EFD Ultra 2400 Series User manual

™

User’s Guide

®

A NORDSON COMPANY

Ultra

®

2400 Series

Dispensing Workstation

Ultra 2400

Ultra 2405

Ultra 2415

Electronic pdf files of EFD manuals are also available at www.efd-inc.com/manuals.html

Welcome to the Ultra 2400 Series, the most complete dispensing system on the market.

This User’s Guide will help you maximize the usefulness of your new workstation.

Please spend a few minutes to become familiar with the controls and features. Follow our

recommended testing procedures. Review the helpful information we have included, which is

based on more than 30 years of industrial dispensing experience.

Most questions you will have are answered in this guide. However, if you need assistance,

please do not hesitate to contact EFD or your authorized EFD distributor.

In the USA, call 800-556-3484 between 8:30 a.m. and 5:30 p.m. Eastern time.

In Europe, call +44 (0) 1582 666334.

In Asia, call +86 (21) 5854 2345.

In all other areas, call your authorized EFD distributor or +1-401-434-1680.

The EFD Pledge

We pledge that you will be completely satisfied with our products. We endeavor to ensure that every

EFD product is produced to our no-compromise quality standards.

If you feel that you are not receiving all the support you require, or if you have any questions or

comments, I invite you to write or call me personally.

Our goal is to build not only the finest equipment and components, but also to build long-term customer

relationships founded on superb quality, service, value and trust.

Peter Lambert, President

Introduction

2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Filling the Syringe Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Vacuum Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Syringe Barrel Loaders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Input/Output Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Helpful Hints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Productivity Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

This manual is for the express and sole use of EFD dispenser purchasers and users, and no portion of it may be reproduced in any form.

Contents

3

Safety

4

Introduction

Read and follow these safety instructions. Task- and equipment-specific warnings, cautions and

instructions are included in equipment documentation where appropriate.

Qualified Personnel

Equipment owners are responsible for making sure that EFD equipment is installed, operated and serviced

by qualified personnel. Qualified personnel are those employees or contractors who are trained to safely

perform their assigned tasks. They are familiar with all relevant safety rules and regulations, and are

physically capable of performing their assigned tasks.

Intended Use

Use of EFD equipment in ways other than those described in the documentation supplied with the

equipment may result in injury to persons or damage to property.

Some examples of unintended use of equipment include

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained

for EFD equipment will be voided if instructions for installation, operation and service are not followed.

Personal Safety

To prevent injury follow these instructions.

• Do not operate or service equipment unless you are qualified.

• Do not operate equipment unless safety guards, doors or covers are intact and automatic interlocks are

operating properly. Do not bypass or disarm any safety devices.

• If you receive even a slight electrical shock, shut down all electrical or equipment immediately. Do not

restart the equipment until the problem has been identified and corrected.

• Obtain and read Material Safety Data Sheets (MSDS) for all materials used. Follow the manufacturer’s

instructions for safe handling and use of materials, and use recommended personal protection devices.

• To prevent injury, be aware of less-obvious dangers in the workplace that often cannot be completely

eliminated, such as hot surfaces, sharp edges, energized electrical circuits and moving parts that

cannot be enclosed or otherwise guarded for practical reasons.

• This equipment is for indoor use only.

• Use only the power adapter provided with the unit. Contact EFD to purchase a replacement adapter.

• Always keep dispensing end of syringe barrel pointed away from your face and towards the work

piece. Store the syringe barrel in an appropriate holder when not in use.

• Caution: Use EFD filter/muffler (P/N 2170FT) or wear adequate ear protection when operating the

vacuum in close proximity for a prolonged period of time.

• Using incompatible materials

• Making unauthorized modifications

• Removing or bypassing safety guards or

interlocks

• Using incompatible or damaged parts

• Using unapproved auxiliary equipment

• Operating equipment in excess of maximum

ratings

Safety

5

Fire Safety

To avoid a fire or explosion, follow these instructions.

• Shut down all equipment immediately if you notice static sparking or arcing. Do not restart the

equipment until the cause has been identified and corrected.

• Do not smoke, weld, grind or use open flames where flammable materials are being used or

stored.

• Provide adequate ventilation to prevent dangerous concentrations of volatile particles or vapors.

Refer to local codes or your material MSDS for guidance.

• Do not disconnect live electrical circuits when working with flammable materials. Shut off

power at a disconnect switch first to prevent sparking.

• Know where emergency stop buttons, shutoff valves and fire extinguishers are located.

• Clean, maintain, test and repair equipment according to the instructions in your equipment

documentation.

• Use only replacement parts that are designed for use with original equipment. Contact your EFD

representative for parts information and advice.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system immediately and perform

the following steps:

• Disconnect and lock out system electrical power.

• Identify the reason for the malfunction and correct it before restarting the system.

Disposal

Dispose of equipment and materials used in operation and servicing according to local and national

codes.

Part Name Toxic or Hazardous Substances and Elements

Lead Mercury Cadmium Hexavalent Polybrominated Polybrominated

Chromium Biphenyls Diphenyl Ethers

(Pb) (Hg) (Cd) (Cr6) (PBB) (PBDE)

All brass fittings XO O O O O

O: Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this

part, according to EIP-A, EIP-B, EIP-C is below the limit requirement in SJ/T11363-2006.

X: Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this

part, according to EIP-A, EIP-B, EIP-C is above the limit requirement in SJ/T11363-2006.

China RoHS Hazardous Material Declaration

Getting

Started

6

The Ultra 2400 workstation is designed to provide complete process control for precise, repeatable

fluid dispensing.

Key features include

• All-digital, multi-function display with simultaneous readout of air pressure, time, vacuum,

deposit shot count and time of day

• Unique air management reservoir and high-speed solenoid system for consistent, repeatable

deposits

• Time increment adjustments as small as 0.0001 seconds for precise deposit control

• Workstation panels to hold a variety of useful accessories, including light, ergonomic syringe

barrel holder, magnifier and more

First Steps

First: Place the dispenser in your work area. The Ultra 2400 is equipped with “stay put” rubber pads.

It can be placed on the benchtop or any flat surface.

Second: Connect to power and air supplies, and program the unit. For step-by-step setup

instructions, see the Ultra 2400 Quick Start Guide.

Third: Now is a good time to activate your Ten Year Warranty. Please register your warranty online at

www.efd-inc.com/warranty/ten. Or if you prefer, follow the instructions in the enclosed “Welcome”

letter to contact your area EFD representative.

Specifications

7

Cabinet size: 14.3 W x 18.1 H x 17.3 D cm (5.63 x 7.12 x 6.82")

Weight: 2.3 kg (5.0 lb)

Power adapter:

AC input voltage: 100 to 240 VAC

AC input frequency: 47 to 63 Hz

DC output: 24 VDC @ 1.25A

End-of-cycle feedback circuits: 5 to 24 VDC; 100mA maximum

Initiate circuits: Foot pedal, finger switch or 5 to 24 VDC signal

Cycle rate: Exceeds 600 cycles per minute

Time range: Programmable from 0.0001 to 999.9999 seconds

Ambient operating conditions:

Temperature: 5°C to 45°C (41°F to 113°F)

Humidity: 85% RH at 30°C non-condensing

Height above sea level: 2000 meters max (6,562 feet)

Meets or exceeds CE and CSA requirements

Ultra 2400

Air input: 80 to 100 psi (5.5 to 6.9 bar)

Air output: 0 to 100 psi (0 to 6.9 bar)

Ultra 2415

Air input: 80 to 100 psi (5.5 to 6.9 bar)

Air output: 0 to 15 psi (0 to 1.0 bar)

Ultra 2405

Air input: 80 to 100 psi (5.5 bar to 6.9 bar)

Air output: 0 to 5 psi (0 to 0.34 bar)

Note: Specifications and technical details are subject to change without prior notification.

+

+

120.6 mm

4.75 "

143.0 mm

5.63 "

173.2 mm

6.82 "

180.8 mm

7.12 "

159.5 mm

6.28 "

Features &

Controls:

Front Panel

8

Dispense Mode

When powered for the first time, the Ultra 2400 Home screen displays in

TIMED mode. Otherwise, it displays in the mode last used.

You can verify what mode you’re in by checking the top left corner of the

display screen. It will be TIMED, TEACH, STEADY or MEMORY.

• You can return to TIMED mode from TEACH or STEADY by pressing

TIMED in the bottom right corner of the display.

• You can return to TIMED mode from MEMORY by pressing MENU, then

selecting TIMED.

See the appropriate section below for details on each dispense mode.

Dispense Time

Dispense time, shown with an hourglass icon, displays from 000.0001 to 999.9999 seconds.

Follow these steps to set the dispense time.

• Begin in TIMED mode.

• Press the left/right arrows to highlight the first number you want to change.

• Press the up/down arrows to set the time. Or if you prefer, you can also

use the timer dial (top right knob) to set the time.

• Repeat as needed to adjust the other numbers in the dispense time row.

Timed

Mode

display navigation

dispense time

multi-function controls

pressure regulator vacuum regulator

power

data/time control

output air

dispense pressure

cycle counter

time of day

mode indicator

vacuum pullback

menu

See the Ultra 2400 Icon Guide, included with your dispensing system, if you are

working in Chinese, Japanese, or Korean. Sample icons:

(Timed) (Steady) (Teach) (Menu) (Select) (Home)

Features &

Controls:

Front Panel

9

Air Pressure

Air pressure is displayed in psi. See page 20 to change the display of pressure from psi to bar or

kPa. It is shown with the icon of an arrow pushing into a syringe barrel. Follow these steps to set air

pressure.

• Pull the air pressure regulator knob out to unlock it (bottom left knob).

• Turn the knob clockwise to the desired pressure setting.

• To reduce pressure, turn the knob counterclockwise until the display

reads a lower pressure than needed. Then increase the pressure until you

reach the correct setting.

• Push the knob in to lock the pressure setting.

For all Ultra 2400 Series units (models 2400, 2415, and 2405): Set plant air

supply within 80 to 100 psi (5.5 to 6.9 bar).

Vacuum

Vacuum is displayed in inH2O (inches of water). See page 20 to change the display of vacuum from

inH2O to inHg, kPa, mmHg, or Torr. It is shown with the icon of an arrow pulling out of a syringe

barrel. Follow these steps to set vacuum pressure.

• Pull the vacuum regulator knob out to unlock it (bottom right knob).

• Turn the knob clockwise to the desired setting. You can adjust the

vacuum in increments of 0.1 inH2O.

• Push the knob in to lock the vacuum setting.

• Caution: Use EFD filter/muffler (P/N 2170FT) or wear adequate ear

protection when operating the vacuum in close proximity for a prolonged

period of time.

Clock

A real time clock is displayed in the top right corner. Follow these steps to set the clock.

• Press MENU.

• Press the down arrow to highlight SET CLOCK.

• Press SELECT.

• Press the left/right arrow to highlight the number to change.

• Press the up/down arrow to adjust the time. Or use the timer dial (top

right knob) to adjust the time or toggle between AM (morning) and PM

(afternoon/evening).

• Press SAVE. This saves the time and automatically returns you to the

Home screen.

Features &

Controls:

Front Panel

10

Power

Press the power button to turn the unit on. An EFD logo will briefly appear before the Home screen

displays. The Ultra 2400 will go into sleep mode when it’s inactive for more than 90 minutes. Simply

press any button or the foot pedal to reactivate the screen.

Menu

You can access the menu screen by pressing MENU. From here press the up/down and left/right

arrows to select from a variety of screens, including:

See page 20 for details on various Menu functions.

Shot Count

The shot count is displayed in the top center section of the display screen. It displays the number of

deposits that have been dispensed. Follow these steps to reset the shot count.

• Press MENU.

• Press the down arrow to highlight CLEAR COUNT.

• Press SELECT. This resets the shot count to 0 and automatically returns you to the Home screen.

Timed Mode

In TIMED mode, the Ultra 2400 will dispense a single deposit each time you press the foot pedal or

finger switch. Deposit size is based on dispense time and pressure settings shown on the display.

Steady Mode

In STEADY mode you can dispense for as long as you press the foot pedal or finger switch. From

TIMED mode, press STEADY. This toggles the display so that the top left corner is now selected for

STEADY mode. See Initial Test Procedures, page 16, for more details on STEADY mode.

Teach Mode

In TEACH mode you can “teach” the deposit based on physical size. Begin in the Home screen for

TIMED mode. Press TEACH. This toggles the display so that the top left corner is now selected for

TEACH mode. See Initial Test Procedures, page 16, for more details on TEACH mode.

Output Air Port

The Ultra 2400 features two output air ports. You can connect the Ultra adapter assembly to the port

on the front panel or the back panel, whichever is most convenient.

TIMED TEACH MEMORY

CLEAR COUNT UNITS OF PRESSURE UNITS OF VACUUM

SECURITY LANGUAGE SAVE JOB

SET CLOCK INFO

Power Input Port

The power input port is located at the top left corner of the Ultra 2400. The Ultra 2400 power pack

automatically adjusts for 100 to 240 VAC.

Use only the universal power pack provided with the Ultra 2400 workstation. The unit is shipped with

four power plugs (one USA and three international plugs) and a 5.9 ft (1800 mm) length power cord.

• Connect the DC plug from the cord into the Ultra 2400 power input port.

• Connect the power cord into your local power source.

Communication Port

The Ultra 2400 communication port, located on the top row of ports, is for EFD use only.

Input/Output 8 Pin Interface Connector

Input/output features are used when the Ultra 2400 is interfaced with external control circuits.

The 8 pin connector is located on the top row of ports. See page 22 for details.

• An End-of-Cycle signal, in the form of a solid-state switch, closes upon completion of the

dispense cycle.

Foot Pedal /

Finger Switch

Power

Input Port

Exhaust Output air Input air

Communication

Port

Input/

Output

Auxiliary

Port

Features &

Controls:

Back Panel

11

Auxiliary Port

The auxiliary port, a 6 pin mini DIN connection, is located on the top row of ports. It is designed to

power the Ultra 2400 accessories such as the workstation lamp. The auxiliary port is

interchangeable with the foot pedal / finger switch port.

Foot Pedal / Finger Switch Port

The switch port, a 6 pin mini DIN connection, is located on the top right corner of the Ultra 2400. It

is used to connect the foot pedal or finger switch that activates the dispense cycle. The switch port

is interchangeable with the auxiliary port, described above. Be sure to align the foot pedal or finger

switch cord connector so that arrow on the connector is on top.

Exhaust Port

The exhaust port is the larger 8 mm pneumatic fitting located at the bottom left corner of the Ultra

2400 workstation.

• If needed, you can connect a cleanroom filter muffler to filter output air to meet Fed 209-B

(0.5 micron particulates). Specify EFD part #2400FT.

• Caution: Use EFD filter/muffler (P/N 2170FT) or wear adequate ear protection when operating

the vacuum in close proximity for a prolonged period of time.

Air Output Port

The Ultra 2400 features two air output ports to provide regulated air pressure to the syringe barrel.

Both ports have quick-connect fittings and are interchangeable, sharing the same air source.

• You can connect to the port on the front panel or the back panel, whichever is most convenient.

• On the back panel, the air output is the center port on the bottom row.

• Push in the black quick-connect from the EFD adapter assembly to the air output port and twist

to lock. Note: air does not flow through the port until a quick-connect is installed.

Air Input Port

The air input port is the smaller pneumatic fitting (6 mm) located at the bottom right corner of the

Ultra 2400 workstation.

• Push one end of the air input hose into the input fitting on the back of the Ultra 2400. An 8 ft

(2438 mm) air hose is provided.

• Connect the other end of the air input hose to your plant air supply. A standard 1/4-inch NPT

fitting is included with your unit.

Note: clean, dry filtered factory air is required to meet warranty. If your air supply is not filtered, order

the five-micron filter regulator (specify EFD part #2000F755).

Warning! Bottled nitrogen can be used. If high pressure bottled air or nitrogen is used, a high

pressure regulator must be installed on the bottle and set at 100 psi (6.9 bar) maximum. In this

instance, the 2000F755 filter regulator is not required.

Features &

Controls:

Back Panel

12

Caution: Do not completely fill syringe barrels. The optimum fill is a maximum 2/3 of the barrel

capacity and 1/2 of the barrel capacity when using the EFD blue LV Barrier™piston.

For best results, we strongly recommend that you use a piston as part of your dispensing system.

The white EFD SmoothFlow™piston is

appropriate for most fluids and has

several advantages.

• First, vacuum adjustment is less

sensitive.

• Second, the piston prevents fumes

from the fluid being exhausted into

the work environment.

• Third, the piston prevents fluid

backflow into the dispenser if the

syringe barrel is inadvertently turned

upside down.

• Fourth, the piston makes it easy and

safe to change tips without dripping.

For watery solvents and cyanoacrylates,

request the blue EFD LV Barrier piston,

available in 3cc and 10cc sizes. If you are

dispensing an RTV silicone and find that

the piston bounces and causes stringing,

request the EFD orange, flat wall piston.

Filling procedure for pourable low and medium

viscosity fluids

If the fluid you are dispensing is pourable, take the syringe barrel, twist on

an orange tip cap and pour your fluid in. Insert a white SmoothFlow piston

and carefully press down until it contacts the fluid. The syringe barrel is

now ready for use.

Filling procedure for thick fluids

If your fluid is thick or non-leveling, you can spoon it into the syringe barrel with a spatula. Or, if the

fluid comes packed in a 1/10 gallon (300 ml) cartridge, try loading the barrel with a caulking gun.

Then, press the SmoothFlow piston to move the fluid to the bottom of the

syringe barrel and remove trapped air.

Trapped air in thick fluids can lead to drooling and oozing. Also, repetitive air

cycles can bore tunnels through non-leveling fluids, causing spitting and

inconsistent deposits. The SmoothFlow piston eliminates these problems. It

prevents tunneling by providing a barrier to the pulsed-air cycles. And it

prevents oozing by responding to the pressure of trapped air with a slight suck-

back movement after the dispense cycle.

Filling

the Syringe

Barrel

13

Remember

For best results, EFD strongly recommends the use of a

piston as part of your dispensing system.

Do not tip the barrel

upside down or lay flat.

This will cause the liquid

to run into the dispenser.

When changing tips

or attaching a tip cap,

snap the safety clip

completely closed to

prevent any dripping

or bubbling.

Open

Closed

If you choose to not use a piston when dispensing

thin fluids, remember these important points.

Fumes cannot

escape.

No air gap when

using the

SmoothFlow

piston.

caulking gun

2/3 maximum fill

SmoothFlow piston

prevents fluid backflow.

2/3

maximum

fill

SmoothFlow

piston

Filling

the Syringe

Barrel

14

Filling procedure for watery fluids and vacuum control

The Ultra 2400 vacuum regulator allows low viscosity fluids, even water, to be consistently dispensed

without dripping between cycles. A vacuum is exerted above the fluid in the barrel to prevent

dripping. For medium to high viscosity fluids, the recommended vacuum setting is 0.0.

If you are dispensing watery solvents, cyanoacrylates or anaerobics, request the blue LV Barrier

piston and follow these steps to fill the syringe barrel and set the vacuum control.

1. Twist an orange tip cap onto an empty syringe barrel and pour your

fluid in. Insert the blue LV Barrier piston. Allow an air gap between

piston and fluid as shown. (If you are using the SmoothFlow piston,

push the white piston down until it comes in contact with the fluid.)

2. Attach the syringe to the EFD adapter assembly.

3. Snap the safety clip tightly closed to prevent any dripping.

4. Remove the tip cap and attach a precision dispense tip.

5. Set air pressure at 2 psi (0.1 bar).

6. From TIMED mode, press STEADY.

7. With the syringe barrel pointing down over a container, unsnap the

safety clip. Press and hold the foot pedal or finger switch to fill the tip.

8. As a drop begins to form at the end of the tip, slowly turn the vacuum regulator knob clockwise

to stop the drip. Wipe the tip and adjust vacuum as necessary.

9. Return to TIMED mode.

10. Rest the tip on the Dot Standards sheet. Press the foot pedal and release. Check the dot size.

Increase or decrease by adjusting pressure or time as needed.

Caution: Use EFD filter/muffler (P/N 2170FT) or wear adequate ear protection when operating the

vacuum in close proximity for a prolonged period of time.

Note: For best results when dispensing watery-thin fluids, EFD recommends the use of the Vacuum

Suck-Back Filter Trap (part #2435). This is guaranteed to prevent fluid from being sucked back into

the dispenser. See page 26 for a sample drawing, or call EFD or email [email protected] for details.

1/2 maximum fill

LV Barrier

Air gap

Vacuum

Control

Barrel Rack

#905BR for 3cc & 5cc barrels

#910BR for 10cc, 30cc and 55cc barrels

EFD #920BL Barrel Loader

(Specify #940BL for prefilled 1/10 gal (300 ml) caulking

tubes)

Filling the

cartridge

for the barrel

loader

#2160 Luer-to-luer fitting

60

80

90

5

7

6

70

4

50

3

40

30

2

20

1

10

100

0

Fluid Pressure

10

12

11

13

14

9

8

0.6

0.4

5

6

7

0.2

0.8

1.0

15

0

3

4

1

2

Power

Cylinder Pressure

Start

Stop

Barrel Fill Station

Start Fill

Stop Fill

5cc

3cc

10cc

30cc

55cc

POSITION BAND

ABOVE LINE

EFD #8000BF Barrel Filling Station

2/3 Maximum Fill

Syringe

Barrel

Loaders

15

Syringe Barrel Loading Alternatives

EFD offers productive alternatives to traditional syringe barrel loading methods. Here are a few

suggestions that can help keep your work area clean, save time and reduce the chance of entrapped

air in the fluid.

1. You could use the EFD #920BL barrel loader. Pack the fluid into the 12 ounce cartridge as

shown. Then place the pre-filled cartridge into the barrel loader. Using air pressure, the barrel

loader fills the syringe barrel (with a piston installed) from the bottom up.

If the fluid comes packed in a 1/10 gallon (300 ml) caulking type cartridge, use the EFD

#940BL barrel loader.

For fast, volumetric filling, the automated 8000BF system is an accurate, easy and fast system

to fill syringe barrels.

2. If you receive frozen epoxies or other fluids in medical type syringes with a manual plunger,

request the EFD luer-to-luer fitting #2160 to transfer the material.

Please contact an EFD fluid application specialist for additional assistance.

Deposit size is controlled by time, pressure and tip size.

Please follow these instructions to test each function. Use the convenient Dot Standards sheet

included in your dispensing system kit.

Setup for Testing

1. Attach an EFD syringe barrel filled with your

assembly fluid to the adapter assembly as

shown.

2. Keep the vacuum set at 0.0 during initial

testing. (If you are dispensing a watery fluid,

see Vacuum Control, page 14).

3. Replace the orange tip cap with an EFD

precision dispense tip.

4. Slide the syringe barrel into the hand grip. Snap in place.

5. Run through the following tests to demonstrate the ease at which deposit sizes can be

established using the various dispense modes.

Testing in Steady Mode

• Select STEADY mode.

• Pull the air pressure regulator knob out until it clicks into the unlocked position. Start with

pressure set to 0 psi (0.0 bar).

• Press and hold the foot pedal or finger switch.

• Slowly, turn the pressure knob clockwise until your fluid begins to dispense out of the tip in a

controlled flow (not too fast, not too slow).

• Push the air pressure knob in to lock setting.

Correct angle for

consistent deposits.

Remember - always bring the

tip in contact with the work

surface at the illustrated angle.

After the tip is in position, press

the foot pedal. Release pedal and

remove tip by lifting straight up.

Initial Test

Procedures

16

45º

Testing in Timed Mode

• Follow steps in “Testing in Steady Mode” to purge your dispensing tip with fluid.

• Change to TIMED mode.

• Set time to 000.0250 seconds.

• Rest the dispense tip on the Dot Standards sheet.

• Press the foot pedal (or finger switch) to activate the dispense cycle. Note: the pedal only needs

to be pressed for a moment. The complete time will run once you activate the dispense cycle.

• Changing the time changes the deposit size. If your dot is too small, increase the dispense

time to increase the deposit size. If your dot is too large, decrease the dispense time to

decrease your deposit size.

Testing in Teach Mode

• Follow steps in “Testing in Steady Mode” to purge your dispensing tip with fluid.

• Change to TEACH mode.

• Rest the dispense tip on the Dot Standards sheet.

• Press the foot pedal to establish your dot size. Tapping the foot pedal repeatedly will have a

cumulative effect on the dot size and dispense time.

• Continue to press the foot pedal until you achieve the correct deposit size.

• Save the dispense time setting you just created by pressing SAVE. This automatically exits

TEACH mode and returns you to TIMED mode.

• If needed, press CLEAR to start over.

If you have any questions at this point, please call us now.

In the USA, call 800-556-3484 between 8:30 a.m. and 5:30 p.m. Eastern time.

In Europe, call +44 (0) 1582 666334.

In Asia, call +86 (21) 5854 2345.

In all other areas, call your authorized EFD distributor or +1-401-434-1680.

Initial Test

Procedures

17

The Ultra 2400 dispensing workstation allows you to store the dispense time, pressure and vacuum

settings for up to 16 different job programs. Programs are saved even with power removed and will

remain in storage unless changed or erased intentionally.

Job programs are identified as Memory 1 through Memory 16.

Note: Dispense time is automatically adjusted when you select an individual job program. Settings for

pressure and vacuum are stored and can be displayed but you need to manually adjust the pressure

and vacuum regulator knobs to match the stored settings for these values.

To Save a Job Program

1. From TIMED or TEACH mode, set the dispense time, air pressure and vacuum settings to

create a correct deposit size. When you are in TEACH mode, press SAVE after you create your

settings, then return to TIMED mode.

2. Press MENU. Use the up/down arrows to highlight SAVE JOB. Press SELECT.

3. Use the up/down arrows to select the correct job program in which to save these settings

(example, Memory 1 or Memory 2). Remember: to prevent accidental data loss, review the

contents of each job program before selecting and storing a new job into memory.

4. Press SAVE. This automatically saves the settings in the job program and returns you to the

Home screen.

5. Press the foot pedal or finger switch to activate the dispense cycle. The Ultra 2400 workstation

will make the deposit based on the settings in the selected job program.

To Work in a Saved Job Program

1. Press MENU. Use the up/down arrows to highlight MEMORY. Press SELECT.

2. Use the up/down arrows to scroll through the individual jobs until you reach the correct Memory

number.

3. Press and hold SETTINGS to see the stored pressure and vacuum settings for the job.

Remember: Dispense time automatically adjusts when you select a job program. Releasing the

Settings button displays the current values for pressure and vacuum, not the stored values. To

retrieve the stored values, manually adjust air pressure and vacuum, based on the pressure and

vacuum shown when you press Settings.

4. Press the foot pedal or finger switch to activate the dispense cycle. The Ultra 2400 will

automatically make the deposit based on the settings in the selected job program.

5. To escape from Memory, press MENU. Then press TIMED to return to the Home screen. At this

point, you are still in the current memory setting for the previous job program, but you are free

to change time, pressure and vacuum without impacting the stored settings in memory.

Memory

18

To Edit or Clear a Saved Job

Follow these steps to make changes to an existing job.

1. Press MENU. Use the up/down arrows to highlight MEMORY. Press SELECT.

2. Use the up/down arrows to select the correct job program to edit (Memory 1, Memory 2, etc.).

3. If you need to review the stored values for pressure and vacuum, press and hold SETTINGS.

You can adjust the pressure and vacuum from this screen, or you can make adjustments from

TIMED mode. However, note: you can only adjust the dispense time setting from the TIMED

mode screen.

4. Press MENU again.

5. Press TIMED to return to TIMED mode in the selected program.

6. Adjust the settings for dispense time, air pressure and vacuum as needed to achieve the correct

deposit size.

7. Press MENU.

8. Use the up/down arrows to highlight SAVE JOB. Press SELECT.

9. Use the up/down arrows to again select the correct job program.

10. Press SAVE. This automatically saves the changed settings and returns you to the Home screen.

Note: to clear all settings in a specific job program, simply set the time, pressure and vacuum to 0 in

step 6 and follow the other steps as noted.

Memory

19

You can access the menu screen by pressing MENU. From here press the up/down and left/right

arrows to select from a variety of screens.

Timed/Teach mode

See pages 8-10 for details on the Ultra 2400 dispense modes.

Memory/Save Job

See pages 18-19 for details on Memory and Save Job functions.

Clear Count

See page 10 for details on Shot Count and Clear Count functions.

Units of Pressure/Units of Vacuum

You can change the screen display of air pressure units from psi to bar or kPa, or for vacuum units

from inH2O to inHg, kPa, mmHg, or Torr. Follow these steps:

• Press MENU.

• Press the up/down arrow to highlight UNITS OF PRESSURE or UNITS OF VACUUM, then press

SELECT.

• Press the up/down arrow to highlight the appropriate pressure or vacuum display option.

• Press SELECT again to make the change. This automatically returns you to the Home screen.

Language

You can change the screen display from English to another language. Follow these steps.

• Press MENU.

• Press the up/down arrow to highlight LANGUAGE, then press SELECT.

• Press the up/down arrow to highlight the appropriate option.

• Press SELECT again to make the change. This automatically returns you to the Home screen.

Info

The Info screen displays the Ultra workstation’s serial number, model number and contact web site

for customer service. To view INFO, press MENU, use the up/down arrow to highlight INFO, then

press SELECT.

Menu

Functions

20

Other manuals for Ultra 2400 Series

1

This manual suits for next models

2

Table of contents

Other EFD Dispenser manuals

Popular Dispenser manuals by other brands

JohnDow Industries

JohnDow Industries JDI-5DP owner's manual

Schroeder America

Schroeder America 950R Installation instruction, parts list and configuration guide

PVA

PVA MR2 owner's manual

Cornelius

Cornelius FCB 3 H.P. POST-MIX DISPENSER Installation & service manual

Graco

Graco LSR Select instructions

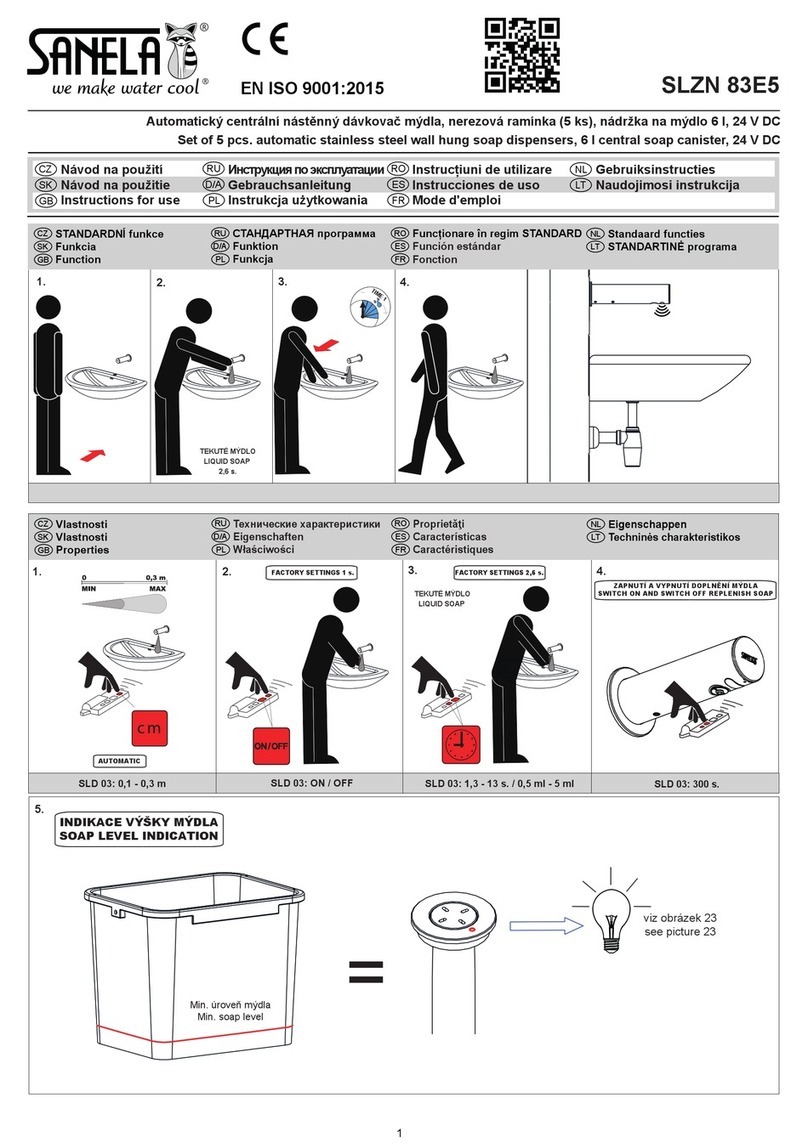

Sanela

Sanela SLZN 83E5 Instructions for use