ceramic in capacitors, e.g.

piezoelectronic devices, or in a glass or ceramic matrix compound

7(c) II

Lead

in dielectric ceramic in capacitors for a rated voltage of 125 V AC or 250 V DC or higher

8(b)

Cadmium

and its compounds in electrical contacts

15

Lead

in solders to complete a viable electrical connection between semiconductor die and carrier within integrated circuit flip

chip packages

34

Lead

in cermet-based trimmer potentiometer elements

This page has been intentionally left blank.

© Edwards Limited 2020. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

D14558880 Issue H

Contents

Section Page

1 INTRODUCTION .................................................................................... 1

1.1 Scope ...................................................................................................................... 1

1.2 Description ................................................................................................................ 1

1.3 Gas Dependency ......................................................................................................... 2

2 TECHNICAL DATA ................................................................................. 3

2.1 Mechanical Data ......................................................................................................... 3

2.2 Performance, Operating and Storage Conditions ................................................................... 3

2.3 Electrical Data ........................................................................................................... 4

2.4 Materials Exposed to Vacuum. ......................................................................................... 4

3 INSTALLATION ..................................................................................... 5

3.1 Unpack and Inspects ..................................................................................................... 5

3.2 Fit the AIM Gauge to the Vacuum System ............................................................................ 5

3.3 Electrical Connections .................................................................................................. 5

3.3.1 Connect To Edwards Controllers or AGD Display .................................................................... 6

3.3.2 Connect To Your Own Supply and Control Equipment ............................................................. 6

4 OPERATION ........................................................................................ 9

4.1 Safety ...................................................................................................................... 9

4.2 Enable and Disable the AIM Gauge .................................................................................... 9

4.3 Pressure Measurement .................................................................................................. 9

4.4 Error Output Signal .....................................................................................................10

5 MAINTENANCE ................................................................................... 11

5.1 Introduction .............................................................................................................11

5.2 Replace the Body Tube ................................................................................................11

5.2.1 Remove the AIM Gauge from the Vacuum System .................................................................11

5.2.2 Fit the New Body Tube .................................................................................................11

5.2.3 Refit the AIM Gauge To the Vacuum System ........................................................................11

5.3 Replace the Electrode Assembly .....................................................................................11

5.4 Replacing the Electronics and Magnet Housing ....................................................................13

5.5 Clean the internal components ....................................................................................... 13

5.6 Fault Finding .............................................................................................................13

6 STORAGE AND DISPOSAL ....................................................................... 15

6.1 Storage ...................................................................................................................15

6.2 Disposal ...................................................................................................................15

6.3 Return the equipment or components for service..................................................................15

7 SPARES AND ACCESSORIES ..................................................................... 17

7.1 Introduction .............................................................................................................17

7.2 Spares .....................................................................................................................17

7.3 Accessories ...............................................................................................................17

GEC/ 2020-AVI-GCN-0011

D14558880 Issue H

Page ii © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Contents

Illustrations

Figure Page

1 General View of the AIM Gauge (showing NW25 flange) ........................................................... 2

2 Dimensions (mm) ........................................................................................................ 3

3 Schematic Diagram of Typical Electrical Connections ............................................................. 7

4 Exploded View of the AIM Gauge .....................................................................................12

Tables

Table Page

1 Pins On the AIM Gauge Electrical Connector Socket ............................................................... 6

2 Pressure and Voltage Characteristics for Nitrogen and Dry Air ..................................................10

Associated publications

Publication title Publication number

Vacuum pump and vacuum system safety P40040100

Trademark credits

Fomblin® is a registered trademark of Ausimont SpA.

LET-LOK® is a registered trademark of HAM-LET Group.

Swagelok™ is trademark of Crawford Fitting Company.

Viton™ is trademark of DuPont Dow Elastomers L.L.C.

© Edwards Limited 2020. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

INTRODUCTION

D14558880 Issue H

1 INTRODUCTION

1.1 Scope

This manual provides installation, operation and maintenance instructions for the Edwards AIM Gauge (Active

Inverted Magnetron Gauge). You must use the AIM Gauge as specified in this manual.

Important safety information is highlighted as WARNING and/or CAUTION instructions which must be followed. The

use of WARNINGS and/or CAUTIONS is defined below.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The units used throughout this manual conform to SI international system of measurement followed by imperial units

in parenthesis; SI (imperial).

The following warning symbols are on the pump:

1.2 Description

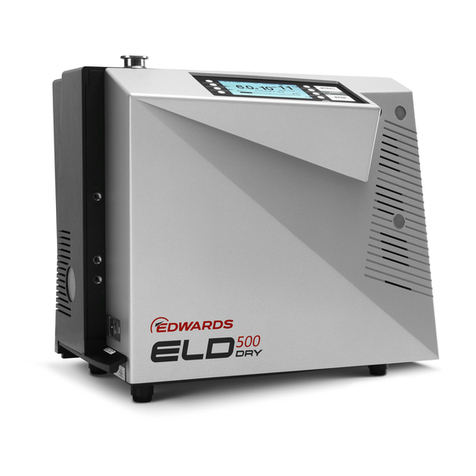

The AIM Gauge, shown in Figure 1, is an inverted magnetron gauge head and gauge controller in a single compact

unit. The gauge operates as a cold cathode ionisation gauge, in which the pressure is measured indirectly as a

function of the current which flows in a Townsend discharge maintained in the body tube.

The measurement range of the AIM Gauge is 1 x 10-8 to 1 x 10-2 mbar. The AIM Gauge vacuum connection is an NW25

flange.

The AIM Gauge requires a 13.5 to 6 V d.c. Power supply; it has a 2 to 10 V d.c. analogue output which is related to

pressure. The AIM Gauge is compatible with all of the Edwards AGCs (Active Gauge Controllers) and with the

appropriate versions of the Edwards AGDs (Active Gauge Displays). Alternatively, you can use an independent power

supply for the AIM Gauge output signal with a voltmeter or an analogue-to-digital converter.

We recommend that you do not operate the AIM Gauge unless the pressure in the vacuum system is 1 x 10-2 mbar or

lower. A gauge enable signal is used to control the operation of the AIM Gauge; refer to Section 4.2 for more

information.

An 8-way electrical connector socket on the AIM Gauge (Figure 1, item 6) is used to connect the AIM Gauge to your

AGC, AGD or electrical supply and voltmeter. Electrical cables fitted with suitable connector plugs are available as

accessories.

A gauge identification signal is available on the electrical connector; this signal is used by Edwards AGCs to identify

which type of Active Gauge is connected.

The AIM Gauge has self-monitoring fault detection circuits. When these circuits detect that the AIM Gauge is not

operating correctly, an error signal is set; this error signal is available on the electrical connector. The device which

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Warning - refer to accompanying

documentation. Warning - risk of electric shock.

D14558880 Issue H

Page 2 © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

INTRODUCTION

sets the error signal is an FET transistor which acts like a switch. When no error is detected, the output of the

transistor is on (closed or low impedance). When the fault detection circuits detect an error, the transistor output

changes to off (open or high impedance).

Note: If you use an Edwards AGC controller or AGD display, the AIM Gauge error signal is not used.

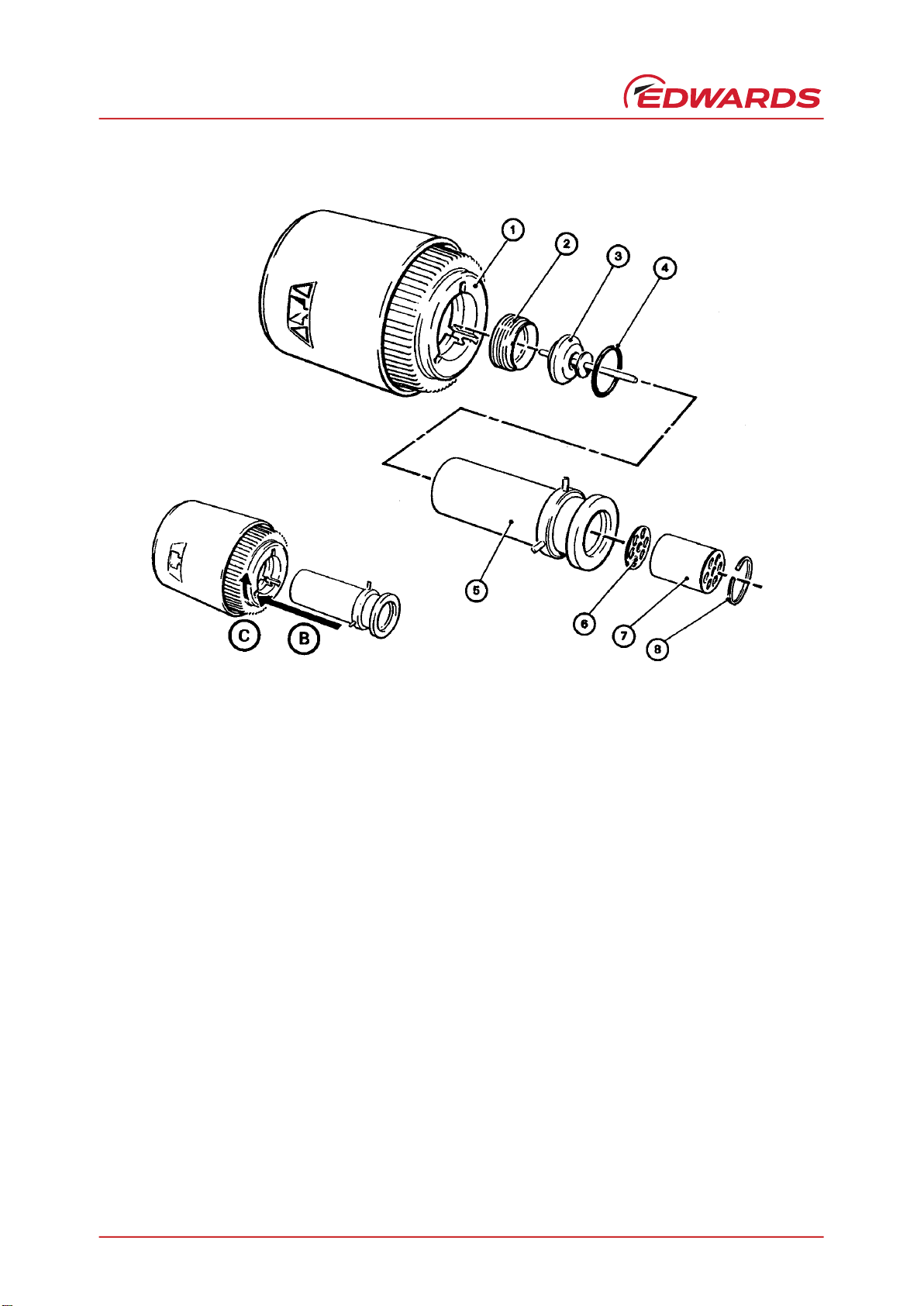

Figure 1 - General View of the AIM Gauge (showing NW25 flange)

1.3 Gas Dependency

The ionisation of the gas in the vacuum system is dependent on both the pressure and the physical properties of the

gas. Therefore, the output signal of the AIM Gauge is gas dependent.

The output signal voltage to pressure conversions in Table 2 apply for nitrogen and dry air.

Calibration graphs for use with argon, neon, krypton, helium and carbon dioxide are available on request; contact

your supplier or Edwards.

KEY

1 End cap 2 Vacuum flange

3 Body tube 4 Magnet housing

5 Cable connector plug 6 AIM gauge connector socket

© Edwards Limited 2020. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

TECHNICAL DATA

D14558880 Issue H

2 TECHNICAL DATA

2.1 Mechanical Data

2.2 Performance, Operating and Storage Conditions

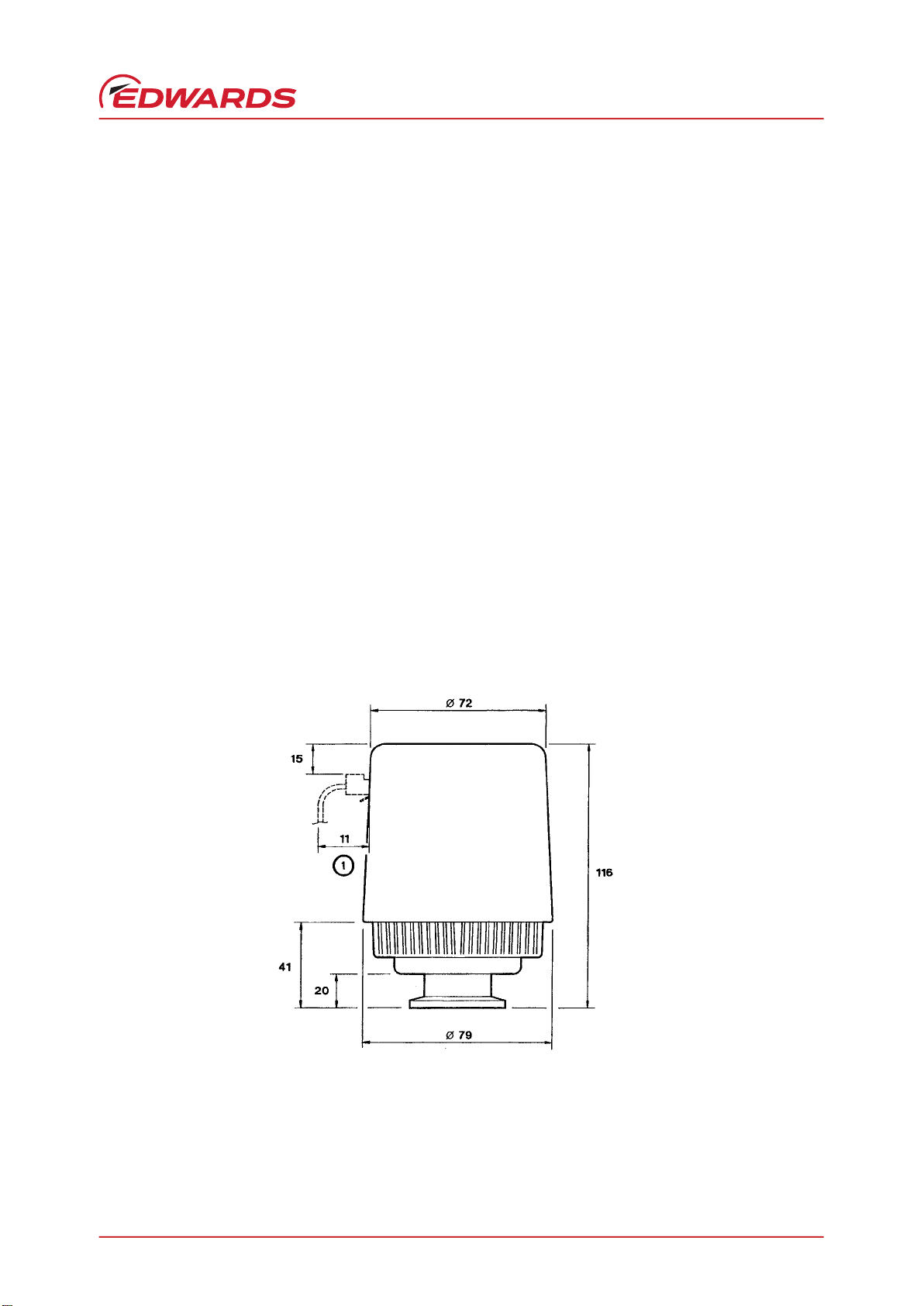

Figure 2 - Dimensions (mm)

Dimensions See Figure 2

Mass 860 g

Volume of gauge tube 26 cm3

Enclosure rating IP403

Ambient temperature

Operation 5 to 60°C

Storage 0 to 70°C

Ambient humidity (operation) 10 to 90% (non-condensing)

Maximum operating altitude 2000m

Maximum internal pressure 10 bar absolute (9 bar gauge)

Pressure measurement range 1 x 10-8 to 1 x 10-2 mbar

Pollution category 1 x 10-8 to 1 x 10-2 mbar

KEY

1 Clearance required for electrical cable

D14558880 Issue H

Page 4 © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

TECHNICAL DATA

2.3 Electrical Data

2.4 Materials Exposed to Vacuum

Electrical supply

Voltage +13.5 to +36 V d.c.

Max voltage ripple 1 V peak to peak

Max source resistance 50 W

Maximum power consumption 3.5 W

Electrical connector FCC68/RJ45 type, 8-way

Pressure output signal

Range 2 < output < 10 V d.c.

Error range output < 2 V d.c. or

output > 10 V d.c.

Impedance 0.1 W

Min load impedance 10 kW

Max current source 1 mA

Gauge enable

Control sense Active low

Active level < 1.3 V

Control impedance 12 kW pull-up to positive supply

Error output

External load rating 40 V d.c., 100 mA max

Back EMF suppression diode*

Min. surge rating 1 A

Min. reverse voltage rating 100 V

Gauge identification resistance 100 kW ± 2%

Stainless steel (AISI 304 and 306)

Fluoroelastomer

Soda lime glass

© Edwards Limited 2020. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

D14558880 Issue H

3 INSTALLATION

3.1 Unpack and Inspect

Remove all packing materials and protective covers and check the AIM Gauge for damage.

If the AIM Gauge is damaged, notify your supplier and the carrier in writing within three days; state the Item Number

of the AIM Gauge together with your order number and your supplier’s invoice number. Retain all packing materials

for inspection. Do not use the AIM Gauge if it is damaged.

If the AIM Gauge is not to be used immediately, replace the protective covers. Store the AIM Gauge in suitable

conditions as described in Section 6.

3.2 Fit the AIM Gauge to the Vacuum System

The AIM Gauge can be mounted in any orientation. To avoid the build- up of debris or condensable material in the

body tube of the AIM Gauge (which will probably cause pressure measurement errors), we recommend that you install

the AIM gauge vertically as shown in Figure 2.

Use an ‘O’ ring / centring ring or Co-Seal and clamp to connect the NW25 flange of the AIM Gauge to a similar flange

on your vacuum system.

If required, you can turn the end-cap (relative to the magnet housing) so that the electrical connection socket is in

a convenient position on your system; refer to Figure 1 and use the following procedure: hold the magnet housing (4)

and turn the end-cap (1) in a clockwise or anticlockwise direction (arrow B) until the electrical connection socket (6)

is in the required position.

3.3 Electrical Connections

When using a cable longer than 30 m, full compliance with European Standards requires an in-line surge suppressor

(please refer to Section 7.3).

WARNING

The AIM gauge incorporates magnets. Keep away from heart pacemakers, computers, credit cards

and any other magnetically sensitive devices.

WARNING

Magnetic Field may interfere with pacemakers. Maintain a distance of minimum 10 cm between

the magnet and the heart pacemaker. You can also use anti-magnetic shield to prevent the

influence of strong magnetic field.

WARNING

If the AIM Gauge malfunctions, the AIM Gauge pressure output may be incorrect. If such a failure

could cause injury to people or damage equipment, you must install a suitable control system to

indicate the failure and, if necessary, to close down your process system.

D14558880 Issue H

Page 6 © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

3.3.1 Connect To Edwards Controllers or AGD Display

Connect the AIM Gauge to the controller or display with a cable which is terminated in suitable connectors. Suitable

cables are available from Edwards (refer to Section 7).

3.3.2 Connect To Your Own Supply and Control Equipment

Note: Do not connect the electrical supply common (pin 2) to the signal common (pin 5). If you do, the AIM Gauge

pressure output signal will be inaccurate.

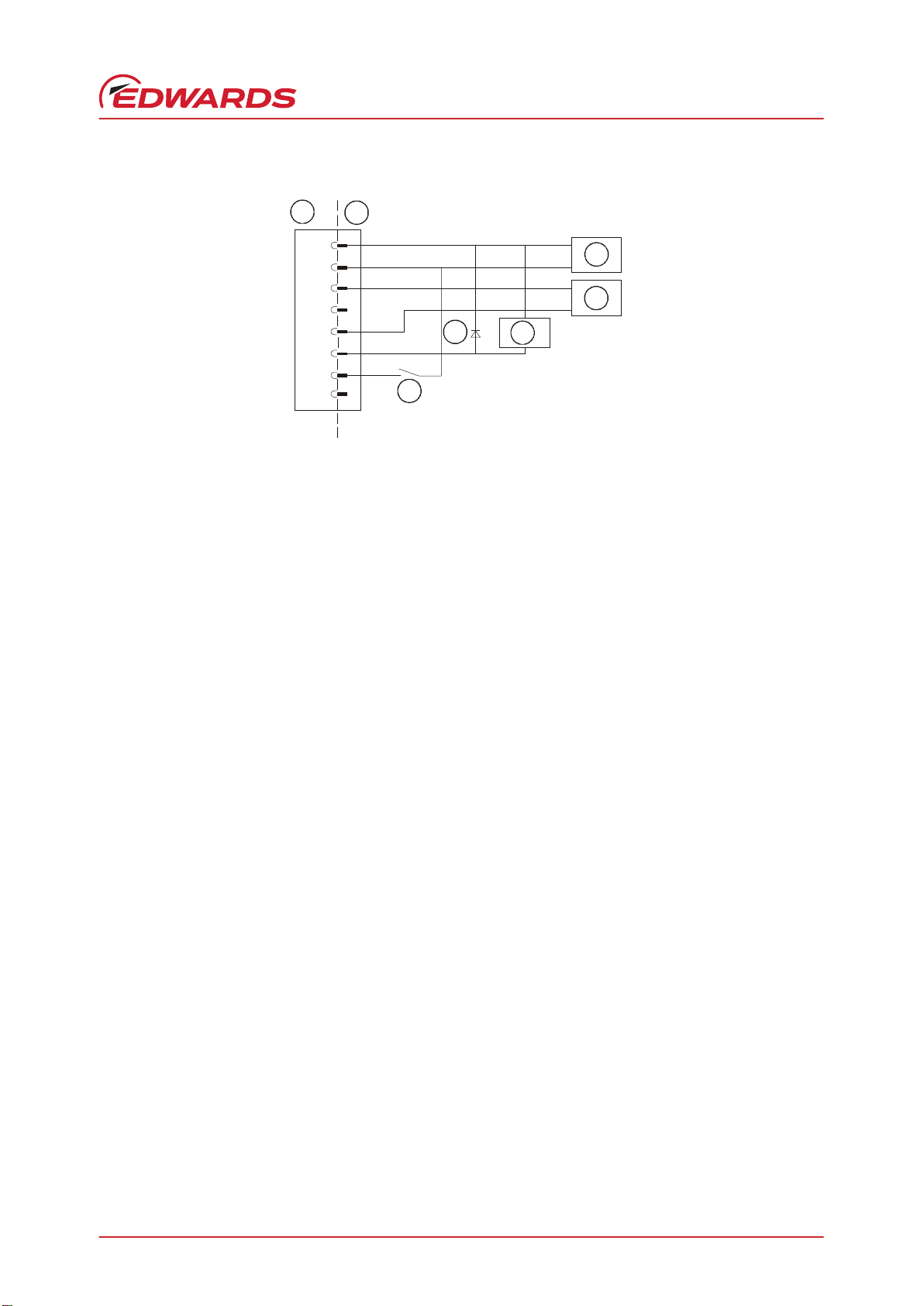

A schematic diagram of the recommended electrical connections to the AIM Gauge is shown in Figure 3.

The pins on the AIM Gauge electrical connection socket are used as shown in Table 1. The specification of the

electrical supply, d.c. relay and back EMF suppression diode are given in Section 2.

The connection to pin 6 is optional. Make the connection to pin 6 if you want to connect the error signal to a d.c.

relay: you must connect a suppression diode between pins 1 and 6 to protect the AIM Gauge from transient voltages

generated when the d.c. relay is switched off.

Connect a switch between pins 2 and 7 to enable and disable the gauge (refer to Section 4.2). If you want to measure

the gauge identification signal (which identifies the AIM Gauge), measure the resistance between pins 4 and 5.

Table 1 - Pins On the AIM Gauge Electrical Connector Socket

Pin

Number Use

1 Electrical supply positive voltage

2 Electrical supply common

3 Pressure measurement output signal

4 Gauge identification signal

5 Signal common

6 Error output signal

7 Gauge enable

8 No connection

© Edwards Limited 2020. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

D14558880 Issue H

Figure 3 - Schematic Diagram of Typical Electrical Connections

KEY

1 AIM Gauge electrical connector socket 2 Cable electrical connector plug

3 Electrical supply 4 Voltmeter

5 D.C. relay (optional) 6 Back EMF suppression diode (optional)

7 Gauge enable switch

1

2

3

4

5

6

7

8

12

3

4

5

6

7

+

0V

+

0V

D14558880 Issue H

Page 8 © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

INSTALLATION

© Edwards Limited 2020. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

OPERATION

D14558880 Issue H

4 OPERATION

4.1 Safety

4.2 Enable and Disable the AIM Gauge

CAUTION

Do not operate the AIM Gauge for long periods when the system pressure is above 1 x 10-2 mbar. If you do, the

anode pin can be damaged and the AIM Gauge can be severely contaminated.

We recommend that you only enable the gauge when the system pressure is lower than 1 x 10-2 mbar and that you

disable the gauge when the system pressure is 1 x 10-2 mbar or higher.

If you have connected the AIM Gauge to an AGC or AGD, refer to the corresponding instruction manual for details of

how to enable (switch on) and disable (switch off) the AIM Gauge.

Otherwise, to enable (switch on) the AIM Gauge, connect pin 7 to pin 2 (or to ground). To disable (switch off) the AIM

Gauge, disconnect pin 7 from pin 2 (or from ground).

4.3 Pressure Measurement

If you connected the AIM Gauge to an Edwards AGC controller or AGD display, the pressure measured by the AIM

Gauge is shown on the display.

If you connected the signal output of the AIM Gauge to a voltmeter, convert the measured voltage to the

corresponding pressure value: refer to Table 2.

If necessary, adjust the pressure reading to compensate for the RMM of the gas in your vacuum system (refer to

Section 1.3).

Generally Magnetron gauges exhibit a delay between switching on and establishment of the discharge. This striking

time increases with decreasing pressure. Typical values for a clean gauge are shown below.

Less than 20 seconds at pressures higher than 10-7 mbar

Less than 2 minutes at 10-8 mbar

WARNING

Do not use the AIM Gauge to measure the pressure of explosive or flammable gases or mixtures.

WARNING

Never operate the AIM Gauge when it is disconnected from the vacuum system or when there are

explosive or flammable gases in the surrounding atmosphere or the vacuum system. High voltages

(up to 3kV) are generated inside the body tube of the AIM Gauge; these could cause injury to

people or could be a source of ignition.

WARNING

The AIM gauge incorporates magnets. Keep away from heart pacemakers, computers, credit cards

and any other magnetically sensitive devices.

D14558880 Issue H

Page 10 © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

OPERATION

4.4 Error Output Signal

Note: The error signal output is not used if you connect the AIM Gauge to an Edwards AGC controller or AGD

display.

The error output signal indicates when the AIM Gauge is operating correctly. If required, you can use the error output

signal to control the operation of your vacuum system. The signal is open (that is, the output of the FET transistor is

off):

For 1.5 seconds after the AIM Gauge is switched on.

When the pressure output signal is out of range, that is the signal is < 1.5 V or > 10.7 V.

When the discharge from the AIM Gauge has failed to strike (ignite); that is, if the voltage after switch-on

fails to rise above 2.5 V.

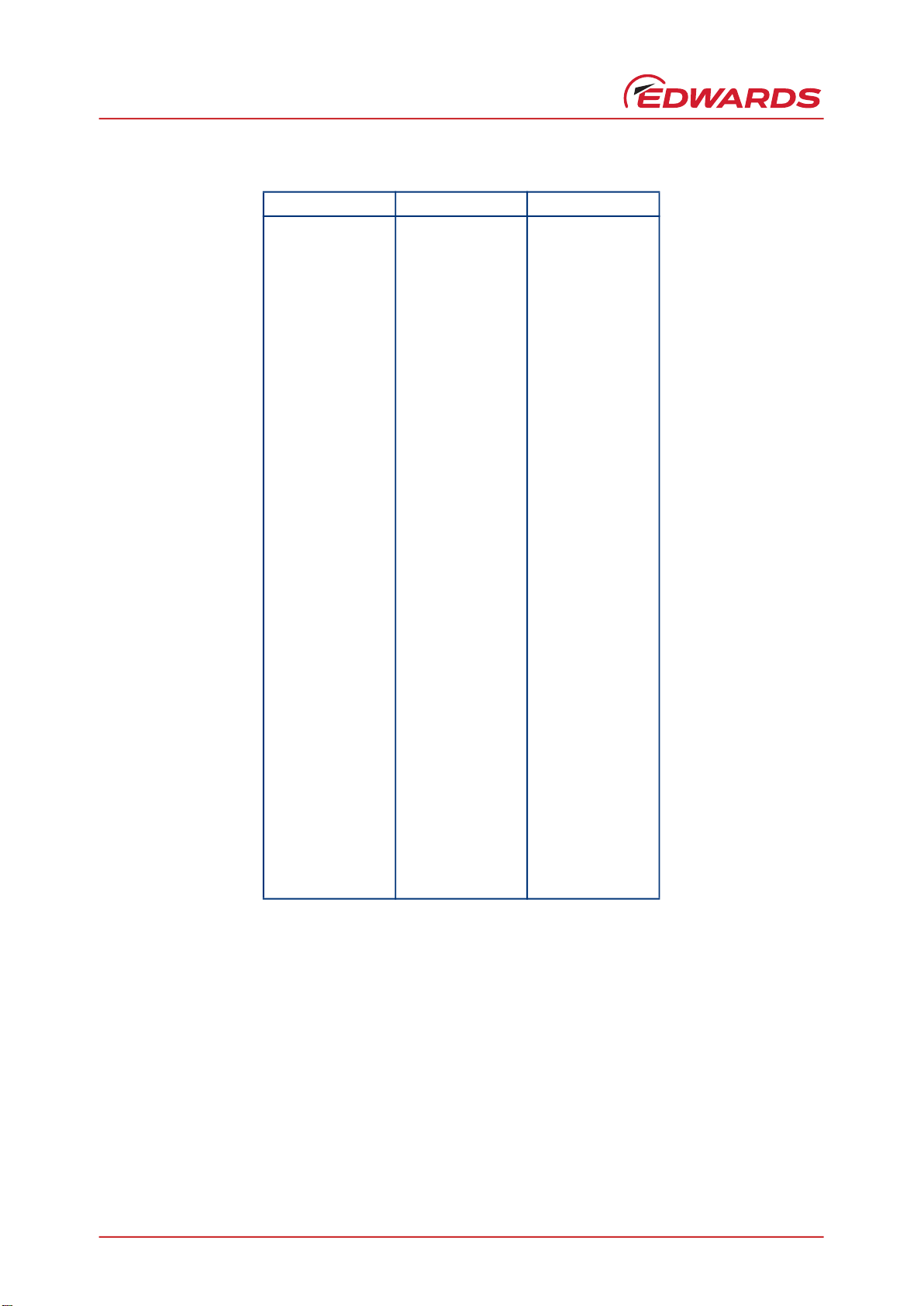

Table 2 - Pressure and Voltage Characteristics for Nitrogen and Dry Air

Pressure (mbar) Output voltage (V) Pressure (torr)

1.0 x 10-8

2.4 x 10-8

5.8 x 10-8

8.2 x 10-8

1.2 x 10-7

2.00

2.50

3.00

3.20

3.40

7.5 x 10-9

1.8 x 10-8

4.3 x 10-8

6.1 x 10-8

8.7 x 10-8

1.6 x 10-7

2.3 x 10-7

3.2 x 10-7

4.4 x 10-7

5.9 x 10-7

3.60

3.80

4.00

4.20

4.40

1.2 x 10-7

1.7 x 10-7

2.4 x 10-7

3.3 x 10-7

4.5 x 10-7

7.9 x 10-7

1.0 x 10-6

1.3 x 10-6

1.6 x 10-6

2.0 x 10-6

2.5 x 10-6

3.1 x 10-6

3.9 x 10-6

4.9 x 10-6

6.1 x 10-6

4 .60

4.80

5.0 0

5.20

5.40

5.60

5.80

6.00

6.20

6.40

5.9 x 10-7

7.6 x 10-7

9.5 x 10-7

1.2 x 10-6

1.5 x 10-6

1.9 x 10-6

2.4 x 10-6

2.9 x 10-6

3.7 x 10-6

4.6 x 10-6

7.5 x 10-6

9.3 x 10-6

1.1 x 10-5

1.4 x 10-5

1.7 x 10-5

2.1 x 10-5

2.6 x 10-5

3.1 x 10-5

3.9 x 10-5

4.8 x 10-5

6.60

6.80

7.00

7.20

7.40

7.60

7.80

8.00

8.20

8.40

5.6 x 10-6

7.0 x 10-6

8.6 x 10-6

1.0 x 10-5

1.3 x 10-5

1.6 x 10-5

1.9 x 10-5

2.4 x 10-5

2.9 x 10-5

3.6 x 10-5

6.1 x 10-5

8.0 x 10-5

1.1 x 10-4

1.8 x 10-4

2.9 x 10-4

5.4 x 10-4

1.5 x 10-3

1.0 x 10-2

8.60

8.80

9.00

9.20

9.40

9.60

9.80

10. 00

4.6 x 10-5

6.0 x 10-5

8.4 x 10-5

1.3 x 10-4

2.2 x 10-4

4.0 x 10-4

1.1 x 10-3

7.5 x 10-3

© Edwards Limited 2020. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

MAINTENANCE

D14558880 Issue H

5 MAINTENANCE

5.1 Introduction

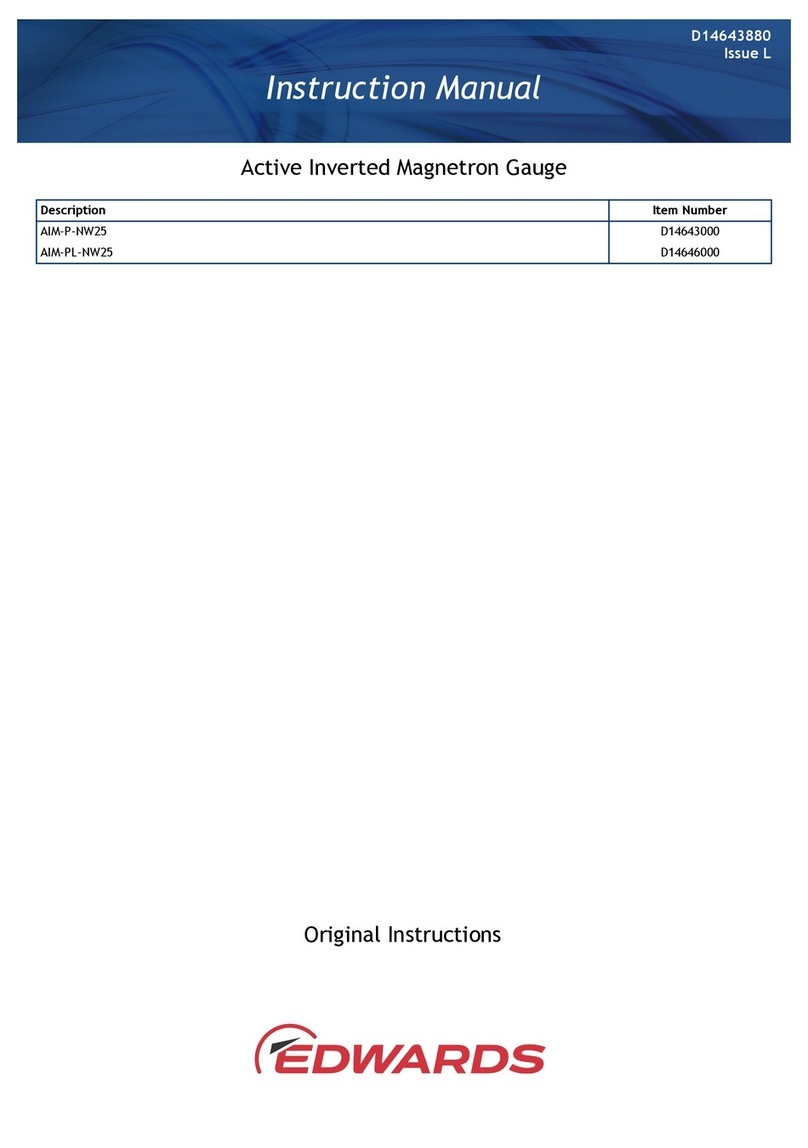

The internal components of the AIM Gauge are shown in Figure 4. The AIM Gauge is designed so that you can easily

clean these components, or use the spares listed in Section 7 to replace these components. Refer to the following

sections for details of the maintenance procedures, which you should do when necessary.

5.2 Replace the Body Tube

Refer to Figure 4 and use the following procedures to replace the body tube:

5.2.1 Remove the AIM Gauge from the Vacuum System

1. Switch off the AIM Gauge electrical supply and ensure that vacuum system is at atmospheric pressure.

2. Disconnect the cable connector plug (Figure 1, item 5) from the AIM Gauge and remove the AIM Gauge from the

vacuum system.

5.2.2 Fit the New Body Tube

1. Hold the magnet housing (1) and turn the body tube (5) anticlockwise (when viewed from the vacuum flange) to

unlock the bayonet fitting. Remove the body tube from the magnet housing.

2. Slide the new body tube into the magnet housing (1) (as shown by arrow B).

3. Hold the magnet housing (1) and turn the body tube (5) clockwise (when viewed from the vacuum flange) to lock

the bayonet fitting (as shown by arrow C).

5.2.3 Refit the AIM Gauge To the Vacuum System

Refit the AIM Gauge to the vacuum system as described in Section 3.2 and refit the cable connector plug to the socket

on the AIM Gauge (Figure 1, item 6).

5.3 Replace the Electrode Assembly

Refer to Figure 4 in the following procedure.

1. Remove the AIM Gauge from the vacuum system as described in Section 5.2.1.

2. Remove the body tube from the AIM Gauge as described in Step 1 of Section 5.2.2.

WARNING

Do not disconnect the electronics and magnet housing from the body tube when the body tube is

connected to the vacuum system. If there is a plasma discharge in the vacuum system near the

body tube, the body tube can become electrically charged.

WARNING

Disconnect the cable from the AIM Gauge before you remove the AIM Gauge from the vacuum

system. High voltages are generated inside the AIM Gauge.

D14558880 Issue H

Page 12 © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

3. Fit the flat spanner supplied in the electrode assembly kit (refer to Section 7) to the two lugs in the end of the

collar (2), then turn the collar anticlockwise to unscrew the collar from the body tube (5) and remove the anode

assembly (3) and the ‘O’ ring (4).

4. Use circlip pliers to remove the circlip (8) from the vacuum flange end of the body tube (5), then remove the

cathode tube (7) and the cathode plate (6).

5. Fit the new cathode plate (6) and cathode tube (7) into the body tube and secure with the circlip (8).

6. Fit the new ‘O’ ring (4) and anode assembly (3) into the body tube (5); ensure that the orientation of the anode

assembly is correct.

7. Refit the collar (2) to the body tube. Locate the flat spanner on the two lugs on the collar and turn the collar

clockwise until it is fully secured in the body tube.

8. Refit the body tube (5) to the magnet housing (1) as described in Steps 2 and 3 of Section 5.2.2. Refit the AIM

Gauge to the vacuum system as described in Section 5.2.3.

Figure 4 - Exploded View of the AIM Gauge

KEY

1 Magnet housing 2 Collar

3 Anode assembly 4 “O” ring

5 Body tube 6 Cathode plate

7 Cathode tube 8 Circlip

© Edwards Limited 2020. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

MAINTENANCE

D14558880 Issue H

5.4 Replacing the Electronics and Magnet Housing

The magnet housing and end-cap contain the AIM Gauge control electronics. Replace the complete unit as described

below.

1. Remove the AIM Gauge from the vacuum system as described in Section 5.2.1.

2. Remove the body tube from the AIM Gauge as described in Step 1 of Section 5.2.2.

3. Dispose of the old magnet housing and end-cap (refer to Section 6).

4. Fit the body tube to the new magnet housing and end-cap as described in Steps 2 and 3 of Section 5.2.2. Refit

the AIM Gauge to the vacuum system as described in Section 5.2.3.

5.5 Clean the internal components

Refer to Figure 4 in the following procedure.

1. Remove the internal components from the magnet housing as described in Steps 1 to 4 of Section 5.3.

2. The anode assembly (3) has two brackets mounted close to the disk on the anode. Use a strip of fine emery

paper to clean the gap between the disk and the brackets.

3. Use a fine screwdriver or feeler gauge and ensure that the gaps are a minimum of 0.25 mm.

4. Degrease the cathode plate (6), cathode tube (7), body tube (5) and anode assembly (3) in a suitable degreasing

agent.

5. Thoroughly soak the components in a suitable laboratory detergent.

6. Rinse the components in clean water to remove the detergent.

7. Rinse the components in methanol to remove all of the water, then thoroughly dry the components.

8. Refit the components in the magnet housing as described in Steps 5 to 8 of Section 5.3.

5.6 Fault Finding

The AIM Gauge has self-monitoring fault detection circuits which close an error output signal when the gauge is not

operating correctly. You can use the error signal output to determine if a fault has been detected, as described in

Section 4.4.

If the AIM Gauge does not operate correctly, ensure that the electrical connections are correct (refer to Section 3)

and ensure that your electrical supply is suitable for the AIM Gauge (refer to Section 2).

D14558880 Issue H

Page 14 © Edwards Limited 2020. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

This manual suits for next models

1

Table of contents

Other Edwards Industrial Equipment manuals

Edwards

Edwards CDP User manual

Edwards

Edwards APG-M-NW16 AL User manual

Edwards

Edwards Iron Worker User manual

Edwards

Edwards AIM-P-NW25 User manual

Edwards

Edwards FL20K User manual

Edwards

Edwards GV250 User manual

Edwards

Edwards Drystar GV80-EH250 User manual

Edwards

Edwards AdaptaBeacon 96DV2-N5 Series User manual

Edwards

Edwards FL20K User manual

Edwards

Edwards E1M40/80 Installation instructions