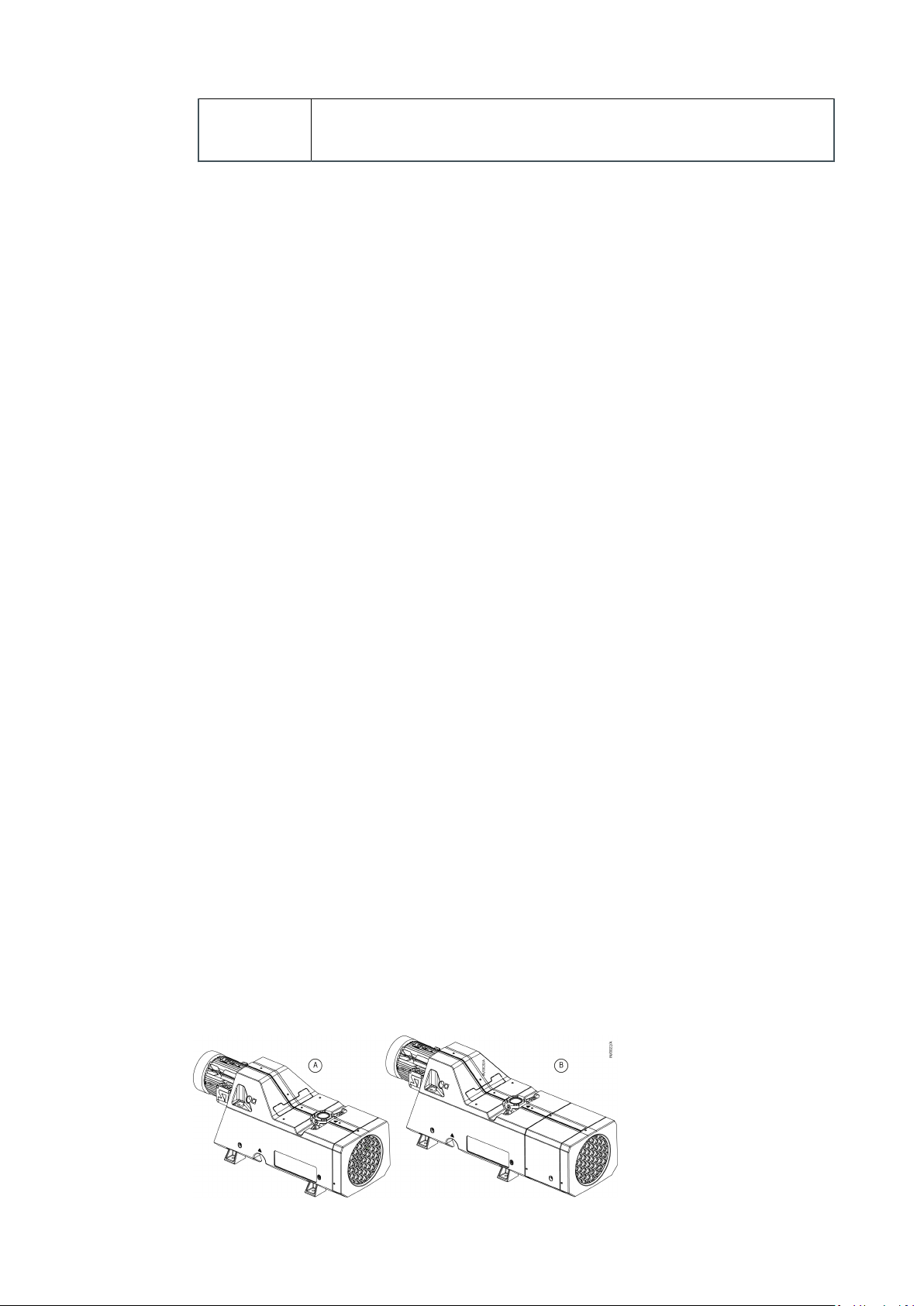

EDS 200 and EDS 300 look the same, they dier only in their performance.

A. EDS 200/300 water-cooled B. EDS 200/300 air-cooled (with heat exchanger)A. EDS 200/300 water-cooled B. EDS 200/300 air-cooled (with heat exchanger)

4.1 Design

The EDS dry pump range has been developed to meet the demanding requirements for

pumping soluons in industrial and chemical applicaons. The EDS pumps in general are

designed for general vacuum use only and operaon in rough and ne vacuum to evacuate

vessels and to pump gas mixtures.

The pump is a dry, posive displacement screw vacuum pump in which pairs of

intermeshing, non-contacng screw rotors are turning contrawise in phase by ming-gears.

The screw rotors are driven by an asynchronous electrical motor. Blow-o valves within the

mechanism minimize pumping power at high pressures and allow the pump to be started

direct-on-line. The rotaonal speed of screw rotors is increased by transmission gears. Gears

and bearings are oil lubricated.

The EDS pumps are supplied with dierent motors concerning main voltage and supply

frequencies.

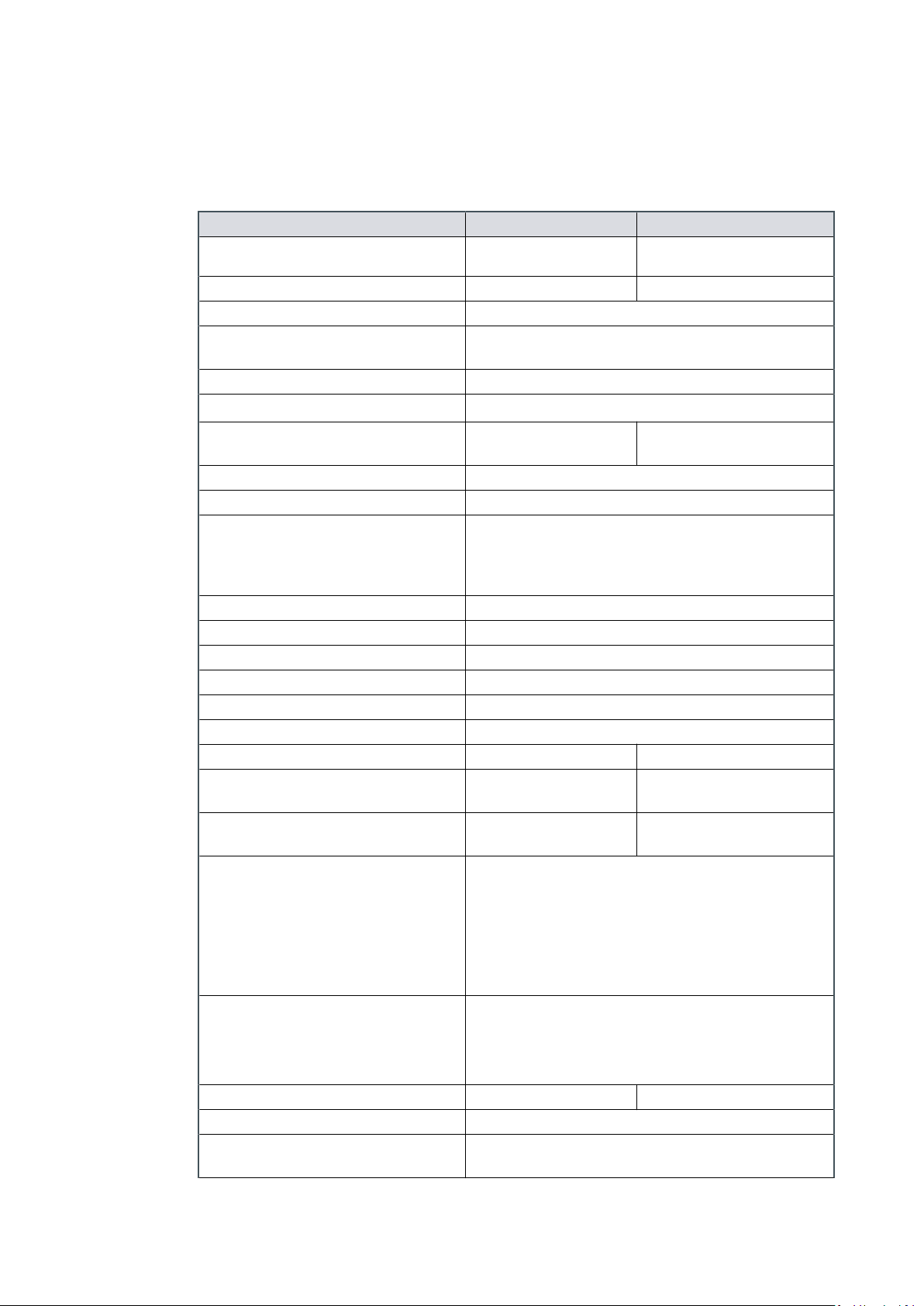

Cooling system

The motor is air-cooled by an integrated cooling-fan. The EDS pump itself is water or air

cooled.

Water cooled: cooling-water circulates around the pump-body and then passes out of the

pump. The cooling system is open-loop and unregulated such that the cooling water ow

rate and temperature will directly the temperature of the pump.

Air cooled: glycol/water mixture circulates around the pump-body and through the water to

air cooled heat exchanger via an integrated water pump. The cooling system is closed-loop.

The pumps have a thermal snap-switch on the pump-body as temperature monitoring.

The output of the thermal snap-switch has two connecons: one will open circuit when the

temperature of pump-body is higher than 90 °C. Use this output to provide a warning of high

temperature. The second output will open circuit when the temperature of pump-body is

higher than 110 °C. Use this output to shut-down the pump when it is too hot.

Gas system

The EDS pumps have a sha-seal purge system and a gas-ballast system.

The sha-seal purge delivers the supplied gas, e.g. dry compressed air or nitrogen, to the

internal sha seal system to protect it and ensure lifeme and funconality. Sha-seal purge

ensures that the sha-seals are maintained at a posive pressure gradient to pumping

chamber during pump operaon; therefore it prevents the entry of corrosive or toxic

process vapours into the pump gearbox; prevents contaminaon of the process gases by

pump oil; prevents damage to sha-seals by debris.

As supplied, the gas-ballast system can deliver ambient air to the pump gas-ballast inlet.

Gas-ballast use depends on your applicaon and can e.g. reduce temperature load or

increase water vapour capability. The air-ow is ltered and is controlled by a valve. A check-

valve in the system prevents the escape of process gases out of the gas ballast. If required

for your applicaon, it is possible to connect dry nitrogen supplies to the pump, to deliver

nitrogen gas ballast and nitrogen sha-seal purge instead of air.

Page 14