4. Operating Instructions

* Disconnect the tubes from the PumpVentValve aswell

asfrom the ControllerVentValve.

* Pull out all plugs from the Electrical Supply Unit.

* Remove the Vacuum Controller from the Support Post

after loosening the clamp assembly.

* Remove the Valve Support Post from the Controller

Support Post after loosening the clamp assembly.

* Removethe Controller Support Postfrom the Baseplate:

-Loosen the Allen screw at the foot of the Vacuum Con-

troller Support Post.

-Slide it out of the BaseplateMounting Slot.

Assembly

* Mount the existing controller onto the new Controller

Support Post: Slide the Vacuum Controller (more ex-

actly: its clamping assembly) into theVacuum Controller

Support Post Mounting Slot andfix theVacuum Control-

ler by tightening the Allen screw.

* SlidetheVacuum Controller Support Post (more exactly:

its clamping assembly) into the BaseplateMounting Slot.

* Fix the Vacuum Controller Support Post by tightening

the Allen screw at the foot of the Support Post.

* Mount theValve Support Post onto the Controller Sup-

port Post.

* Slidethe holding device for theVacuumValves(including

VacuumValves) onto the Valve Support Post Mounting

Slot and fix the device with help of the clampingassem-

bly.

* Tubing of two headed pumps see figure 12.When con-

necting single head pumps,study the Information Sheet

that accompanies the accessories. Choose tube mate-

rial which is resistant to the media being used.

* Electrical connection: seesection3.5.1.

4.1 General Notes

Before using the vacuum pump or the D-LAB system please

observe the following points:

* Choose a safe location (flat surface) for the equipment.

* Ensure that the vacuum pump is securely fastened to

the Baseplate.The two locating pins underneath the pump

must be locked in position.

* Laboratory equipment or additional components con-

nected to a D-LAB -pump or a D-LAB -system must

be compatible with the physical capabilities of the pump.

* When using the high performance condenser the sys-

tem must be connected to a cold water supply or a re-

circulating cooler.

* When using two Vacuum Controllers: two controllers

should only be used with gases which can be mixed safely

together.

* Don't operate the pump/D-LAB-system in an atmos-

phere containing explosive gases.

Before getting started:

* Specific safety instructions for the media being handled

must be observed.

* Observe all safety regulations when handling: corrosive,

explosive, microbiological, radioactive, toxic and other

dangerous materials.

* Ensure the pump outlet is not closed or restricted and

adequate ventilation allowed.

If using a Condenser:

* Ensure that the vapour outlet on the top of the con-

denser isnever blocked (akink in the exhaust hose could

causepressure build up).

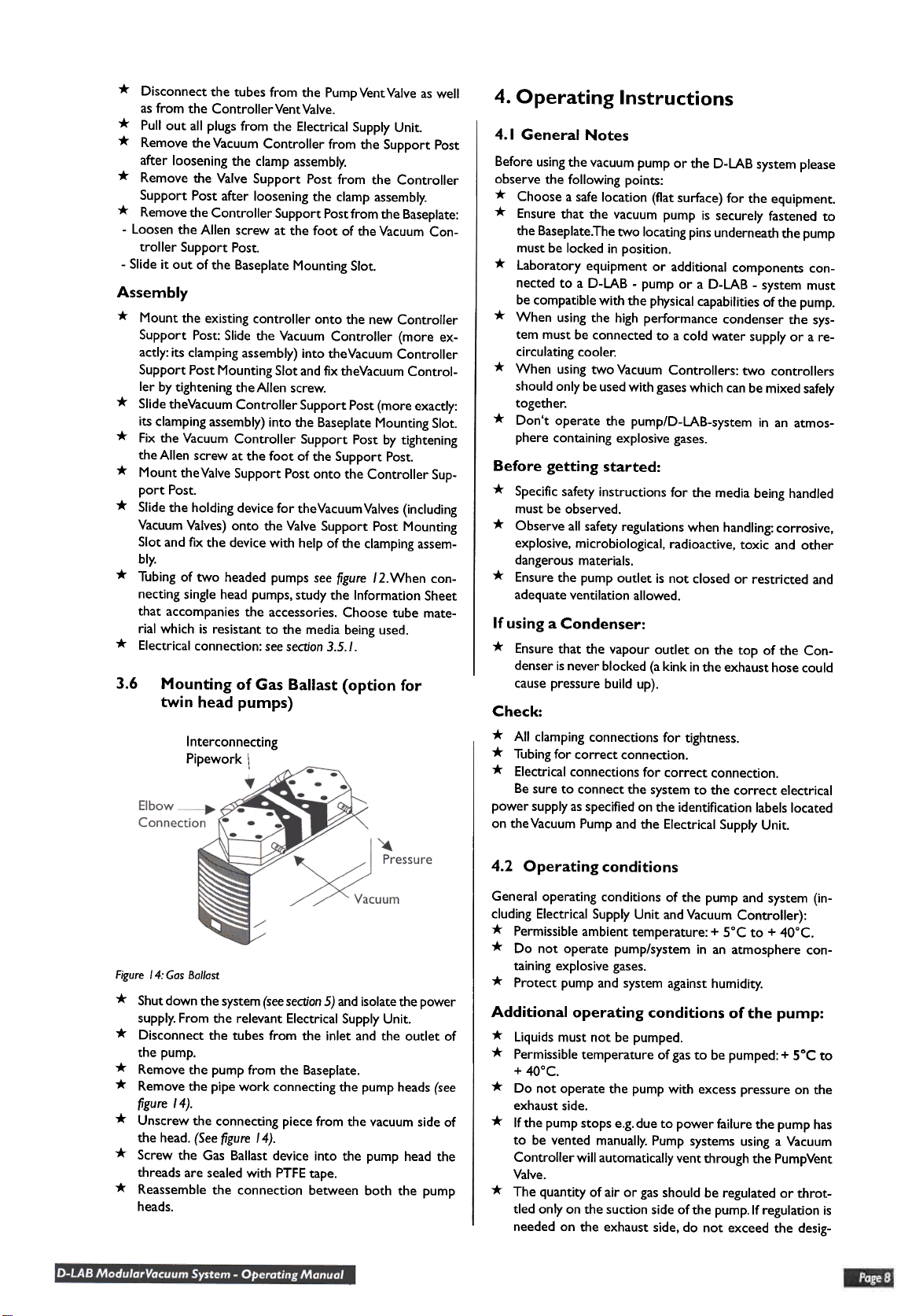

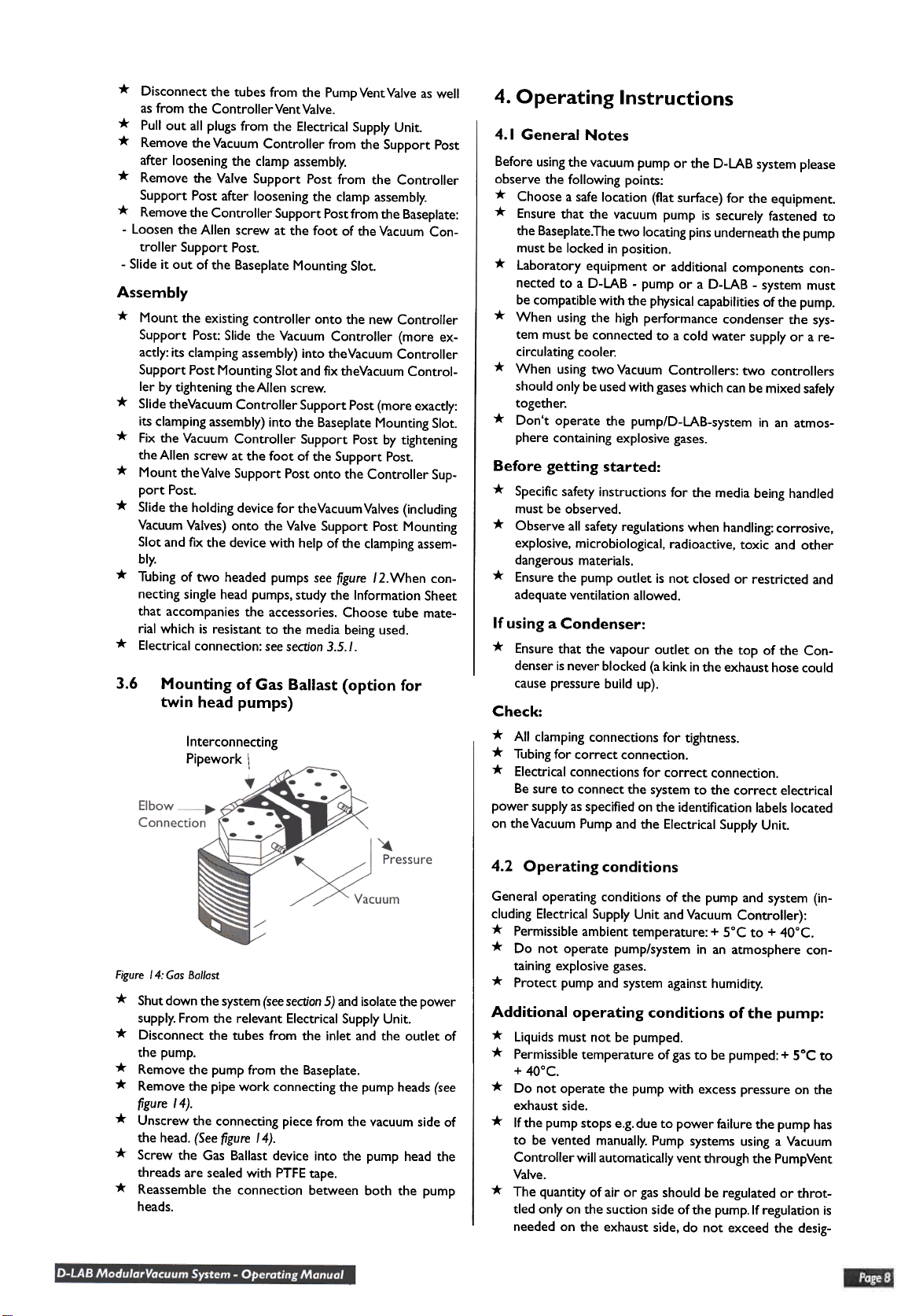

3.6 Mounting of Gas Ballast (option for

twin head pumps)

Interconnecting

Pipework \

Check:

* All clamping connections for tightness.

* Tubingfor correct connection.

* Electrical connections for correct connection.

Be sure to connect the system to the correct electrical

power supplyasspecified on the identification labelslocated

on theVacuum Pump and the Electrical Supply Unit.

4.2 Operating conditions

Figuret4:GasBallast

* Shutdown the system(seesection5) andisolatethe power

supply.From the relevant Electrical SupplyUnit.

* Disconnect the tubes from the inlet and the outlet of

the pump.

* Remove the pump from the Baseplate.

* Remove the pipe work connecting the pump heads(see

figure 14).

* Unscrew the connecting piece from the vacuum side of

the head. (Seefigure 14).

* Screw the Gas Ballast device into the pump head the

threads are sealedwith PTFEtape.

* Reassemble the connection between both the pump

heads.

General operating conditions of the pump and system {in-

cluding Electrical Supply Unit andVacuum Controller):

* Permissible ambient temperature: + 5°C to + 40°C.

* Do not operate pump/system in an atmosphere con-

taining explosive gases.

* Protect pump and system against humidity.

Additional operating conditions of the pump:

* Liquids must not be pumped.

* Permissibletemperature of gasto be pumped: + 5°C to

+ 40°C.

* Do not operate the pump with excess pressure on the

exhaust side.

* Ifthe pump stops e.g.due to power failure the pump has

to be vented manually.Pump systems using a Vacuum

Controller will automatically vent through the PumpVent

Valve.

* The quantity of air or gasshould be regulated or throt-

tled only on the suction side of the pump.If regulation is

needed on the exhaust side, do not exceed the desig-